Method for removing residual polymers from protecting layer of semiconductor device

A protective layer, polymer technology, applied in semiconductor/solid-state device manufacturing, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as collapse and enlargement of protective layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

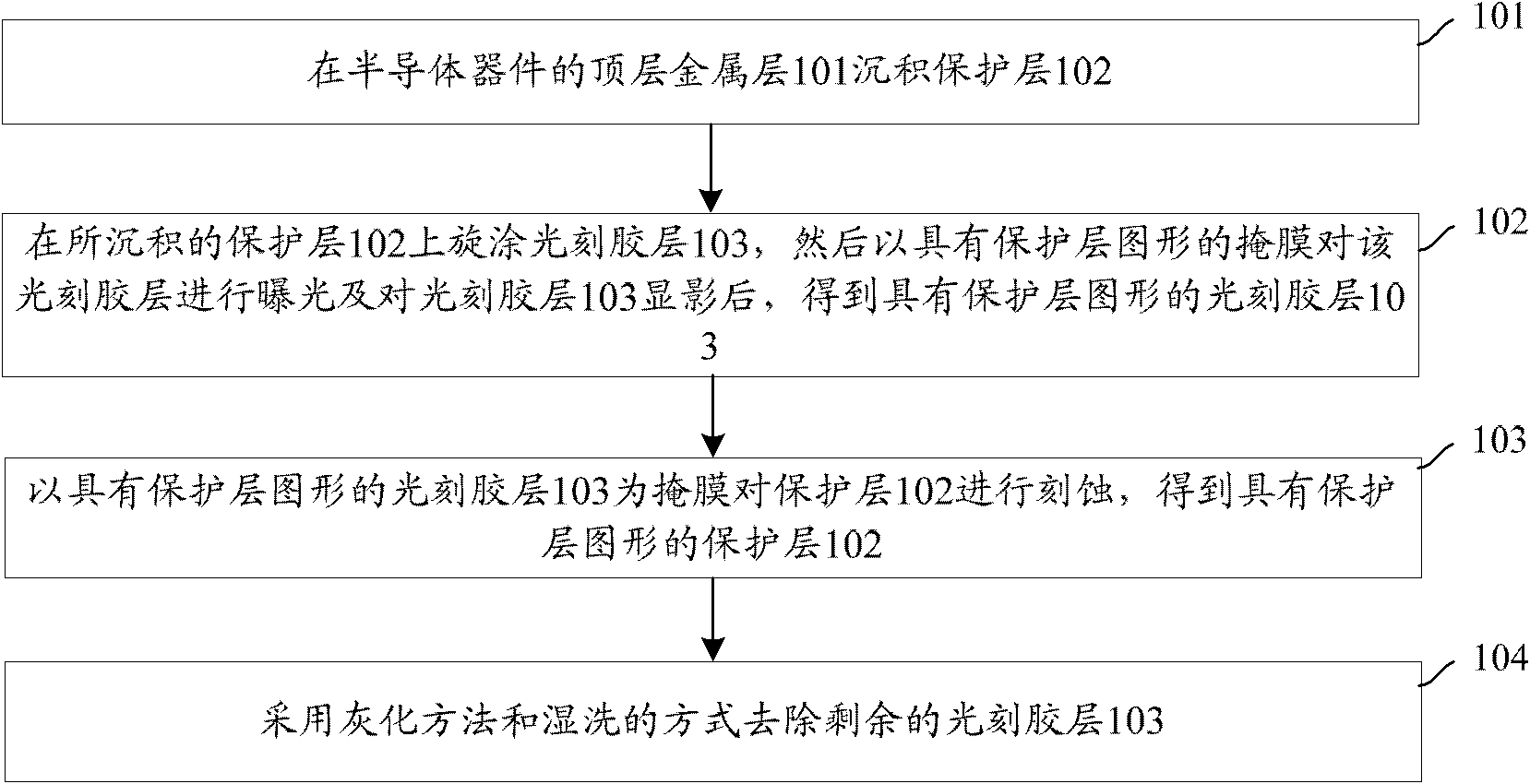

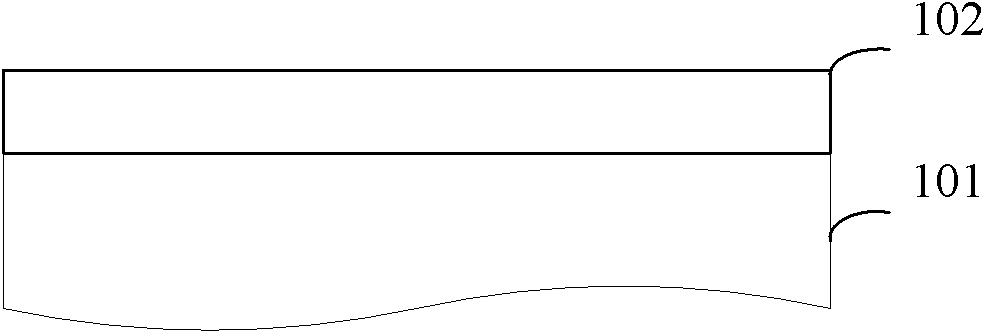

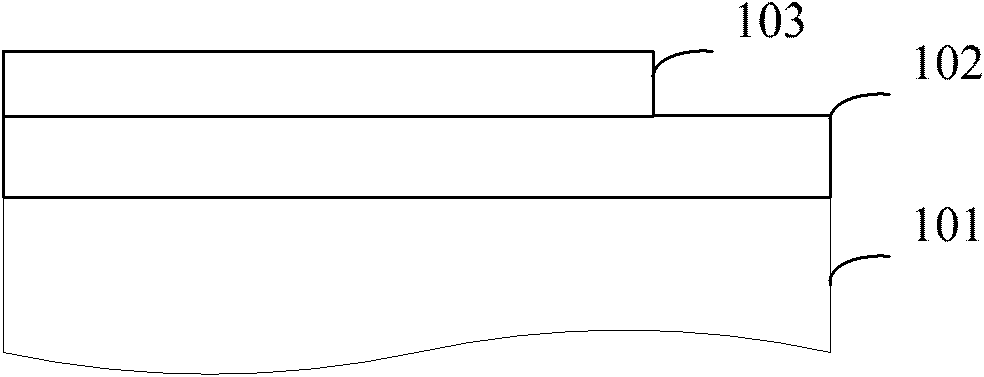

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0032] It can be seen from the prior art that in the process of completely removing the etching residual polymer of the protective layer, the reason for the collapse of the protective layer is that the ultrasonic method or the method of further etching the protective layer will directly act on the surface of the protective layer, making the protective layer The surface pressure increases or damages the surface of the protective layer, resulting in the collapse of the protective layer with an increasing aspect ratio.

[0033] In order to overcome the above problems, the present invention proposes to use deionized water spray cleaning method to remove the etching residue of the protective layer, such as only for the place where there is etching residual po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com