Method for measuring graphic density

A pattern density and pattern technology, which is applied in the photoplate making process of the pattern surface, semiconductor/solid-state device testing/measurement, and original parts for photomechanical processing, etc., can solve the problem of large setting errors of etching and grinding process parameters, Problems such as the large difference between the measured pattern density and the actual pattern density can achieve the effect of improving yield and supporting accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

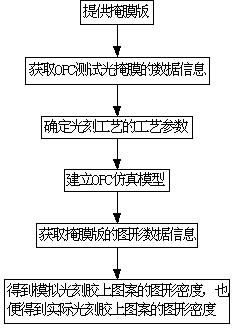

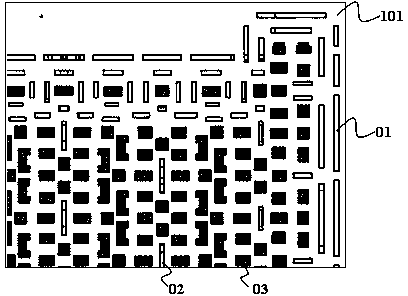

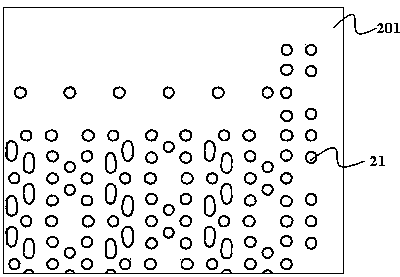

[0043] figure 1 It is a schematic flow chart of the method for measuring pattern density provided by Embodiment 1 of the present invention; figure 2 It is a schematic diagram of the mask pattern to be tested provided by Embodiment 1 of the present invention; image 3 It is a schematic diagram of simulating the pattern on the photoresist provided by Embodiment 1 of the present invention; as shown in the figure, the method for measuring the pattern density is mainly used in the process of measuring the pattern density of the pattern on the photoresist, including the following steps:

[0044]First, according to the process requirements, that is, according to the products required by customers, a test photolithography mask plate with a pattern of multiple OPC test photomasks is provided. At the same time, the mask plate includes all Graphics that may appear.

[0045] Then obtain the data information of the OPC test photomask. The specific operation is: transfer the pattern of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com