Drilling equipment for electronic device machining

A technology of drilling equipment and electronic devices, applied in metal processing equipment, drilling/drilling equipment, boring/drilling and other directions, can solve the problem of insignificant processing efficiency of the shell, and achieve a simplified drilling process and a simple structure. , the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

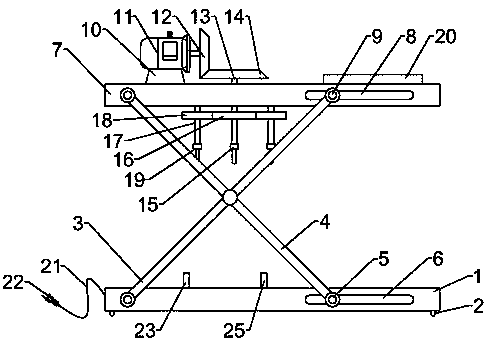

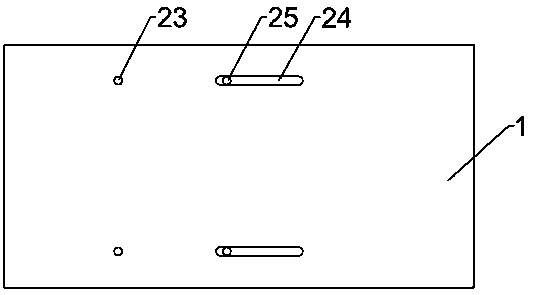

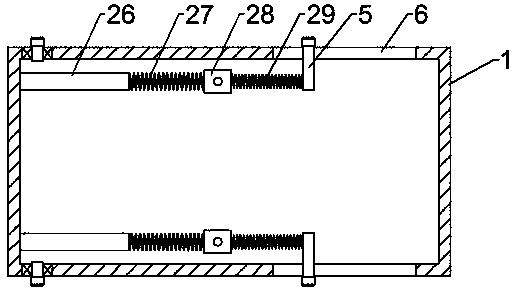

[0021] Example 1: Please refer to Figure 1-3 , a drilling device for processing electronic devices, including a processing base plate 1, the left side of the processing base plate 1 is connected with a first rotating rod 3 symmetrically rotated forward and backward, and the middle part of the first rotating rod 3 is hinged with a second rotating rod 4 of equal length The lower end of the second rotating rod 4 is rotatably connected with the first limit sliding rod 5, and the bottom right side of the processing base plate 1 is provided with the first limit chute 6, and the first limit sliding rod 5 is slidably connected with the first limit chute 6, The top of the second rotating rod 4 is rotatably connected to the top plate 7, and the right side of the top plate 7 is provided with a second limit chute 8, and the top of the first rotating rod 3 is rotatably connected with a second limit slide bar 9, and the second limit slide bar 9 is connected to the second limit slide bar 9. ...

Embodiment 2

[0033] Embodiment 2: This embodiment is a further improvement of the previous embodiment: the stiffness coefficient of the first spring 27 is smaller than the stiffness coefficient of the second spring 29. At this time, when the first spring 27 and the second spring 29 are stretched, The stretched length of the first spring 27 is greater than that of the second spring 29, so as to ensure that the workpiece to be drilled is positioned first, and then the drilling operation is performed.

[0034] The working principle of the present invention is: when in use, the device is energized, and then the motor 11 can be turned on, the rotation of the motor 11 drives the driving bevel gear 12 to rotate, and then drives the driven bevel gear 14 to rotate, and the rotation of the driven bevel gear 14 can drive the first A drill bit 15 rotates, and the driving gear 16 drives the driven gear 18 to rotate simultaneously, so that the second drill bit 19 rotates synchronously, and can drill a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com