Copper bar punching and shearing machine

A punching machine, punching technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

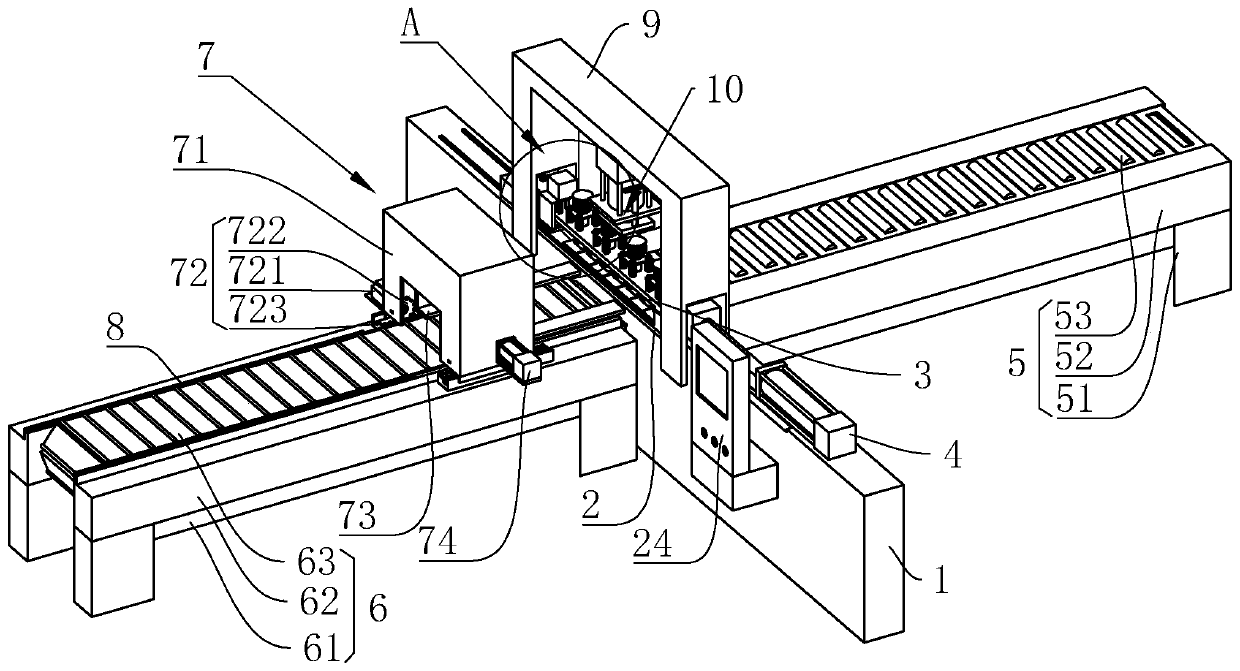

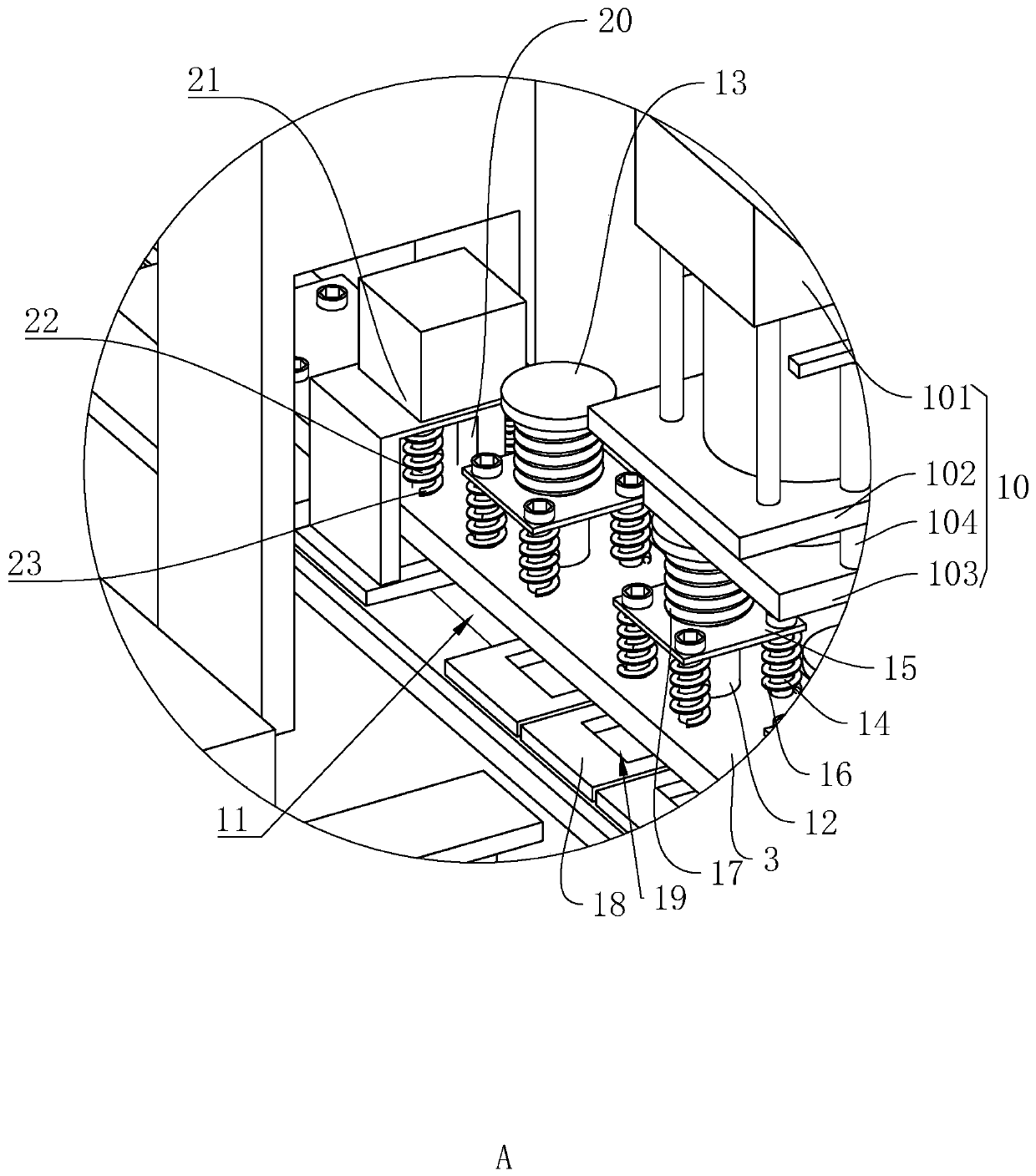

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0033] refer to figure 1 , is a copper bar punching and shearing machine disclosed in the present invention, comprising a cuboid base 1, the base 1 is slid along its length direction and installed with an overall cuboid support plate 2, and the end of the support plate 2 away from the base 1 is fixed by bolts A mold box 3 in the shape of a cuboid is installed, and the base 1 is fixed with bolts to drive the horizontal drive 4 of the mold box 3 to move horizontally. Preferably, the horizontal drive 4 is a hydraulic cylinder. Both sides of the base 1 along its length direction are respectively provided with a feeding mechanism 5 for feeding and a discharging mechanism 6 for discharging. One side of the base 1 is equipped with a console 24 that is in the shape of a cuboid as a whole by bolts.

[0034] The feeding mechanism 5 comprises a feeding support 51, a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com