Oil pipe built-in oil drill pipe

An oil drill pipe, built-in technology, applied in drill pipe, drill pipe, casing and other directions, can solve the problems of cumbersome work process, affecting the efficiency of offshore oil drilling, low work efficiency, etc., to save costs and simplify oil drilling. technology, the effect of improving oil drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

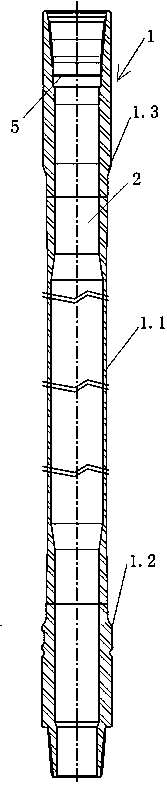

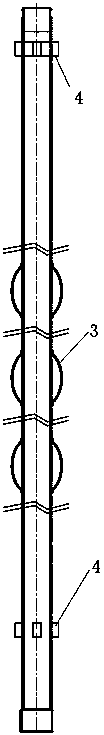

[0011] see figure 1 with figure 2 , the present invention relates to a oil pipe built-in oil drill pipe, including a drill pipe 1 and an oil pipe 2, the drill pipe body 1 is composed of a main rod 1.1 in the middle, male joints 1.2 and female joints 1.3 at both ends, wherein the oil pipe 2 is placed on Inside the drill pipe 1, a plurality of spring centralizers 3 are sheathed on the outside of the middle section of the oil pipe 2. The spring centralizers 3 are used to position the oil pipe 2 and clamp the inner wall of the main rod 1.1 to prevent the oil pipe 2 from shaking. The oil pipe 2 is respectively provided with block centralizers 4 near both ends, and the block centralizers 4 are also used to position the oil pipe 2 and block the inner walls of the male joint 1.2 and the female joint 1.3 to prevent the oil pipe 2 from shaking. When two oil drill pipes are connected, the drill pipe 1 is threadedly connected and matched by the male joint 1.2 and the female joint 1.3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com