Full-automatic PCB punching equipment based on machine vision and punching method

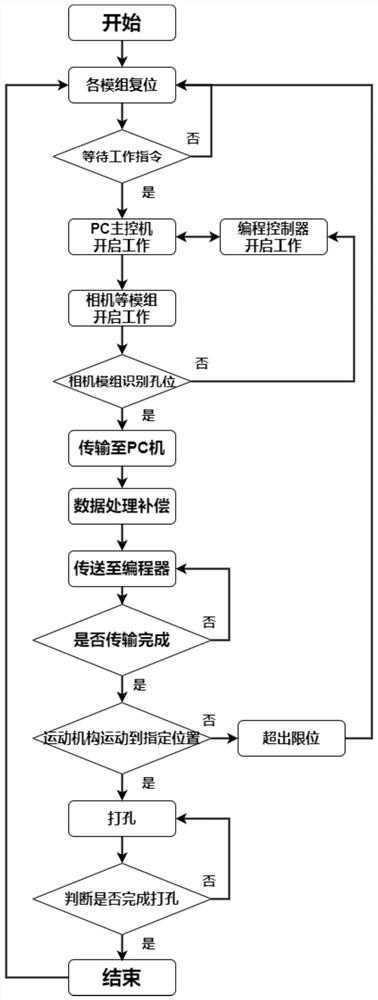

A PCB board and machine vision technology, applied in the field of fully automatic PCB board punching equipment based on machine vision, can solve problems such as reducing punching efficiency and punching accuracy, achieve efficient punching pass rate, shorten punching time, improve The effect of punching precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

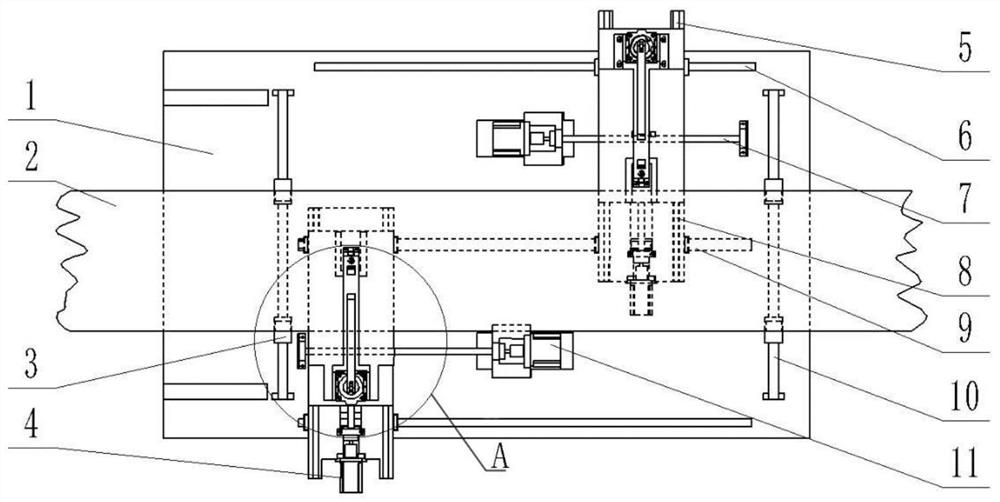

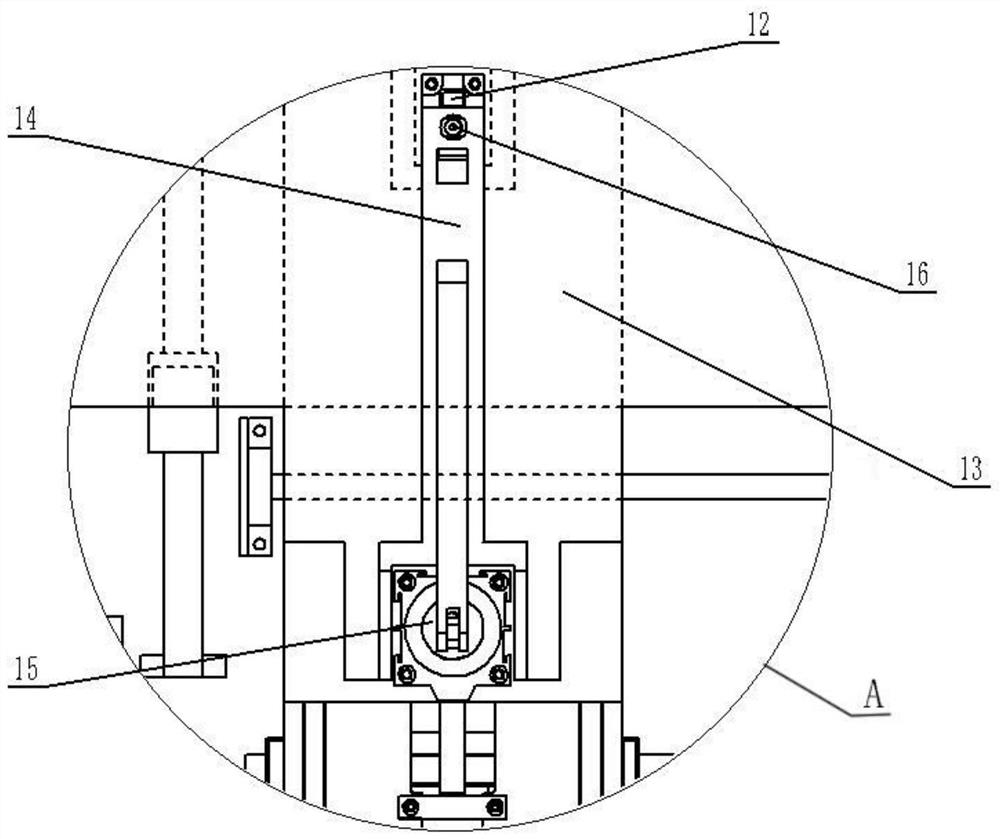

[0047] likeFigure 1-2 Shown embodiment the present invention provides a machine vision based automatic PCB board drilling equipment, comprising a bottom plate, the top plate 1 is provided with a top of the PCB 2, the base plate 1 is fixedly connected with a platform movable rail 9, the bottom plate 1 fixedly connected to the top 10, two opposing ends of the fixed stop plate 10 fixed to the two stop plates are fixedly connected to the PCB stopper 3, a top plate fixed to the movable rail 9 is connected to the platform, the base plate 1 the horizontal axis is fixedly connected to the top slide 6, the slide rail 6 is connected to the horizontal axis and the vertical axis slide 5, the rear end of the vertical axis slide rails 5 connected to the rear end 8, the vertical axis to the top of the sliding rails 5 are connected there platform support frame 13, the support frame 13 is fixed to the top of the platform is connected to the Y-direction moving platform servo motor 4, the Y-directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com