A kind of external heat-proof material and preparation method thereof

A heat-proof material and prefabricated technology, applied in the field of materials, can solve the problems of large brittleness and poor deformation coordination ability of external heat-proof materials, and achieve the effect of ensuring thermal insulation effect, improving mechanical properties, and improving deformation coordination ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

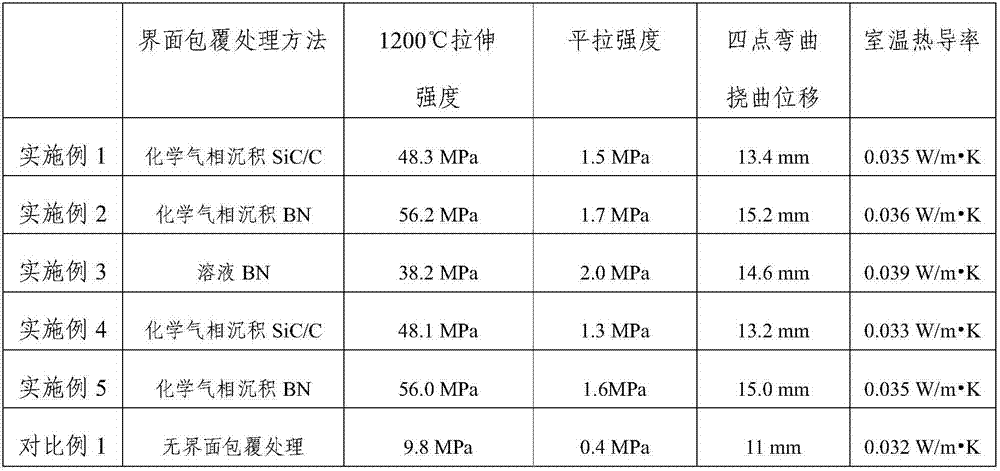

Examples

Embodiment 1

[0061] The materials prepared in this embodiment and the preparation method are as follows:

[0062] Through chemical vapor deposition SiC / C interface coating treatment, the preparation of high temperature resistant, high strain coordinated external heat protection material includes the following steps:

[0063] (1), select alumina fiber, prepare alumina needle felt by needle punching process, the density of the prepared alumina needle felt is 0.13g / cm 3 , sintered at 600°C, remove the wetting agent on the fiber surface, and cut the needle felt to a size of 320mm×320mm×22mm.

[0064] (2) Select alumina fiber, and prepare fiber prefabricated body through 2.5D weaving process, the size is 320mm×320mm×2mm and 320mm×320mm×1mm, the fiber volume content is 40%, the burr is cut off, and the acetone treatment is used to remove organic matter.

[0065] (3) Superimpose the preforms of the above three sizes in the order of 2mm / 22mm / 1mm, place them in the sewing tool, and perform integra...

Embodiment 2

[0074] The materials prepared in this embodiment and the preparation method are as follows:

[0075] Preparation of high-temperature resistant, high-strain coordinated external heat-resistant materials by chemical vapor deposition BN interface coating treatment

[0076] (1) Choose alumina fiber, its long-term use temperature is 1300-1400°C, prepare alumina needle-punched felt through needle punching molding process, density 0.16g / cm3, sinter at 600°C, remove fiber surface wetting agent, cut needles The size of the needle felt is 170mm×170mm×22mm.

[0077] (2) Select alumina fiber and prepare fiber preform by 2.5D weaving process. The size is 170mm×170mm×2mm and 170mm×170mm×1mm, the fiber volume content is 40%, the burr is cut off, and the organic matter is removed by acetone treatment.

[0078] (3) The above three kinds of prefabricated bodies are superimposed in the order of 2mm / 22mm / 1mm, placed in the sewing tool for integrated sewing, and the thickness of the green body af...

Embodiment 3

[0087] The materials prepared in this embodiment and the preparation method are as follows:

[0088] Use boric acid and urea impregnation interface coating treatment to prepare high temperature resistant, high strain coordinated external heat protection material

[0089] (1) Select alumina fibers, and prepare alumina needle-punched felt through needle-punching process, with a density of 0.20g / cm 3 , sintered at 600°C, remove the wetting agent on the fiber surface, and cut the needle felt to a size of 120mm×120mm×22mm.

[0090] (2) Select alumina fiber, and prepare fiber prefabricated body through 2.5D weaving process, the size is 120mm×120mm×2mm and 120mm×120mm×1mm, the fiber volume content is 40%, the burr is cut off, and the acetone treatment is used to remove organic matter.

[0091] (3) The above three kinds of prefabricated bodies are superimposed in the order of 2mm / 22mm / 1mm, placed in the sewing tool for integrated sewing, and the thickness of the green body after sewi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com