Nickel-based dehydrogenation catalyst with core-shell structure and preparation method of catalyst

A technology of dehydrogenation catalyst and core-shell structure, applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalyst, etc., can solve many side reactions, three wastes, catalyst Raney Nickel is easy to deactivate and other problems, to achieve the effect of enhancing the interaction force, facilitating heat and mass transfer, and increasing the catalytic active point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

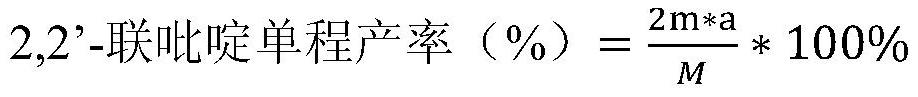

Examples

Embodiment 1

[0027] At 25°C, mix 200g of dimethylformamide and 20g of ethanol, add 3.2g of nickel nitrate and 0.6g of copper nitrate into the mixed solution, then add 6g of 4-pyridinecarboxylic acid, stir for 1h and mix well, then hydrothermally react for 15h at 160°C , filtered after cooling down to room temperature, washed the filter cake with 200g of deionized water and 50g of ethanol respectively, and vacuum dried at 60°C for 12h to obtain Ni / Cu-MOF;

[0028] Take 10g Na 2 S 2 o 3 Dissolve 6 g of the bimetallic Ni / Cu-MOF prepared above in 40 g of deionized water, react at 25 °C for 8 h, filter, wash the filter cake with 50 g of deionized water and 25 g of ethanol, and dry in vacuum at 60 °C for 12 h to obtain Ni / Cu-MOF etchant;

[0029] Add 2g of Ni / Cu-MOF etched product and 0.75g of aluminum nitrate into a mixed solution of 15g of deionized water and 25g of ethanol, react at 50°C for 1h, cool down to room temperature, filter, and wash with 60g of deionized water and 100g of ethano...

Embodiment 2

[0033] At room temperature, mix 200g of dimethylformamide and 20g of ethanol, add 3.2g of nickel sulfate and 0.6g of copper nitrate into the mixed solution, then add 6g of 4-pyridinecarboxylic acid, stir for 0.5h and mix well, then hydrothermally react at 170°C for 12h , filtered after cooling down to room temperature, washed the filter cake with 200g of deionized water and 50g of ethanol respectively, and vacuum dried at 60°C for 12h to obtain Ni / Cu-MOF;

[0034] Dissolve 10 g of potassium persulfate and 6 g of the above-prepared bimetallic Ni / Cu-MOF in 40 g of deionized water, react at room temperature for 8 h, filter, wash the filter cake with 50 g of deionized water and 25 g of ethanol, and vacuum at 60 ° C. Dry for 12 hours to obtain Ni / Cu-MOF etch;

[0035] Add 2g of Ni / Cu-MOF etched material and 0.75g of aluminum sulfate into a mixed solution of 15g of deionized water and 25g of ethanol, react at 60°C for 0.5h, cool down to room temperature and filter, then use 60g of d...

Embodiment 3

[0039] At 25°C, mix 200g of dimethylformamide and 20g of ethanol, add 3.2g of nickel nitrate and 0.6g of copper sulfate into the mixed solution, then add 6g of 4-pyridinecarboxylic acid, stir for 1h and mix well, then hydrothermally react at 150°C for 18h , filtered after cooling down to room temperature, washed the filter cake with 200g of deionized water and 50g of ethanol respectively, and vacuum dried at 60°C for 12h to obtain Ni / Cu-MOF;

[0040] Take 12g Na 2 S 2 o 3 Dissolve 6g of the above-prepared bimetallic Ni / Cu-MOF in 45g of deionized water, react at 25°C for 8h, filter, wash the filter cake with 50g of deionized water and 25g of ethanol, and dry in vacuum at 60°C for 12h to obtain Ni / Cu-MOF etchant;

[0041] Add 2g of Ni / Cu-MOF etched product and 0.75g of aluminum sulfate into a mixed solution of 15g of deionized water and 25g of ethanol, react at 70°C for 1h, filter after cooling down to room temperature, and wash with 60g of deionized water and 100g of ethano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com