Swash plate of automobile air-condition compressor and production method of swash plate

A technology for automobile air conditioners and production methods, which is applied to mechanical equipment, machines/engines, and liquid variable volume machinery, etc. The effect of improving room temperature strength and high temperature strength and volume, improving corrosion resistance and heat resistance, and improving high temperature strength and high temperature hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

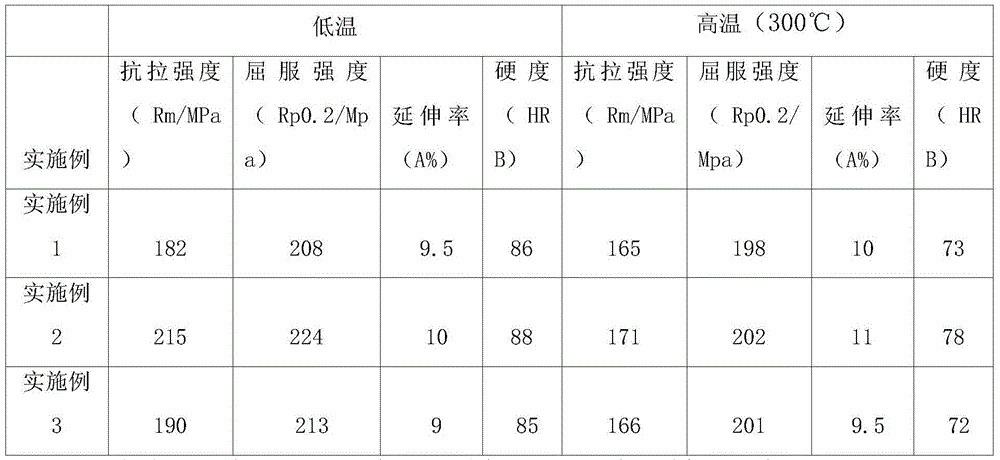

Examples

Embodiment 1

[0076] Add a certain quality of pure aluminum ingots into the crucible, heat to 780°C, melt the pure aluminum ingots into a melt, and then add Al-Fe master alloy, Al-Cu master alloy, Al -Ni master alloy, Al-Mn master alloy, Al-RE master alloy, Al-Si master alloy, Al-Zn master alloy, Al-Ti master alloy, heat up to 840°C, keep it warm for 6 hours, and wait until the solid alloy is completely melted Stir, turn on the electromagnetic stirrer, stir for 1 hour, then cool down to 760°C, add Al-C master alloy and Al-Mg master alloy according to the proportion, turn on the electromagnetic stirrer again, stir for 1 hour, and obtain a melt.

[0077] Refining the above melt with nitrogen, keeping the temperature of the melt at 680° C., blowing nitrogen for 10 minutes, and removing the slag.

[0078] Add the above-mentioned refined melt to the Al-8Sr master alloy for modification treatment. During the modification process, the temperature of the melt was 760°C; the amount of Al-8Sr master...

Embodiment 2

[0087] Add a certain quality of pure aluminum ingots into the crucible, heat to 785°C, melt the pure aluminum ingots into a melt, and then add Al-Fe master alloy, Al-Cu master alloy, Al -Ni master alloy, Al-Mn master alloy, Al-RE master alloy, Al-Si master alloy, Al-Zn master alloy, Al-Ti master alloy, heat up to 845°C, keep warm for 6 hours, after the solid alloy is completely melted Stir, turn on the electromagnetic stirrer, stir for 1 hour, then cool down to 765°C, add Al-C master alloy and Al-Mg master alloy according to the proportion, turn on the electromagnetic stirrer again, stir for 1 hour, and obtain a melt.

[0088] Refining the above melt with nitrogen, keeping the temperature of the melt at 690°C, blowing nitrogen for 13 minutes, and removing slag.

[0089] Add the above-mentioned refined melt to the Al-8Sr master alloy for modification treatment. During the modification process, the temperature of the melt was 805°C; the amount of Al-8Sr master alloy added accou...

Embodiment 3

[0098] Add a certain quality of pure aluminum ingots into the crucible, heat to 790°C, melt the pure aluminum ingots into a melt, and then add Al-Cr master alloy, Al-Cu master alloy, Al -Ni master alloy, Al-Mn master alloy, Al-RE master alloy, Al-Si master alloy, Al-Zn master alloy, Al-Ti master alloy, heat up to 850°C, keep it warm for 6 hours, and wait until the solid alloy is completely melted Stir, turn on the electromagnetic stirrer, stir for 1 hour, then cool down to 770°C, add Al-C master alloy and Al-Mg master alloy according to the proportion, turn on the electromagnetic stirrer again, stir for 1 hour, and obtain a melt.

[0099] Refining the above melt with nitrogen, keeping the temperature of the melt at 700°C, blowing nitrogen for 15 minutes, and removing slag.

[0100] Add the above-mentioned refined melt to the Al-8Sr master alloy for modification treatment. During the modification process, the temperature of the melt was 850°C; the amount of Al-8Sr master alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com