Drilling machine table top and drilling machine

A drilling machine and table top technology, applied in metal processing and other directions, can solve problems such as increasing production costs, increasing automatic adhesive tapes, increasing processes, etc., and achieves the effects of convenient operation, solving uneven structure layers, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

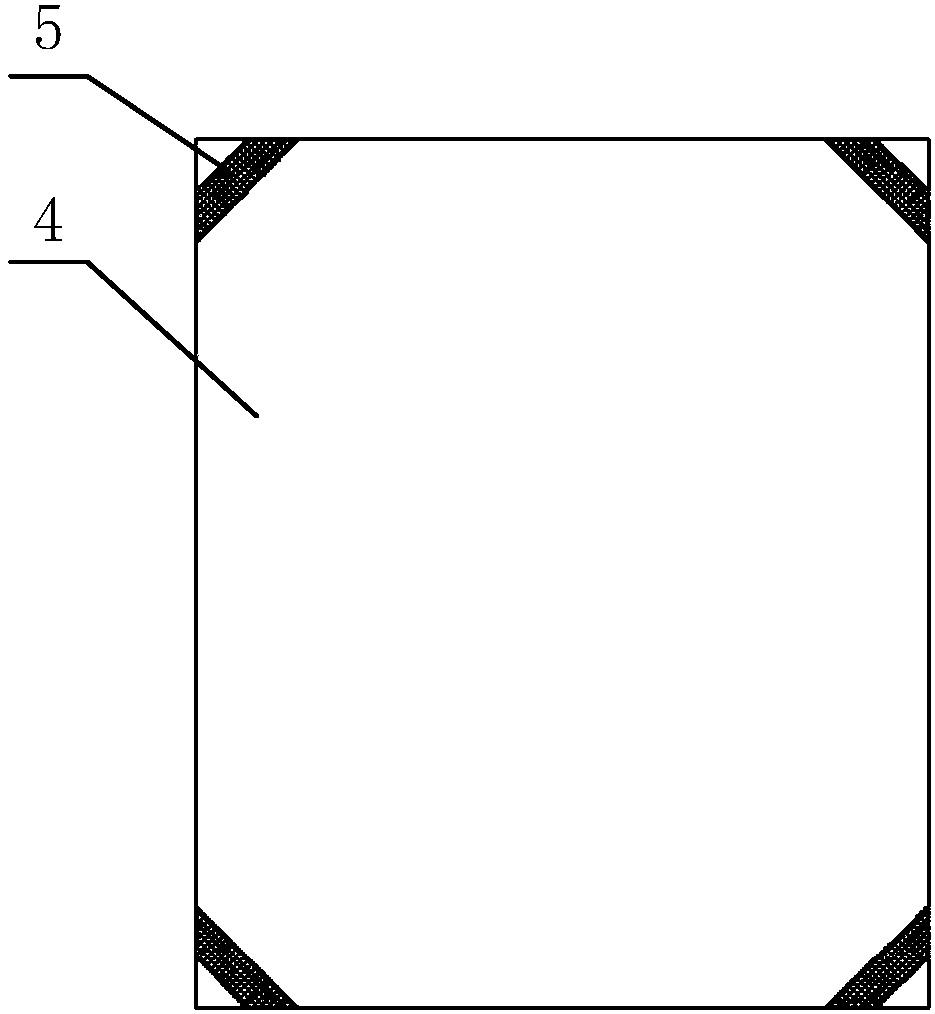

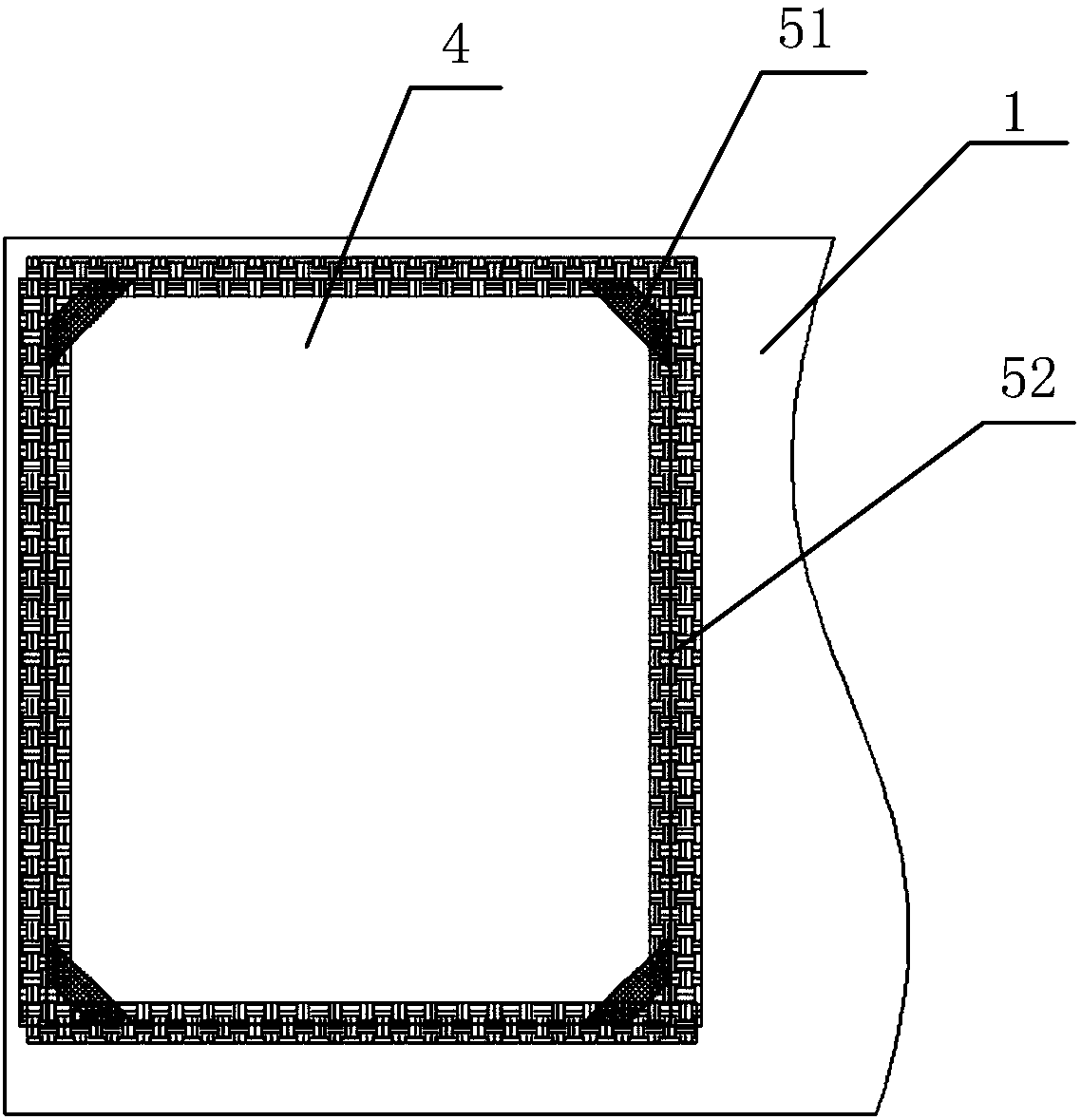

[0050] refer to Figure 4 -8. The embodiment of the present invention provides a drilling machine table, including: a workbench 1, a telescopic device and a vacuum adsorption device;

[0051] One end of the telescopic device is fixed on the workbench 1, and the other end is used to carry the circuit board 4; Bottom space; the vacuum adsorption device is used to butt the bottom surface of the circuit board 4 to adsorb and fix the circuit board 4 on the telescopic device.

[0052] One end of the telescopic device is fixed on the workbench 1, and the other end can move in the vertical direction relative to the workbench 1 to realize the lifting function to lift the circuit board 4 away from the workbench 1, so that the gap between the circuit board 4 and the workbench 1 A lifting space is formed to facilitate loading and unloading equipment to lift the circuit board 4 from the bottom of the circuit board 4 .

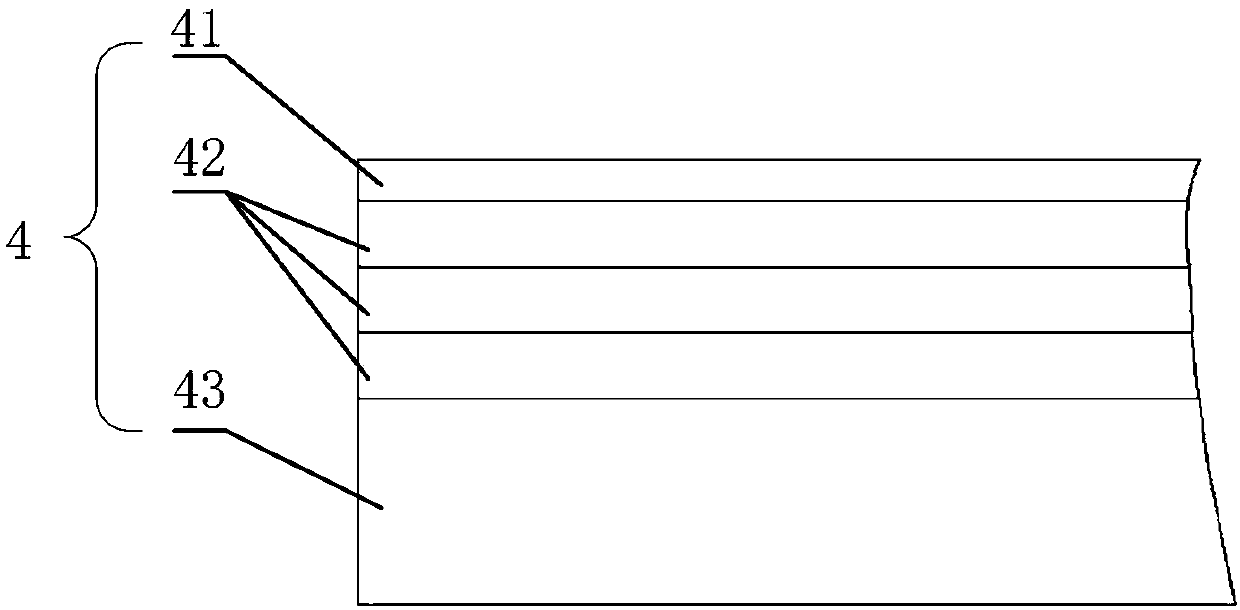

[0053] Wherein, the circuit board 4 on the material rack of the load...

Embodiment 2

[0082] An embodiment of the present invention provides a drilling machine, including any drilling machine table provided in the first embodiment above.

[0083] Wherein, the specific structure of the table top of the drilling machine has been introduced in detail above, and will not be repeated here.

[0084] It can be seen that the drilling machine provided by the embodiment of the present invention can obtain all the beneficial effects of the drilling machine table, simplifies the drilling process of the circuit board 4, and improves the production efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com