High-pressure oriented perforating permeability-increasing method and device

A directional perforation and high-pressure water jet technology, which is applied in mining equipment, earth-moving drilling, gas discharge, etc., can solve the problems of difficult gas extraction, roof collapse, gas accumulation, etc., and achieve low drilling density, avoid collapse, drilling The effect of low pore density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

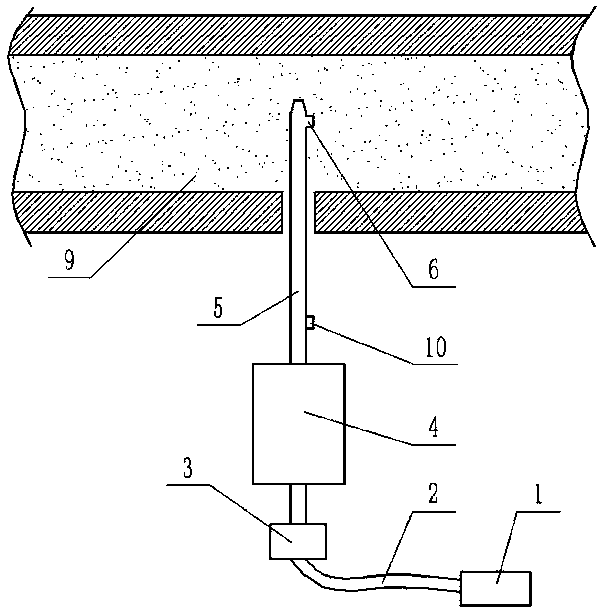

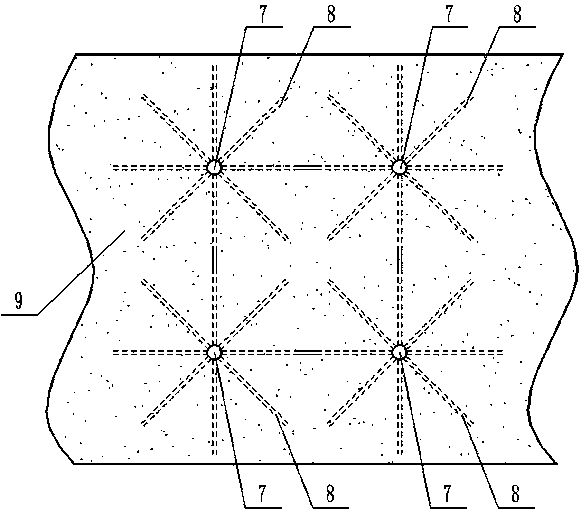

[0030] like figure 1 As shown, a high-pressure directional perforating and anti-reflection equipment includes a high-pressure hydraulic pump 1, a high-pressure rubber hose 2, a high-pressure rotary joint 3, a drilling rig 4, and a high-pressure water jet drill pipe 5. A high-pressure water jet nozzle 6 is installed on the high-pressure water jet drill pipe 5; The lower end of the high-pressure water jet drill pipe 5 is provided with a mark 10 corresponding to the angular position of the high-pressure water jet nozzle 6 .

[0031] A high-pressure directional perforating antireflection method, comprising the following steps:

[0032] Step 1, use a drilling rig to drill four holes from the roadway to the coal seam;

[0033] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com