Patents

Literature

125 results about "Test forms" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

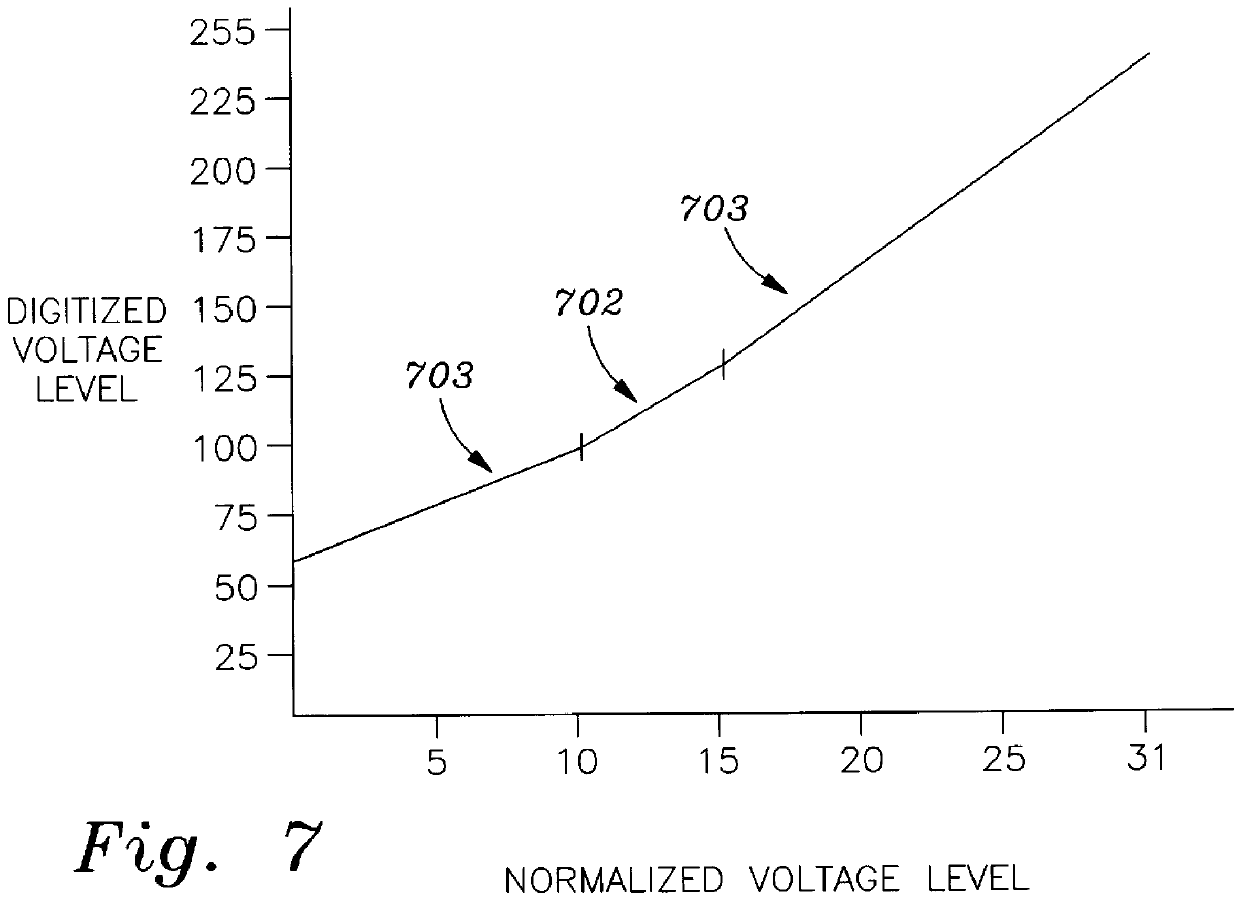

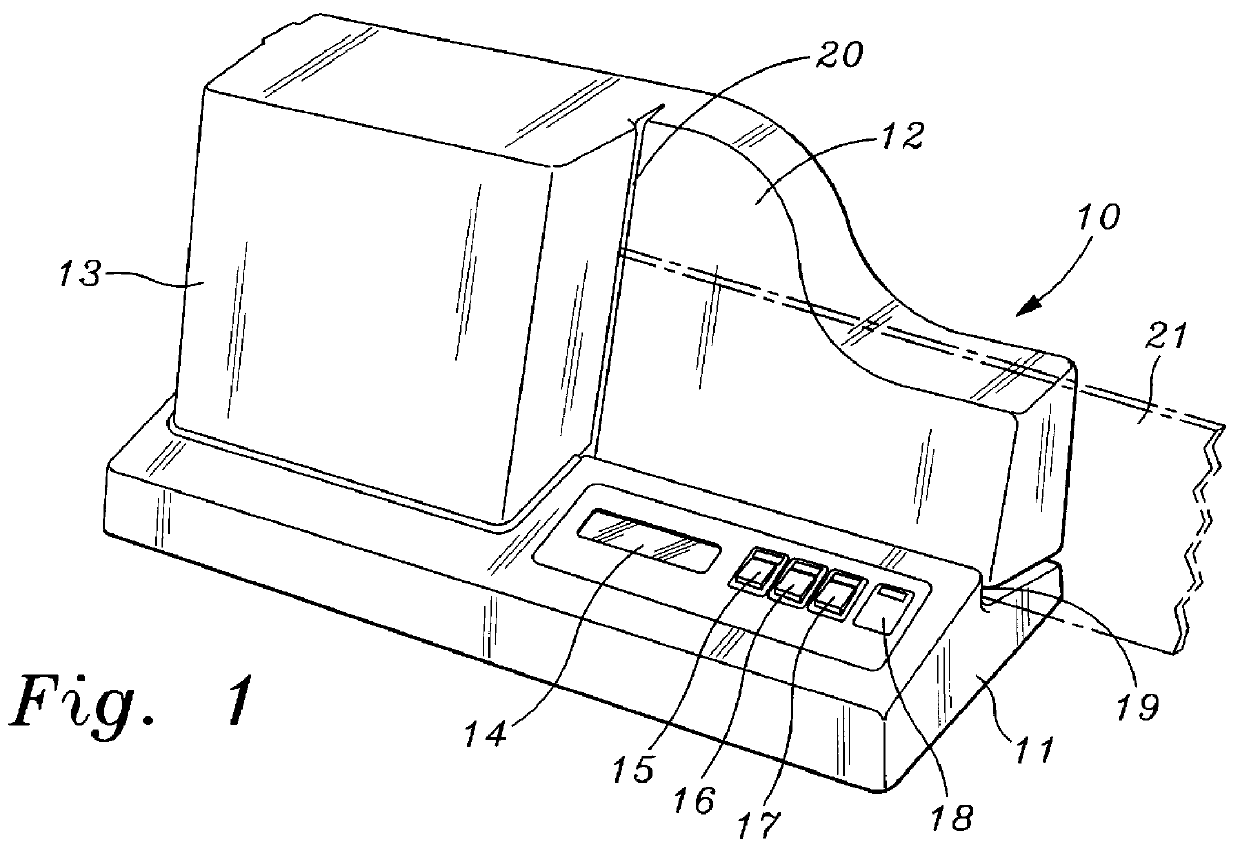

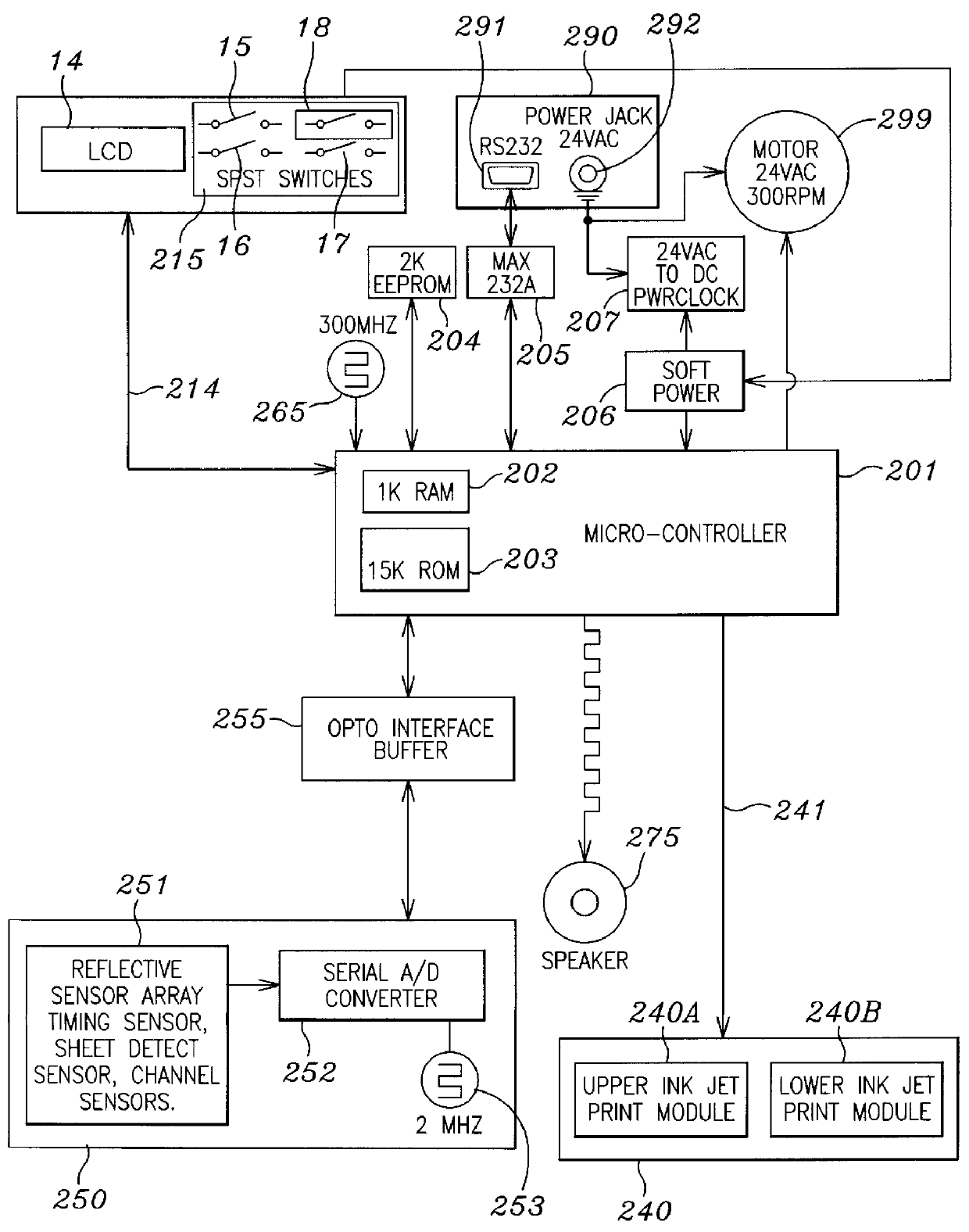

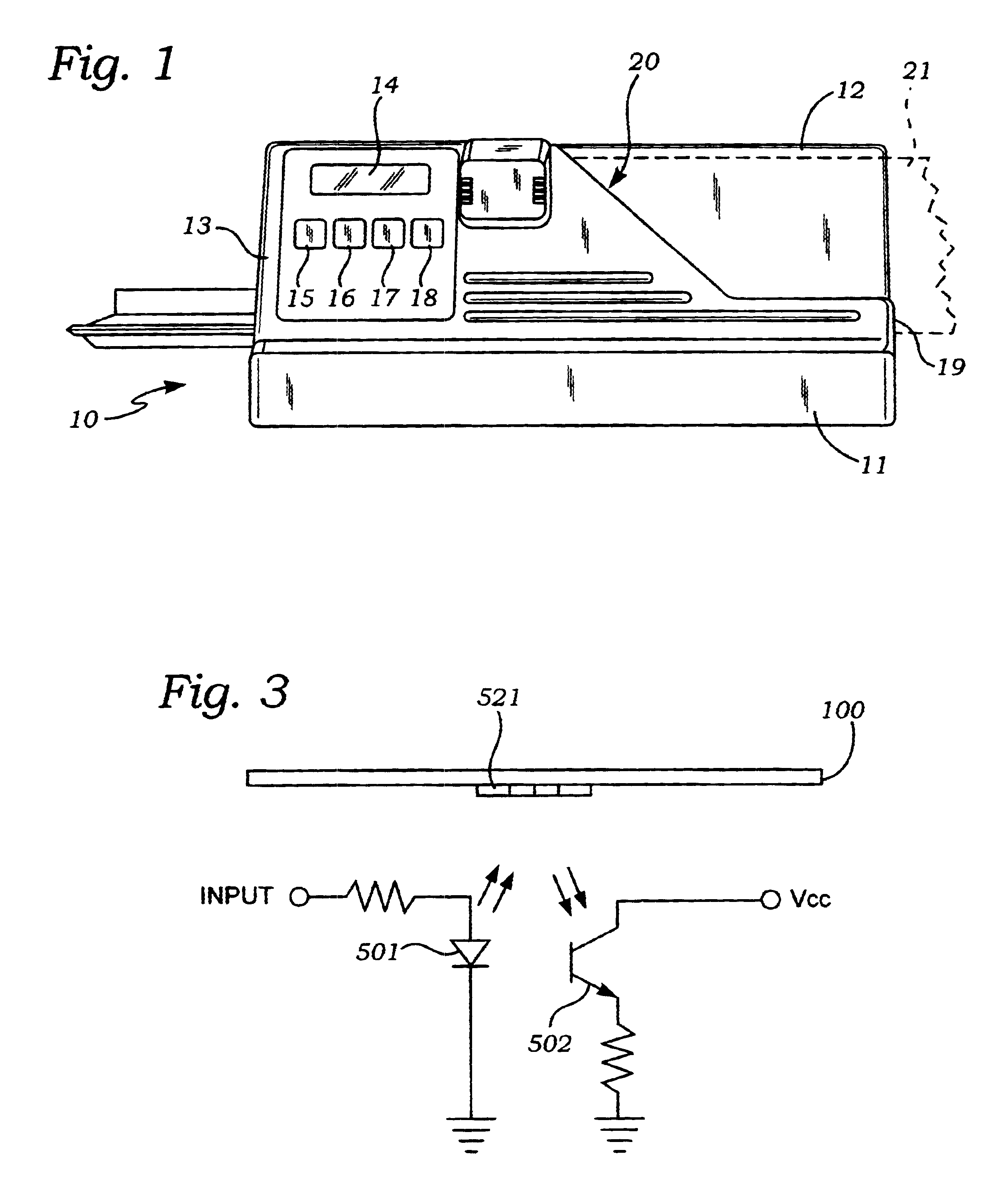

Data processing form using a scanning apparatus

This invention is directed to an optical mark sensing device known as a mark read scanner for reading marks on a form. This scanner is a stand-alone device that has an internal micro-controller with the controlling software therein. An external personal computer is not required to operate the scanner in its intended manner. "Graphic switches" are printed on the form to define the characteristics of a form to be scanned. The expense of replacing the internal program of a scanner when a user requests a variation of a test form that had not been pre-programmed into the original specifications of the scanner is eliminated.

Owner:WILLIAM C APPERSON

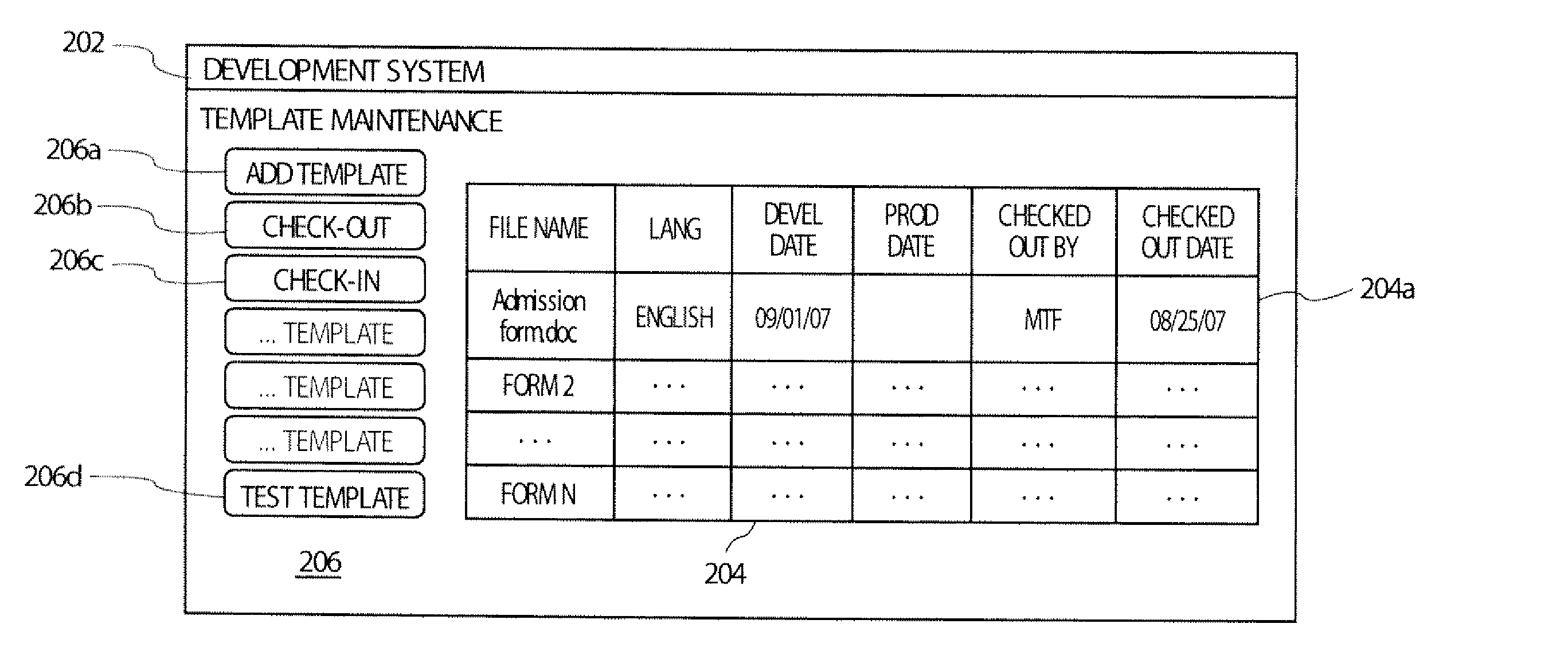

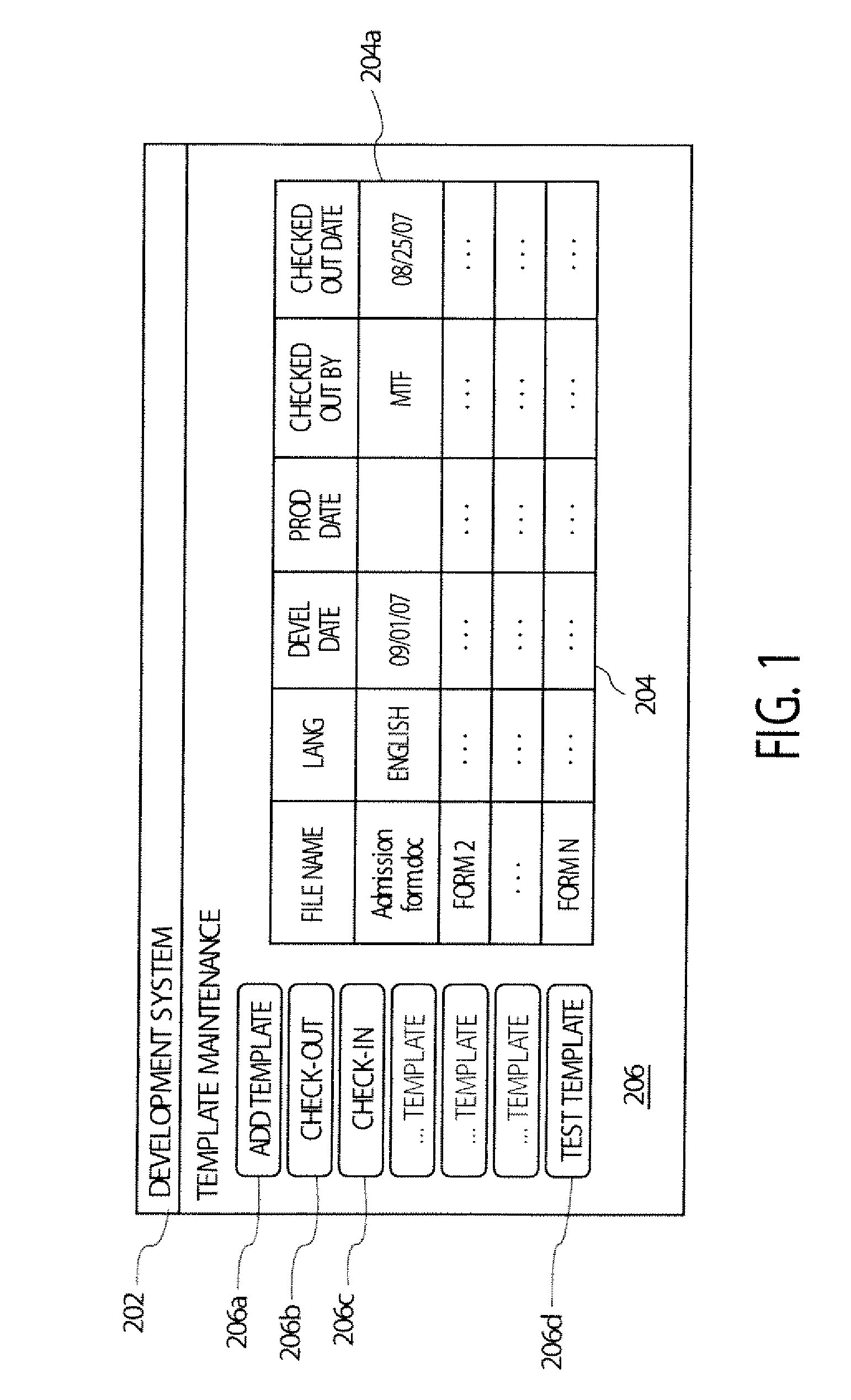

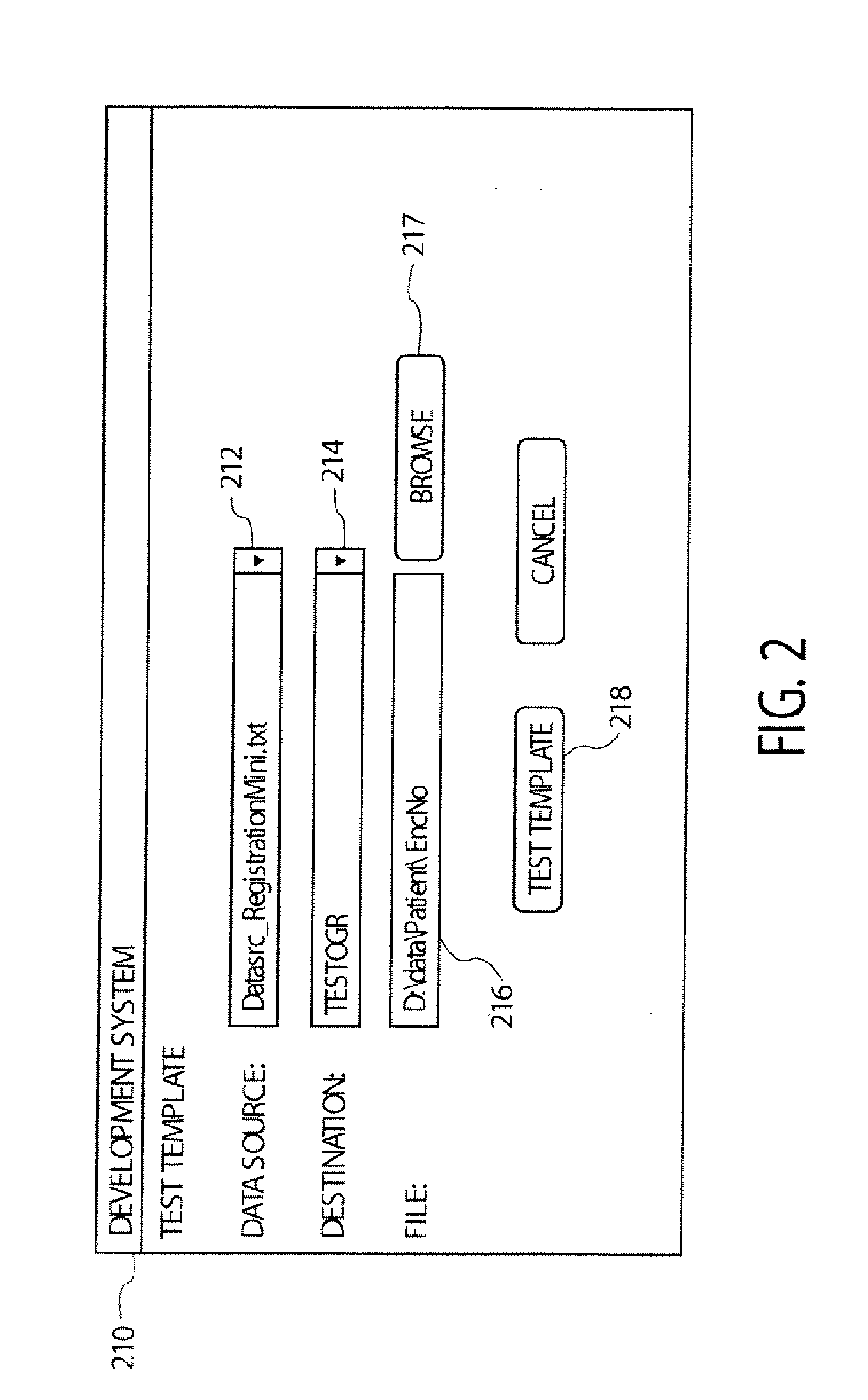

System for Processing and Testing of Electronic Forms and Associated Templates

A system processes and tests forms and associated templates. A form repository includes data representing different electronic forms. A repository of information includes a plurality of sets of HIPAA compliant test data associated with a plurality of different electronic forms. The HIPAA compliant test data is used in populating a plurality of different electronic forms for review. A user interface provides data representing at least one display image enabling a user to select an electronic form from the form repository. A test form generator uses the test data to automatically populate an electronic form selected by a user via the user interface with a HIPAA compliant set of data. An output generator provides a populated electronic form to a user for reproduction and review.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

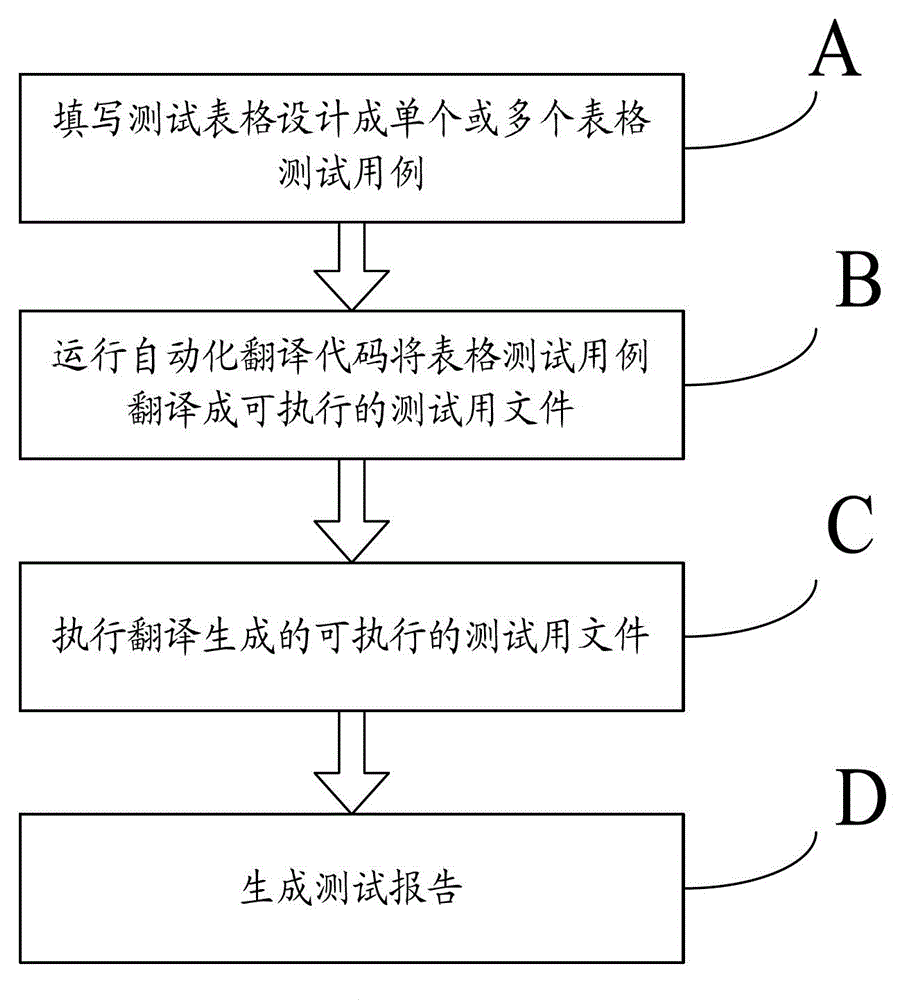

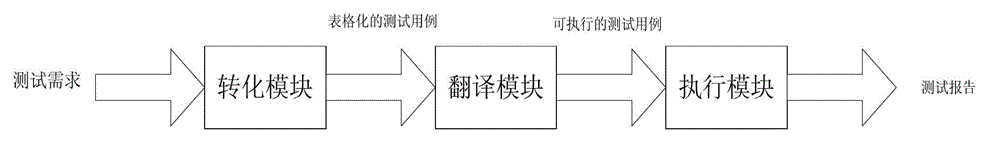

Method and system of electronic control unit (ECU) hardware-in-loop simulation automated testing

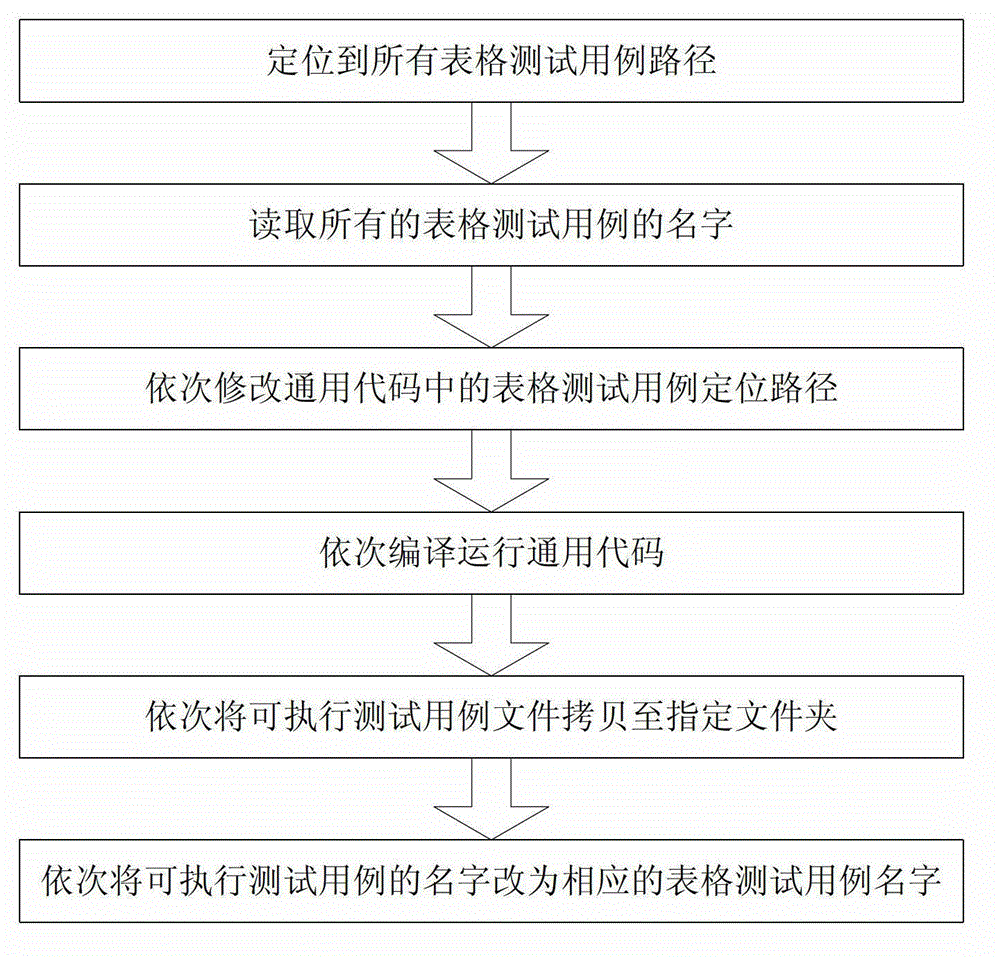

ActiveCN103064403AImprove unityImprove regularityElectric testing/monitoringCode TranslationAutomatic testing

The invention discloses a method and a system of electronic control unit (ECU) hardware-in-loop simulation automated testing. The method comprises the following steps: a test form is filled in so that one or a plurality of test form cases, an automation code is run to enable the form test cases to generate executable files for testing, the test is executed, and a test report is generated. An automated interpreter code is needed to design only once and is permanently effective, and an automated testing development engineer is enabled to be out of a lot of test case code translation work. By adoption of a form test case development mode, the method and the system of ECU hardware-in-loop simulation automated testing are simple, efficient, universal and flexible, and cost performance is high and practical. After a lot of form tests are developed by a testing project, corresponding executable test cases are generated by queue with one key and are automatically executed with one key, so that hardware-in-loop (HIL) automated testing of the ECU is achieved in the real sense.

Owner:WEICHAI POWER CO LTD

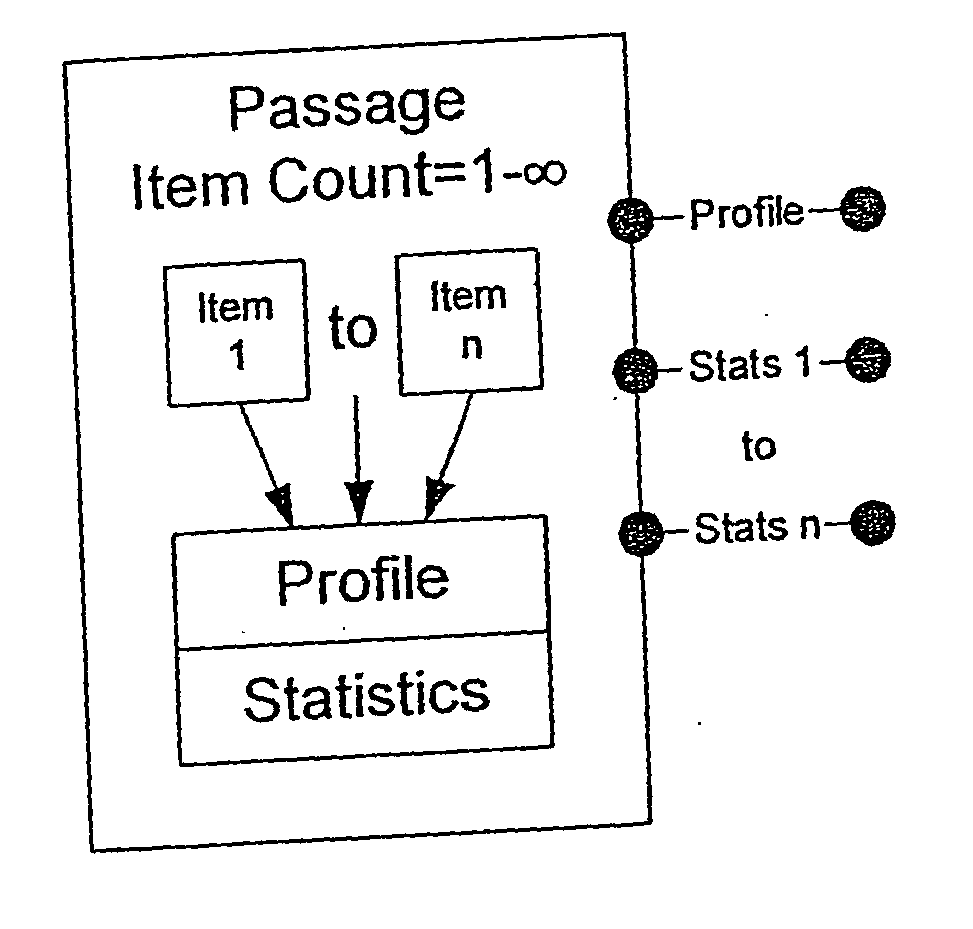

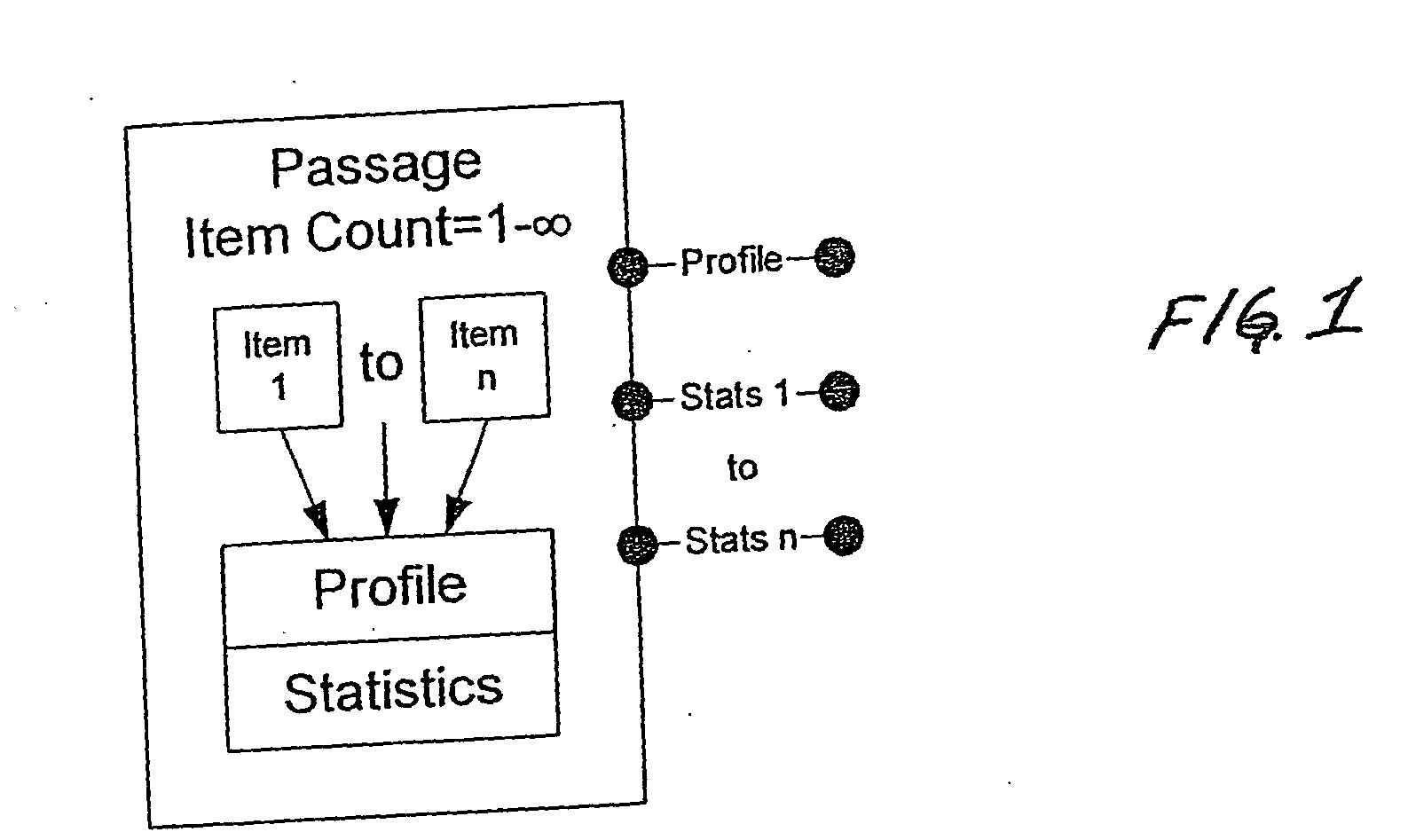

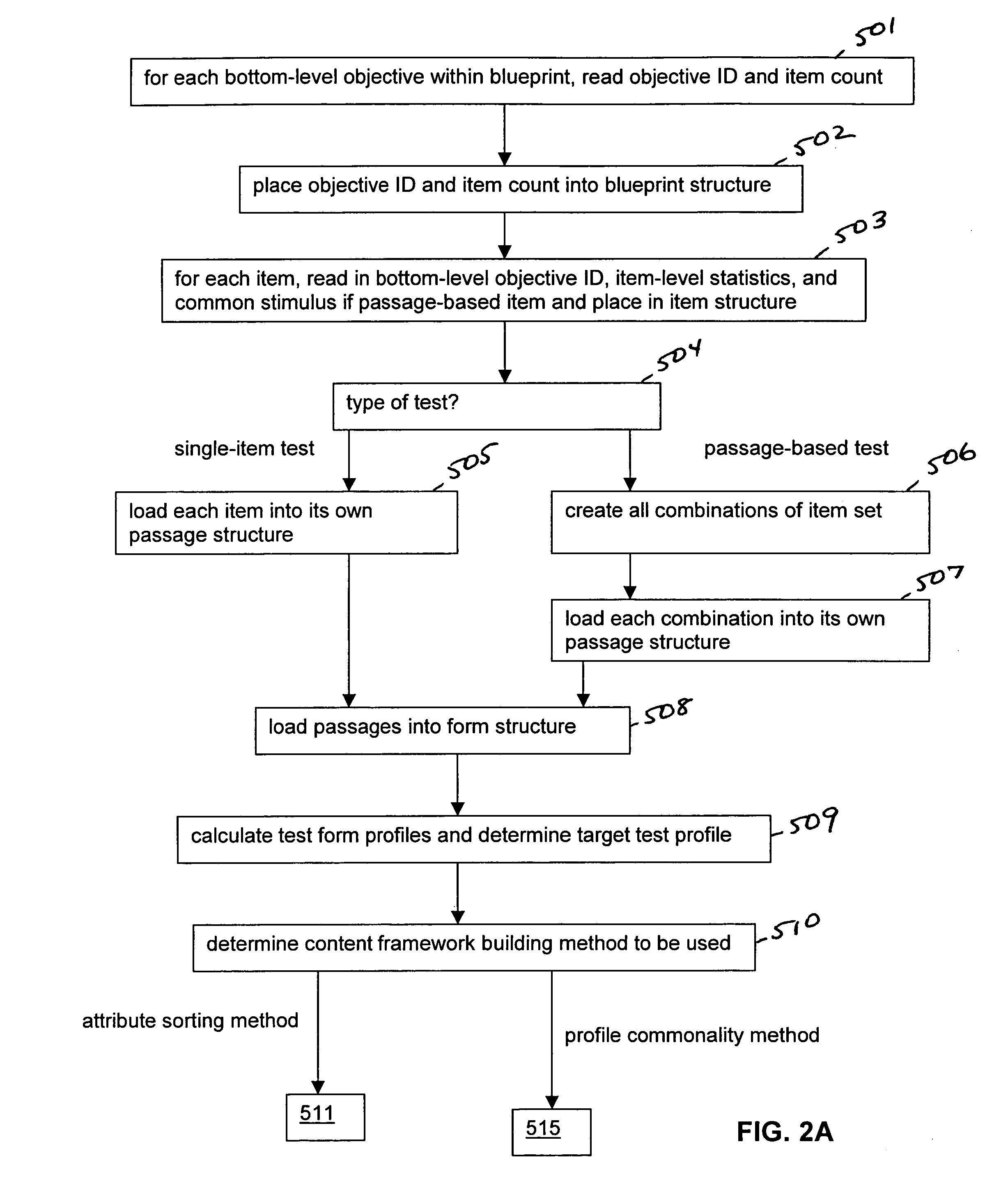

Automated assessment development and associated methods

InactiveUS20060099561A1Efficient searchElectrical appliancesMechanical appliancesData miningBlueprint

Owner:PSYCHOLOGICAL CORPORATION

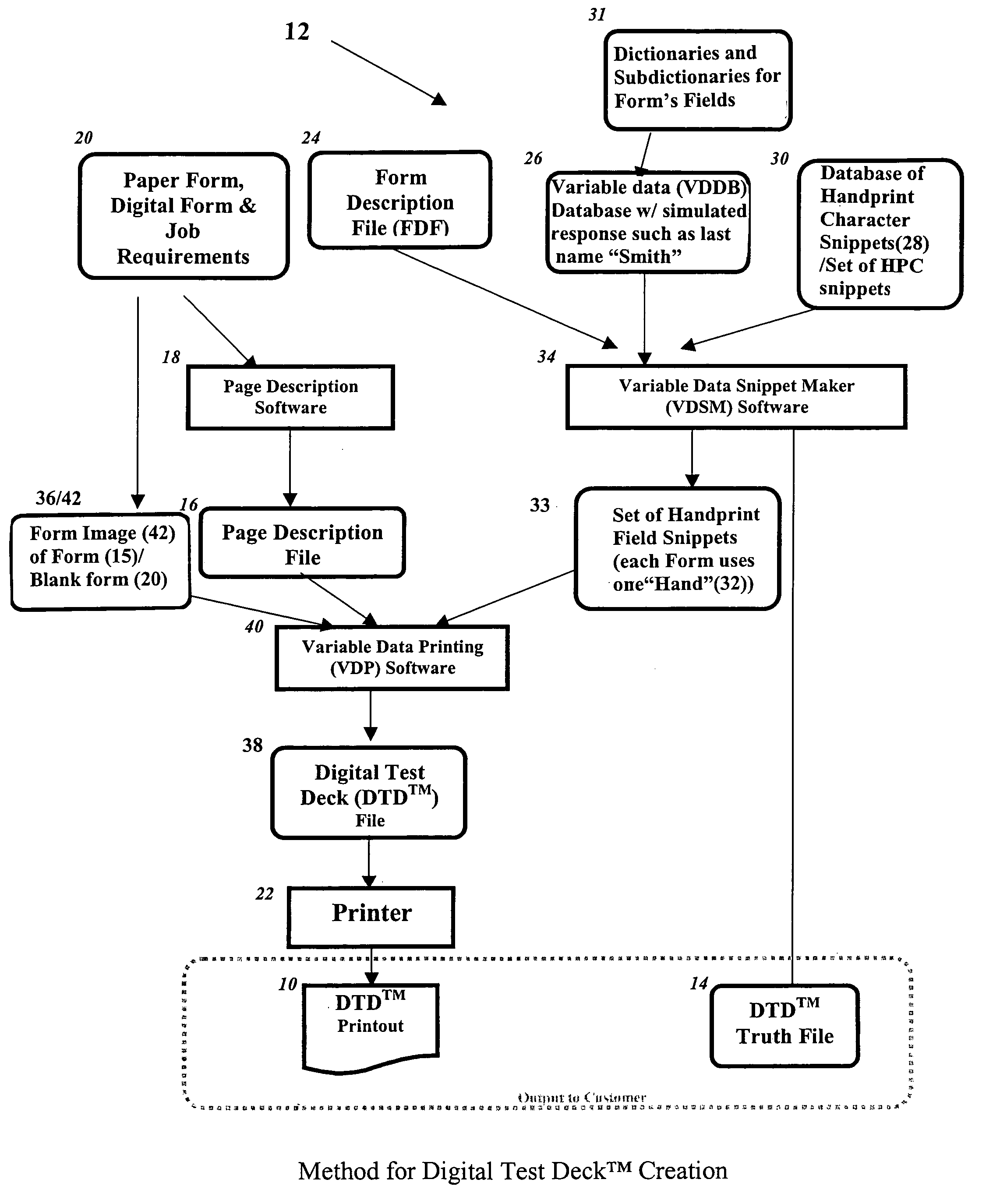

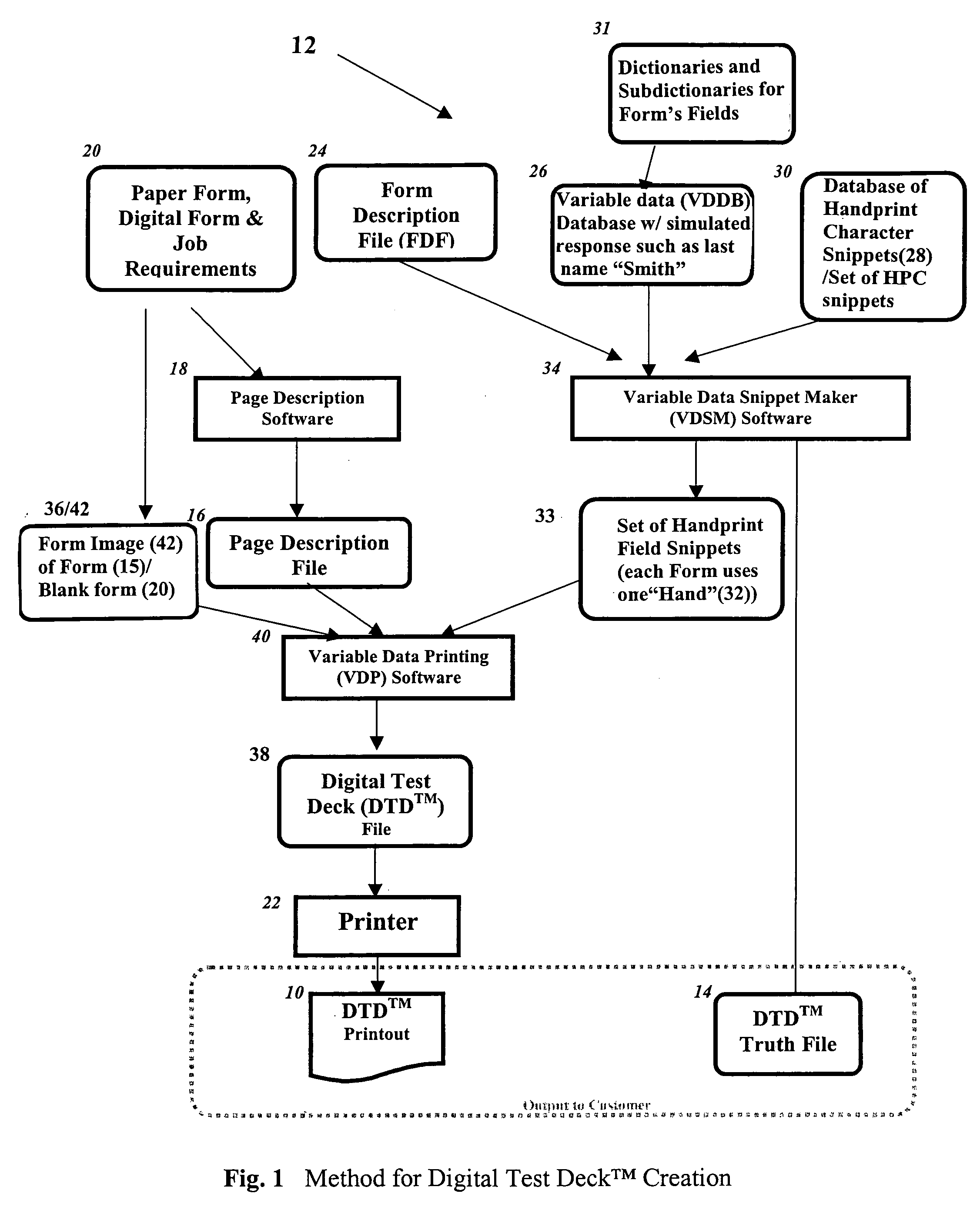

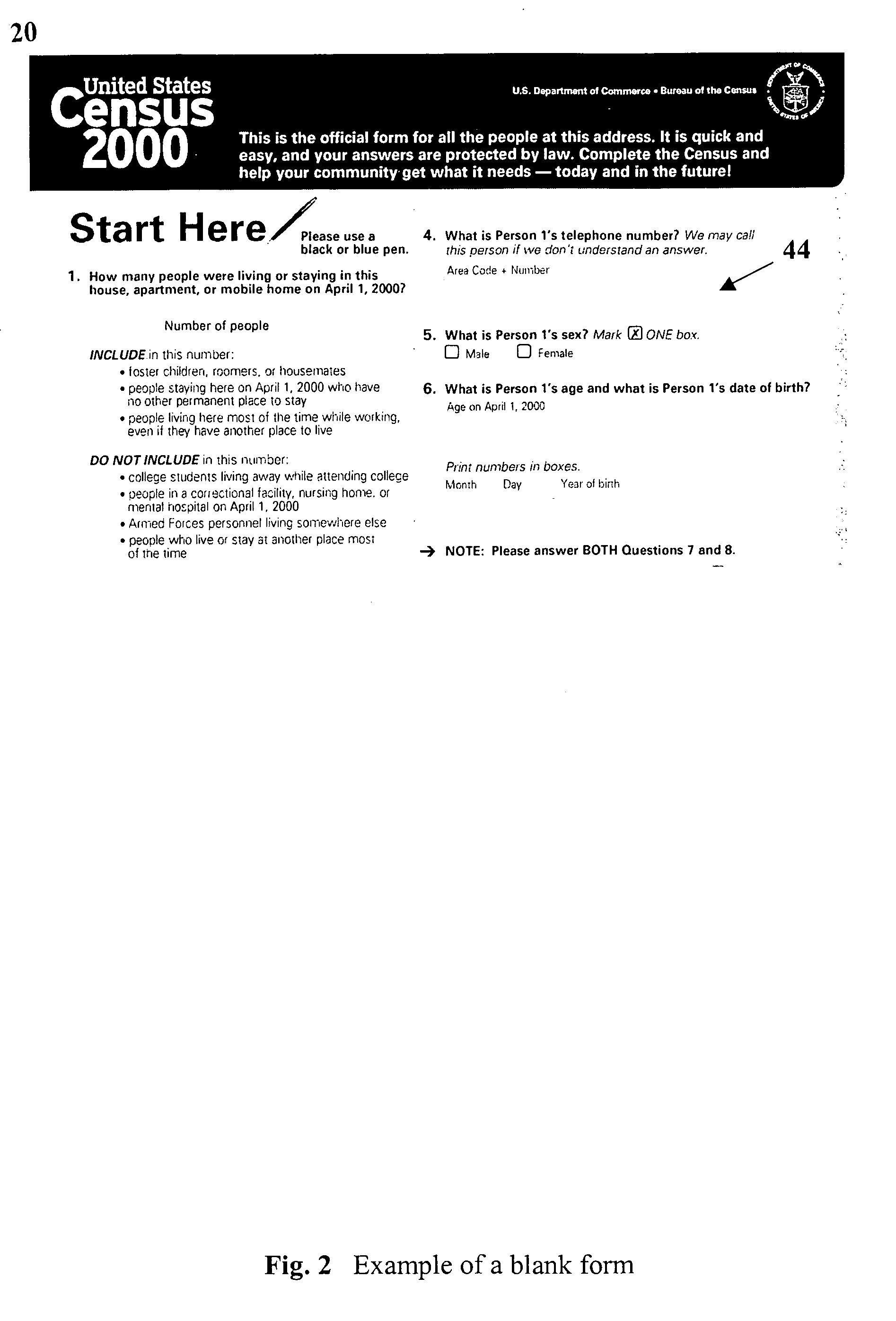

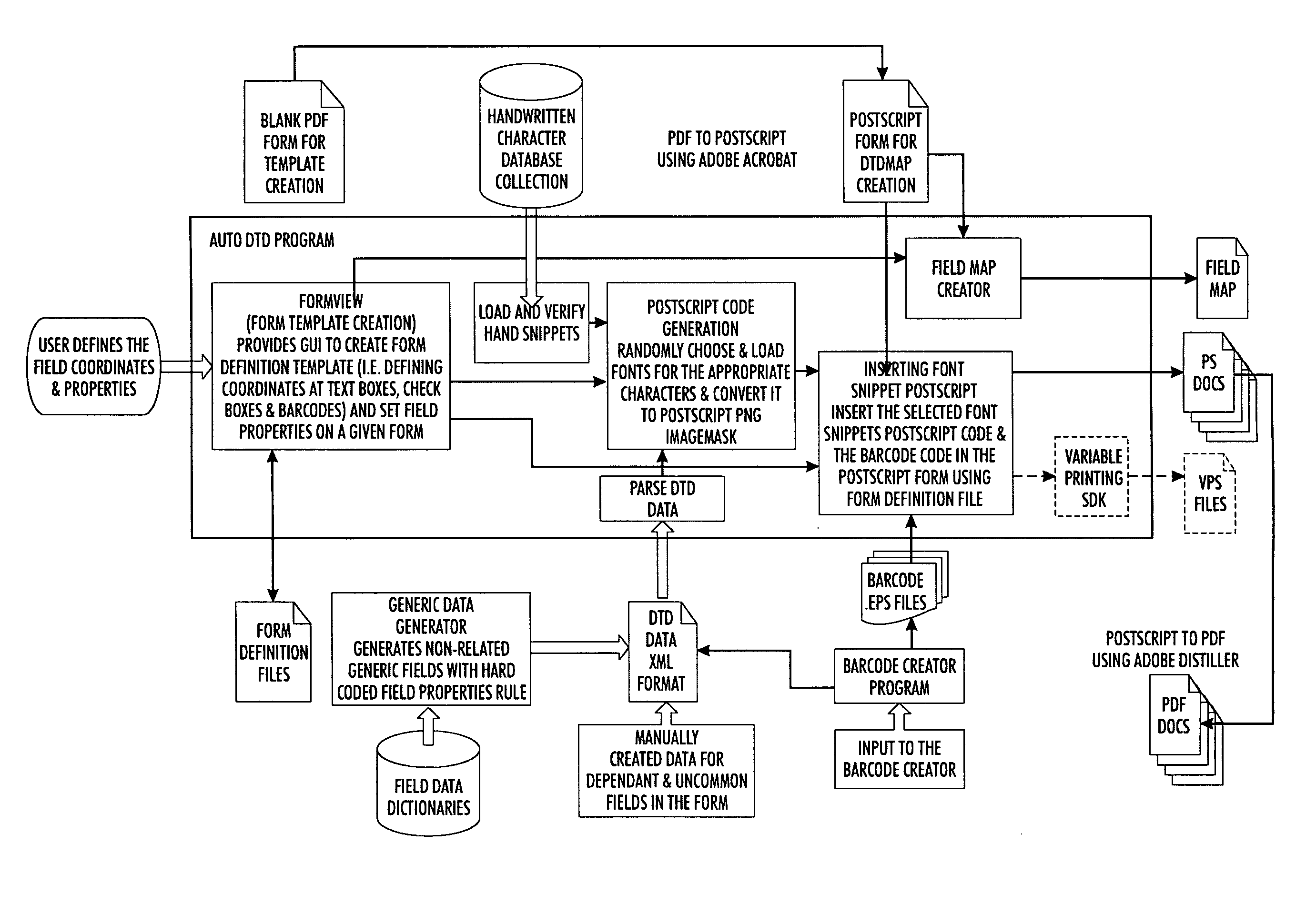

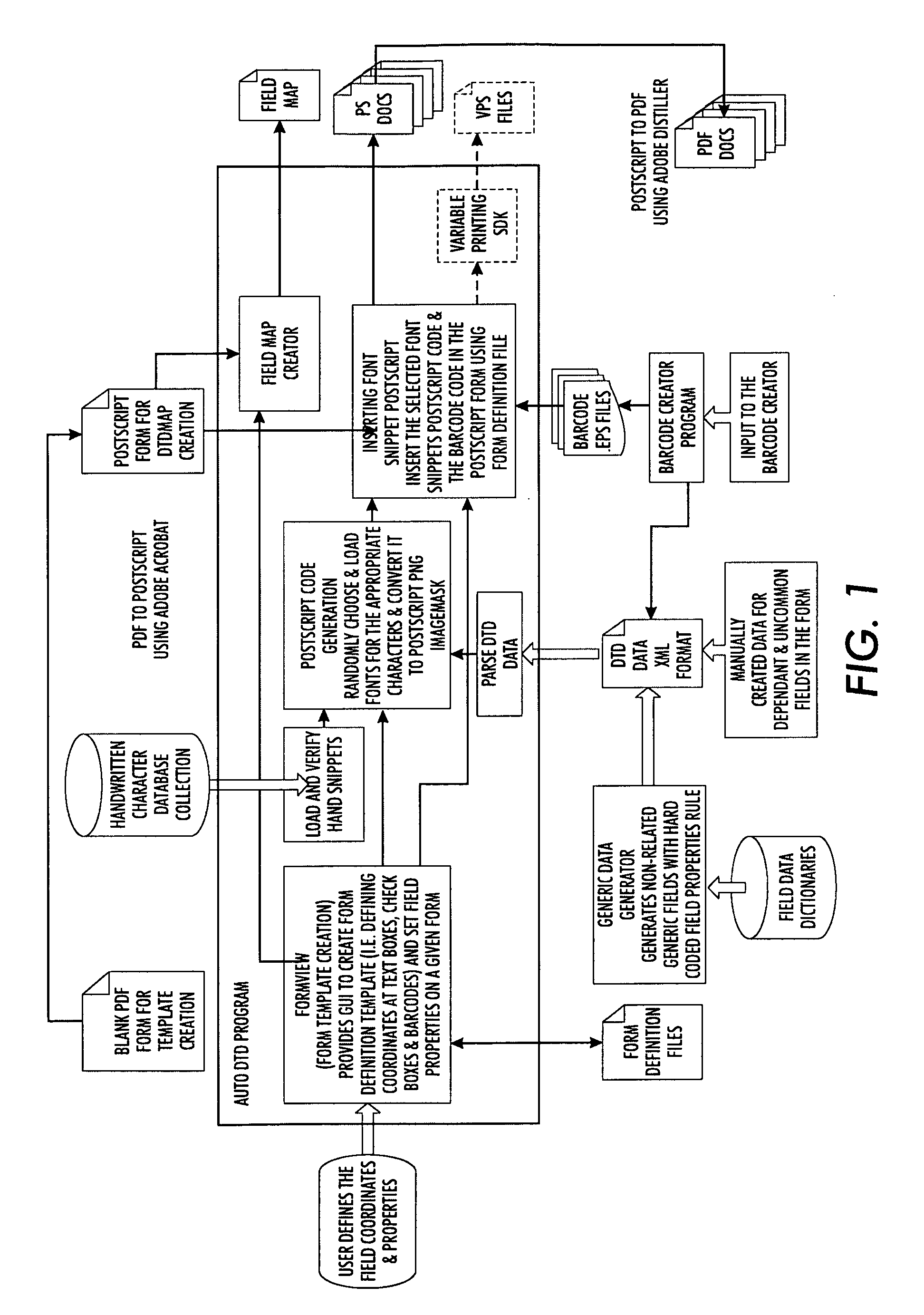

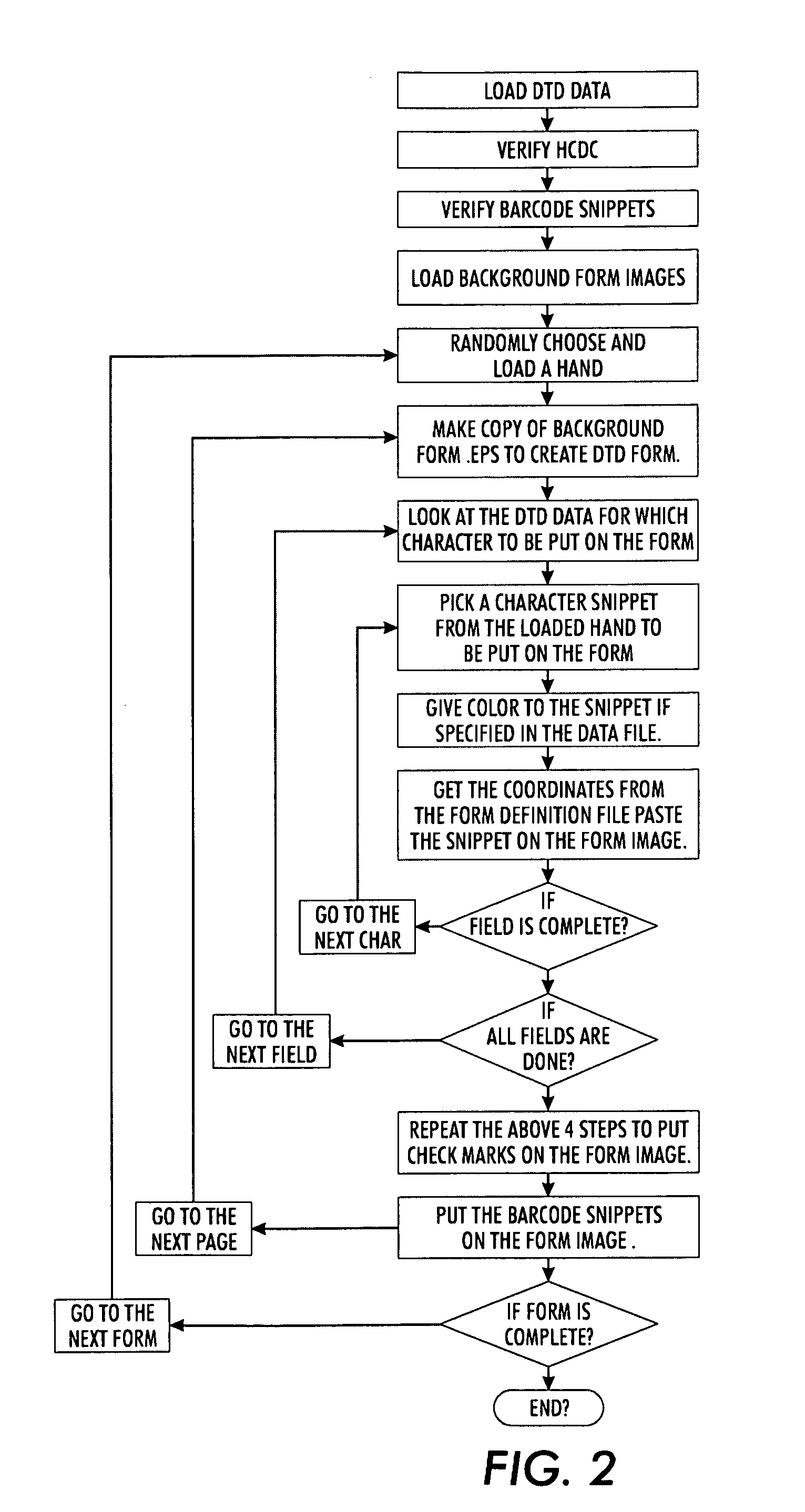

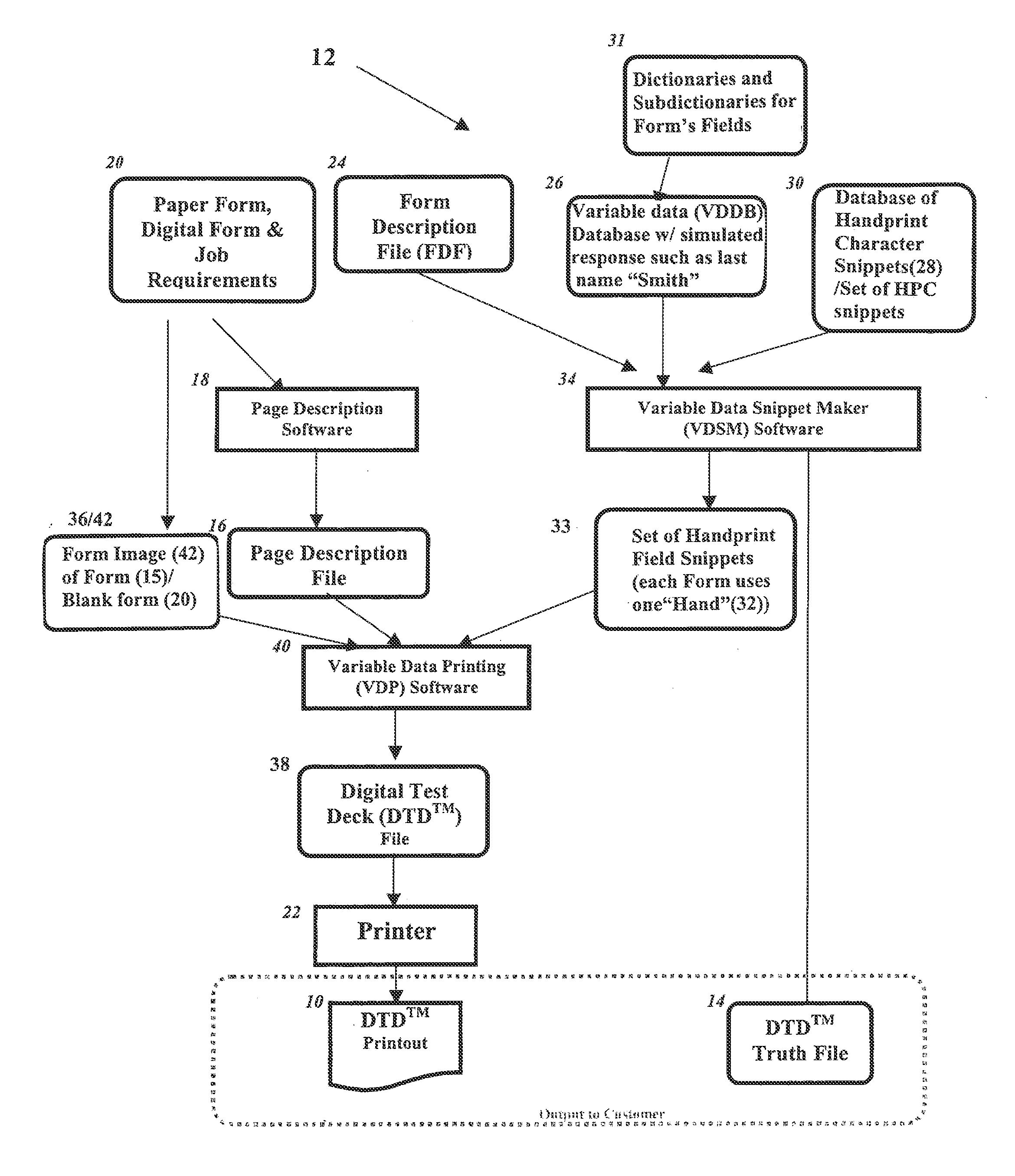

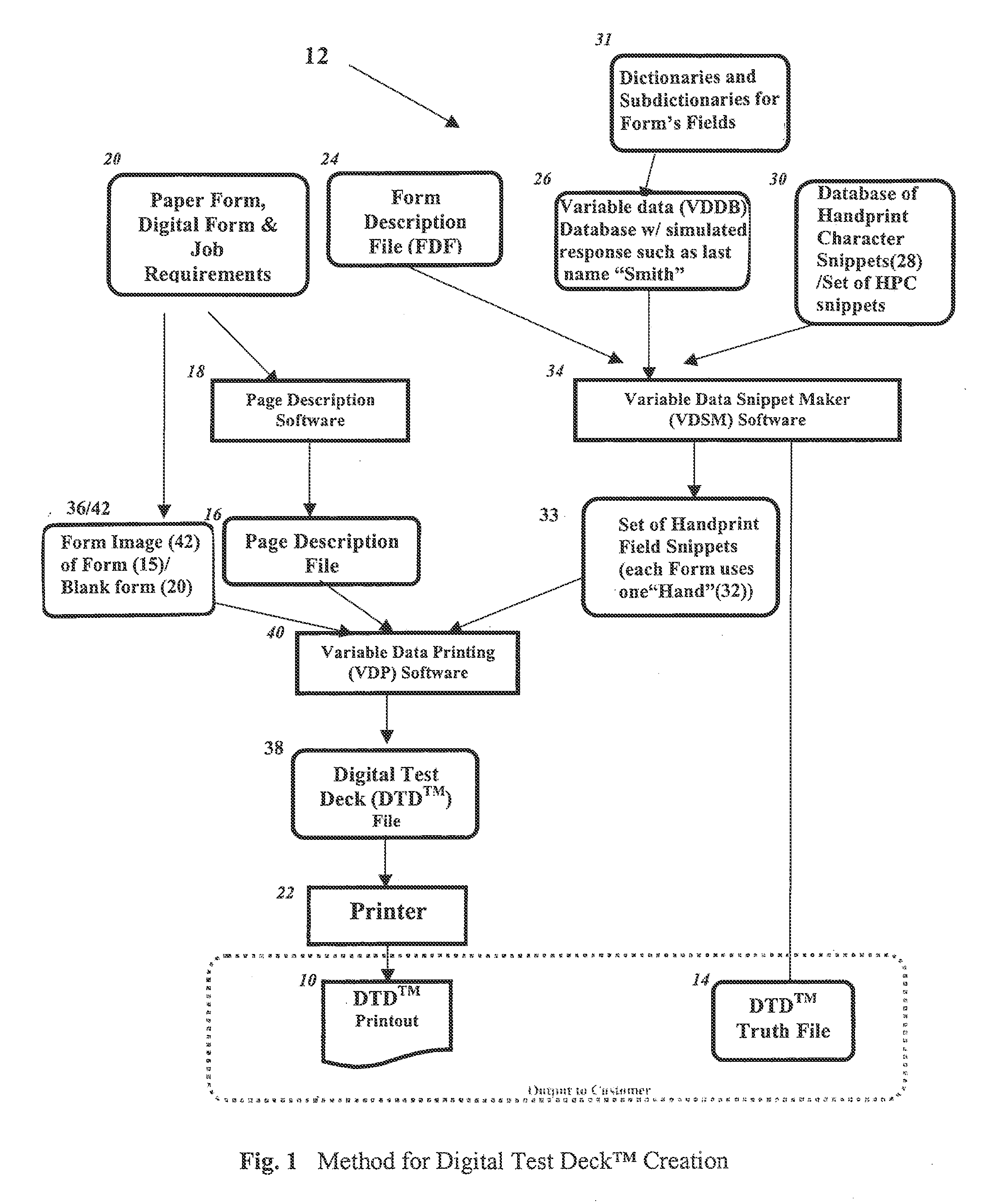

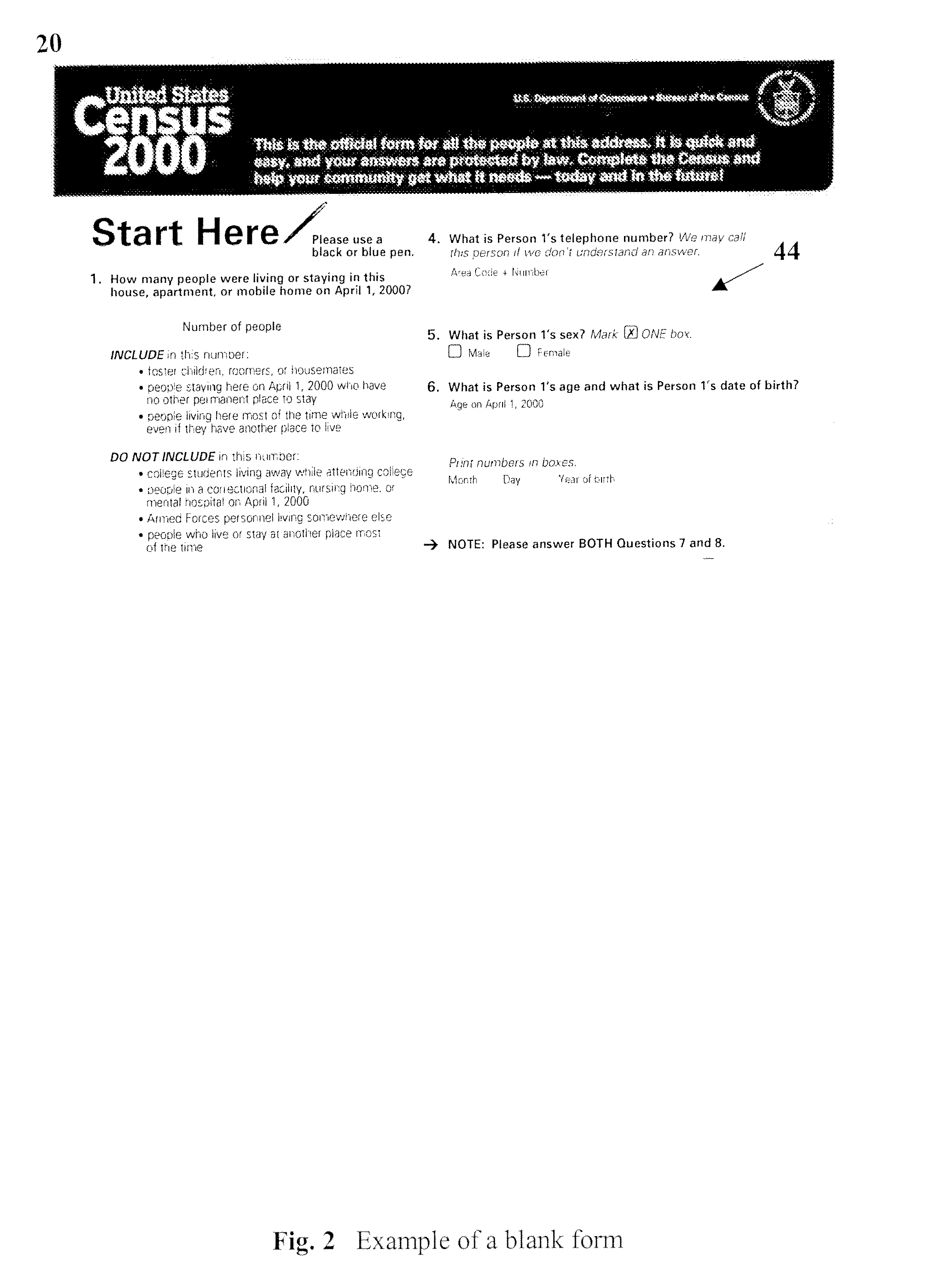

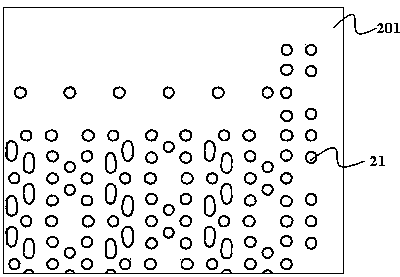

Handprint recognition test deck

A system and method for creating a test deck to qualify and test forms processing systems, including preparing a handprint snippet data base containing labeled handprint image snippets representing a unique hand, preparing a form description file and a data content file, selecting handprint snippets from the handprint snippet data base to formulate a form using the data content file, creating a form image using the selected snippets according to the form description file and printing the form image.

Owner:ADI

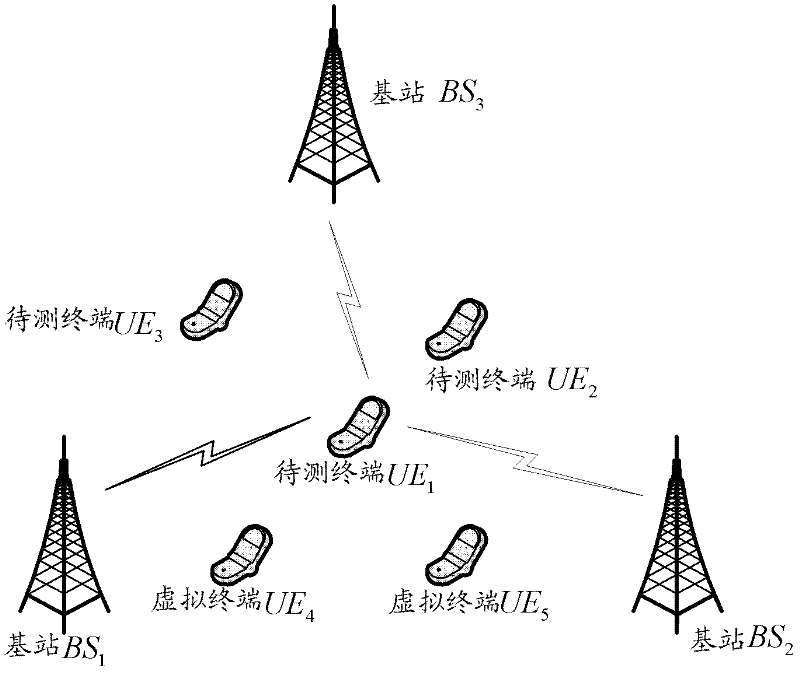

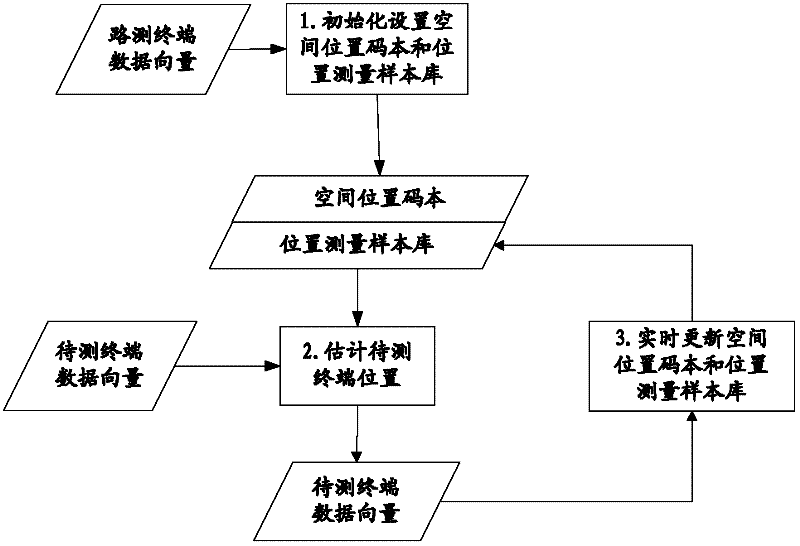

Group location method based on location measurement samples in mobile communication network

InactiveCN102291817AAdapt to the status quo of uneven distributionHigh positioning accuracyWireless communicationEngineeringMobile communication systems

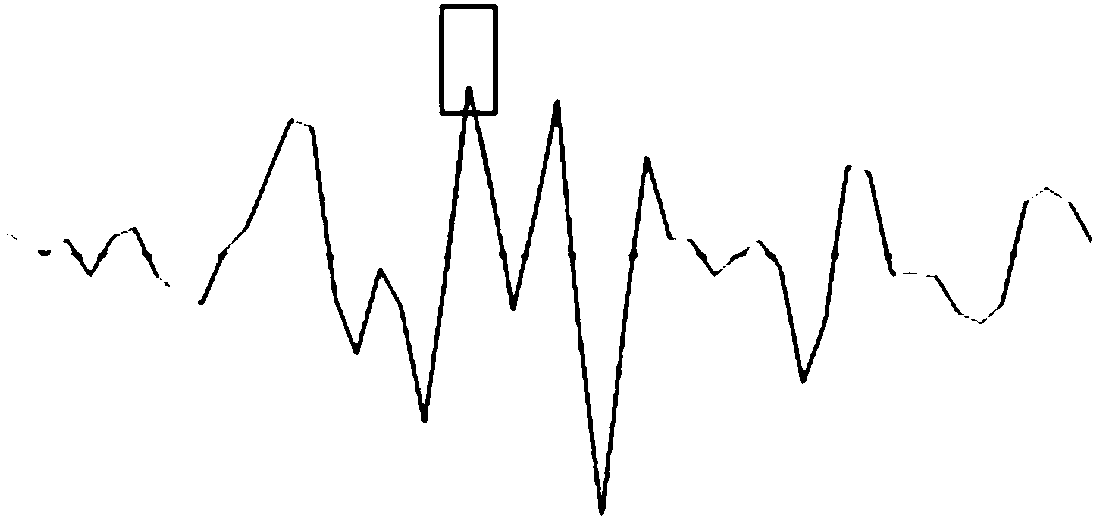

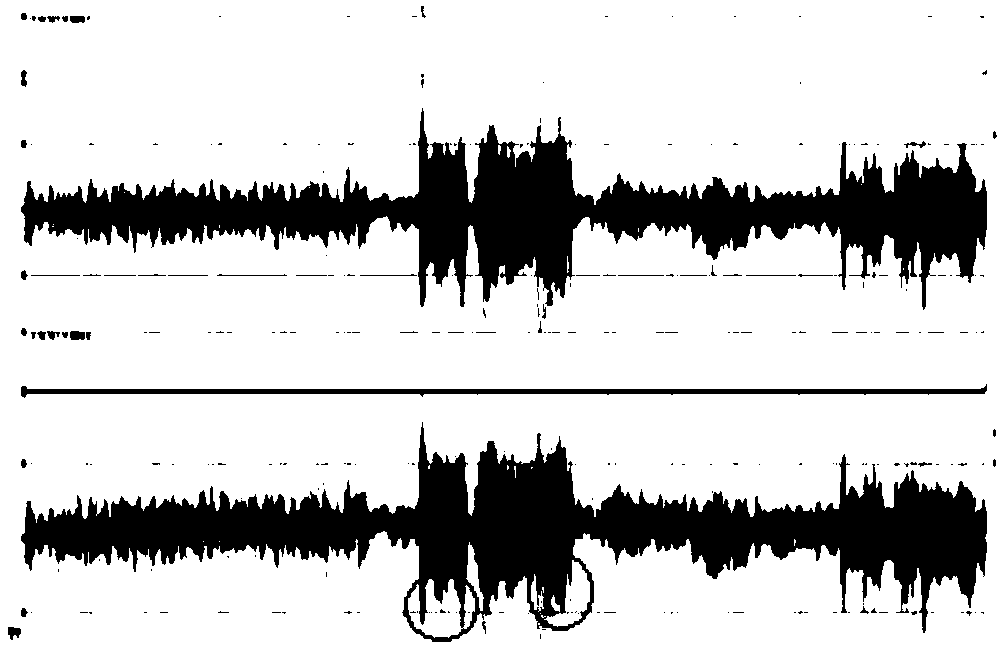

The invention relates to a group positioning method based on a location measurement sample in a mobile communication network, which comprises the steps that mobile terminals to be tested transmit pilot signals to base stations at first, the base stations obtain the signal time of arrival (TOA) and the signal receiving power W of each mobile terminal from received signals, and the two measurement data and the plane coordinates (x, y) of the locations of the mobile terminals to be tested form measurement data vectors (TOA, W (x, y)); and after each base station calculates the positioning location of each mobile terminal according to the received measurement data vector of each mobile terminal, in combination with the data of a spatial location codebook and a location measurement sample database, each base station transmits the positioning location information to the corresponding mobile terminal. The group positioning method based on the location measurement sample in the mobile communication network has the advantages that in combination with history measurement data in a cell and the measurement parameters of the current multiple mobile terminals, only one time of positioning calculation is required, the group positioning demands of multiple users can be satisfied, the positioning accuracy is high, the measurement data can be obtained very easily and conveniently and the method is suitable for all kinds of existing mobile communication systems.

Owner:BEIJING UNIV OF POSTS & TELECOMM

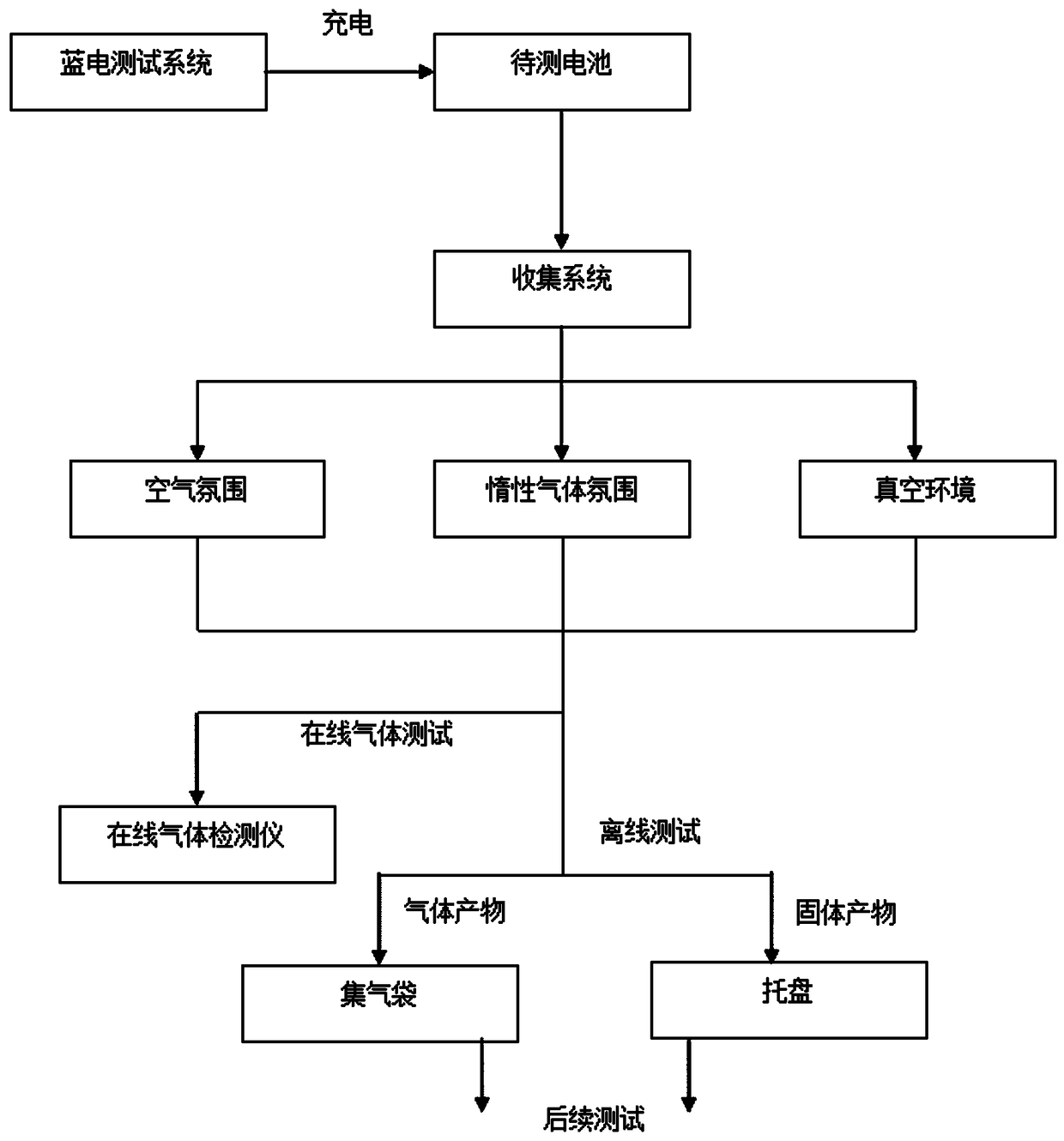

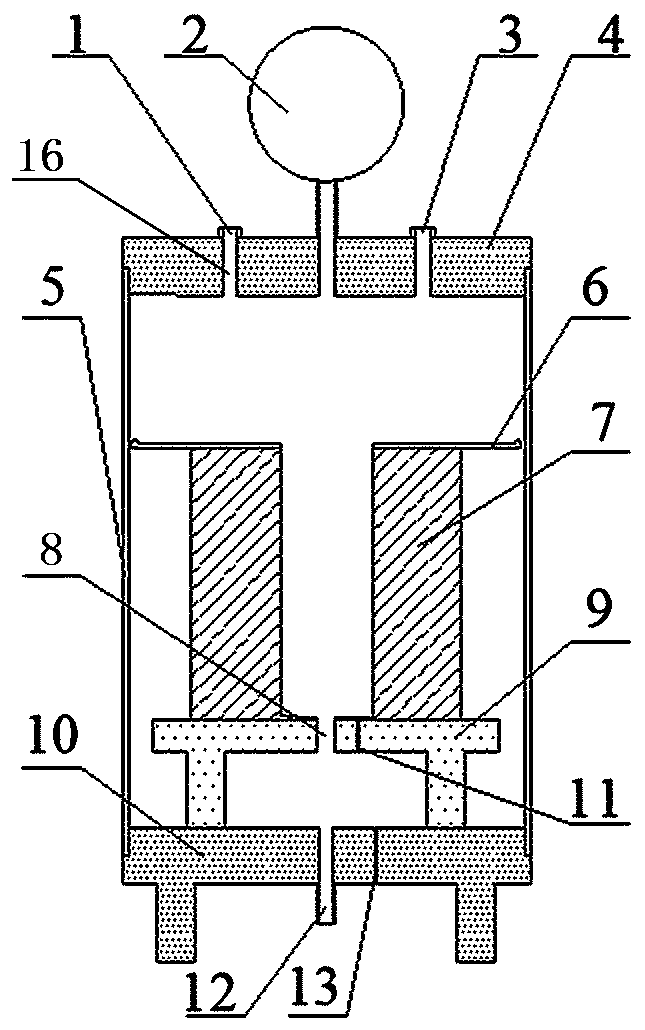

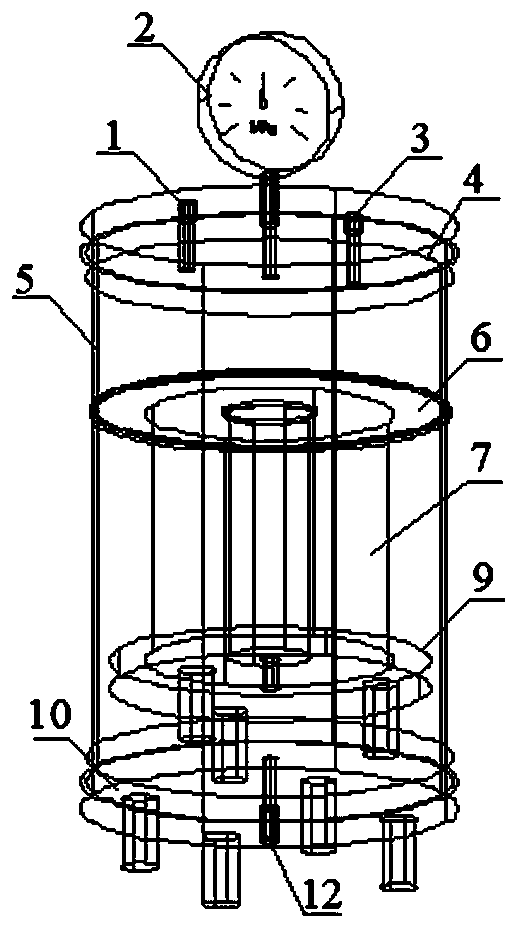

Lithium ion battery thermal runaway product collection and test method

InactiveCN109270111AQuantitative data of precise risk degreeMaterial heat developmentVent arrangementsElectricityResearch Object

The invention discloses a lithium ion battery thermal runaway product collection and test method, related to a lithium ion battery thermal runaway gaseous and solid product collection and online and off-line test method, which is particularly suitable for collection and test of thermal runaway products under different parameter conditions. The lithium ion battery thermal runaway product collectionand test method comprises the following steps: 1) setting a battery thermal runaway condition, and using an electric heating mode to make a battery to be tested come up thermal runaway under the setcondition; 2) collecting and obtaining the gaseous and solid products after the battery is thermal runaway; 3) testing the gaseous products collected in step 2); and 4) testing the solid products collected in step 2). The lithium ion battery thermal runaway product collection and test method disclosed by the invention takes the thermal runaway products of the lithium ion battery as the research object, and adopts different collection and test methods for different environmental atmospheres, different thermal runaway products and different test forms to obtain quantitative data of the dangerousdegree of the thermal runaway products of the lithium ion battery.

Owner:NANJING TECH UNIV

Automating Creation of Digital Test Materials

InactiveUS20080235263A1Quick to useNot easy to make mistakesNatural language data processingSpecial data processing applicationsData contentTest material

A system and method for automatically creating a digital test materials to qualify and test forms processing systems, including preparing a handprint snippet database containing labeled handprint image snippets representing a unique human hand, preparing a form description file and a data content file, selecting handprint snippets from the handprint snippet data base to formulate a form using the data content file, creating a form image using the selected snippets according to the form description file, and, if desired, printing the form image.

Owner:ADI

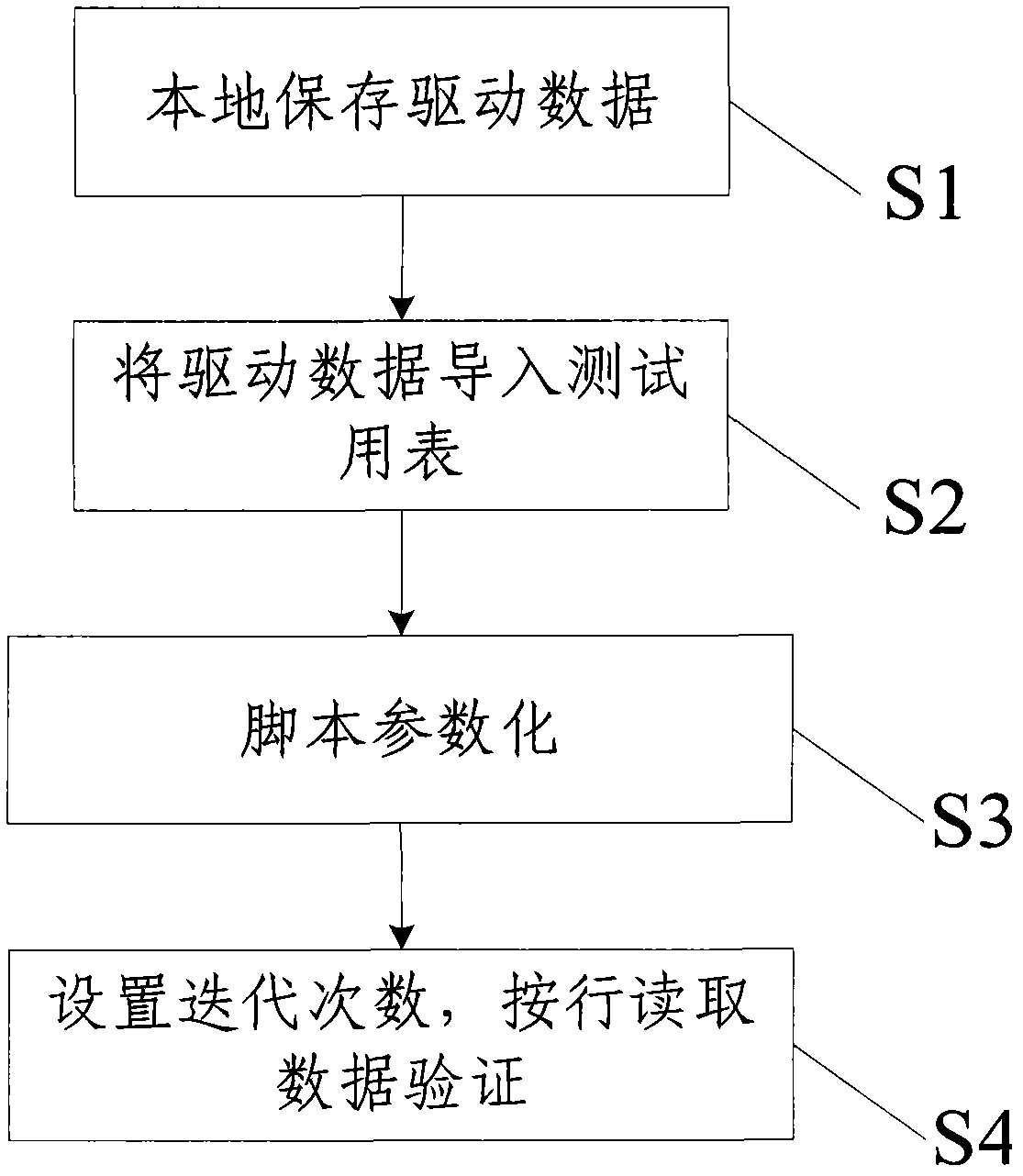

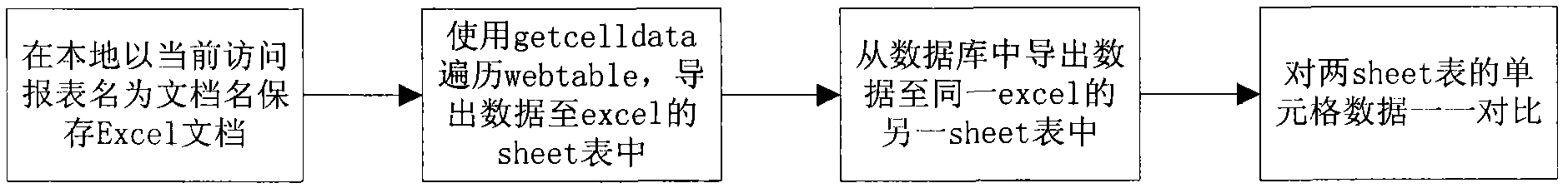

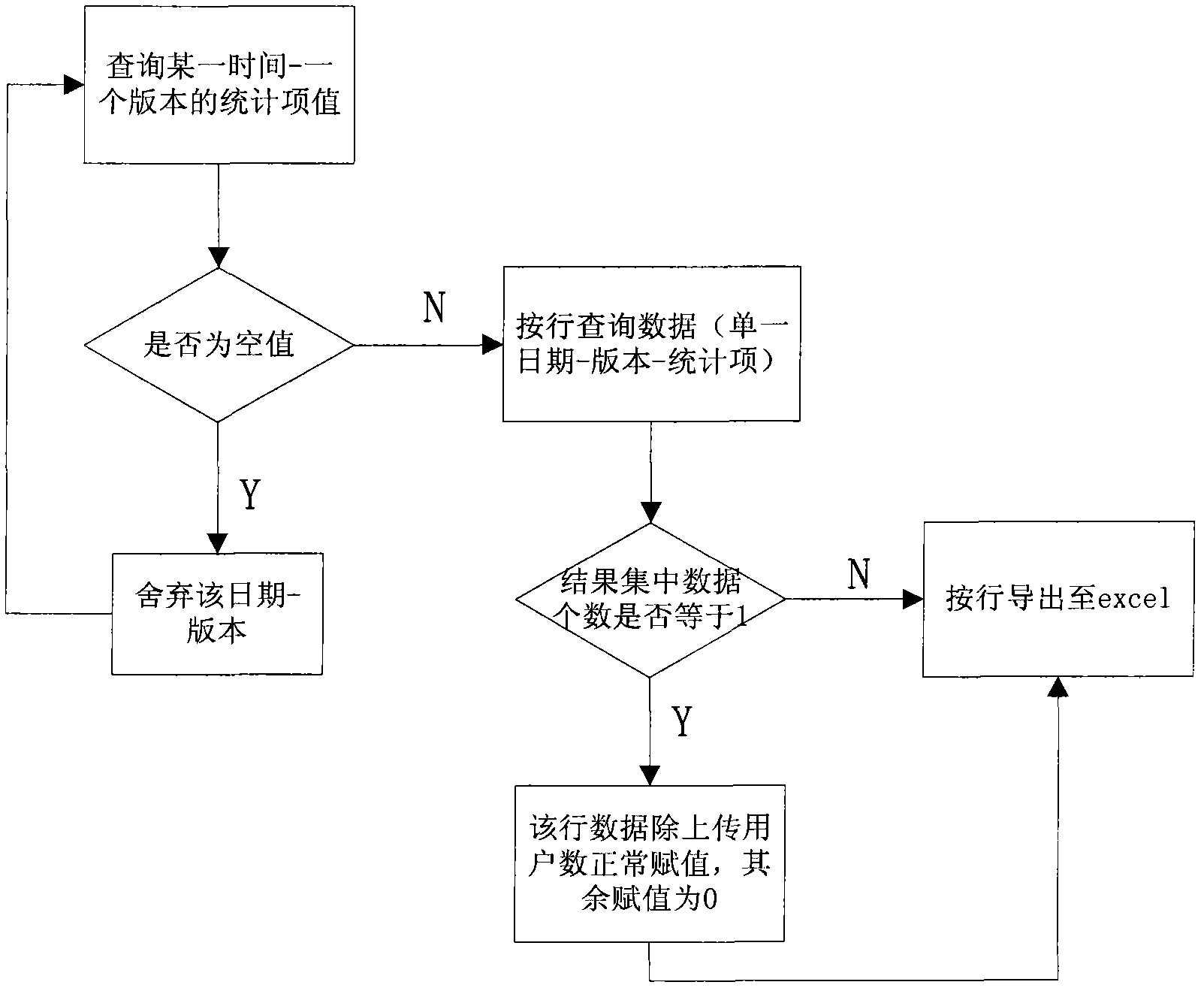

Method and device for verifying data correctness

ActiveCN103186467AReduce maintenance costsIncrease profitSoftware testing/debuggingSpecial data processing applicationsData validationTest script

The invention relates to the technical field of data test and provides a method and a device for verifying data correctness. The method comprises the following steps: establishing a document for storing driving data in a local computer; importing the driving data to a test form; parameterizing a script according to a column name of the driving data in the test form; and setting an iteration and reading in sequence substitution parameters of all lines of driving data in the test form to drive the test script to execute data verification according to the setting of the iteration. With adoption of the method, the test data is separated from the script, data read from a data file in a parameterization manner is written on the script, and one-time execution of the script can achieve test of data in multiple pieces of report forms, so that maintenance cost of the script is greatly reduced, and the script utilization ratio that QTP (quick test professional) verifies correctness of data in a web report form is effectively improved.

Owner:BEIJING FEINNO COMM TECH

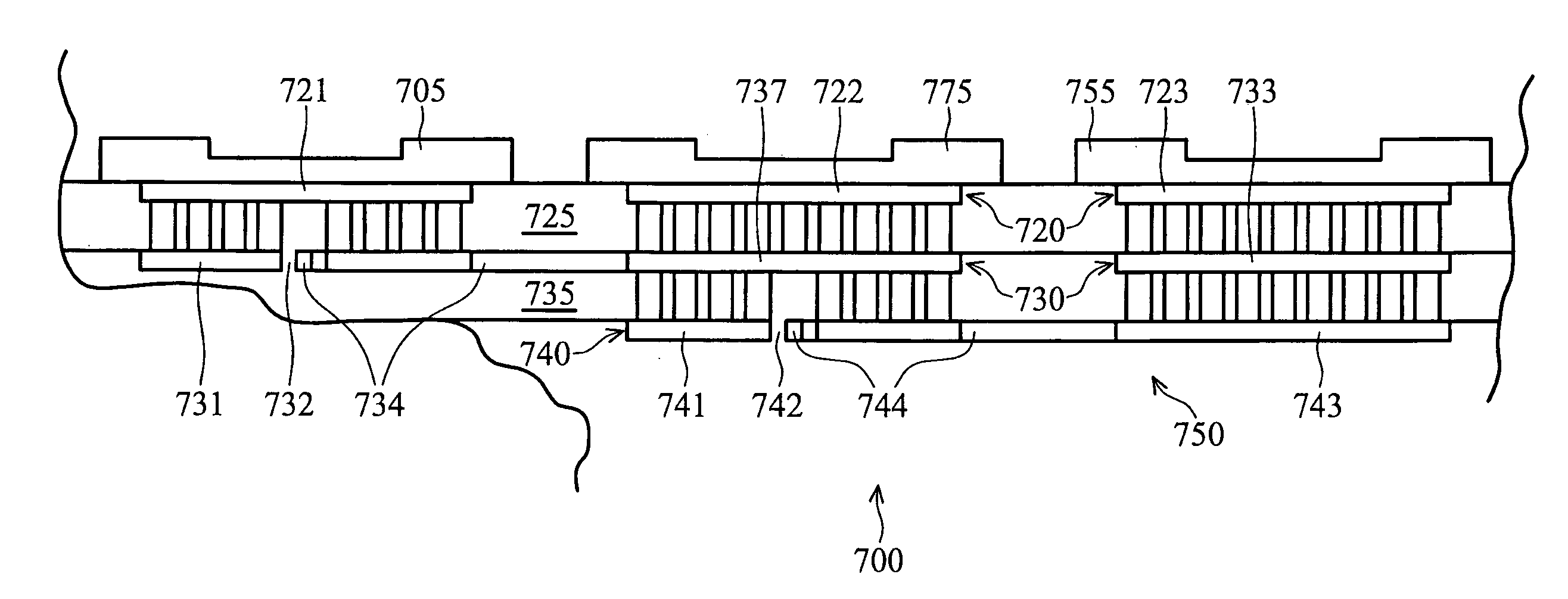

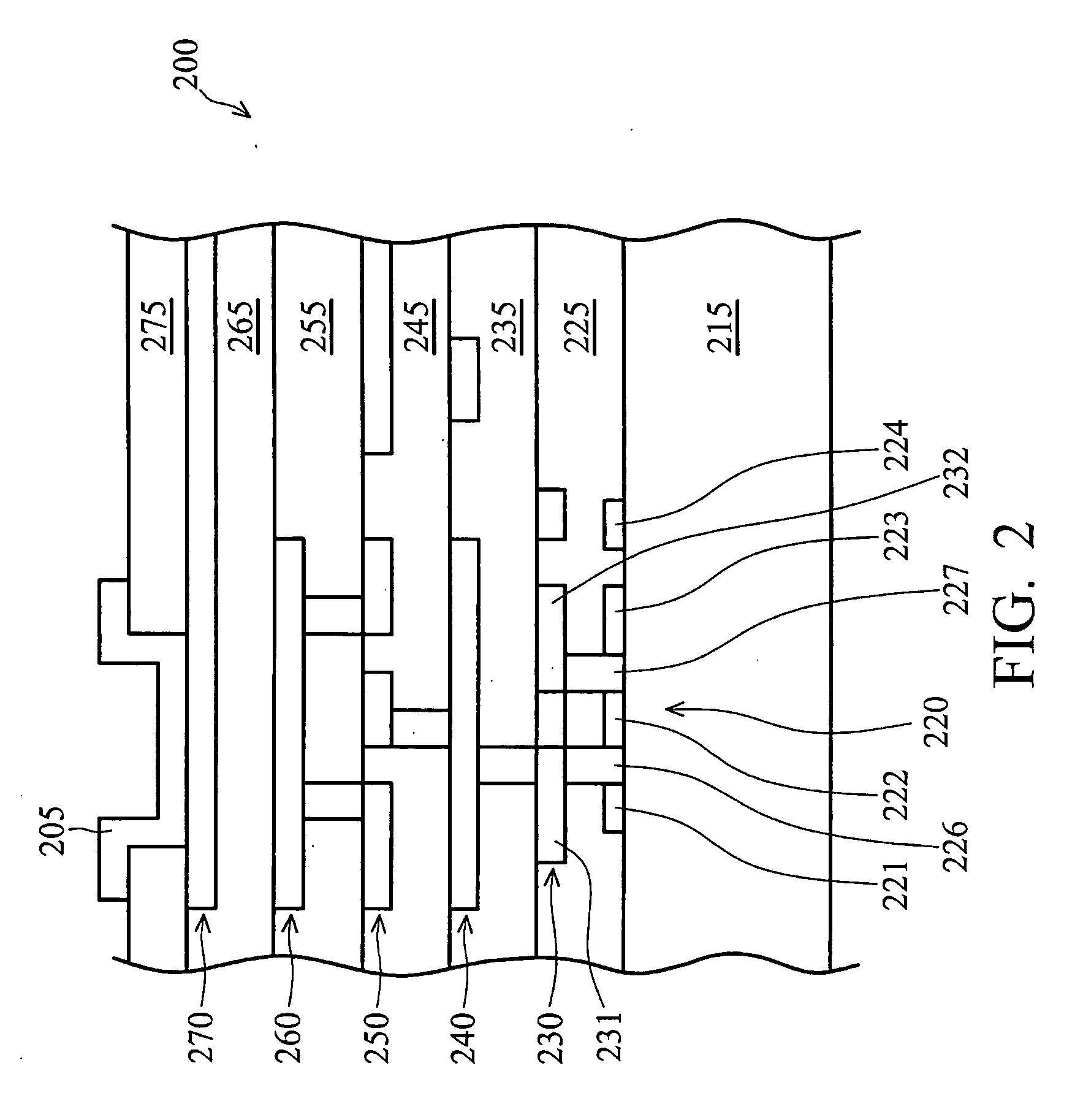

Test structure

ActiveUS20080135840A1Efficient detectionFabrication process is not delayedSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsDielectricMostly True

A test structure to detect vertical leakage in a multi-layer flip chip pad stack or similar semiconductor device. The test structure is integrated into the semiconductor device when it is fabricated. A metal layer includes at least two portions that are electrically isolated from each other; one portion being disposed under a test pad, and another portion being disposed under a pad associated with a pad structure being tested. The metal layer in most cases is separated from a top metal layer directly underlying the pads by an inter-metal dielectric (IMD) layer. A metal layer portion underlying the pad to be tested forms a recess in which a conductive member is disposed without making electrical contact. The conductive line is electrically coupled to a test portion of the same or, alternately, of a different metal layer. The test structure may be implemented on multiple layers, with recesses portions underlying the same or different pads.

Owner:TAIWAN SEMICON MFG CO LTD

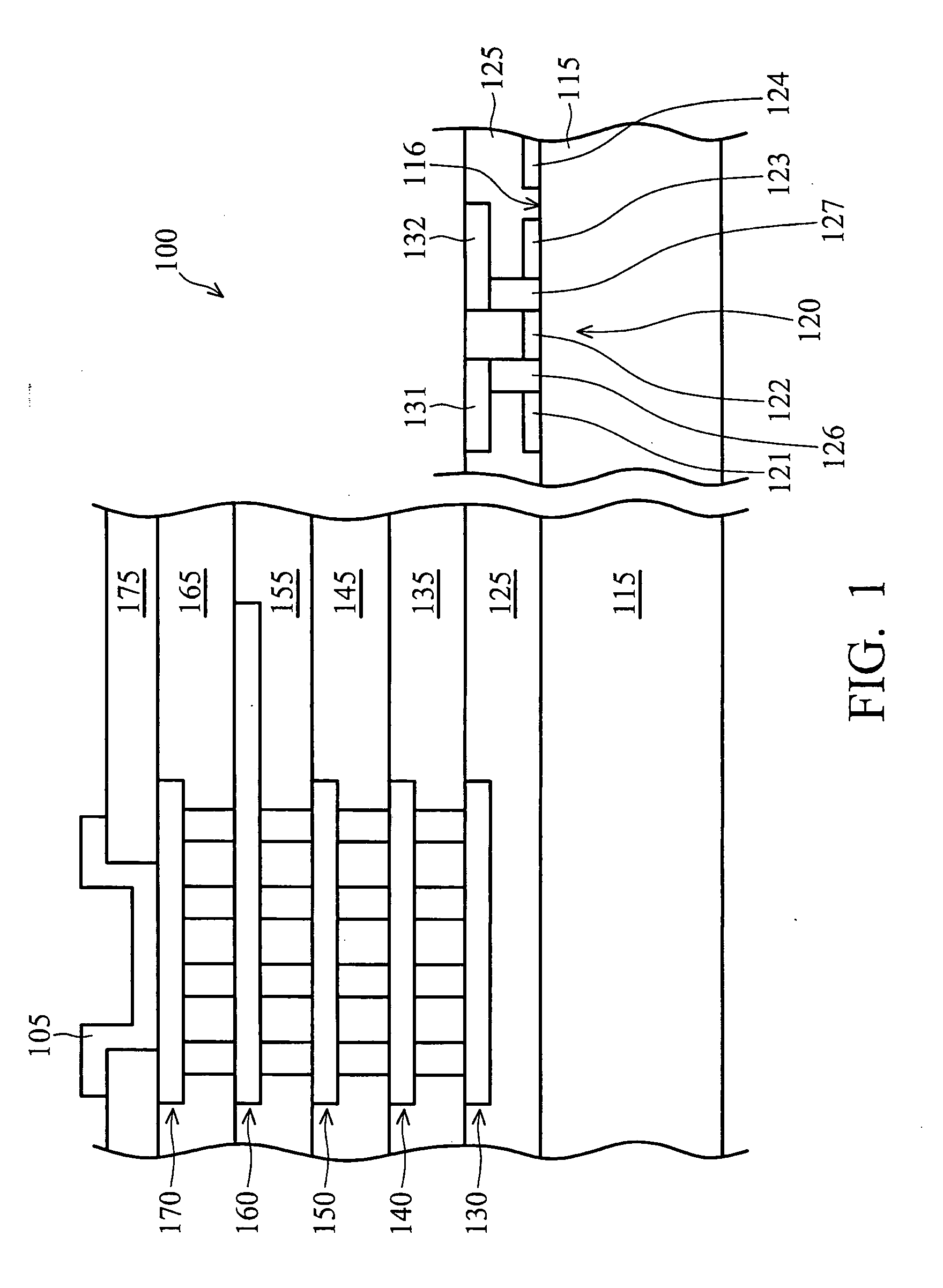

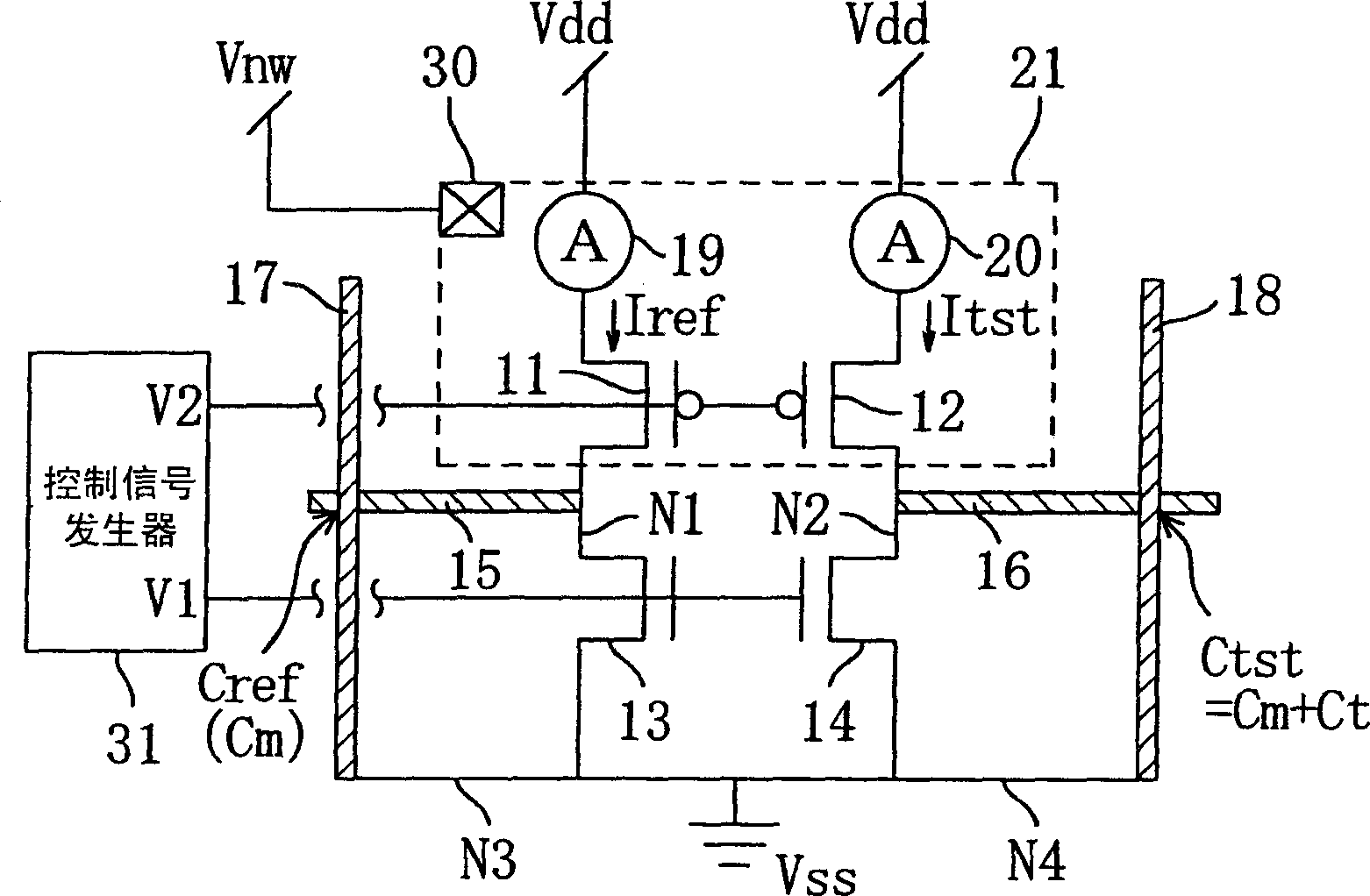

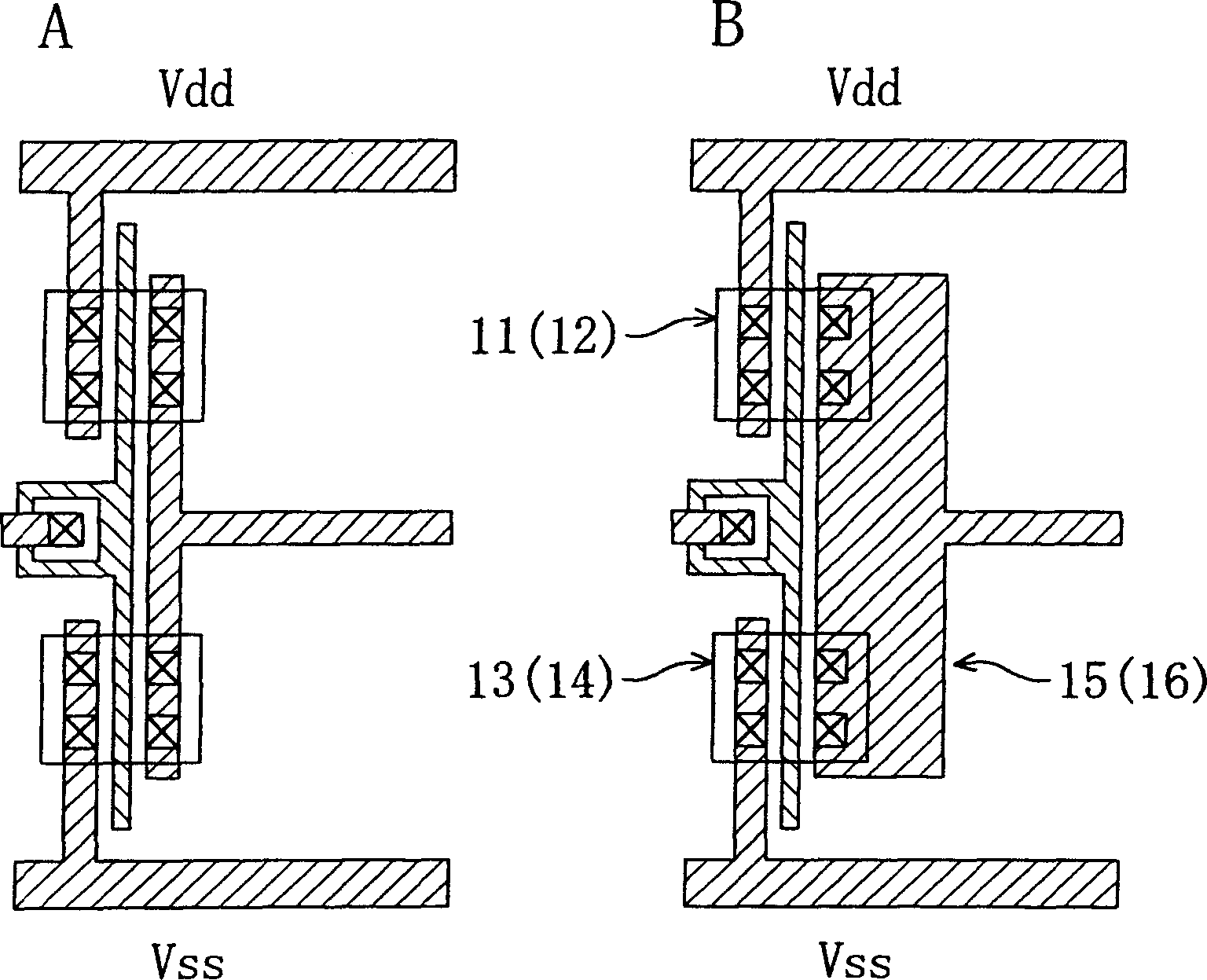

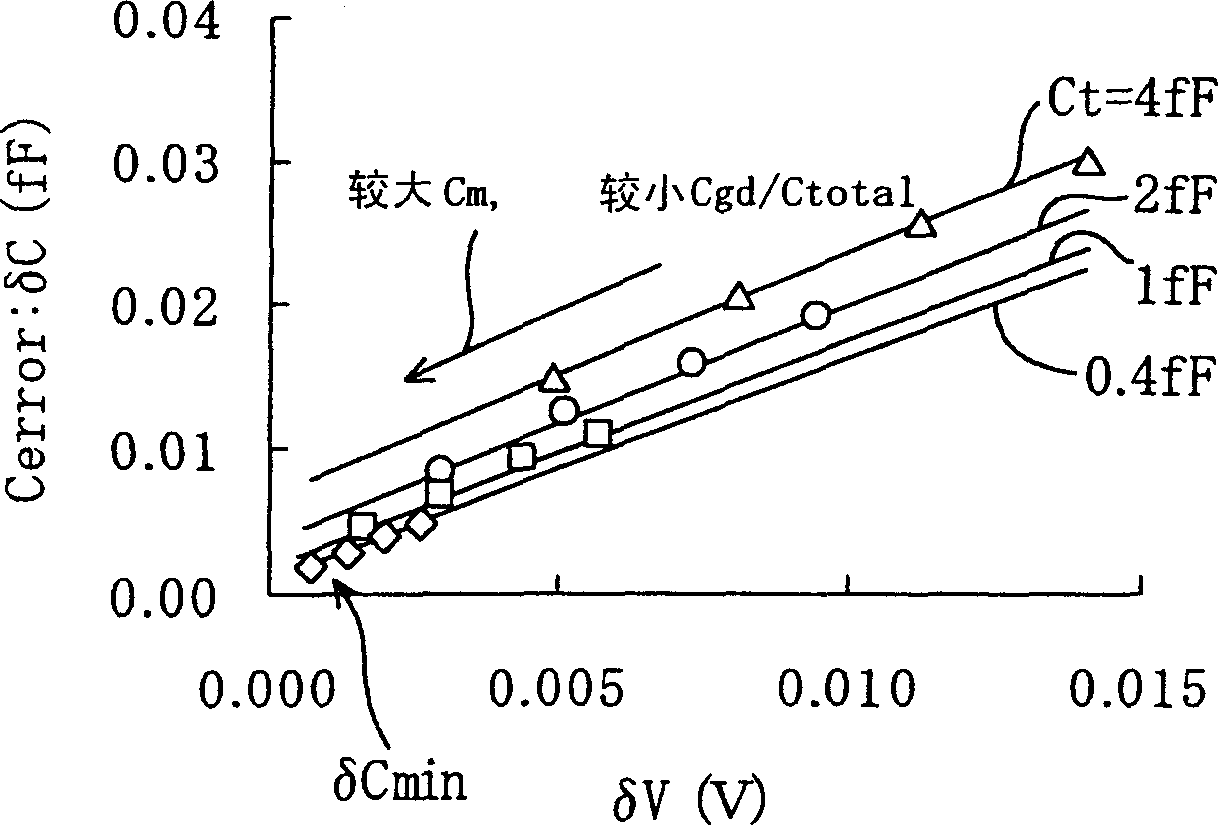

Semiconductor device and capacitance measuring method

InactiveCN1462068AHigh measurement accuracySemiconductor/solid-state device testing/measurementResistance/reactance/impedenceElectrical conductorMeasurement device

The invention provides a semiconductor device with the measurement accuracy of capacity or a method for measuring the capacity. A CBCM measurement device comprises PMIS transistors 11, 12, NMIS transistors 13, 14, a first conductor 15 for reference connected to a first node N1, a second conductor 17 for reference forming a dummy capacitor between the first conductor 15 for reference and itself, a first conductor for a test connected to a second node, and a second conductor 18 for the test forming a test capacitor between the first conductor for the test and itself. The capacity of a target capacitor in the test capacitor is measured from a current flowing in the first and the second nodes by controlling the ON-OFF action of each transistor with control voltages V1, V2. The measurement accuracy of the capacity is improved by increasing dummy capacity.

Owner:PANASONIC CORP +1

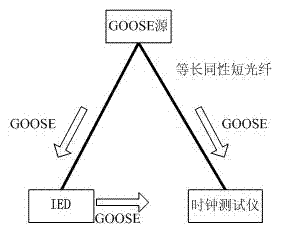

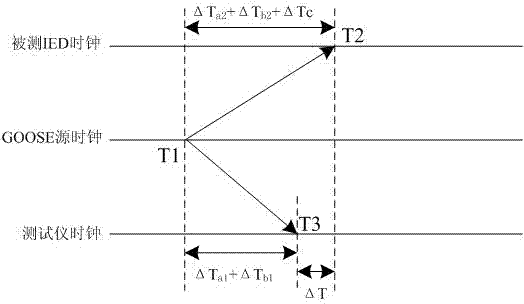

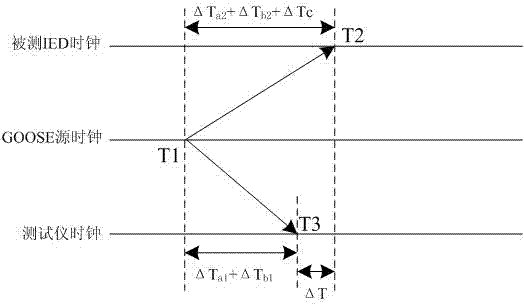

Test method of IED network clock synchronization precision based on GOOSE mechanism

ActiveCN102315928ANo negative impactTransmission delay offsetData switching networksSynchronising arrangementSmart substationNetwork clock

The invention relates to a test method of IED network clock synchronization precision based on a GOOSE mechanism. The method is characterized in that: two short-range optical fibers, which have a same length and a same nature and are led from a GOOSE source, are respectively connected with a clock tester and an IED to be tested; the IED to be tested forms clock synchronization with the clock tester; the GOOSE source sends a GOOSE message simultaneously to the clock tester and the IED to be tested; the IED to be tested and the clock tester receive the message and respectively acquire a time label T2 and a time label T3; the IED to be tested sends the GOOSE message to the clock tester and a difference between the time label T2 and the T3 is a clock synchronization error value of the IED to be tested. Each function in the method is independent. The clock synchronization precision test of a plurality of synchronization modes, such as IEEE1588, SNTP and the like, can be realized according to demands. During the precision test, a negative effect on an IED clock synchronization process can not generated. The method can be directly applied in an intelligent transformer station clock synchronization precision test established based on an IEC61850 standard.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +2

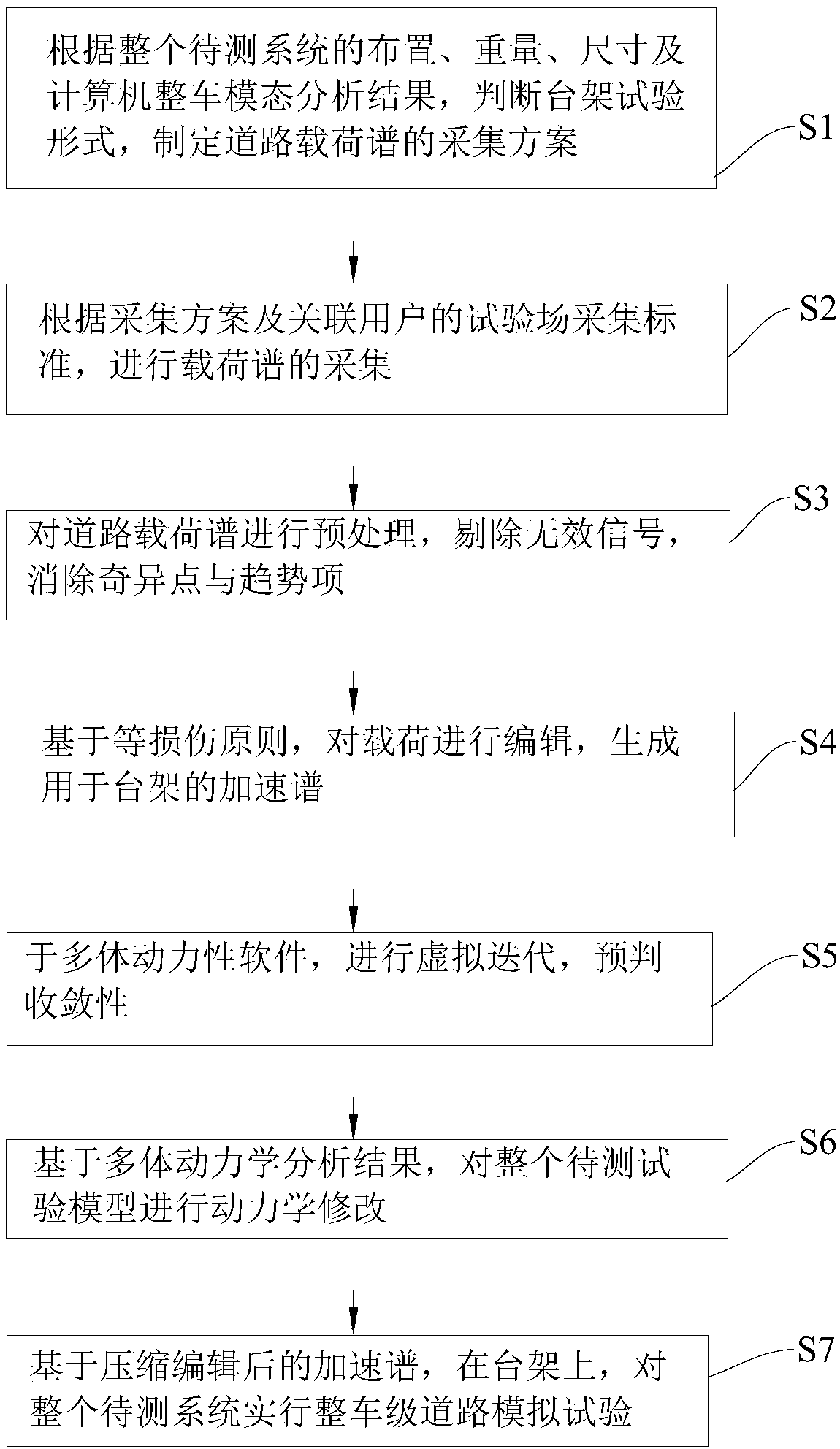

Complete vehicle level road simulation test method

PendingCN109684782AAvoid non-convergenceGuaranteed to proceed normallyDesign optimisation/simulationSpecial data processing applicationsAcquisition SchemeMulti body

The invention discloses a complete vehicle-level road simulation test method, which comprises the following steps of: judging a rack test form according to the arrangement, weight and size of a wholesystem to be tested and a computer whole vehicle modal analysis result, and formulating a road load spectrum acquisition scheme; Acquiring a load spectrum according to the acquisition scheme and the test field acquisition standard of the associated user; Based on an equal damage principle, editing the load, and generating an acceleration spectrum for the rack; carrying out Virtual iteration on multi-body dynamic software, and prejudging convergence; Based on a multi-body dynamics analysis result, carrying out dynamics modification on the whole to-be-tested test model; And based on the compressed and edited acceleration spectrum, carrying out a whole vehicle-level road simulation test on the whole system to be tested on a rack. Therefore, the method can improve the test precision, shorten the verification period and the verification cost, and reduce the verification risk.

Owner:BEIJING FOTONDAIMLER AUTOMOTIVE

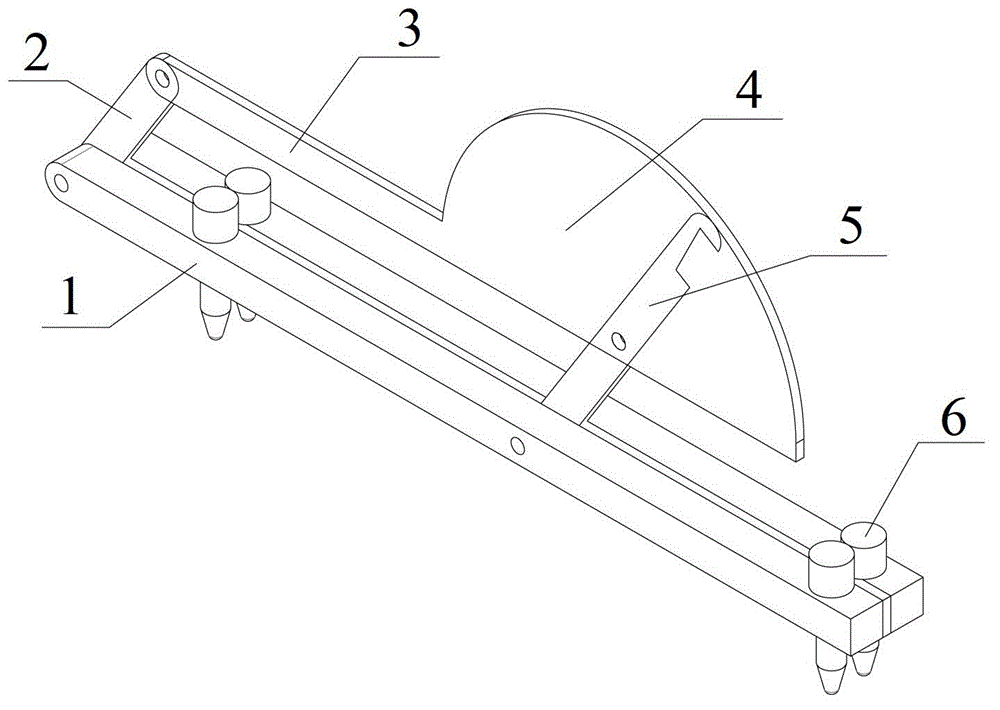

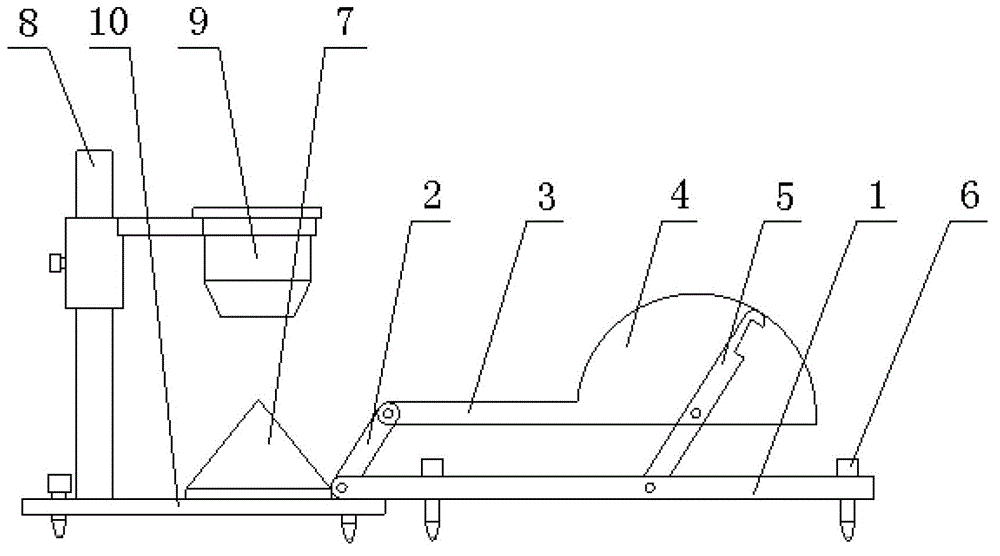

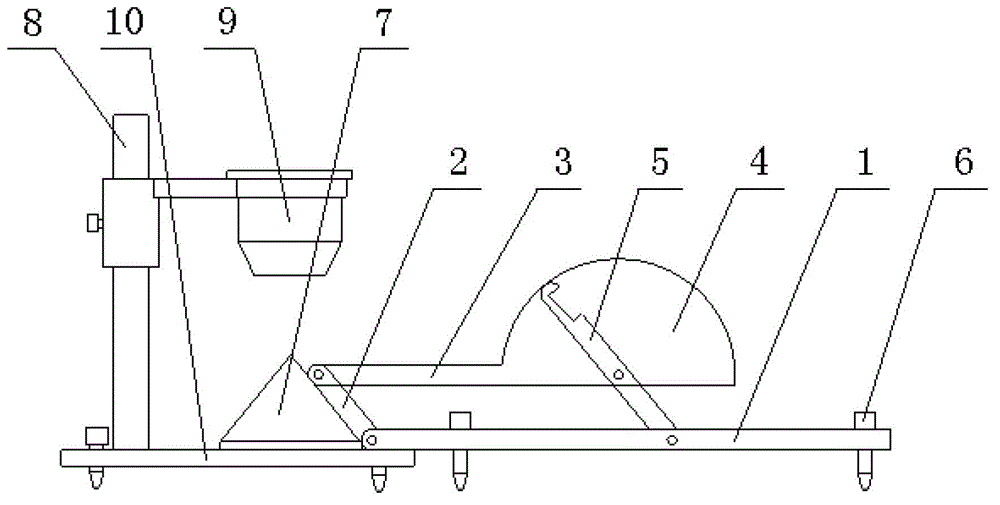

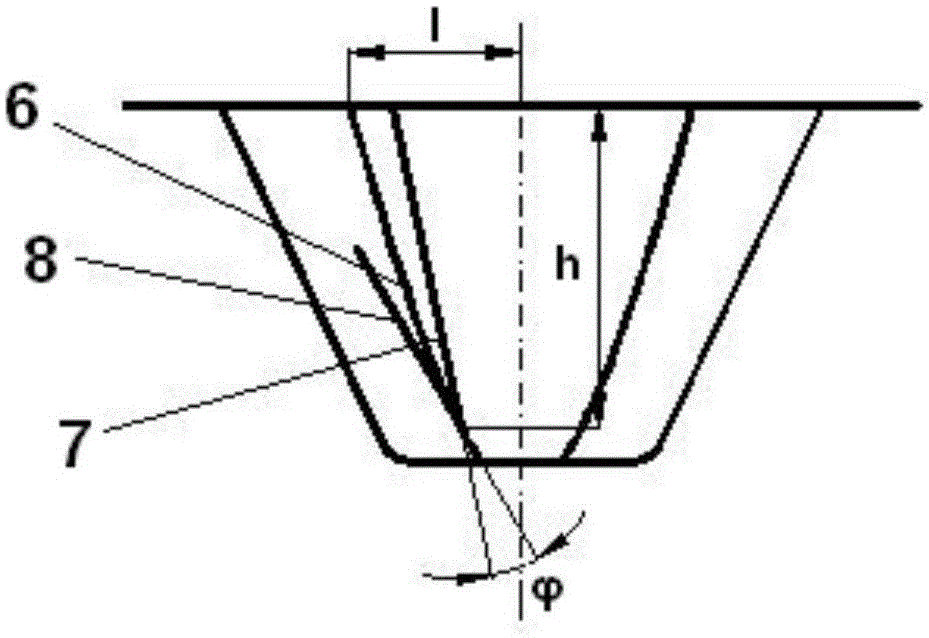

Angle measuring device for measuring repose angle of dust

The invention discloses an angle measuring device for measuring a repose angle of dust. The angle measuring device comprises an angle meter, an indicator, a connecting rod and a base. One end of the connecting rod is hinged to the end of the base, and the other end of the connecting rod is hinged to the end of the angle meter. The indicator is parallel to the connecting rod, one end of the indicator is hinged to the base, the other end of the indicator is hinged to the circle center of the angle meter, and the bottom edge of the angle meter is parallel to the upper surface of the base. When the connecting rod rotates around a hinged point of the connecting rod to the base, the indicator also rotates around the circle center of the angle meter, and the angle of the indicator pointing at the angle meter is an included angle of the indicator and the horizontal plane. A sample to be tested forms a dust heap on a dust pan, the connecting rod is rotated to be parallel to a bus line of the dust heap, then an angle pointed by the indicator on the angle meter is read, and the angle is the repose angle of dust. The angle measuring device for measuring the repose angle of dust is simple in structure and convenient in measurement process, the dust heap cannot be influenced in measurement process, and the measured repose angle is high in accuracy.

Owner:FUJIAN LONGKING

Handprint Recognition Test Deck

ActiveUS20120218575A1Digitally marking record carriersDigital computer detailsData contentComputer science

A system and method for creating one of a plurality of test decks to qualify and test forms processing systems, including preparing a handprint snippet data base containing labeled handprint image snippets representing a unique hand, preparing a form description file and a data content file, selecting handprint snippets from the handprint snippet data base to formulate a form using the data content file, creating a form image using the selected snippets according to the form description file and printing the form image.

Owner:ADI

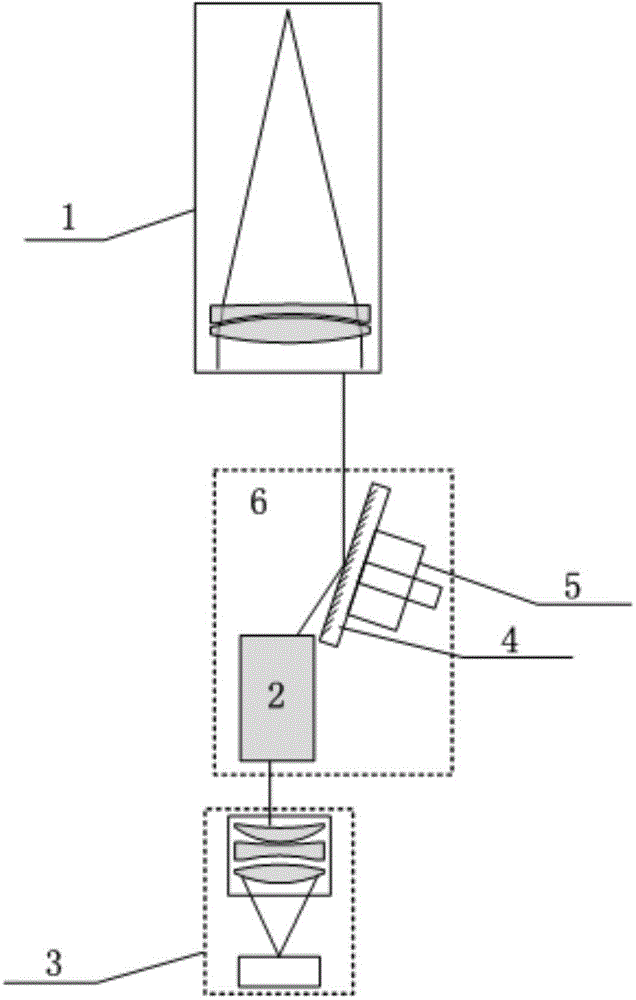

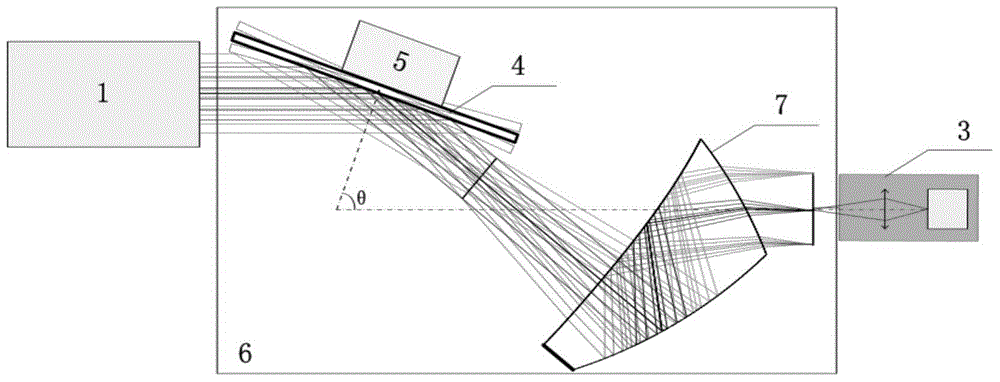

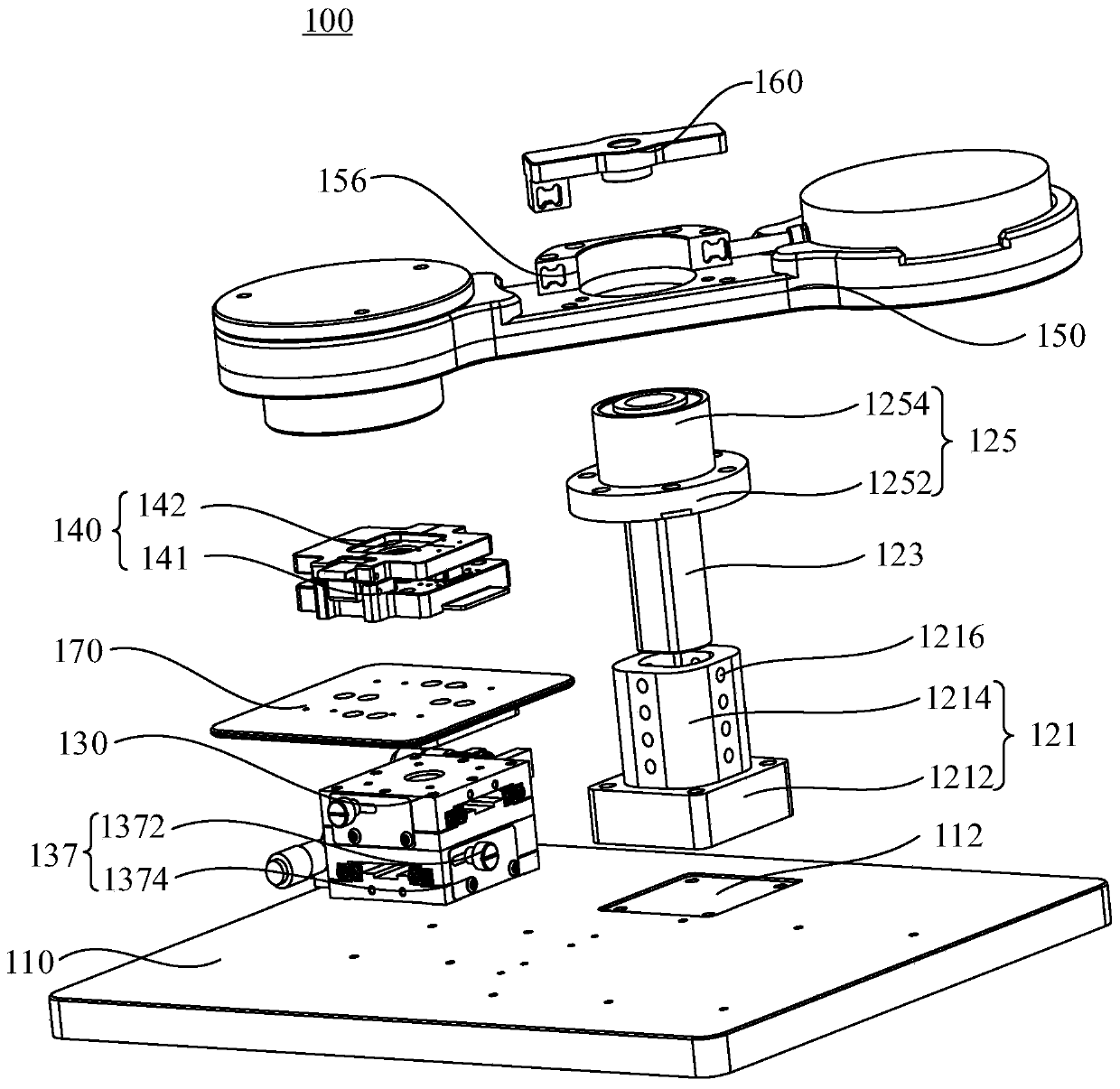

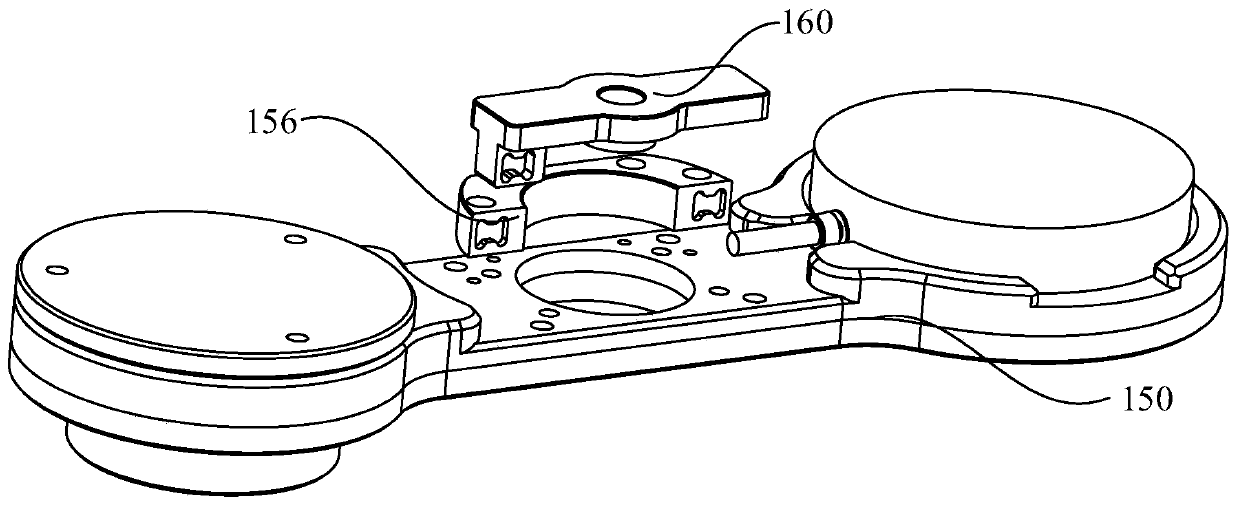

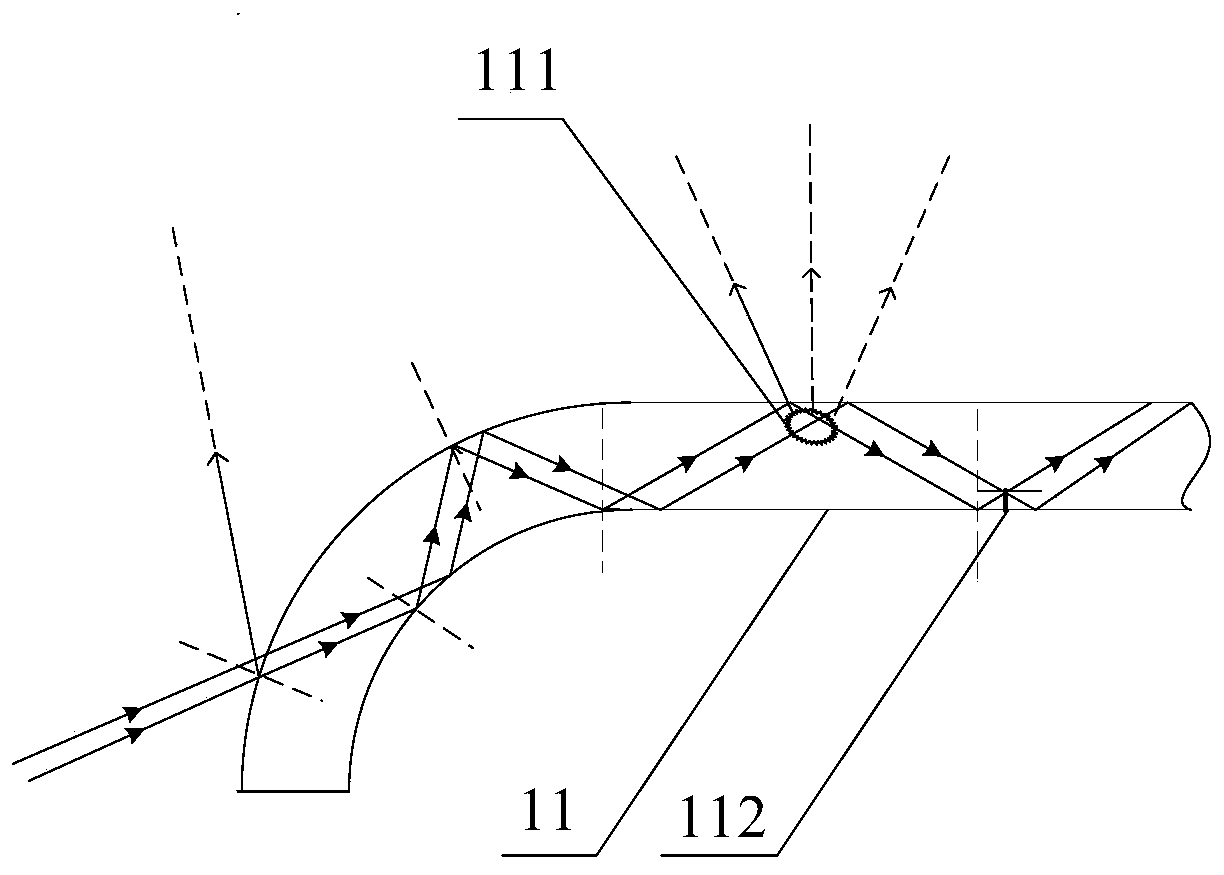

MTF test apparatus and method for small off-axis optical system

ActiveCN104931239AAchieve parallelismSimple structureTesting optical propertiesTest efficiencyOff-axis optical system

The invention provides an MTF test apparatus and method for a small off-axis optical system. The apparatus is mainly composed of a collimator, an MTF detection system, a planar reflector and a two-dimensional rotating mechanism, wherein the two-dimensional rotating mechanism is in rigid connection with the plane reflector, the collimator and the MTF detection system are located at the same optical axis, and the plane reflector is located between the collimator and the MTF detection system. With the MTF test apparatus and method for the small off-axis optical system of the invention adopted, a test adjustment mechanism is simplified greatly, and is convenient to operate; and the plane reflector and an optical system to be tested form a test module, and therefore, a series of optical performance modular tests can be carried out, and operation procedures can be simplified, and test efficiency can be improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

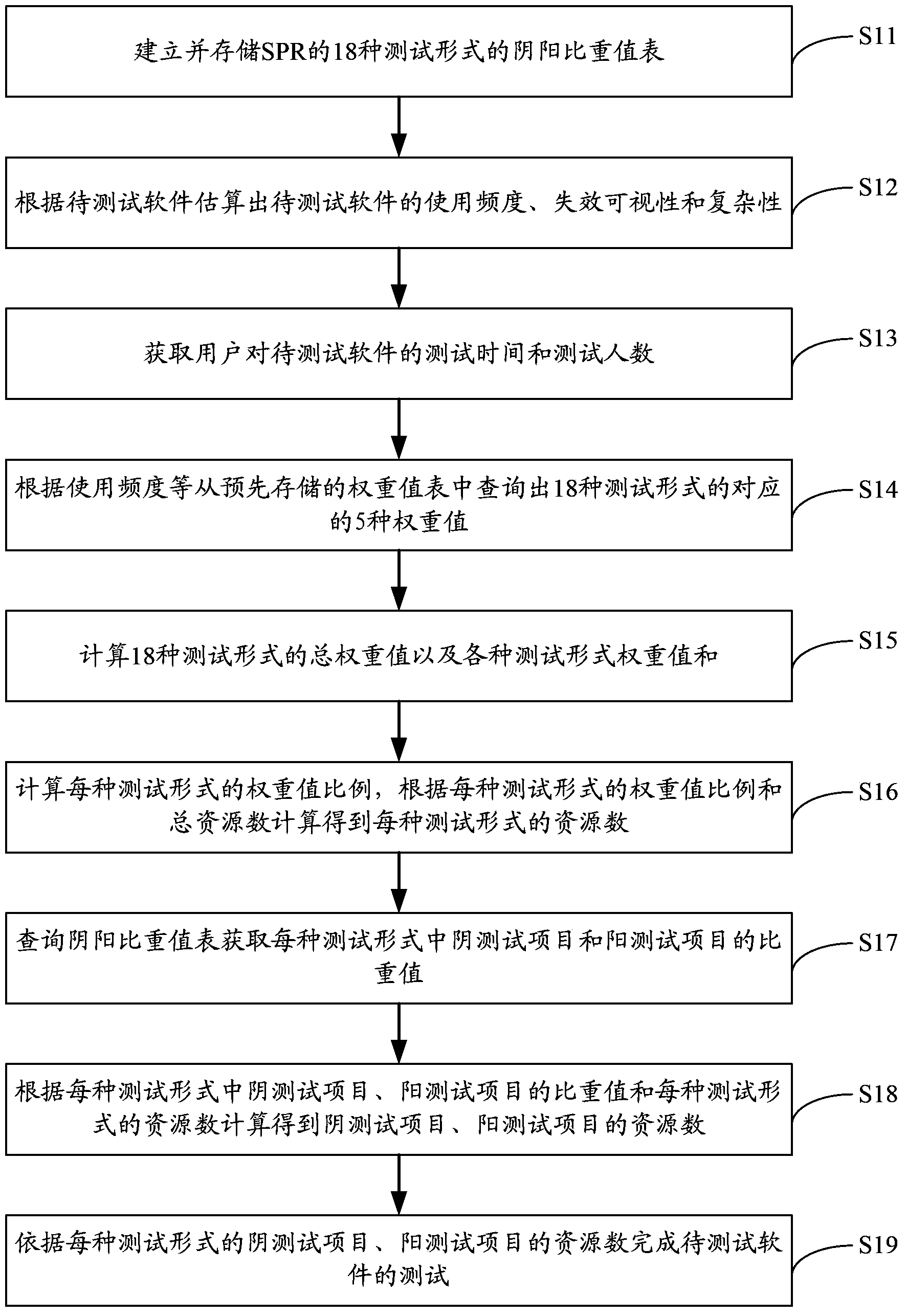

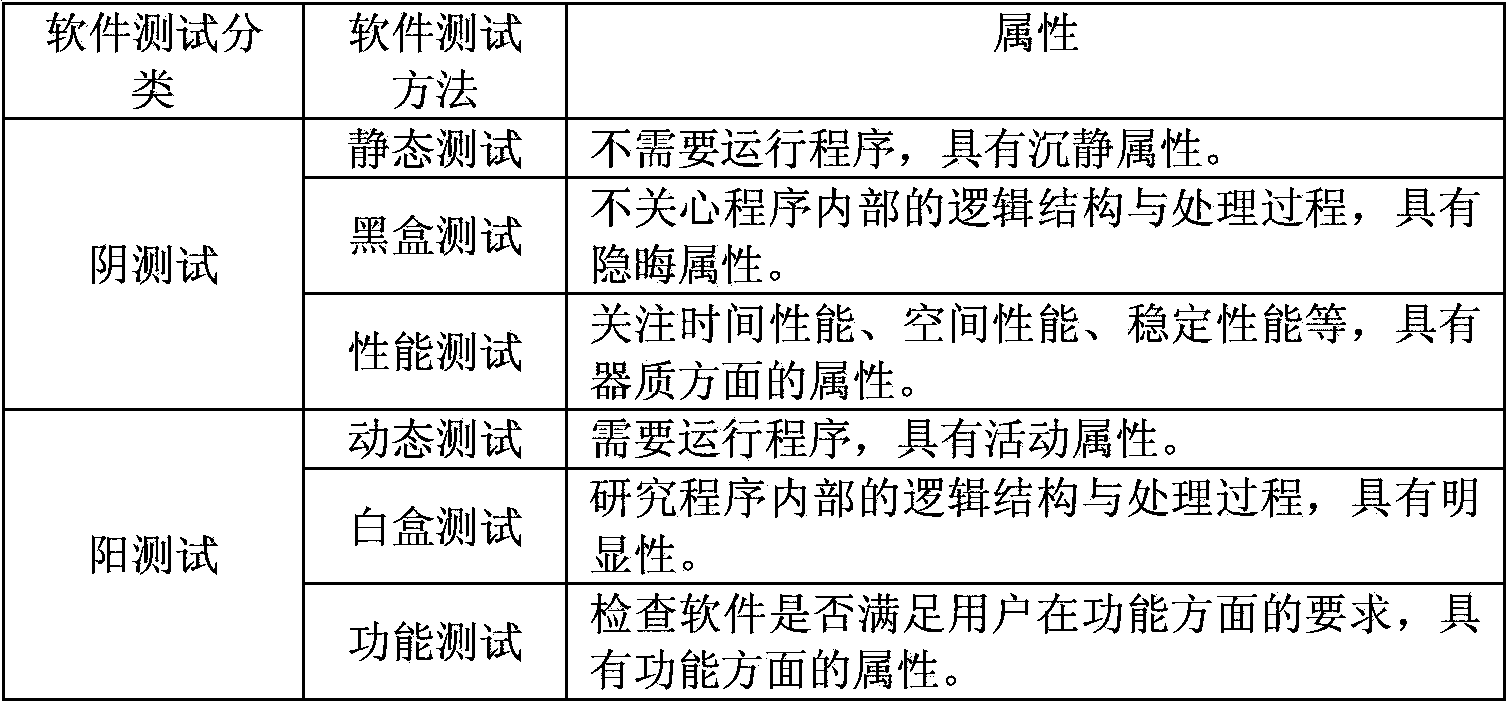

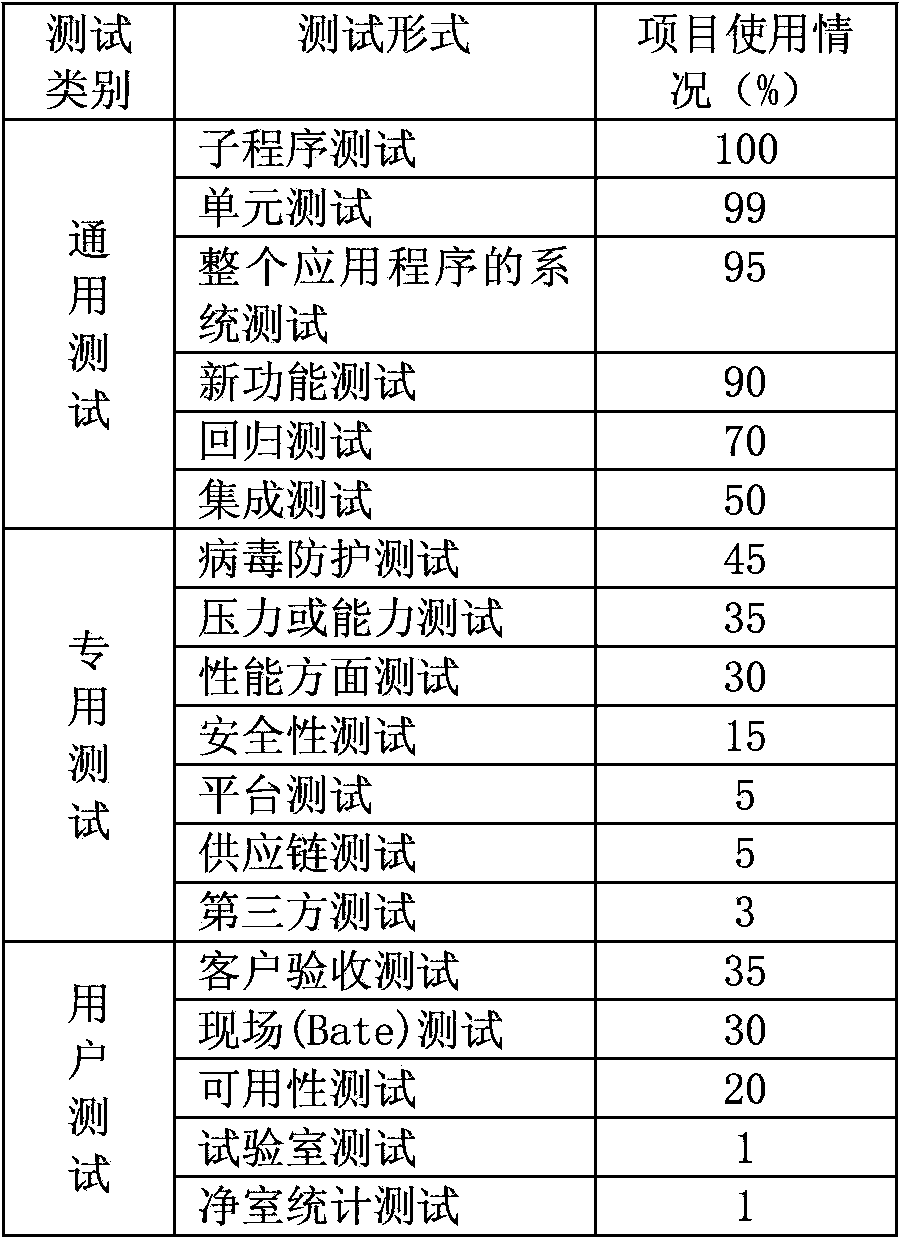

Software test method

The invention is applicable to the field of computers and provided a software test method and system. The software test method includes: setting Yin test attributes and Yang test attributes for 18 kinds of test forms of SPR (software productive research); estimating weighted values corresponding to each of the 18 kinds of test forms according to software to be tested; acquiring time information and cumulative defect clearance inputted by a user and determining test phases according to the time information and the cumulative defect clearance inputted by the user and a relation table of the test phases, test workload and the defect clearance; determining a test method and test quantities according to gravity values of the Yin test attributes, the gravity values of the Yang test attributes, the weighted values of each test form and the test phases, and then completing software test according to the test method and the test quantities. The software test method has the advantages that test effect is good by adopting a mode of combining a relatively fixed form with each flexible comprehensive balanced factor.

Owner:SHENZHEN INSTITUTE OF INFORMATION TECHNOLOGY

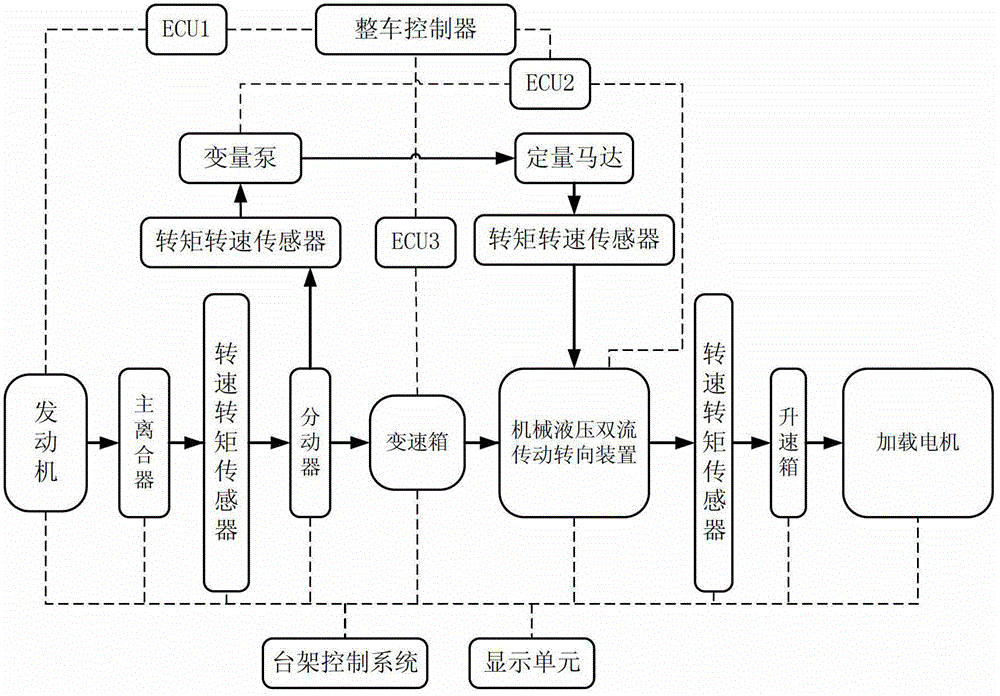

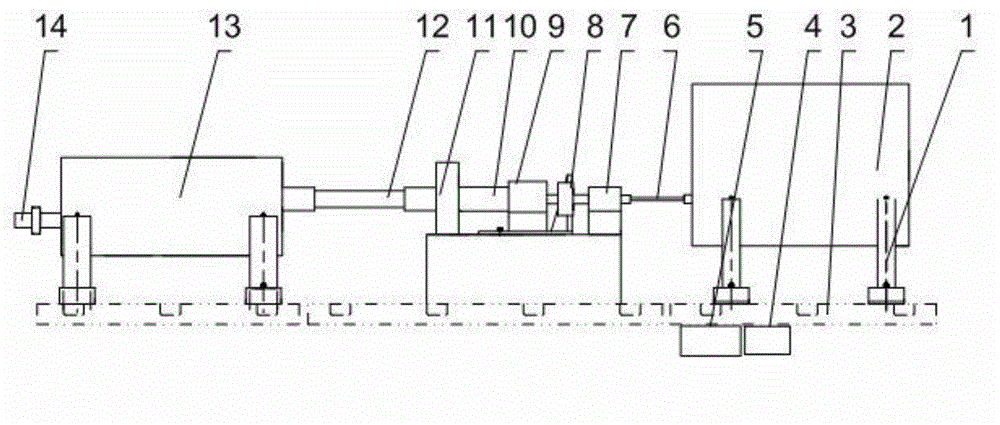

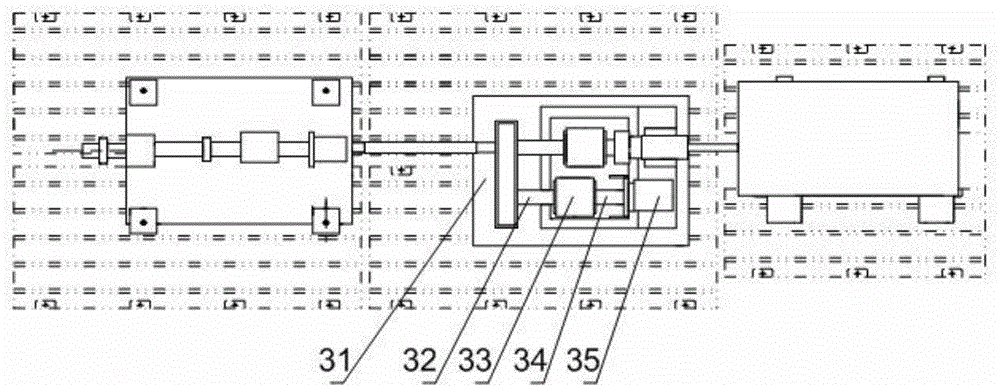

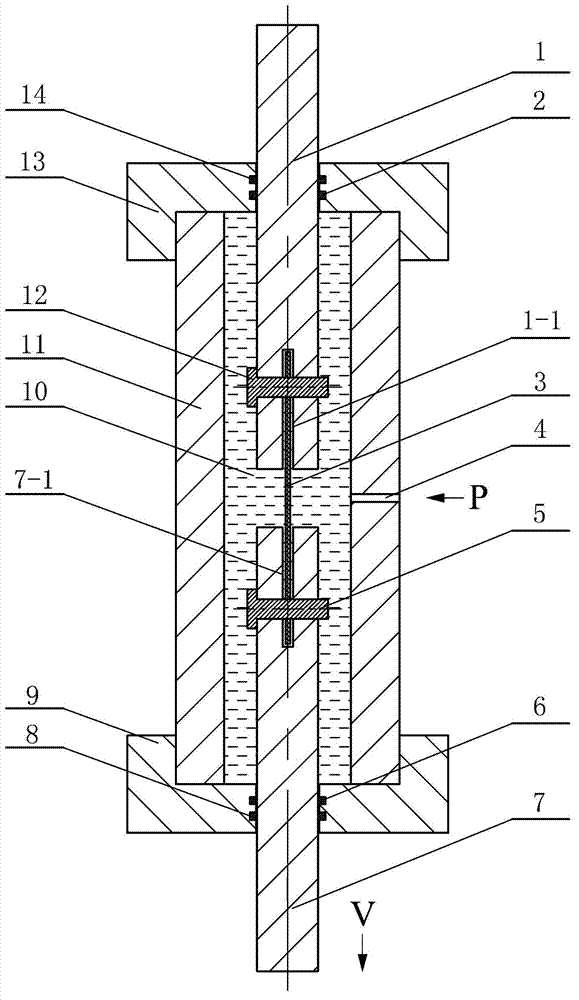

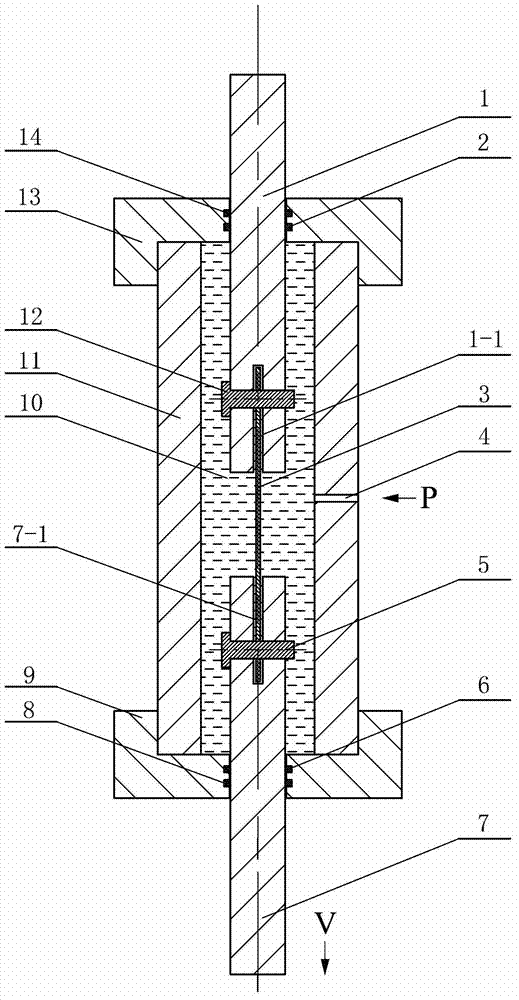

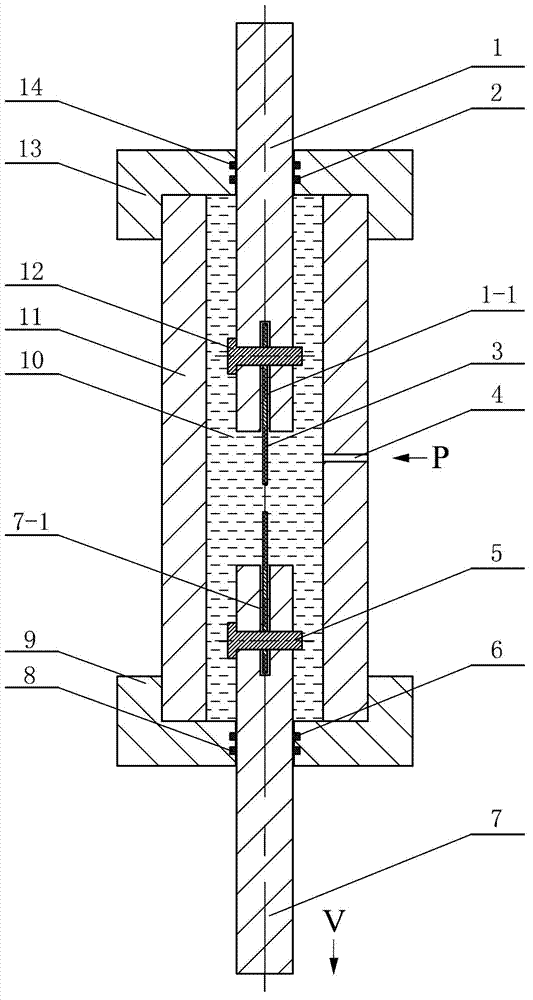

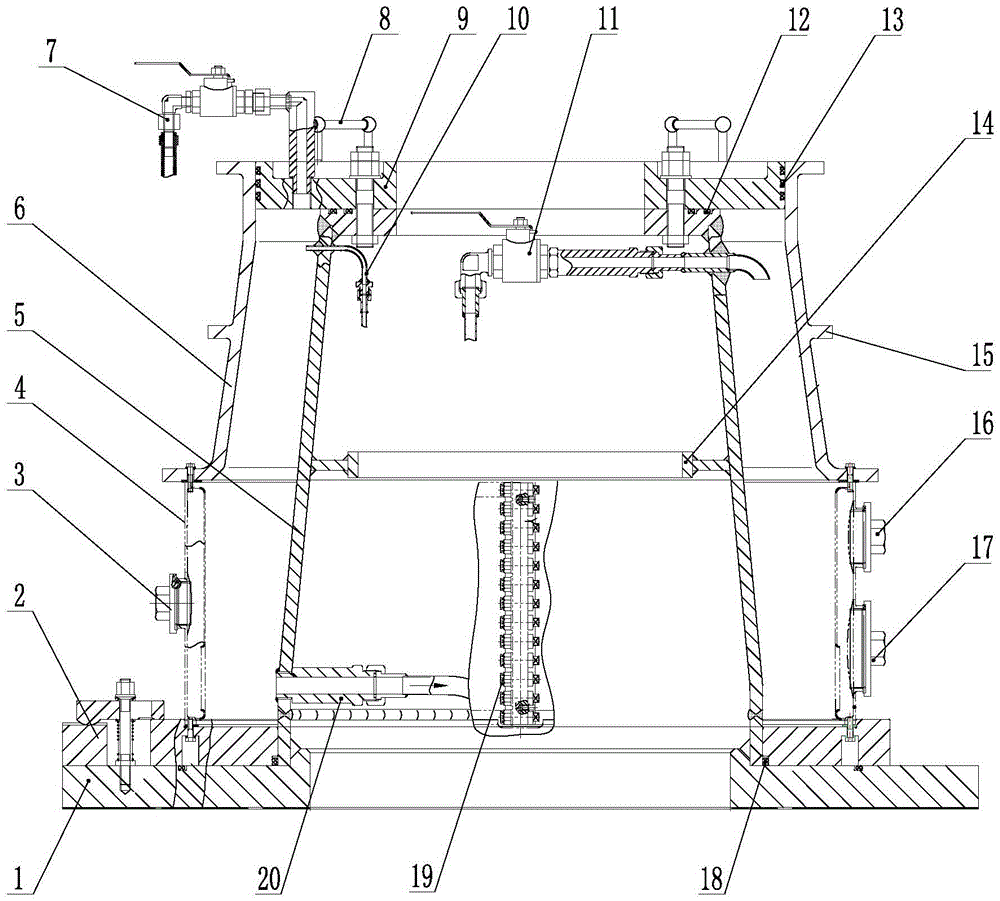

Vehicle mechanical and hydraulic dual-flow transmission steering device test bench and system

InactiveCN103149038ASimple structureReduce design difficultyVehicle steering/rolling behaviourPilot systemTest bench

Owner:HENAN UNIV OF SCI & TECH

Device and method for testing forming property of sheet material under effect of fluid pressure

InactiveCN103196758AAchieve mechanical propertiesRealize data collectionInvestigating material ductilityEngineeringHigh pressure

The invention provides a device and a method for testing the forming property of a sheet material under the effect of fluid pressure, belongs to the field of a sheet material hydraulic forming technology, and aims at the problems that in a conventional sheet material forming property test, real-time testing and accurate evaluation can not be hardly carried out under a fluid pressurizing condition, and dynamic sealing is hard to carry out under a fluid high-pressure condition due to that a sheet material test sample is provided a non-circular section. The technical points are as follows: an end cover is matched with clamping pieces in a manner of adopting a piston cylinder; a connection region of the upper and lower clamping pieces is connected with the sheet material test sample in a manner of adopting a cylindrical pin; and the testing method sequentially comprises the following steps of: placing a test sample, combining a testing device, connecting a tester, applying hydraulic pressure and downwards moving a lower chuck, taking out the cut test sample and carrying out size measurement. The matching by adopting the piston cylinder manner can enable the sheet material test sample with a rectangular section to realize the fluid high-pressure dynamic sealing; and a simplified structure design of the device can enable the the hydraulic pressure in a cavity and the sheet material extension rate to be independently and accurately controlled. By using the device and the method disclosed by the invention, shape and size diversified forming property tests on the sheet material test sample can be realized.

Owner:HARBIN UNIV OF SCI & TECH

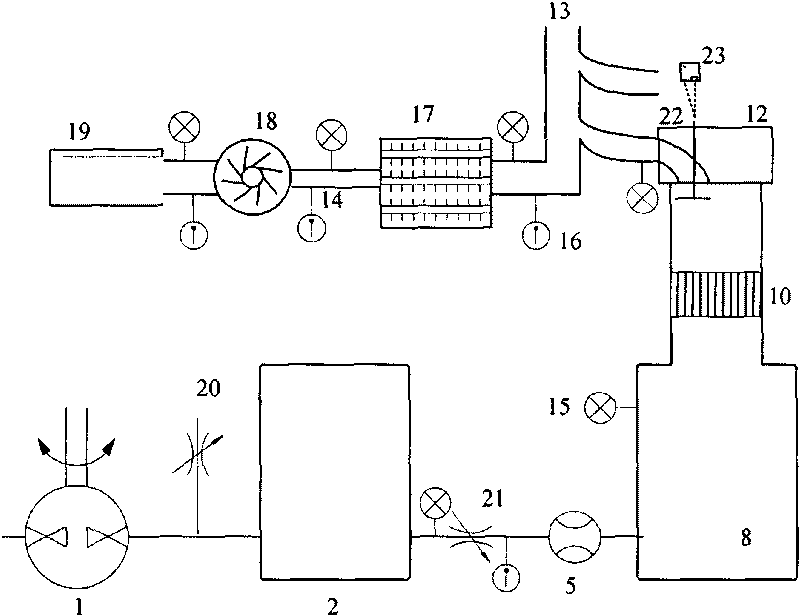

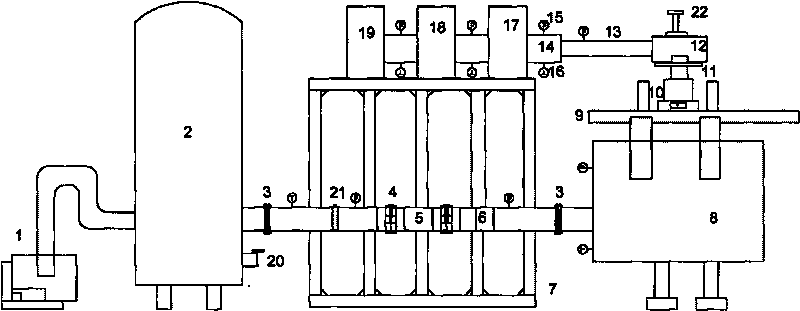

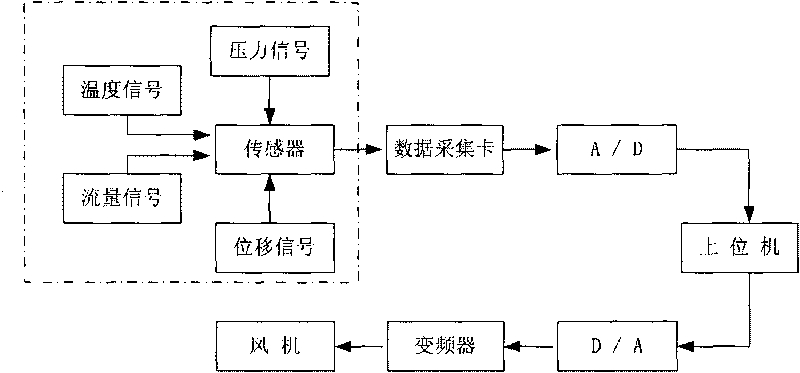

Air intake management and test system for internal combustion engine

InactiveCN101718628AFunction increaseShorten the development cycleInternal-combustion engine testingInterference fitAir filter

The invention provides an air intake management and test system for an internal combustion engine, belonging to the technical field of the power machinery. The air intake management and test system comprises an air intake pipe, an intercooler, a pressurizer, an air filter and a vacuum pump or a blower; the intercooler, the pressurizer and the air filter are communicated with each other in sequence; the vacuum pump or the blower is connected with a pressure stabilizing tank; the pressure stabilizing tank is connected with a current stabilizing tank through a pipeline which is provided with a flowmeter; a support is arranged on the top of the current stabilizing tank; a vortex measuring device and a cylinder sleeve are arranged on the support; a cylinder cover and the cylinder sleeve are sealed by interference fit; an air valve lift range control device is arranged above the cylinder sleeve; a displacement sensor is arranged above the air valve lift range control device; the air intake pipe is arranged on the cylinder cover and is connected with the intercooler through a measure section; and a pressure sensor and a temperature sensor area arranged on the measure section. The air intake management and test system can flexibly adopt the test form according to different test purposes, has wide air intake flow rate range, can be controlled in a wide range with a flexible method and can be arranged flexibly and is very practical.

Owner:ZHEJIANG UNIV

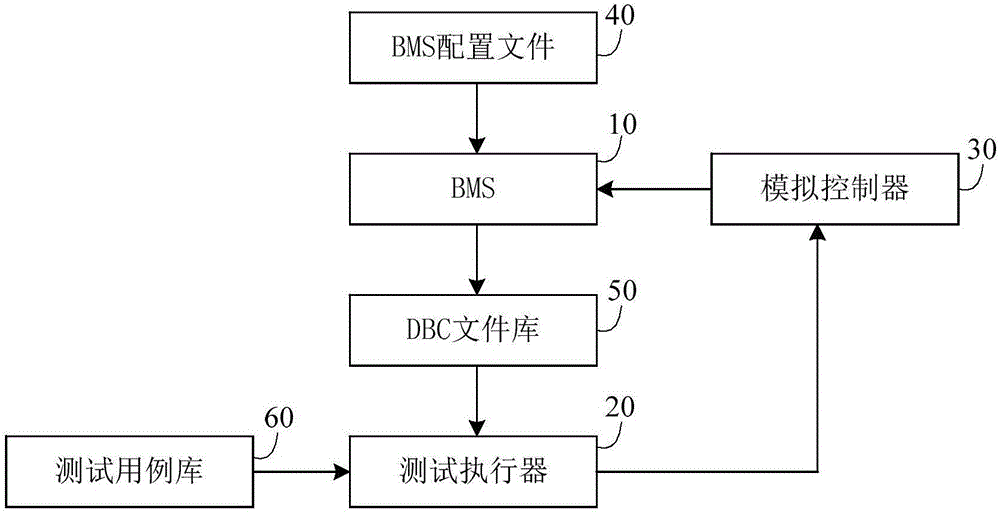

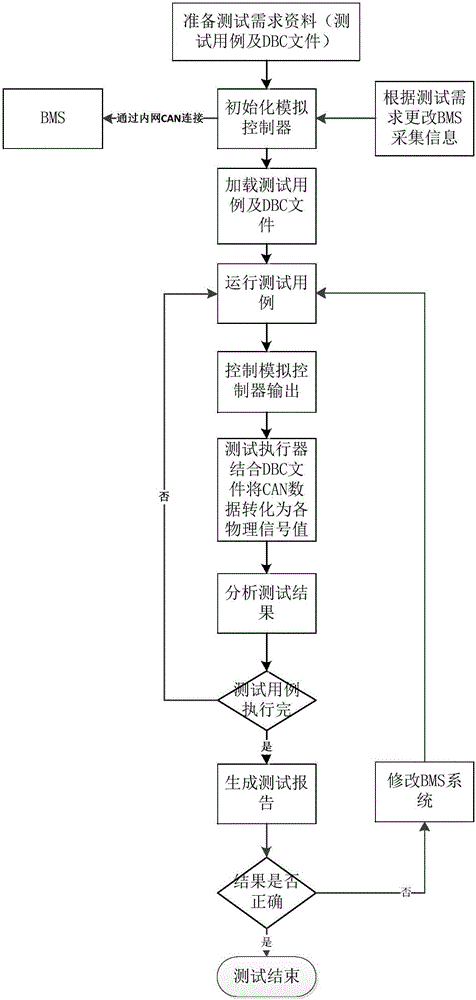

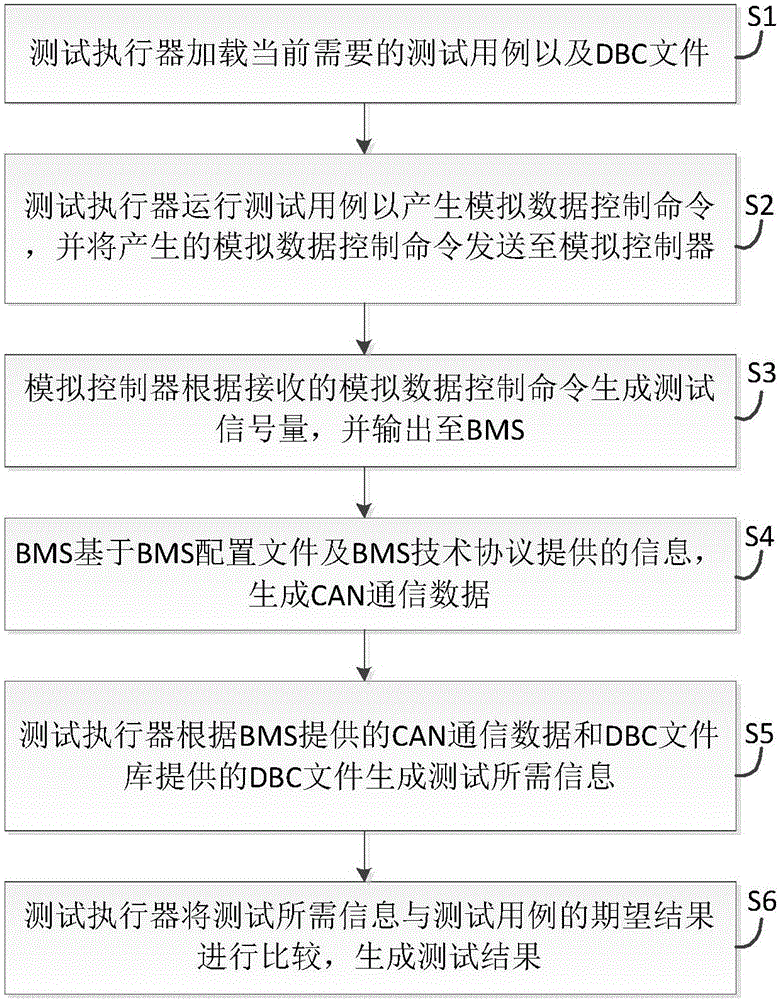

Battery management system standard DBC interface automatic testing system and method

ActiveCN106707065AImprove test efficiencyAvoid test case omissionsElectrical measurement instrument detailsTesting electric installations on transportDBcSystem testing

The invention discloses a battery management system standard DBC interface automatic testing system and method, and belongs to the BMS system testing technical field; the system comprises a BMS, a test performer, a simulation controller, a BMS configuration file, a DBC file database and a test case database; the test performer can form test needed information according to the DCB file and CAN communication data formed by the BMS, and the test needed information can serve as test determination basis in testing; the whole process is an in-loop automatic test formed by the BMS, the simulation controller, the DBC file and test cases; in addition, the invention also provides a battery management system standard DBC interface automatic testing method; the whole BMS test process is automatic, thus preventing test case leakage and BMS test condition debug complexity problems in an artificial testing process, and greatly saving labor cost.

Owner:安徽优旦科技有限公司

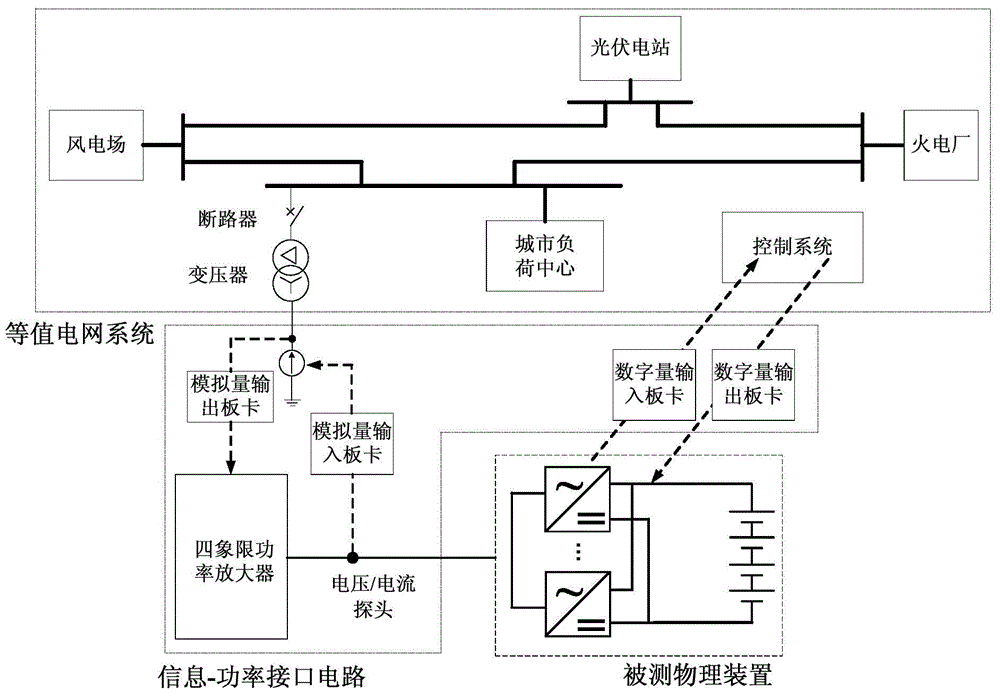

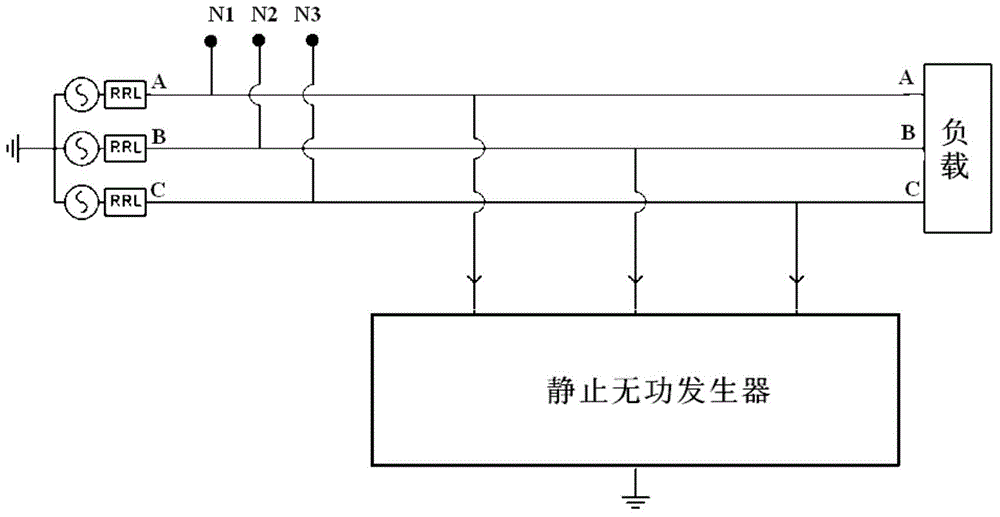

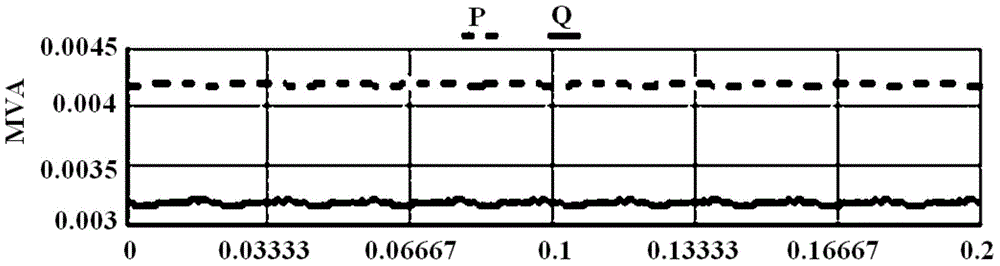

Power closed-loop real-time simulation test system and power closed-loop real-time simulation test method

ActiveCN104834229AImprove R&D efficiencySmooth transitionSimulator controlSoftware development processClosed loop

The invention provides a power closed-loop real-time simulation test system and a power closed-loop real-time simulation test method. The system comprises an equivalent grid system based on a real-time digital simulator, and an information-power interface circuit. The equivalent grid system sends an analog signal to the information-power interface circuit; the analog signal, after processed by the information-power interface circuit, is sent to a tested physical device to supply power to the tested physical device; an analog feedback signal of the tested physical device is sent to the equivalent grid system through the information-power interface circuit; and the equivalent grid system sends a digital signal to the tested physical device to remotely control a switch in the tested physical device. According to the invention, simulation and test form an organic whole, an advanced technical means is provided for the research and development of novel physical devices, the efficiency of research and development can be increased, smooth transition between sub research and development processes is ensured, problems and defects existing in equipment can be found in the early stage of research and development, and better guidance is provided for equipment research and development.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

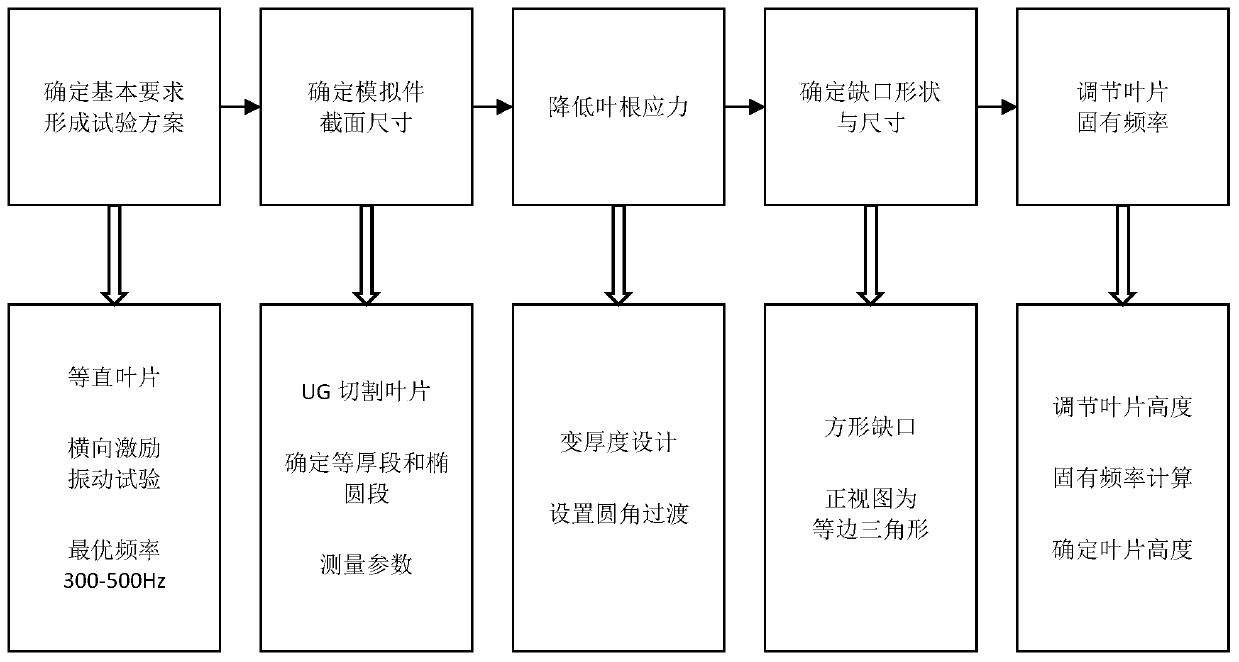

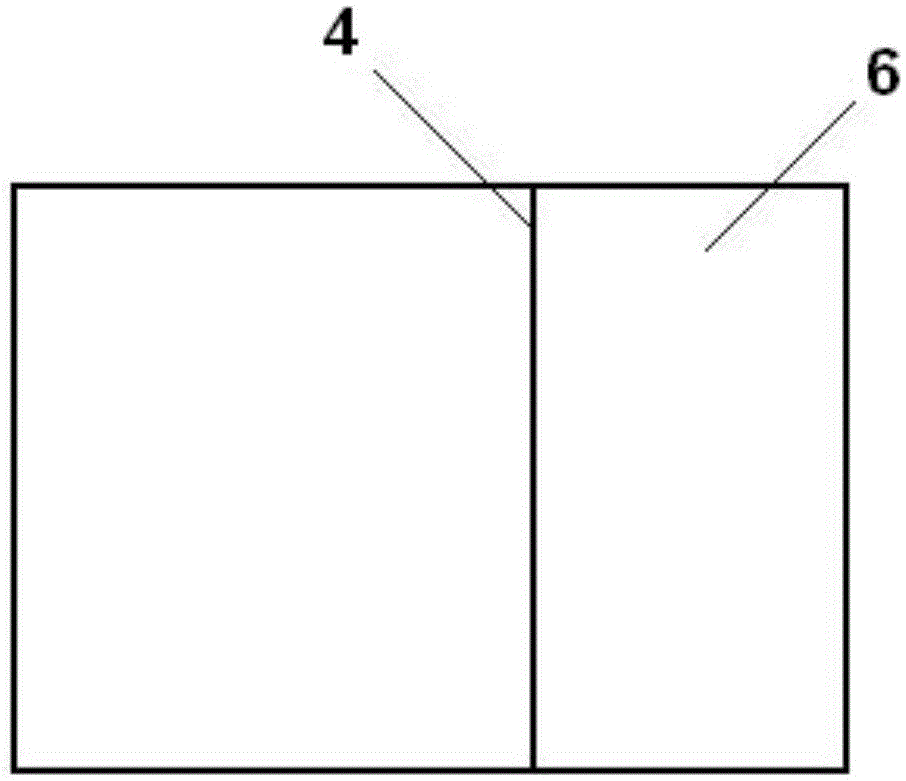

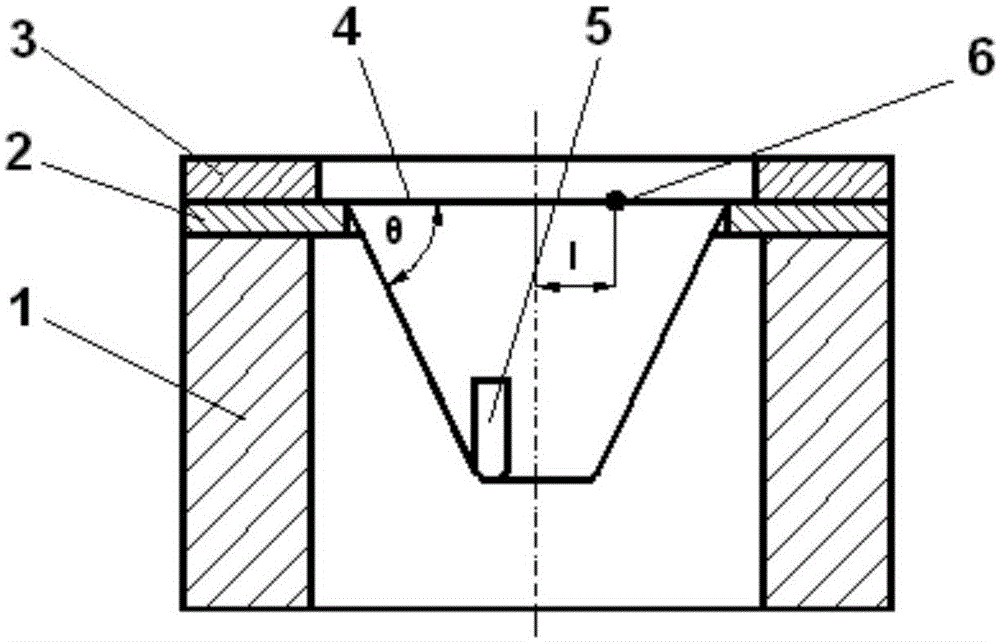

A design method of an aero-engine blade simulation part

Owner:BEIHANG UNIV

Method for testing forming limit of tailor welded blank during metal plate incremental forming

InactiveCN105136589AEasy to operateInvestigating material ductilityNumerical controlDimensional modeling

The present invention discloses a method for testing forming limit of a tailor welded blank during metal plate incremental forming, a part model needed by forming is constructed in three-dimensional modeling software, and a numerical control code is generated; the tailor welded blank is mounted between a fixture support plate and a pressure plate, and the weld joint offset position can be determined by marking on the support plate; a tool head is used for forming a plate, when the weld joint ruptures, the processing is stopped, and the depth of the rupture position is measured; according to the rupture depth, an included angle of a weld joint tangent line and a first principal strain position in the rupture position can be read out in the model, and the relation curve of the included angle and the forming angle can be drawn. The method for testing the forming limit of the tailor welded blank during metal plate incremental forming is simple in operation steps; the data needed to draw the curve can be obtained by forming of a small amount of the plate; and the rupture forming Phi- Theta diagram can provided a basis for testing the forming limit of the tailor welded blank during metal plate incremental forming.

Owner:NANJING INST OF TECH

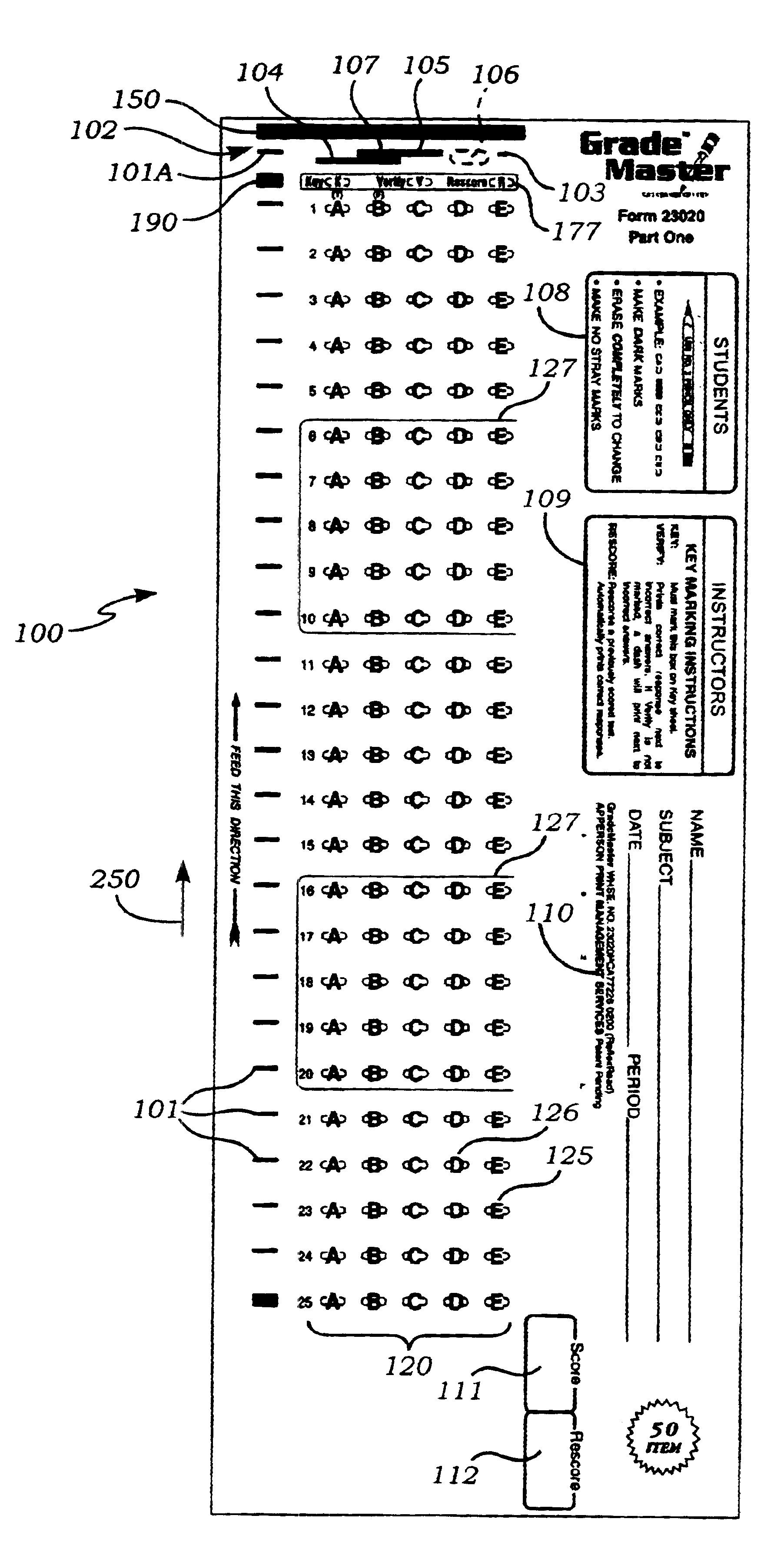

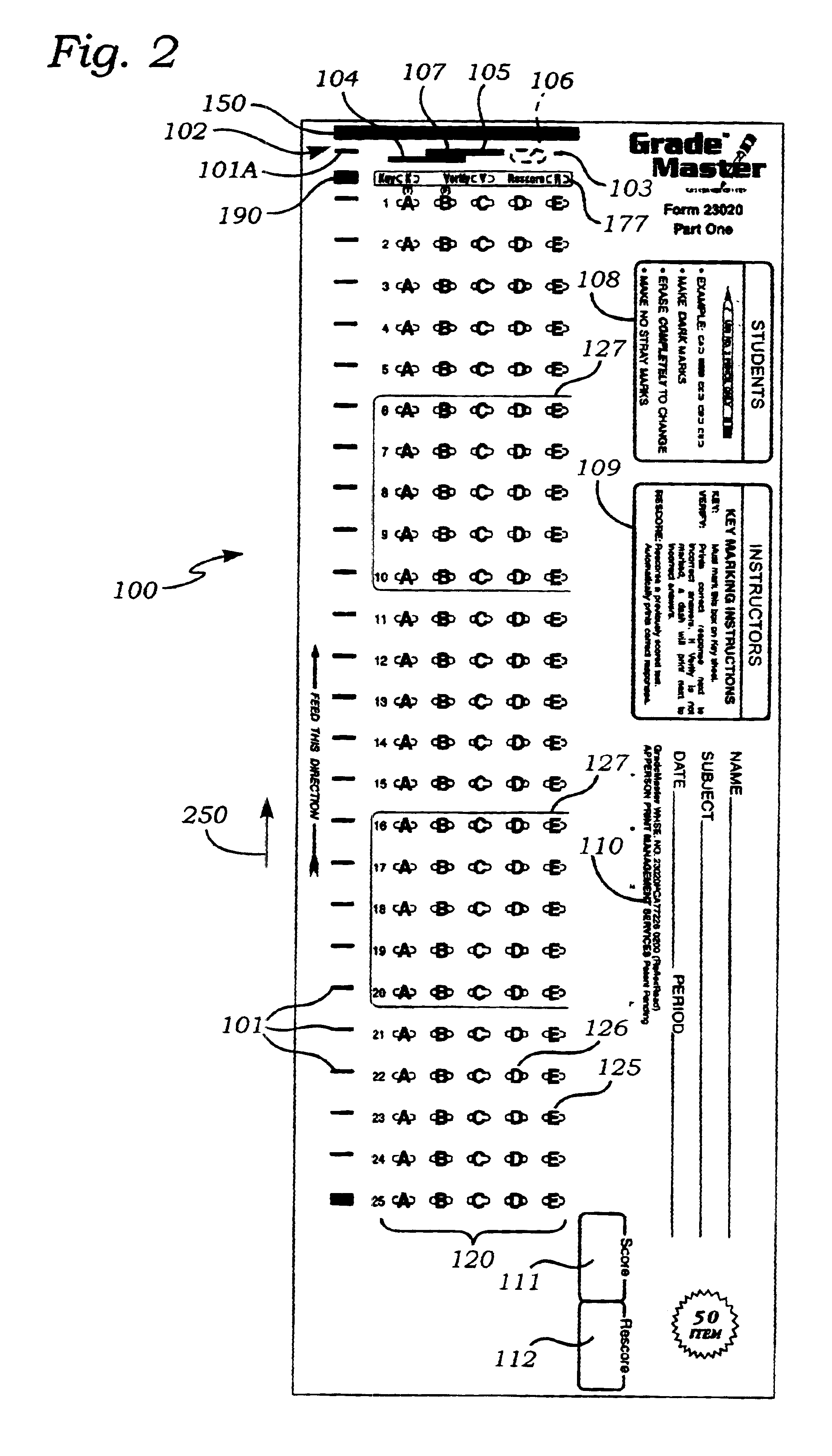

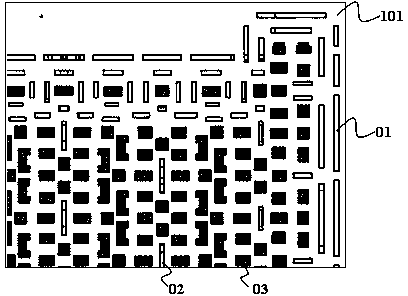

Data processing form for use with a scanning apparatus

InactiveUS6695216B2Improve versatilityConveying record carriersRecord carriers used with machinesGraphicsLeading edge

This invention is directed to a unique type of form to be used with an optical mark sensing device known as a mark read scanner for reading marks on the form. Form characteristics are defined by "graphic switches" printed near the lead edge of the form. Each "graphic switch" has four distinct settings. The expense of completely replacing the internal program of a scanner when a user requests a variation of a test form that had not been pre-programmed into the original specification of the scanner is eliminated.

Owner:APPERSON WILLIAM

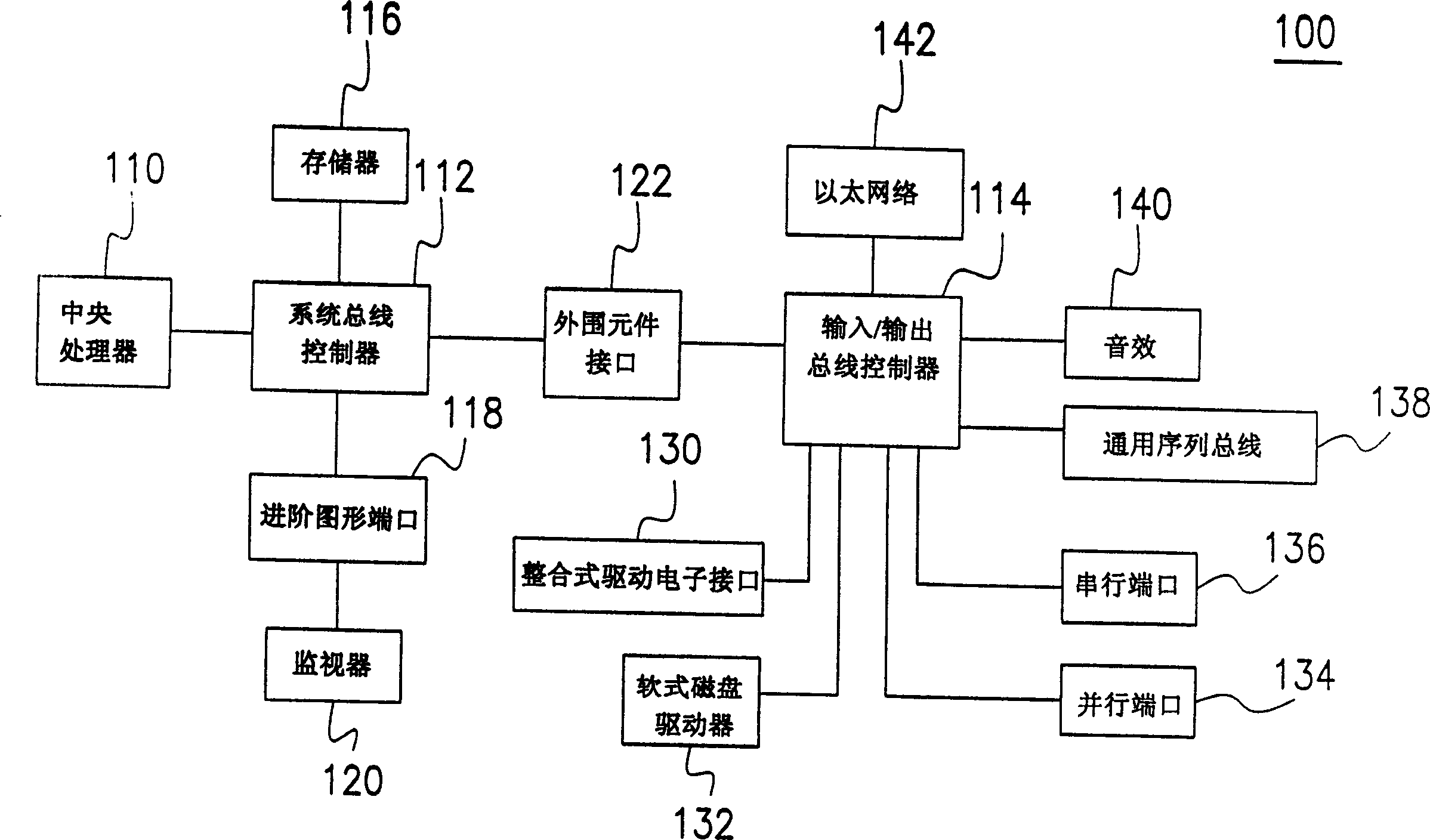

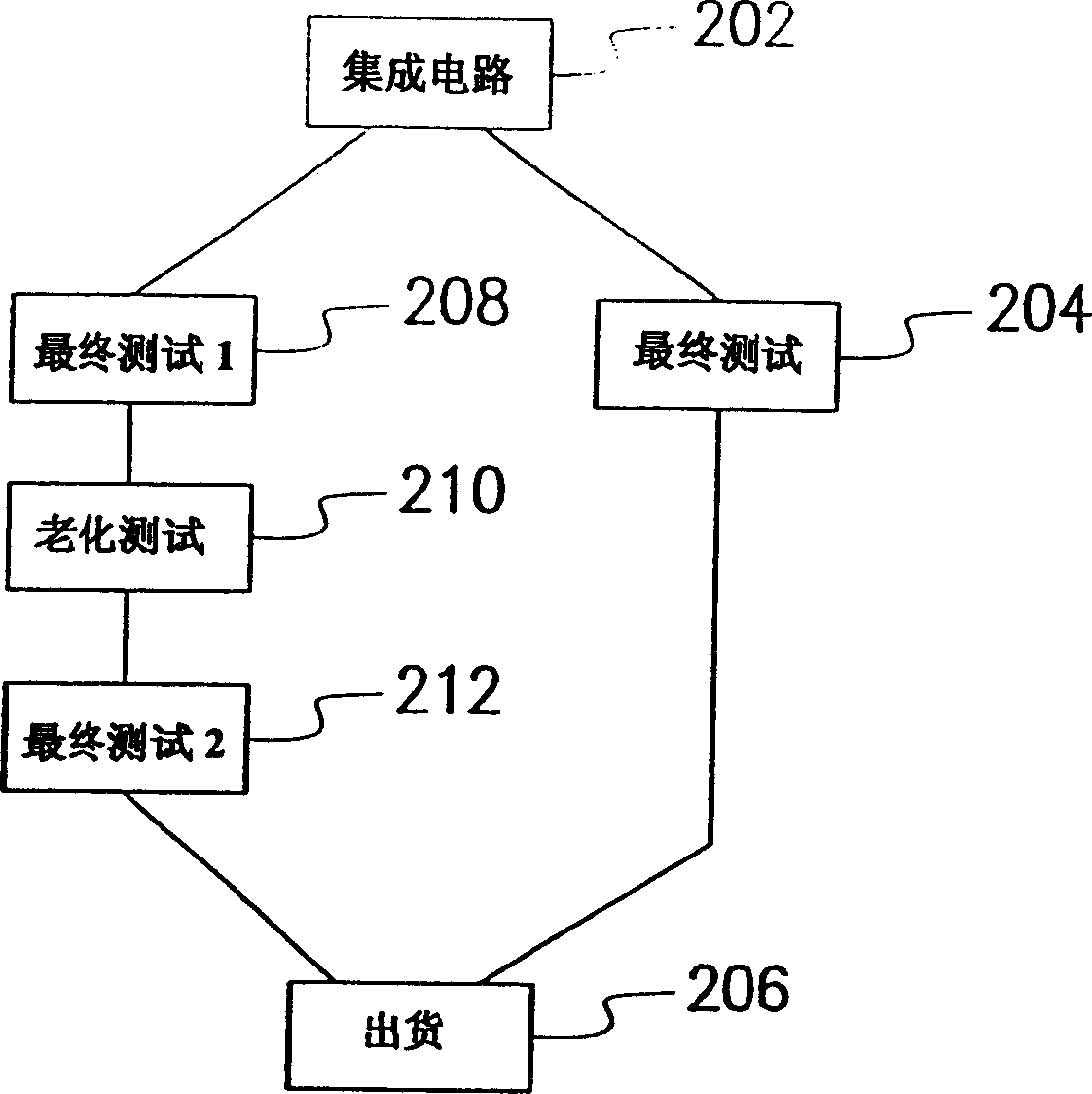

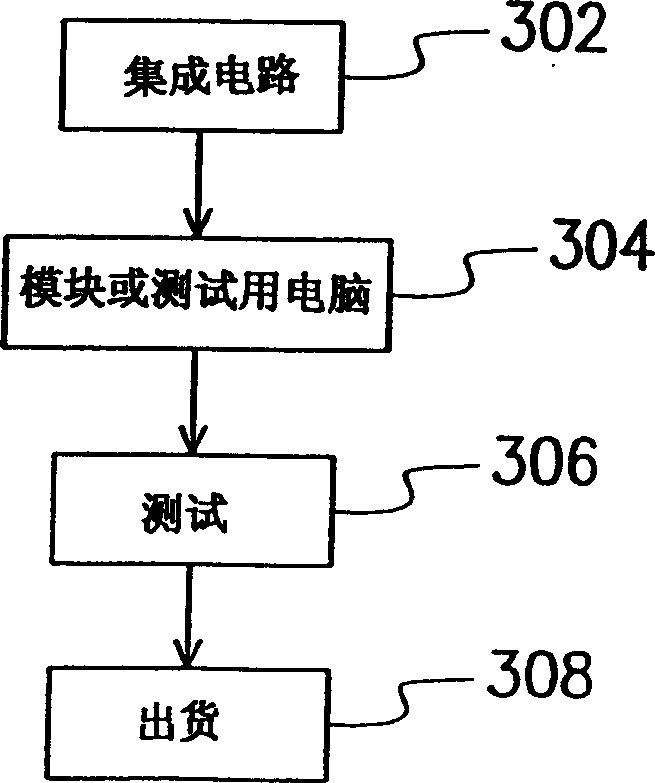

System, equipment and method for automatic testing IC complete device

InactiveCN1416163AGuarantee the quality of useLow costSemiconductor/solid-state device testing/measurementContactless circuit testingOutput deviceTest fixture

The testing device includes the testing computer and at least one of the image-sensing device. The testing computer is used for holding and testing the IC to be tested. The testing computer combines the IC to be tested forming an integrated computer so as to carry out the integrated testing. The testing computer includes at least one output device to output the result of testing the IC. The image-sensing device can pick up the image in the outupt device and can send the image picked to the control unit where the image picked is compared with the image data stored in the database in order to find out the difference between them.

Owner:VIA TECH INC

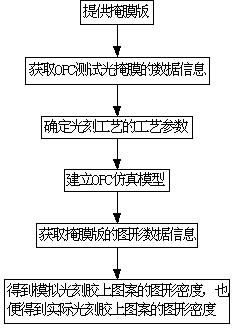

Method for measuring graphic density

ActiveCN103439869AOvercome densityOvercoming the problem of large setting errorsSemiconductor/solid-state device testing/measurementPhotomechanical exposure apparatusData informationPhotoresist

The invention discloses a method for measuring graphic density. An OPC (optical proximity correction) simulation model is constructed through a lithography process simulation module supplied by OPC software by acquiring data information of an OPC test photomask and technical parameter information of a lithography technology; the graph of a mask to be tested is introduced into the constructed OPC simulation model, so that patterns of the mask to be tested formed on photoresist can be simulated, and the graphic area of the patterns on the photoresist can be simulated; furthermore, the graphic density of the simulated patterns formed on the photoresist can be obtained, namely the graphic density of actual patterns formed on the photoresist is obtained. According to a simulation method, the graphic density of the patterns on the photoresist can be precisely obtained, so that the problem that the measured graphic density is greatly different from the actual graphic density because of no effective method for measuring the graphic density in the prior art is solved, and the graphic density is accurately measured; accurate data support is supplied to the subsequent manufacture procedure development such as etching and grinding, and the yield of a product is further improved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Hydraulic test device for detachable housing of combustion chamber case of aeroengine

ActiveCN105486508AReduce weightEasy to carryEngine testingFluid-tightness measurement using fluid/vacuumCombustion chamberEngineering

The invention discloses a hydraulic test device for a detachable housing of a combustion chamber case of an aeroengine. The test device comprises a pedestal, a base plate, an inner cylinder, a cover plate, an outer cylinder and a plug, wherein the base plate is arranged on the pedestal and connected with the lower end of the detachable housing of a part to be tested, the inner cylinder is placed at the inner lower end of the detachable housing and connected with the base plate and / or the pedestal, the cover plate is connected with the upper end of the inner cylinder, the outer cylinder is placed at the outer lower end of the inner cylinder and connected with the upper end of the detachable housing, the upper end of the outer cylinder is connected with the cover plate, and the plug is used to plug an opening in the detachable housing. The base plate, the inner cylinder, the cover plate, the outer cylinder and the detachable housing to be tested form a hydraulic annular enclosed space, and a part of the hydraulic annular enclosed space is provided with a hydraulic medium injection pipeline interface assembly, a hydraulic medium discharge pipeline interface assembly and an internal air discharge pipeline interface assembly of the annular enclosed space. The device can be used to detect the intensity, rigidity and welding compactness of the detachable housing, product is prevented from blindness, and guarantee is provided for producing combustion chamber cases, which satisfy using requirements, of the aeroengine.

Owner:CHENGDU ENGINE GROUP

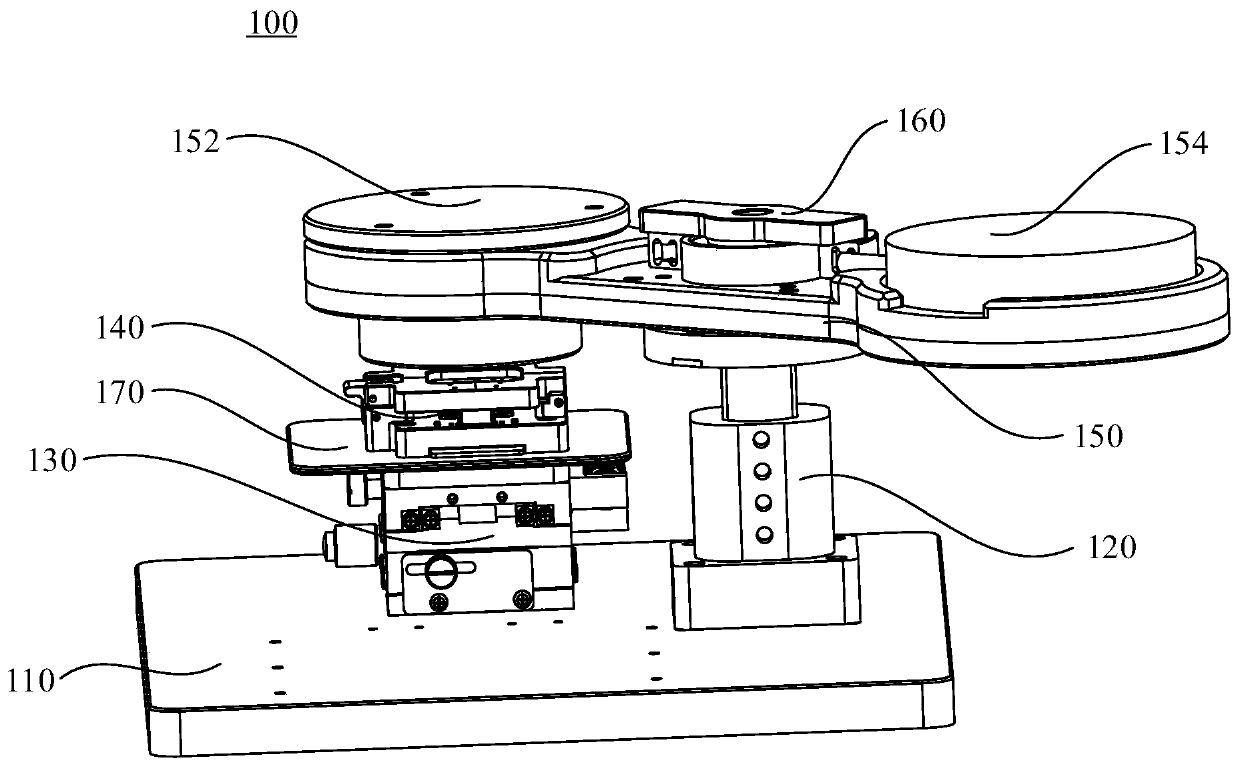

Photosensitive module testing device

PendingCN111458110AEasy to testEasy to adjust the positionTesting optical propertiesIlluminanceOptical testing

The invention discloses a photosensitive module testing device, and relates to the technical field of optical testing. The testing device comprises a bottom plate, and a height adjusting assembly anda horizontal adjusting platform which are arranged on the bottom plate. A test fixture is arranged on the horizontal adjusting platform and used for fixing a to-be-tested photosensitive module. The height adjusting assembly is provided with a rotating support rotationally connected with the height adjusting assembly. A blackboard and a light source with uniform illumination are respectively arranged on the rotary support; the light source or the blackboard corresponds to the to-be-tested photosensitive module when the rotary support is rotated, and the photosensitive module testing device further comprises a testing assembly which is electrically connected with the photosensitive module to be tested and used for testing the to-be-tested photosensitive module. The test form of the photosensitive module can be simplified, the detection efficiency is improved, the operation difficulty and the operation intensity are reduced, and the production cost is further reduced.

Owner:DONGGUAN VISIONX-TECH CO LTD

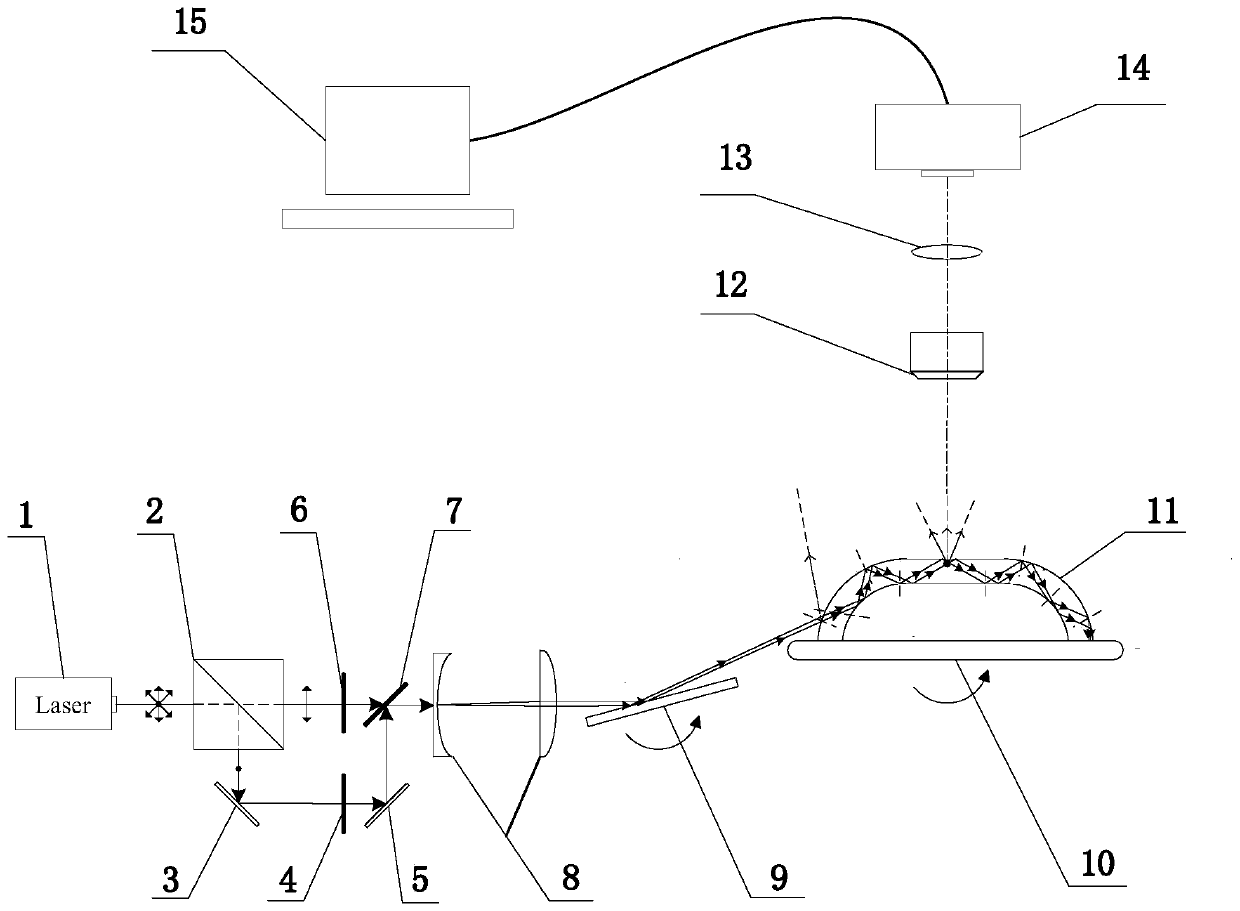

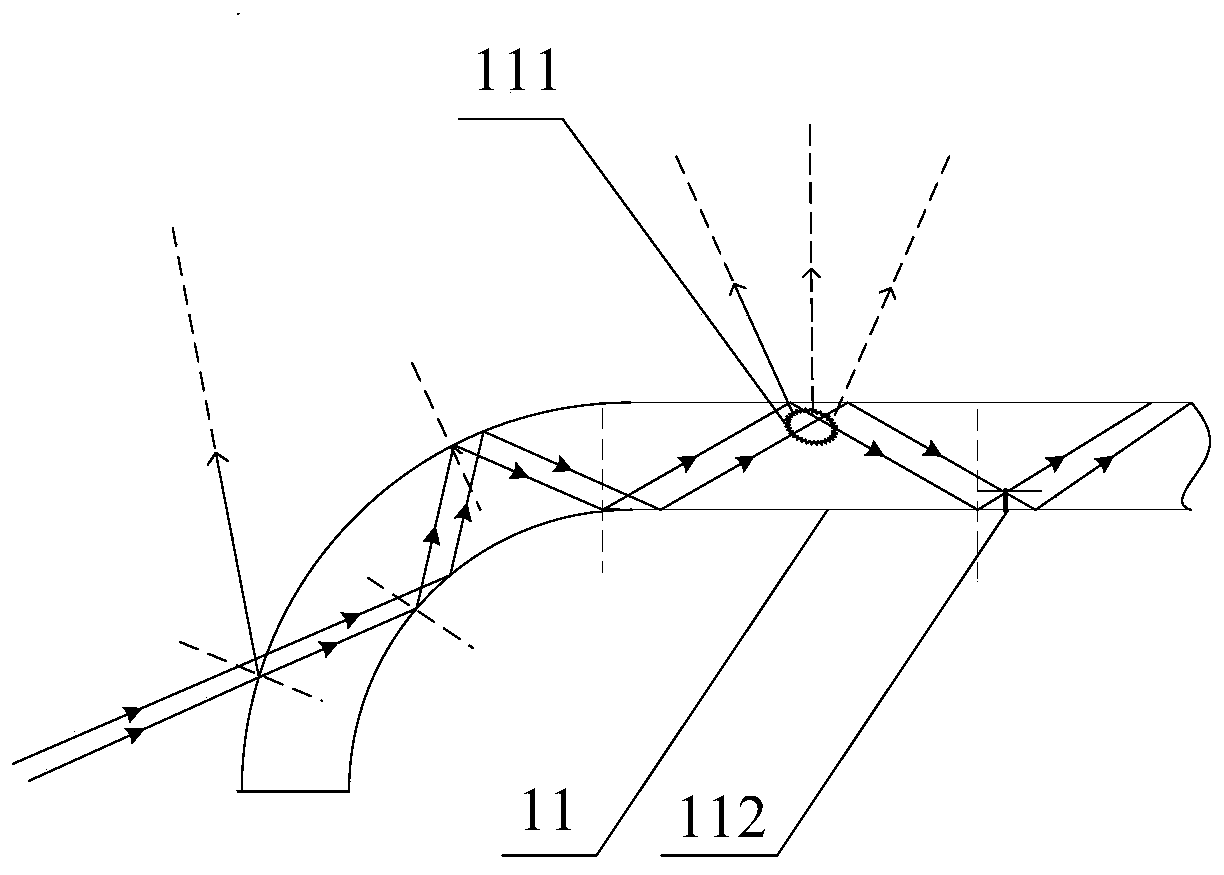

Bent glass subsurface defect detection method based on dark-field illumination

InactiveCN110044930AImprove detection efficiencyIncrease contrastMaterial analysis by optical meansNon destructiveTotal internal reflection

The invention discloses a bent glass subsurface defect detection method based on dark-field illumination. The method comprises the following steps: vertically irradiating a polarizing prism via the laser generated by a laser light source to obtain a P wave and a S wave, in which emitting directions thereof are vertical to each other; shielding the S wave, irradiating the bent glass to be tested via the P wave after beam expansion, wherein the light of the P wave generating total internal reflection in the bent glass to be tested forms a standing wave with the P wave to perform first time dark-field illumination on the bent glass to be tested; focusing a subsurface of the bent glass to be tested under the first time illumination, adjusting the incidence direction of the P wave according toa focused image, and fixing the P wave; shielding the P wave, making the light path of the S wave coincide with that of the P wave, irradiating the bent glass to be tested via the S wave after beam expansion, wherein the light of the S wave generating total internal reflection in the bent glass to be tested forms a standing wave with the S wave to perform second time dark-field illumination on thebent glass to be tested; and collecting an image containing a bent glass surface defect under the second time illumination. According to the bent glass subsurface defect detection method disclosed bythe invention, twice illumination is performed to perform non-destructive detection on defects in the bent glass, and the detection efficiency and the detection contrast are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com