Constant punching device

A technology of a punching device and a puncher, which is applied in the direction of the drilling mold used for workpieces, etc., which can solve the problems of inability to ensure accurate punching positions, waste of human resources, and occurrence of errors, so as to achieve accurate punching positions and reduce labor intensity , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

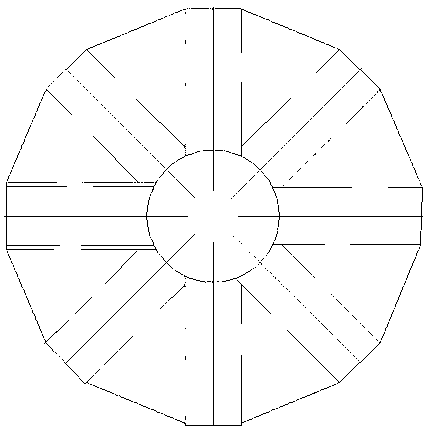

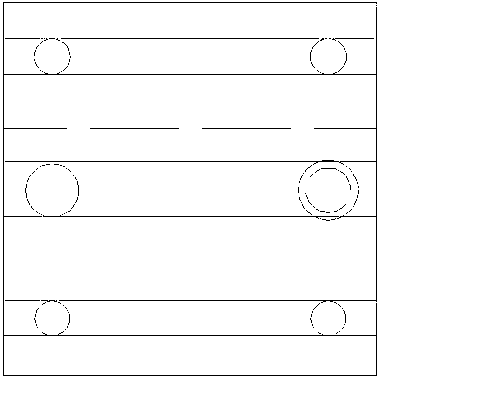

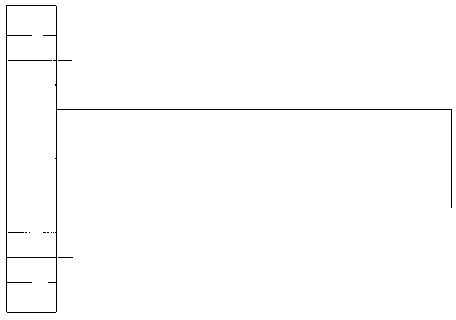

[0015] The constant punching device includes a constant puncher and a positioning bolt 7, the constant puncher is a polygonal prism 5, the end face of the polygonal prism is provided with a workpiece entry hole 1, and the side of the polygonal prism is provided with a plurality of working holes 3, and the polygonal prism The side of body is also provided with positioning screw hole 2, and positioning screw hole matches with positioning bolt, and working hole, positioning screw hole are connected with workpiece entry hole; Need to punch workpiece 8 and put into the end face of polygonal prism to set workpiece entry hole, locate The bolt fixes the workpiece to be drilled in the workpiece entry hole through the positioning screw hole, and drills the hole in the working hole of the polygonal prism with a drill bit to drill a hole with a fixed size, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com