Rotary water spraying type glass bottle punching auxiliary clamping support

An auxiliary clamping and glass bottle technology, applied in work accessories, manufacturing tools, stone processing equipment, etc., can solve the problems of smoothness and difficult to fix, and achieve the effect of convenient use, simplified drilling operation process, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with specific embodiments of the accompanying drawings.

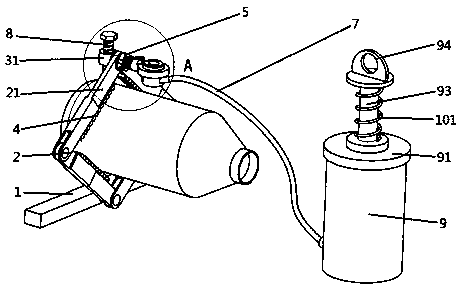

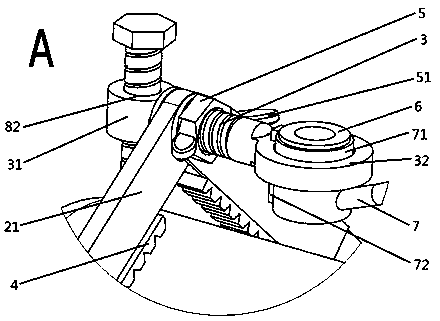

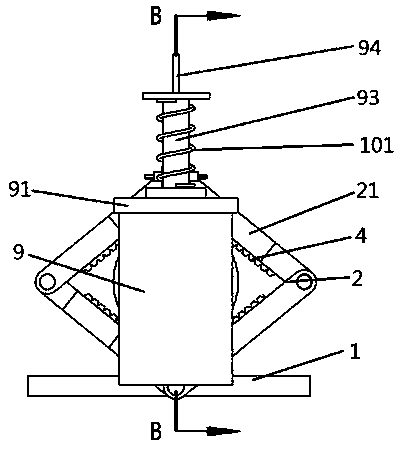

[0024] Such as Figure 1-8 As shown, a rotary spraying type glass bottle perforating auxiliary clamping bracket according to the present invention is characterized in that: the main body is a quadrilateral lock frame 2 composed of a bucket 9 and a movable connection through a connecting rod 21, and the quadrilateral The bottom of the lock frame 2 is provided with a fixed seat 1 to support; the described water bucket 9 is provided with a fixed cover 91 and a slide bar 93 that can slide up and down in the middle of the fixed cover 91 through the fixed cover 91 is the main body, and the bottom of the water bucket 9 is provided with a The water pipe 7 connected to the inside of the bucket 9; the top of the quadrilateral lock frame 2 is provided with a threaded rod 3 passing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com