Cheese fiber removal method for producing hemp/cotton and linen/ high count cotton yarns

A flax and hemp technology, applied in the direction of yarn, textiles, papermaking, dry-cleaning fiber products, etc., can solve the problems of affecting subsequent processing, easy entanglement of skeins, low yarn strength, etc., to overcome the reduction of fabric density and yarn Good quality and even effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

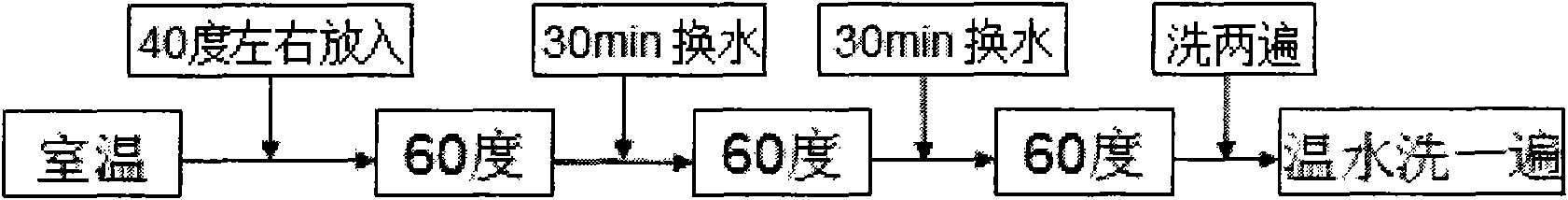

[0019] Adopt the present invention to realize the bobbin dedimensionalization to hemp / cotton / vinylon single yarn, get 40 after dedimensionalization S Hemp / Cotton High Count Yarn. The main technological process is: after mixing 49.5wt% of hemp fiber, 40.5wt% of cotton fiber and 10wt% of vinylon fiber soluble in 40°C water, spinning into 36 S The blended single yarn, and then the blended single yarn is wound to a winding density of 0.35g / cm 3 The bobbin, the bobbin yarn weight is 0.3kg, in the bath ratio is 1:10, the specific flow rate is 50L / kg·min, and the vinylon is removed by three water changes in water at 60°C.

[0020] After completely removing vinylon, dry it at 100°C for 4 hours to obtain a fineness of 40 S The hemp / cotton single yarn, and then the single yarn is plied to obtain a fineness of 40 S / 2 hemp / cotton strands. The hemp / cotton single yarn and strand quality that present embodiment makes are as shown in table 1:

[0021]

[0022] Table 1

Embodiment 2

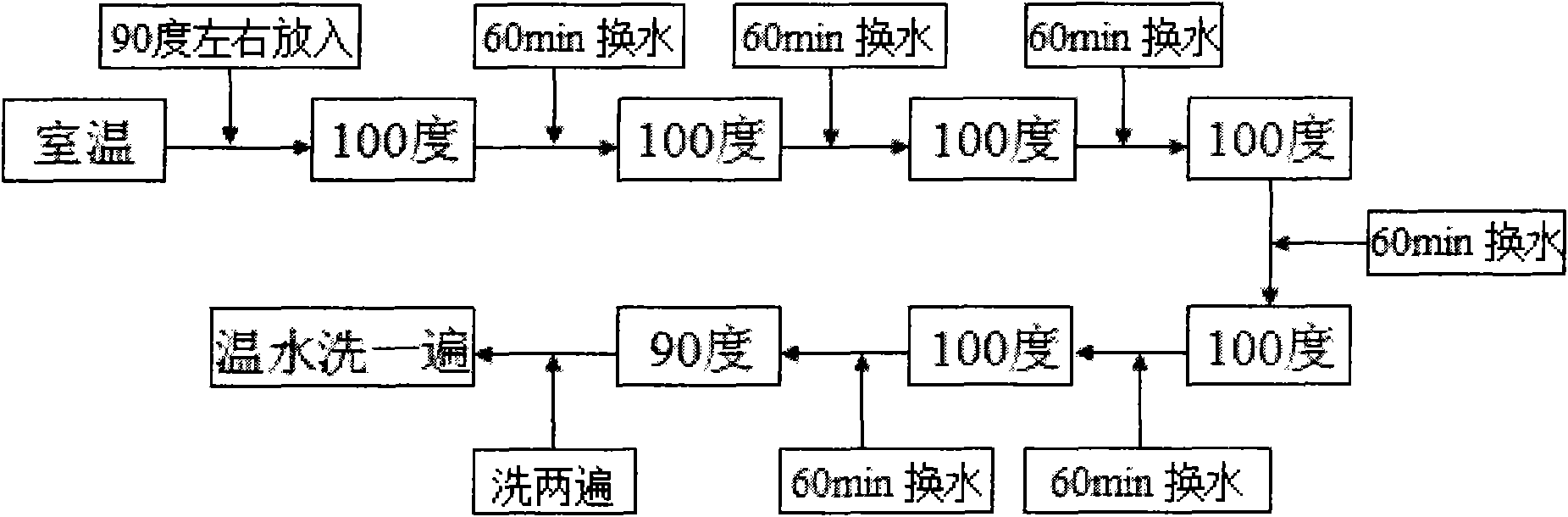

[0024] Adopt the present invention to realize the dedimensionalization of the package of hemp / cotton / vinylon single yarn, and get 100 after dedimensionalization S Hemp / Cotton High Count Yarn. The main technological process is: after mixing 16.5wt% of hemp fiber, 13.5wt% of cotton fiber and 70wt% of vinylon fiber soluble in 90°C water, spinning into 70 S Hemp / cotton / vinylon blended single yarn, and then the blended single yarn is wound to a winding density of 0.45g / cm 3 The bobbin, the bobbin yarn weight is 0.5kg, in the bath ratio is 1:30, the specific flow rate is 70L / kg·min, and the vinylon is removed by six water changes in 100°C water.

[0025] After the vinylon is completely removed, dry it at 100°C for 4 hours to obtain a fineness of 100 S The hemp / cotton single yarn, and then ply the single yarn to obtain a fineness of 100 S / 2 hemp / cotton strands. The hemp / cotton single yarn and strand quality that present embodiment makes are as shown in table 2:

[0026]

[0...

Embodiment 3

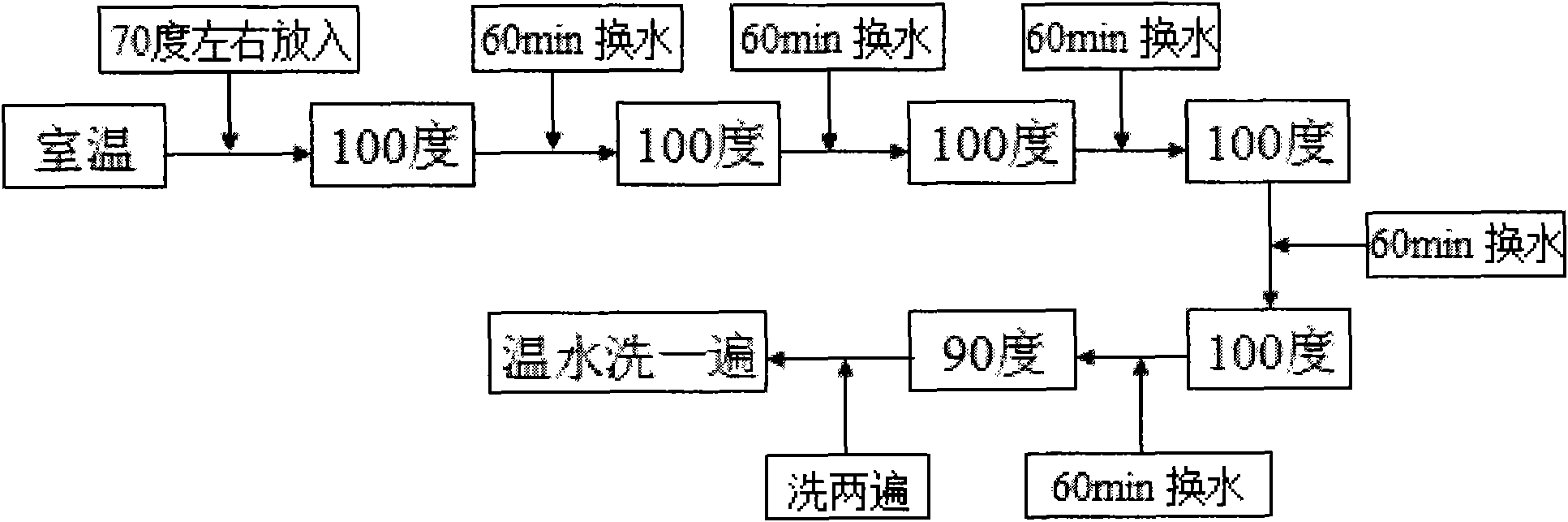

[0029] Adopt the present invention to spin 55 S / 2 linen / cotton high count yarn. The main process flow is: after mixing 44wt% of flax fiber, 36wt% of cotton fiber and 20wt% of vinylon fiber soluble in 70°C water, spinning into 55 S flax / cotton / vinylon blended single yarn, and then the blended single yarn is plied into 44S / 2 strands, and then the strands are wound to a winding density of 0.4g / cm 3 The bobbin, the bobbin yarn weight is 0.4kg, in the bath ratio is 1:25, the specific flow rate is 60L / kg·min, and the vinylon is removed by six water changes in 100°C water.

[0030] After completely removing vinylon, dry it at 100°C for 4 hours to obtain a fineness of 55 S / 2 linen / cotton strands. The hemp / cotton single yarn and strand quality that present embodiment makes are as shown in table 3:

[0031]

[0032] table 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com