Patents

Literature

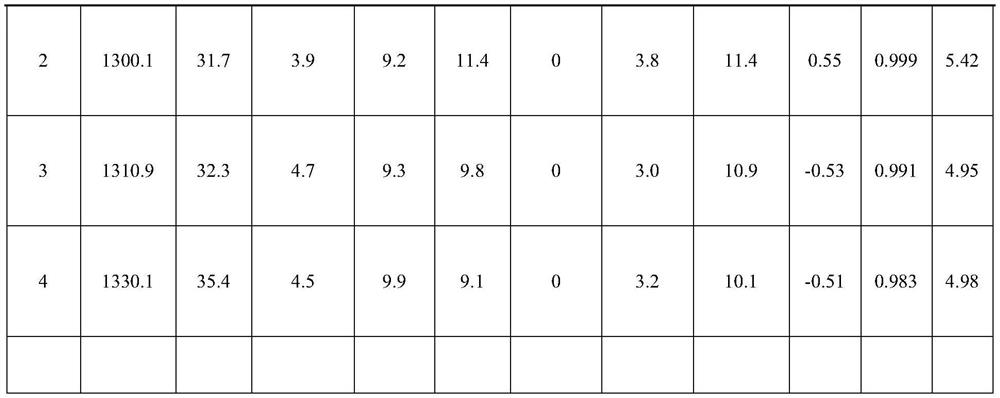

30results about How to "Good quality yarn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spinning apparatus for producing low-torque ring-spun yarn

The present invention provides a spinning apparatus for producing low-torque ring-spun yarns, wherein the apparatus comprises a ring spinner and a false-twist device; the false-twist device is arranged between a pair of output rollers of the ring spinner and a yarn guiding ditch, and a yarn orienting device is installed between the false-twist device and the yarn guiding ditch; the yarn orienting device comprises an orientation member, wherein the upper portion of the orientation member is provided with a yarn supporting curved surface, and yarns are leaned against the yarn supporting curved surface of the orientation member. The present invention is advantageous in that the structure of the spinning apparatus is simple, the existing ring spinner can be conveniently reconstructed with low cost, and the qualities of the produced yarns are good. The spinning apparatus provided by the invention can be applied to the solospun, siro spining, Sirofil spining and compact spinning devices for ring spining or combinations of the devices.

Owner:NINGBO DECHANG PRECISION TEXTILE MACHINERY

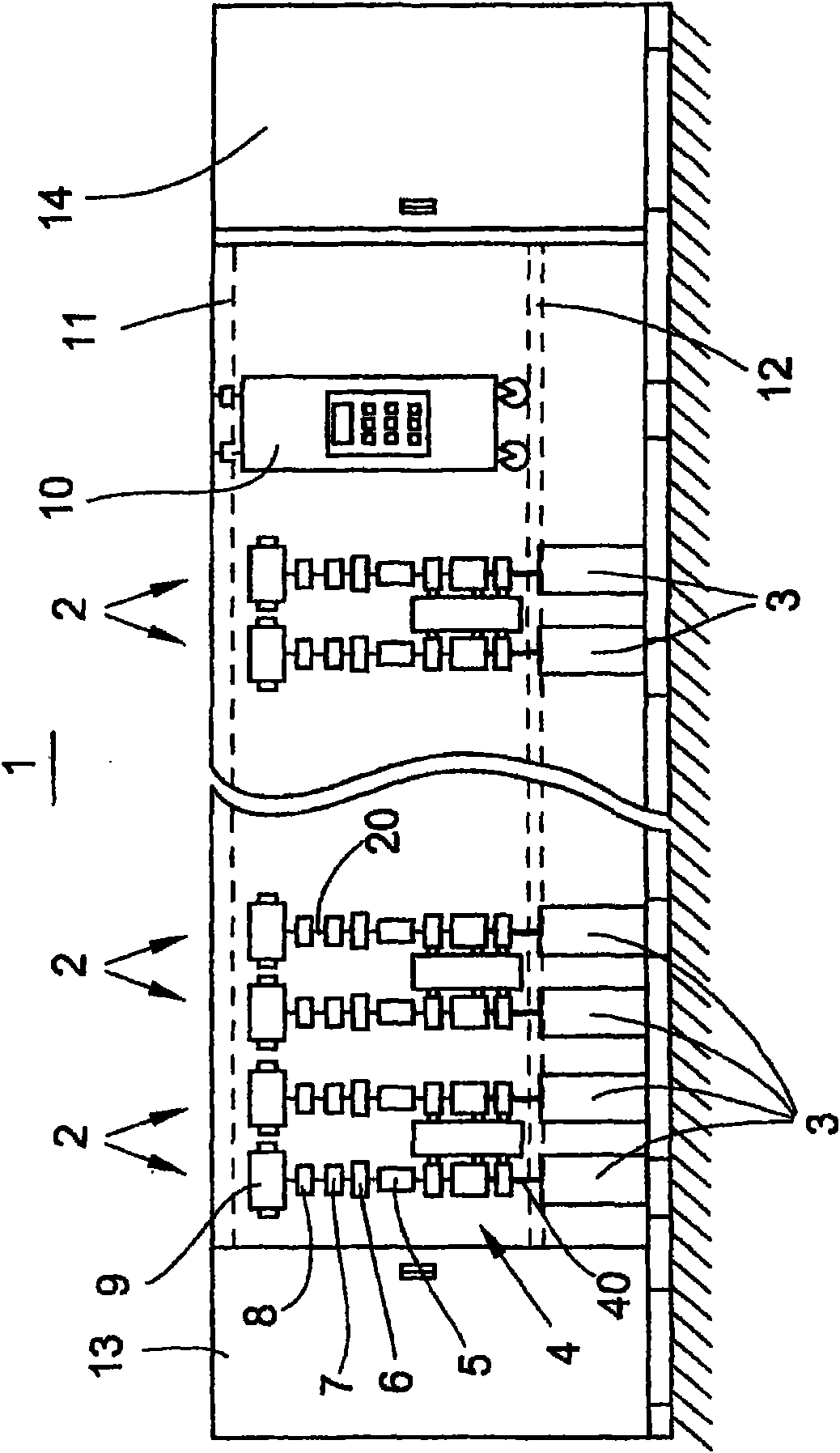

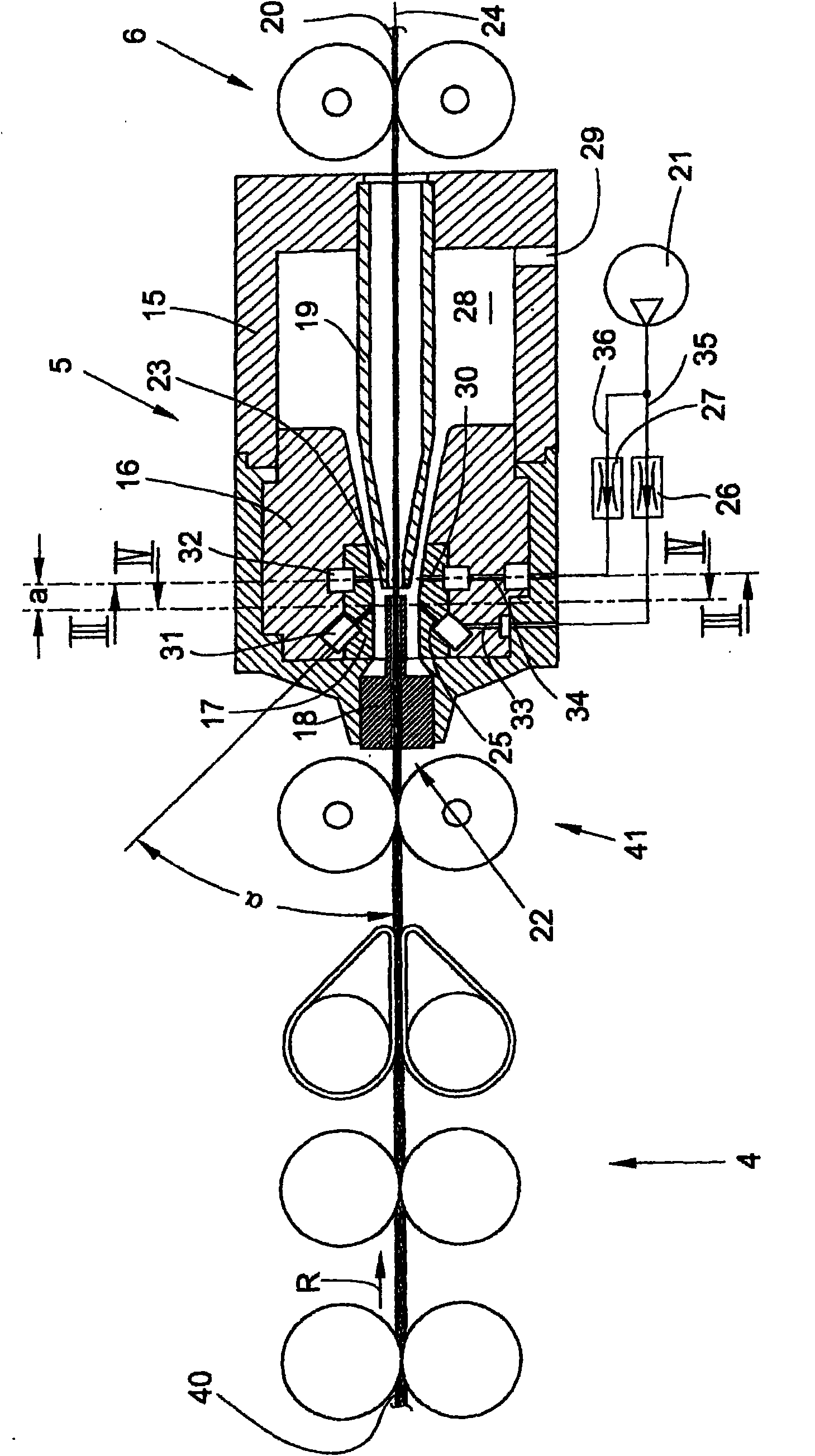

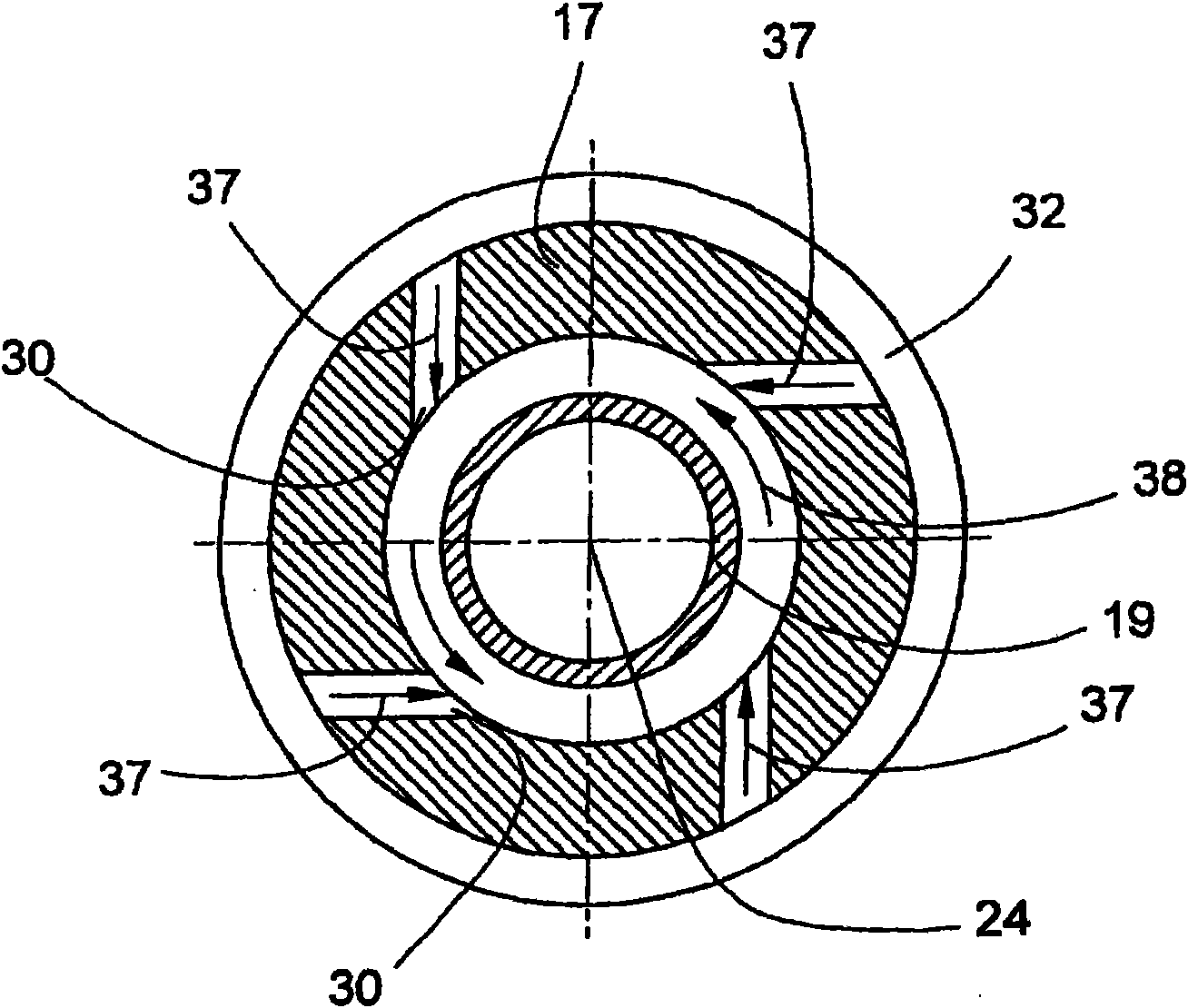

Jet spinning apparatus

ActiveCN101600826AEffective assistanceSoft treatmentContinuous wound-up machinesOpen-end spinning machinesYarnUltimate tensile strength

The invention relates to a jet spinning apparatus (5) for producing a thread (20) by means of a circulating airflow, having a hollow spinning cone (19) which is arranged in a spinning housing (15), and having two separate groups of blown air nozzles (25, 30) which can be loaded with compressed air independently of one another, wherein the strength of a vacuum flow which acts on a sliver inlet opening (22) during the spinning process can be set via the arrangement of a first group of blown air nozzles (25) and the strength of an airflow which circulates in the region of the spinning cone (19) can be predefined via the arrangement of a second group of blown air nozzles (30). There is provision according to the invention for the blown air nozzles (25) of the first group to be arranged offset at a spacing (b) with regard to the longitudinal centre axis (24) of the jet spinning apparatus (5), with the result that an airflow can be introduced into the jet spinning apparatus (5) via the blown air nozzles (25) during the spinning process, which airflow has a tangential blown air component in order to assist the airflow which circulates in the region of the spinning cone (19).

Owner:SAURER GERMANY GMBH & CO KG

Terylene and viscose blended yarns

The invention provides terylene and viscose blended yarns, which comprises the following components in percentage by weight: 60 to 70 percent of terylene fibers and 30 to 40 percent of viscose fibers, wherein the terylene fibers may be the terylene fibers with fineness of 1.2D and 1.5D; and the viscose fibers may be the viscose fibers with fineness of 1.2D and 1.5D. The terylene and viscose blended yarns in the invention have the technical advantages that: 1) the process is simple, and the characteristics of the terylene fibers and viscose fibers can be complemented well; 2) the blended yarns have better yarn characteristics; and 3) fabrics prepared from the blended yarns in the invention have better service functions and meet requirements of people on comfortable dressing.

Owner:NANTONG SUZHONG TEXTILE

Acrylic fiber and wool blended yarn

The invention provides an acrylic fiber and wool blended yarn which comprises the following components in percent by weight: 80-90 percent of acrylic fiber and 10-20 percent of wool fiber, wherein the fineness of the acrylic fiber is 1.5D and the length of the acrylic fiber is 38mm. The acrylic fiber and wool blended yarn has the advantages that: 1, the process is simple, and characteristics of the acrylic fiber and the wool fiber can be better compensated; 2, better yarn properties are obtained; and 3, the fabric made of the blended yarn has better taking function and meets the requirement on comfortable clothes for people.

Owner:NANTONG SUZHONG TEXTILE

Method and apparatus for spinning staple fibres on ring-spinning machines

Owner:DITF DEUT INST FUR TEXTIL UND FASERFORSCHUNG DENKENDORF

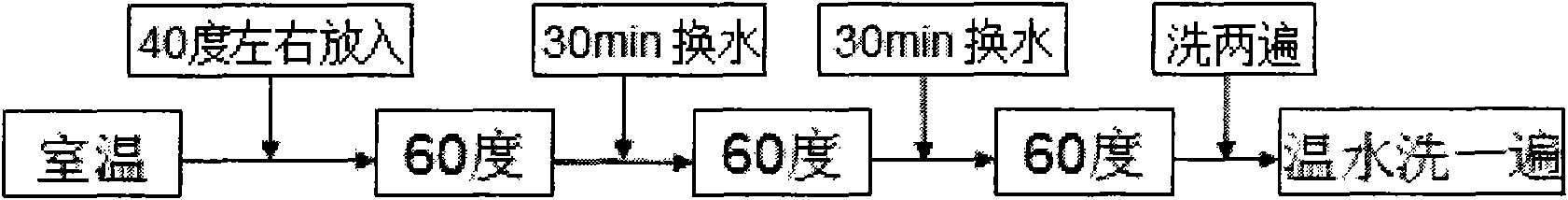

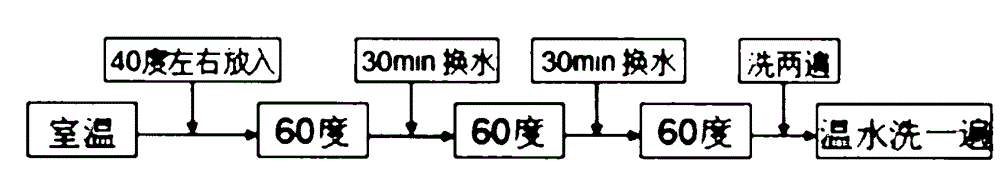

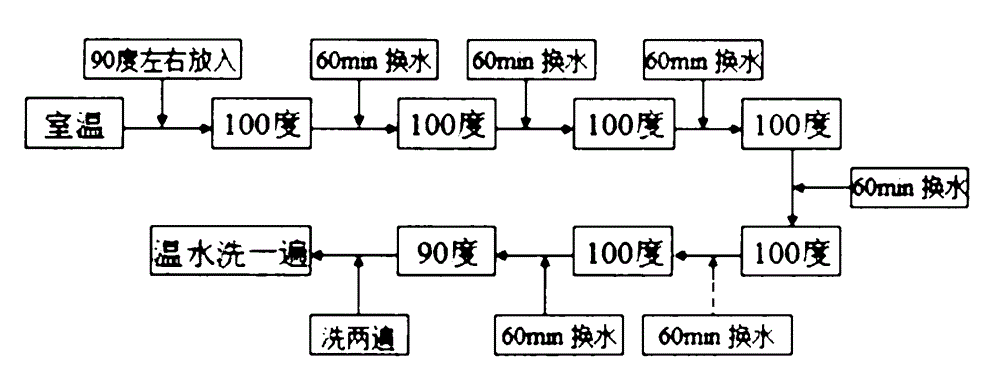

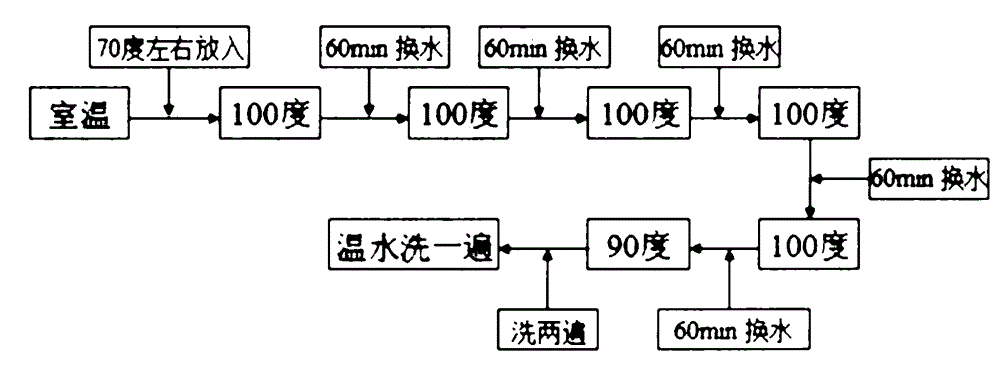

Cheese fiber removal method for producing hemp/cotton and linen/ high count cotton yarns

InactiveCN102051724AOvercome densityOvercoming Loose FabricDry-cleaning apparatus for textilesYarnYarnFiber

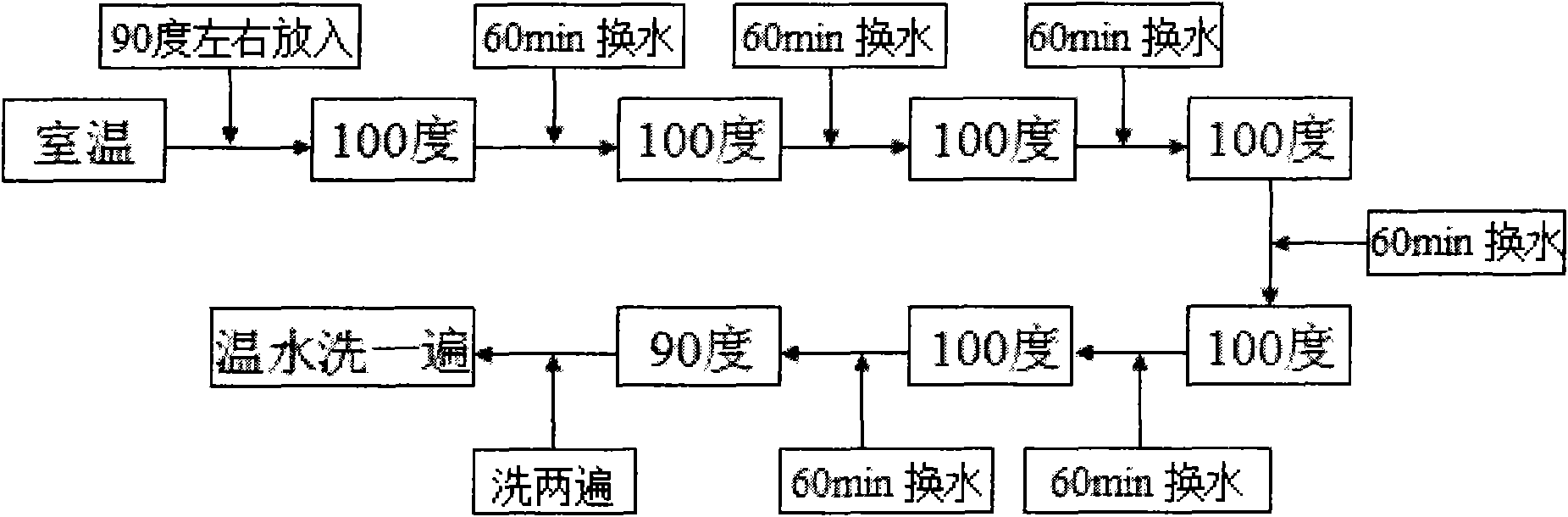

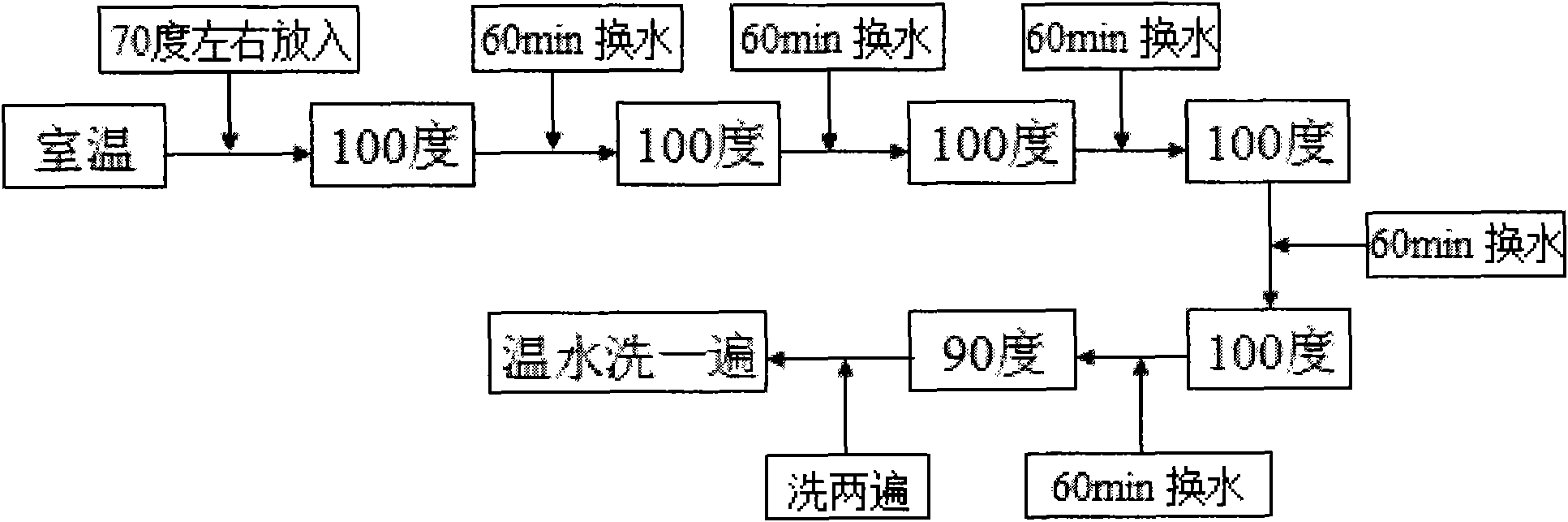

The invention provides a cheese fiber removal method for producing hemp / cotton and linen / high count cotton yarns, which comprises the following steps of: (1) winding blended spinning single yarns or blended spinning compound yarns on a loose type cheese winder into cheese; (2) controlling the following production conditions on a cheese dyeing machine: a temperature of between 60 and 100 DEG C, a liquor ratio of between 1:10 and 1:30, water exchange times of 1 to 6, a specific discharge of 50 to 70L / kg.min, and fiber removal time of 1 to 6 hours; and (3) removing water soluble PVA fibers from the cheese to obtain high count single yarns or high count compound yarns of hemp / cotton or linen / cotton. The single yarns or the compound yarns obtained after fiber removal by the method have the advantages of uniform fiber removal, capability of realizing high-speed unwinding without winding, and capability of being directly used in post processing of weaving and knitting, thereby laying the foundation for revealing the superior performances of the hemp / cotton and the linen / cotton, widening the application scope of hemp / cotton and linen / cotton products, and producing thin hemp / cotton and linen / cotton products with high quality.

Owner:DONGHUA UNIV +1

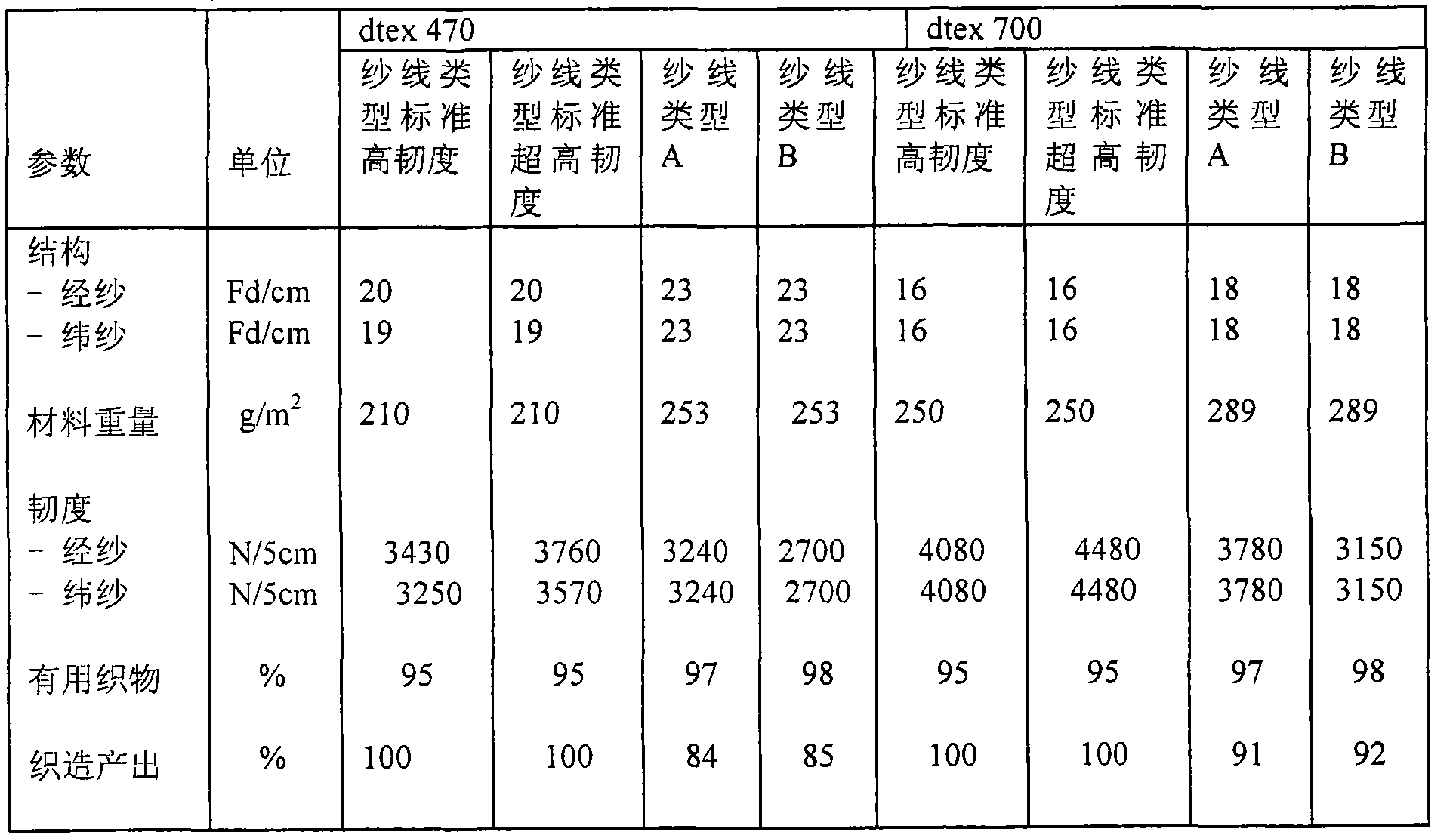

Airbag fabric

InactiveCN101421451AImprove performanceReduce manufacturing costPedestrian/occupant safety arrangementWoven fabricsYarnDifferential pressure

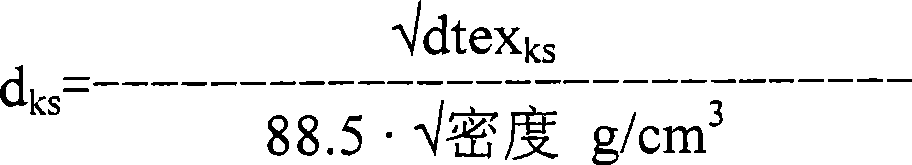

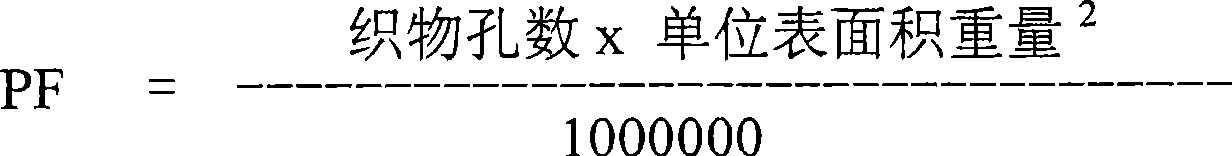

Fabric for an airbag, comprising warp threads and weft threads, in particular using multifilaments, characterized by a weave density greater than the 95% Professor Walz standard. It can also have a permeability (LD) of less than 3 l / dm<2> / min (at 500 Pa differential pressure) pursuant to ISO 9237, and can be characterized by a warp / weft insertion ratio greater than 1.

Owner:ITG AUTOMOTIVE SAFETY TEXTILES GMBH

Flame-retardant anti-molten-drop antistatic core-spun yarn and preparation method thereof

The invention discloses flame-retardant anti-molten-drop antistatic core-spun yarn and a preparation method thereof. The preparation method of the flame-retardant anti-molten-drop antistatic core-spunyarn comprises the following steps that aramid fibers, flame-retardant viscose fibers and antistatic fibers are mixed and then subjected to combing, drawing and roving in sequence, and the mixture and mixed nylon filaments are subjected to core spun yarn spinning; spooling is carried out, and the core-spun yarn is obtained, wherein the nylon filaments are a mixture obtained through drawing and mixing of flame-retardant nylon filaments and non-flame-retardant nylon filaments. According to the method, the aramid fibers, the flame-retardant viscose fibers, the flame-retardant nylon filaments, the high-strength non-flame-retardant nylon filaments and conductive fibers serve as main components, and a flame-retardant anti-molten-drop fabric is prepared through blending spinning and weaving technologies. The fabric has the advantages of being retardant to flame, resistant to molten drops, high in strength, antistatic, easy to dye, low in cost, simple in process, good in yarn quality and thelike, can be used for meeting requirements in the aspect of special operations and can also meet requirements in the aspects of uniforms and the like.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA

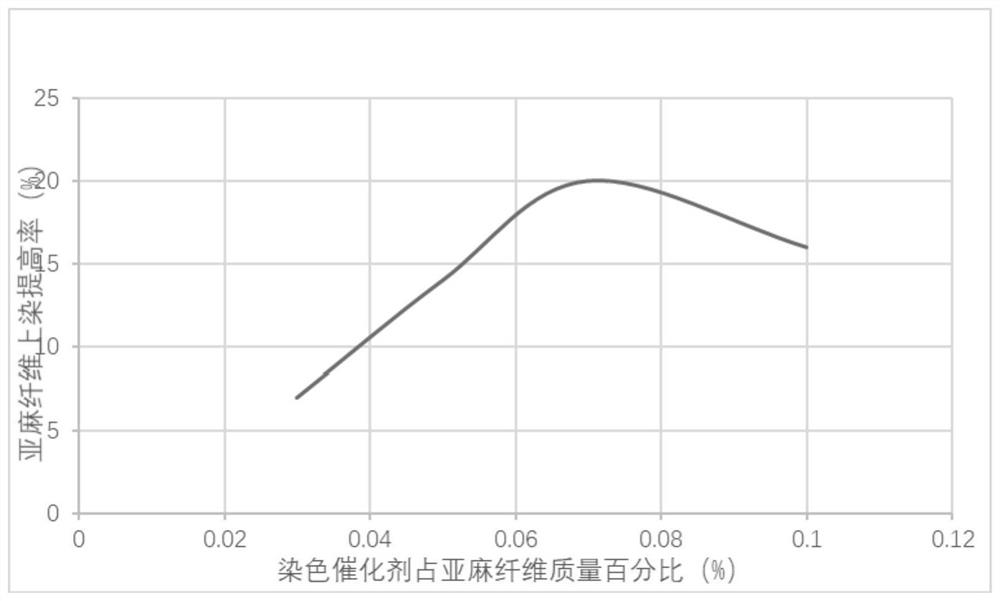

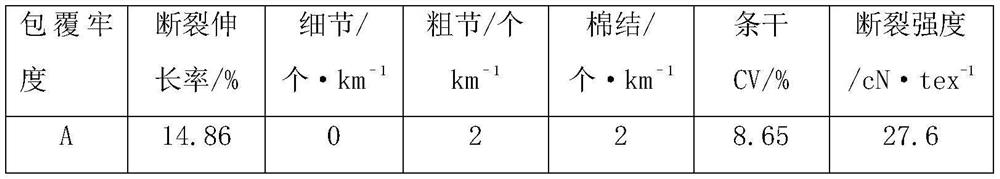

Tencel/flax vortex spinning elastic core-spun yarn and preparation method thereof

InactiveCN113005580AOvercome the disadvantage of poor wrinkle resistanceImprove the problem that the color is lighter than Tencel fiberContinuous wound-up machinesOpen-end spinning machinesYarnPolymer science

The invention relates to a tencel / flax vortex spinning elastic core-spun yarn and a preparation method thereof. The core-spun yarn is composed of a central T400 composite elastic filament and an outer wrapping fiber, wherein the outer wrapping fiber is composed of tencel and flax. The prepared tencel / flax vortex spinning elastic core-spun yarn and a subsequent fabric are overhung, elegant, moisture-absorbing, breathable, smooth in silk quality, antibacterial, mildew-proof, green and environment-friendly, and the core-spun yarn integrates the advantages of the elastic core yarn and is comfortable to wear and good in shape retention; and compared with a traditional flax blended product, the problem that the dyeing degree of flax fibers is lighter than that of tencel fibers after dyeing, and the problem that the blending ratio of the flax fibers of a final product is reduced can be remarkably solved.

Owner:DONGHUA UNIV +3

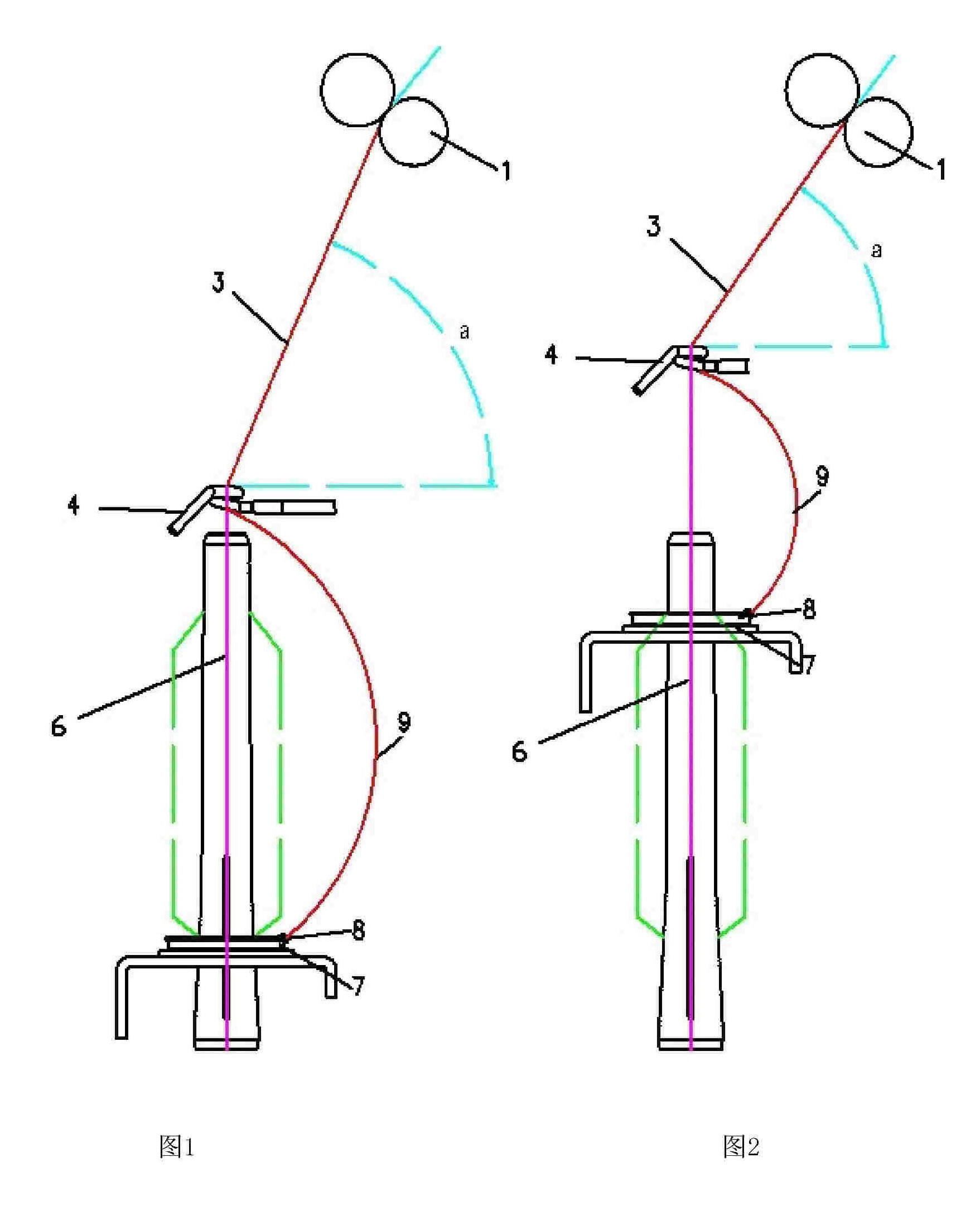

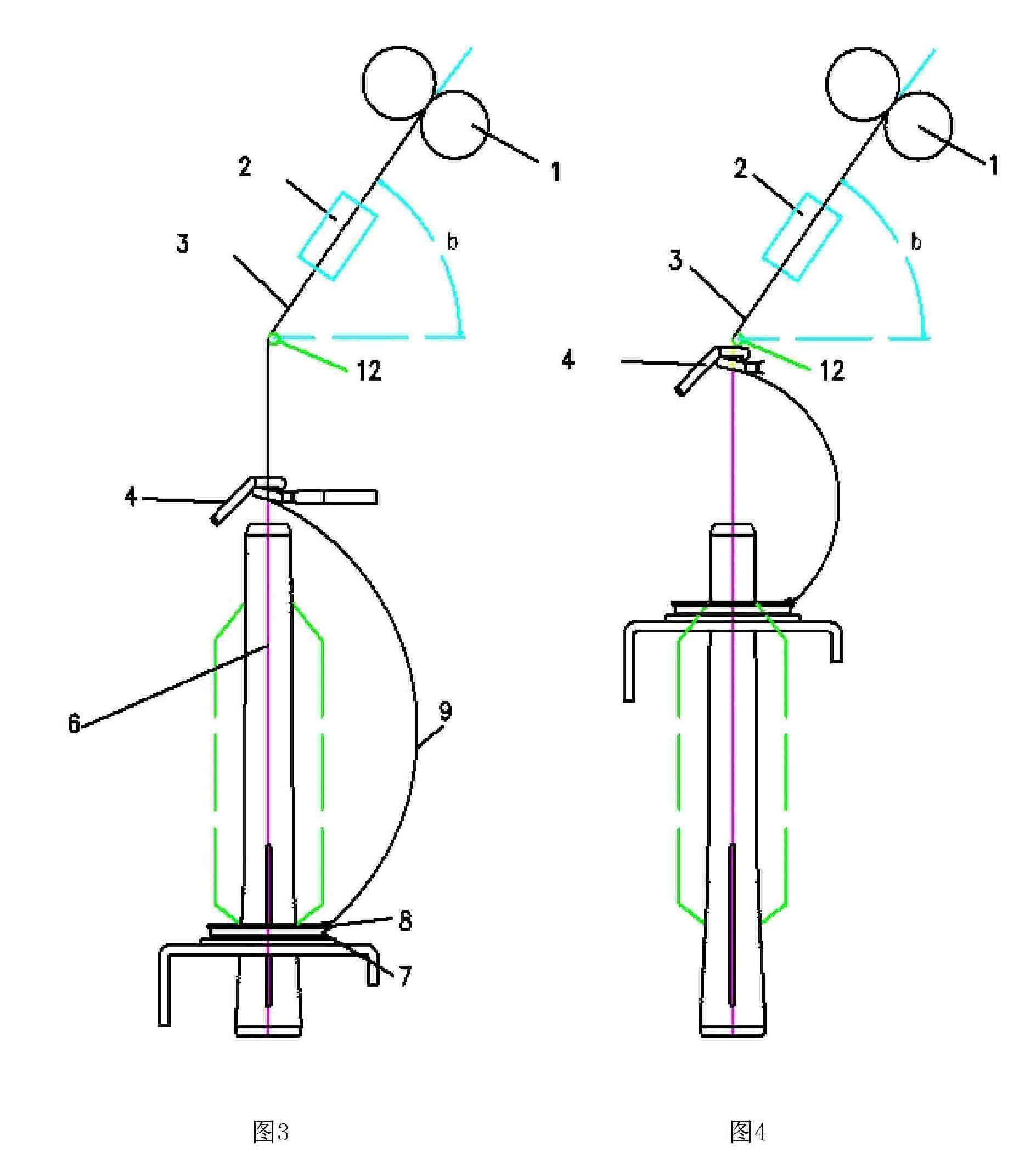

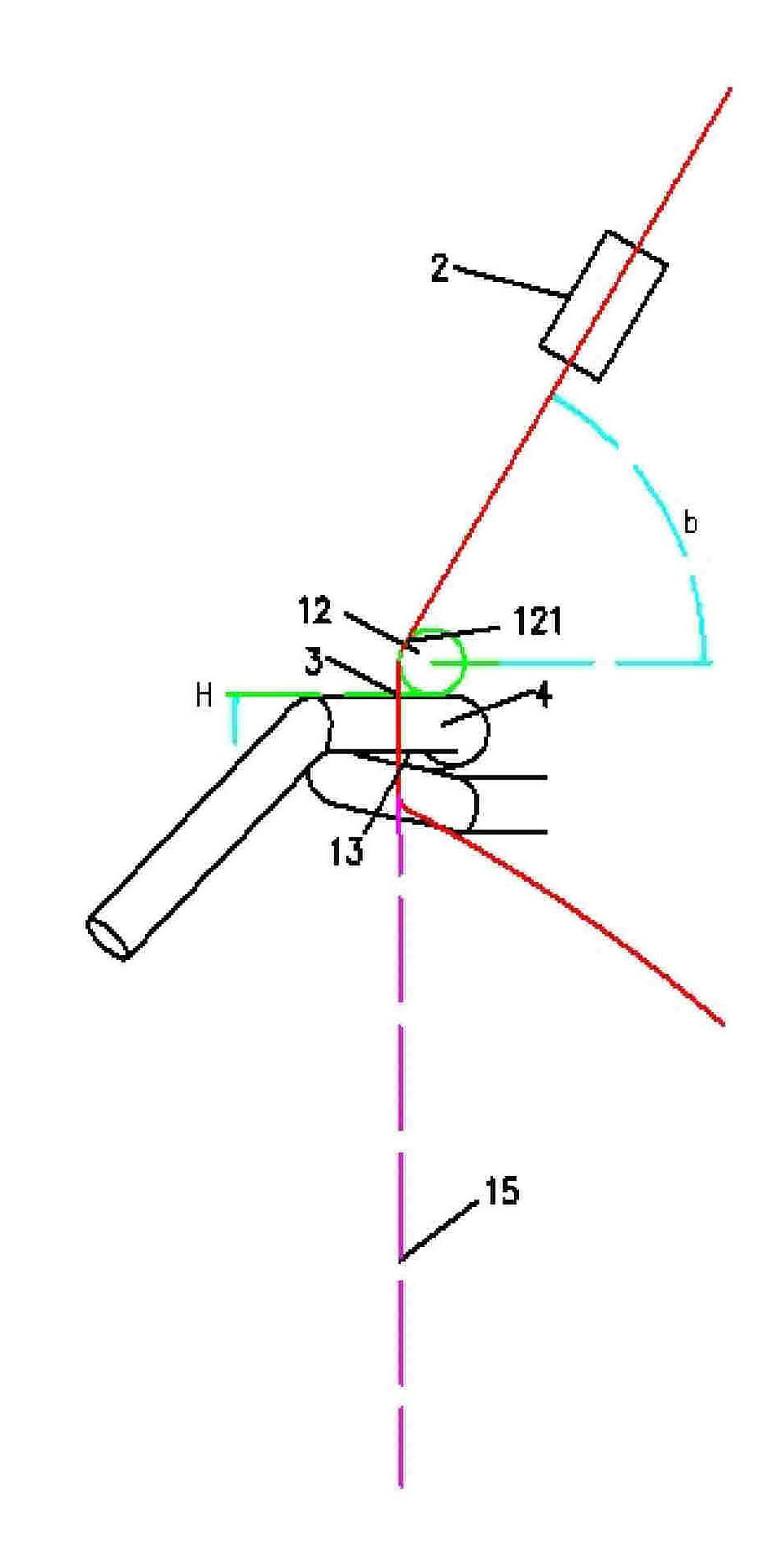

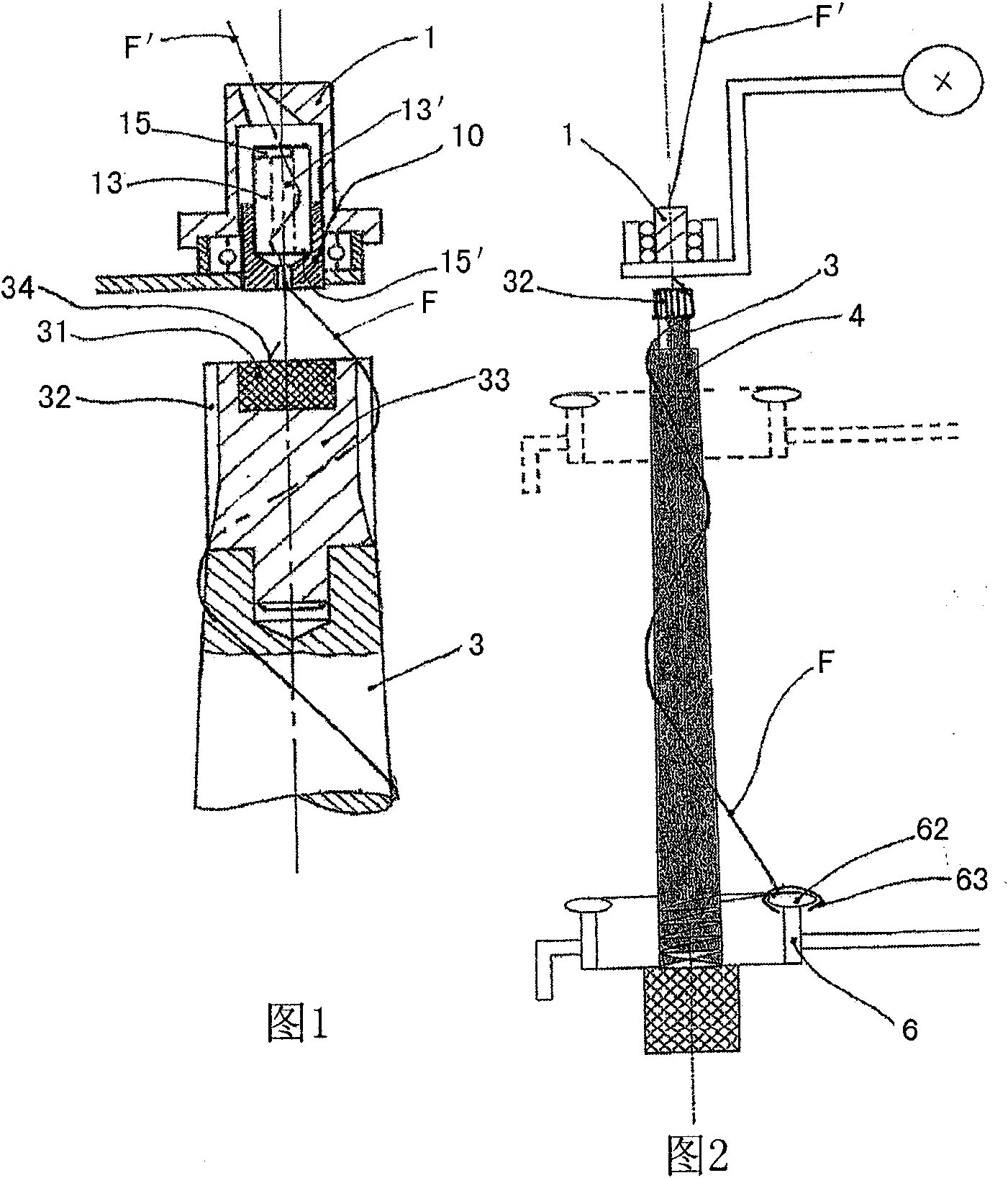

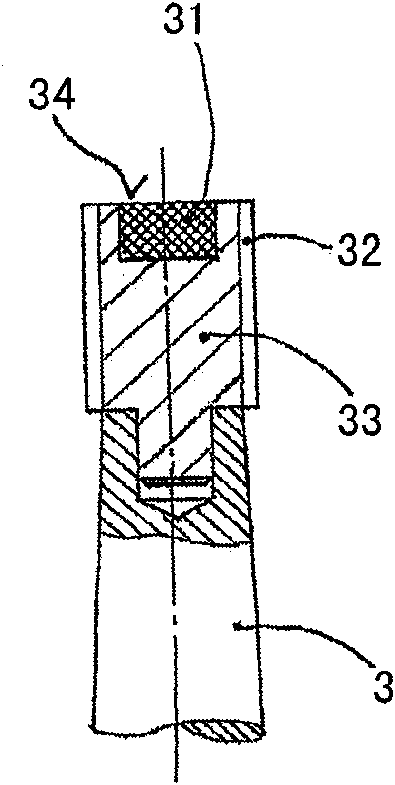

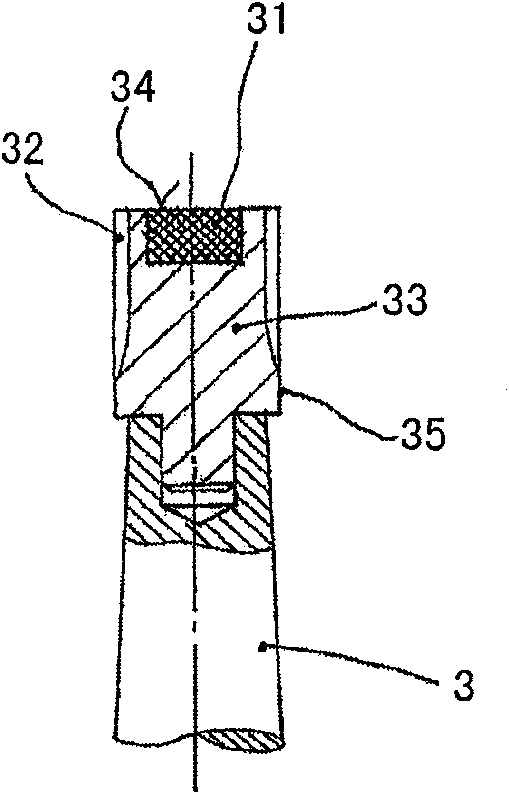

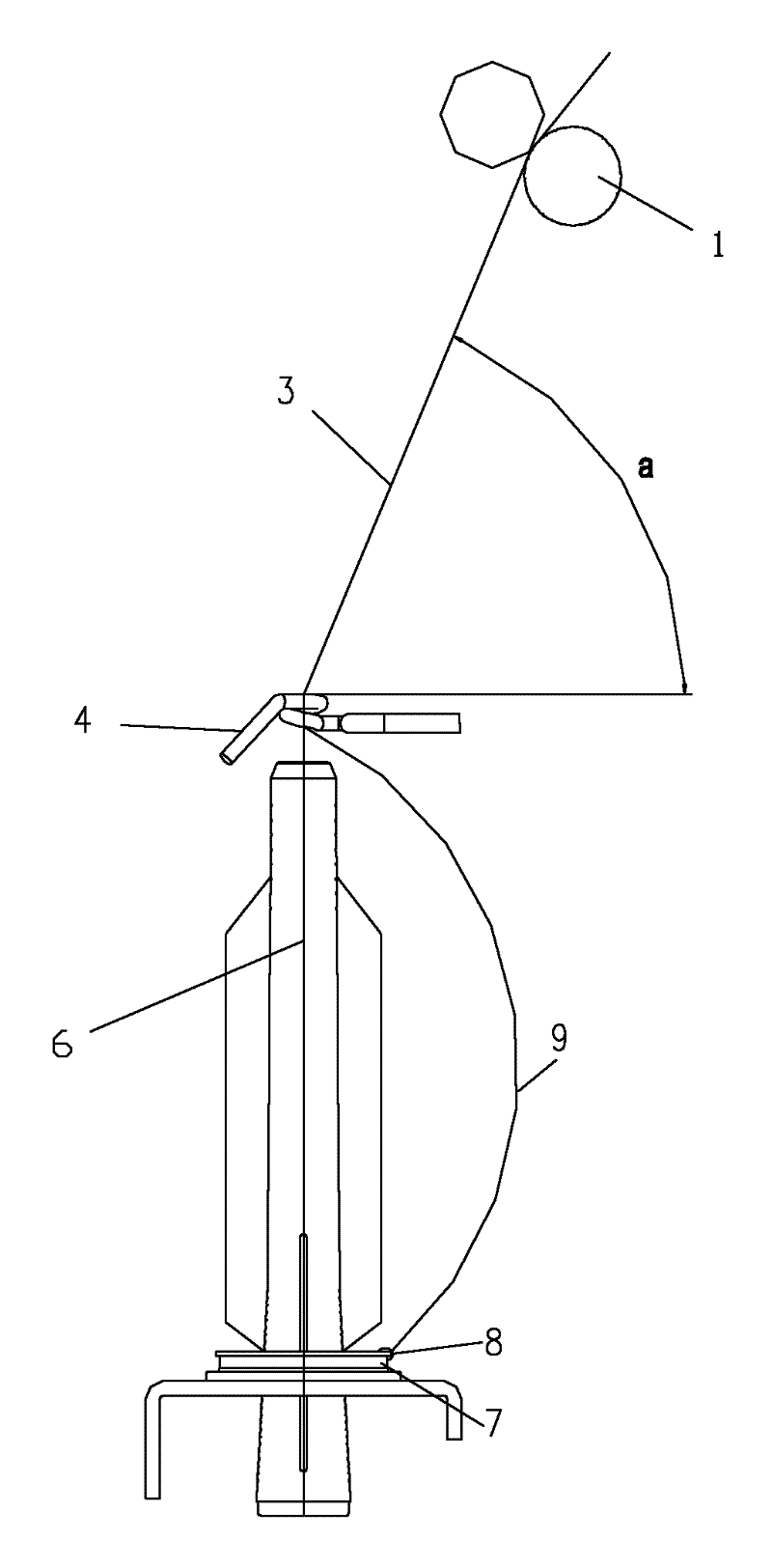

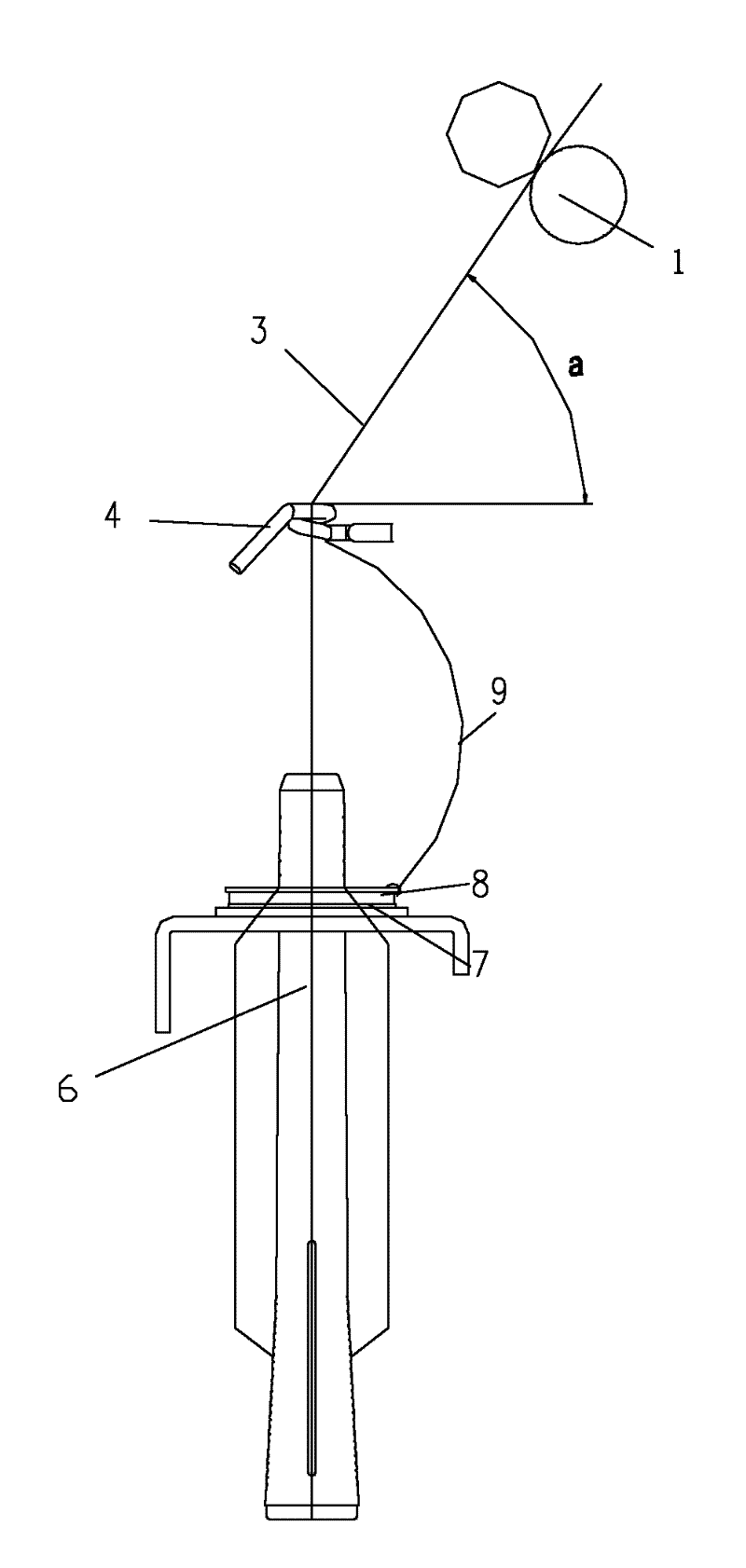

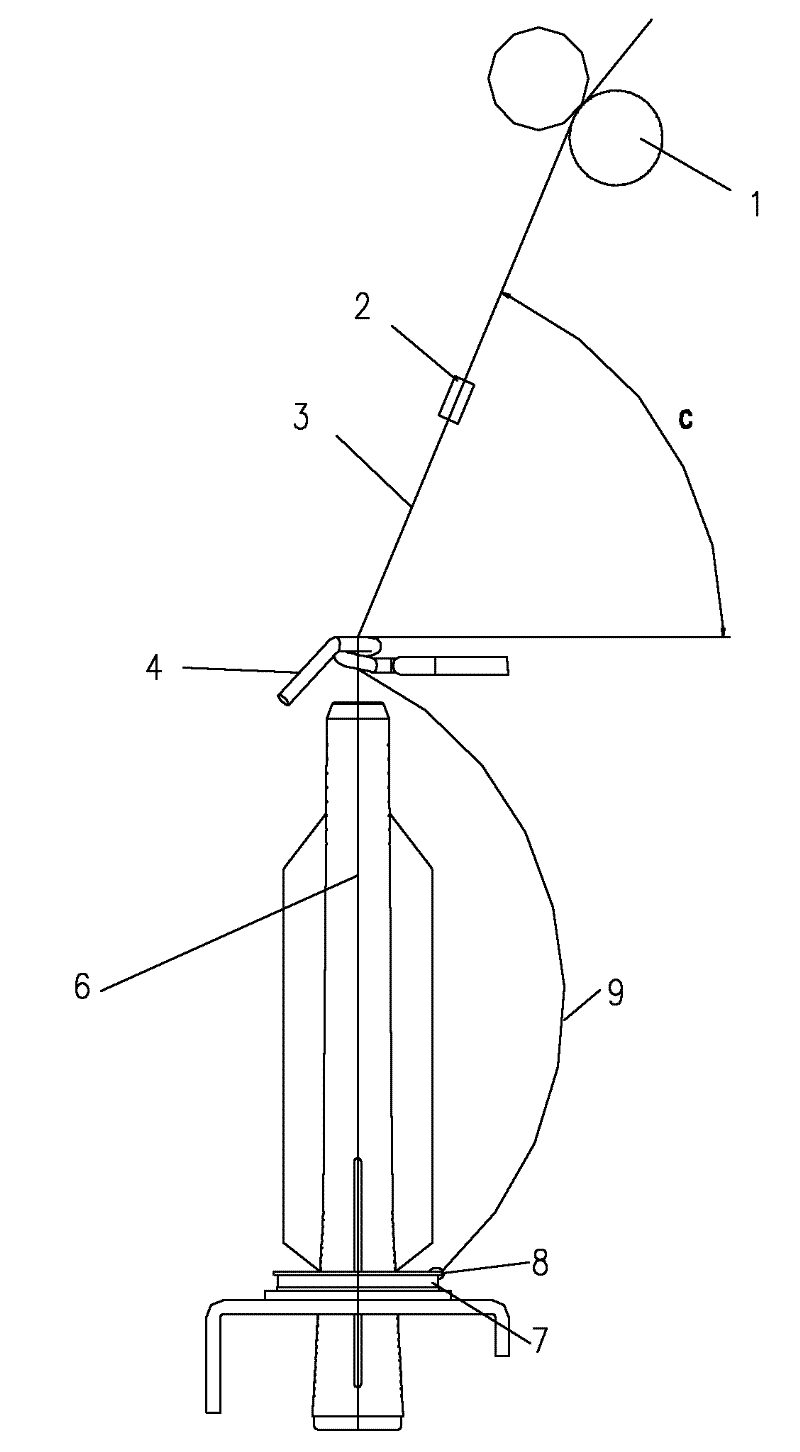

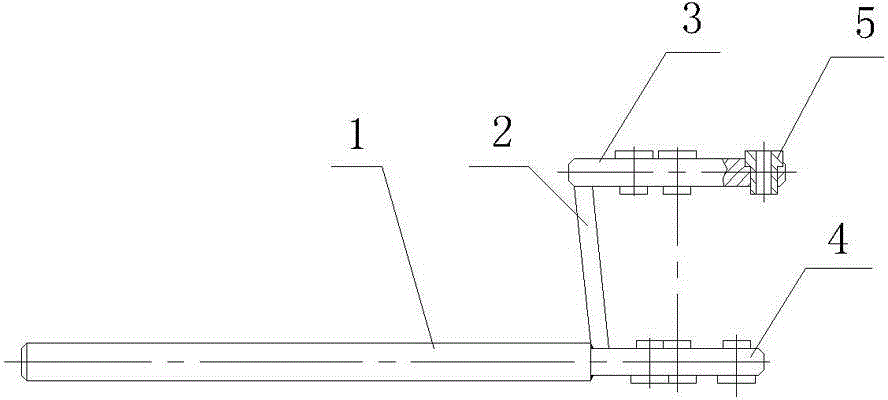

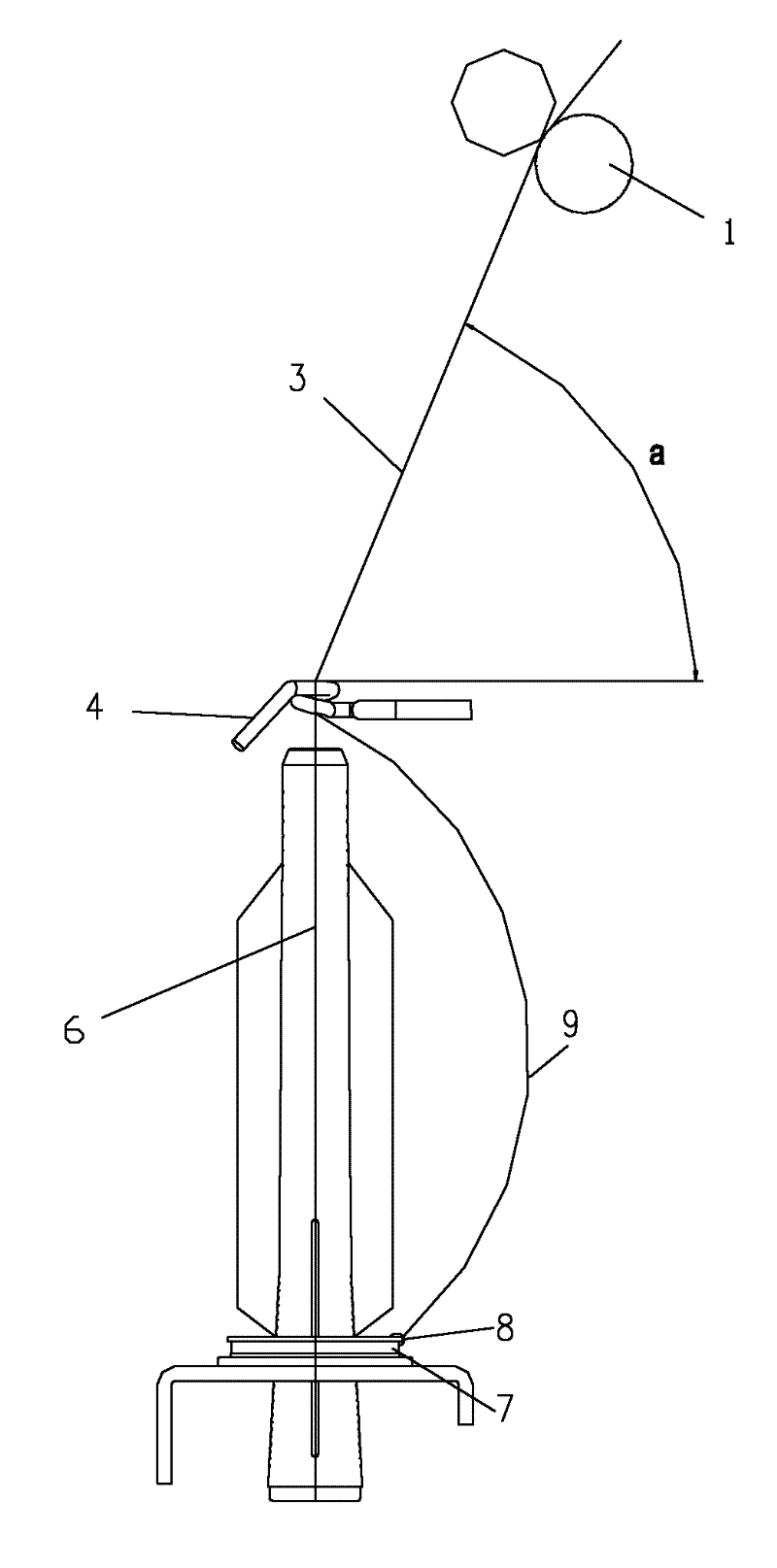

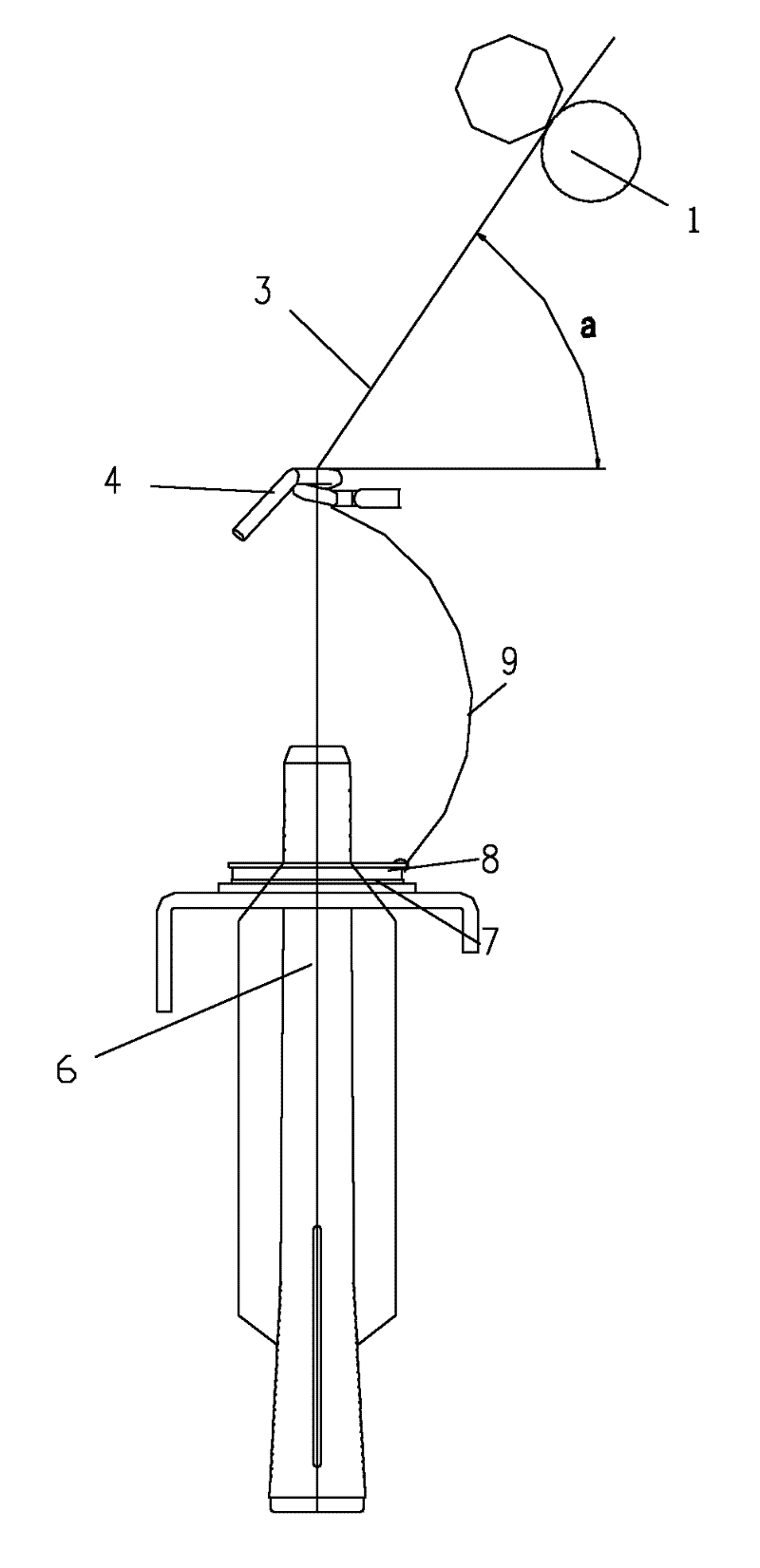

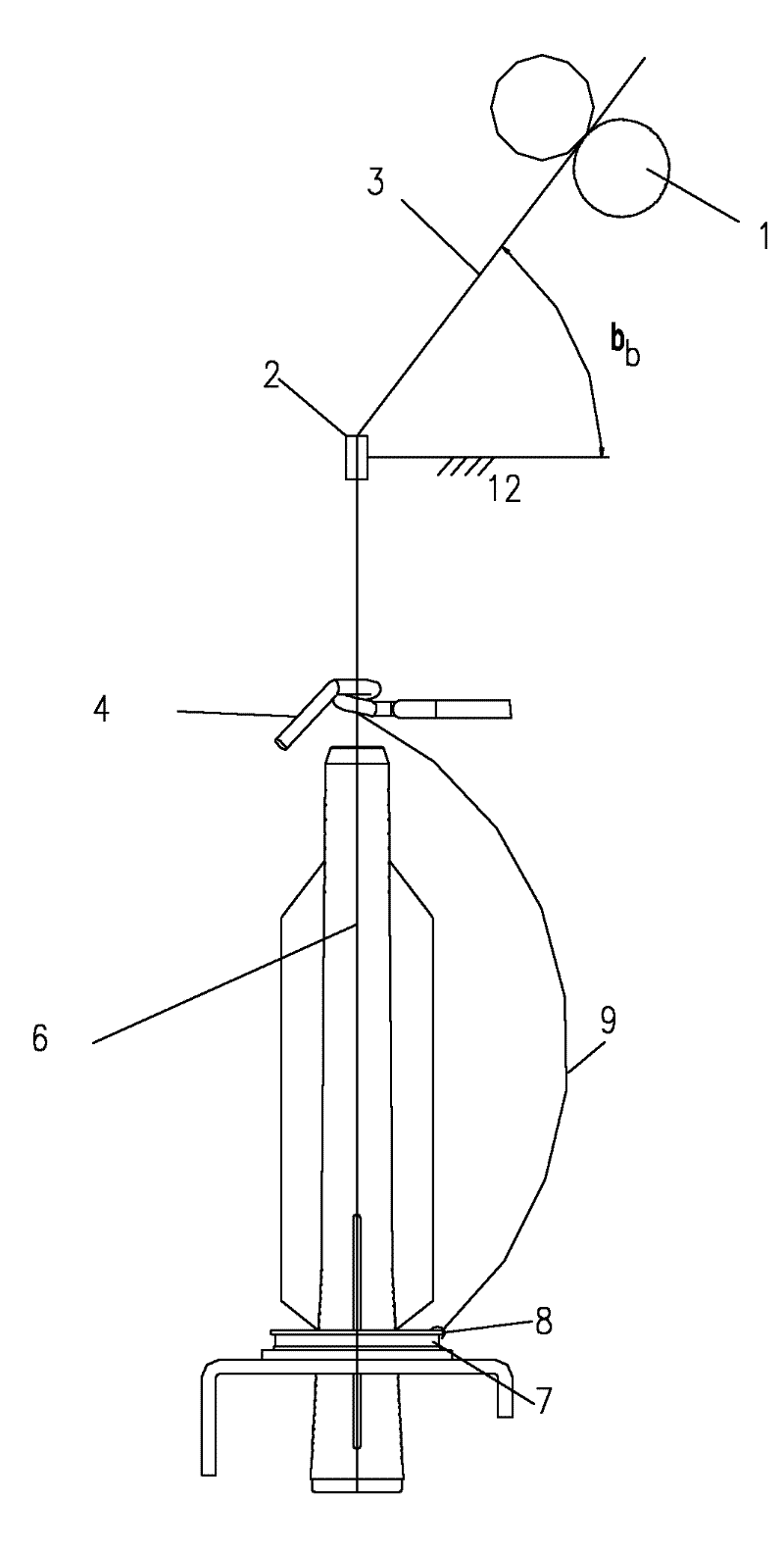

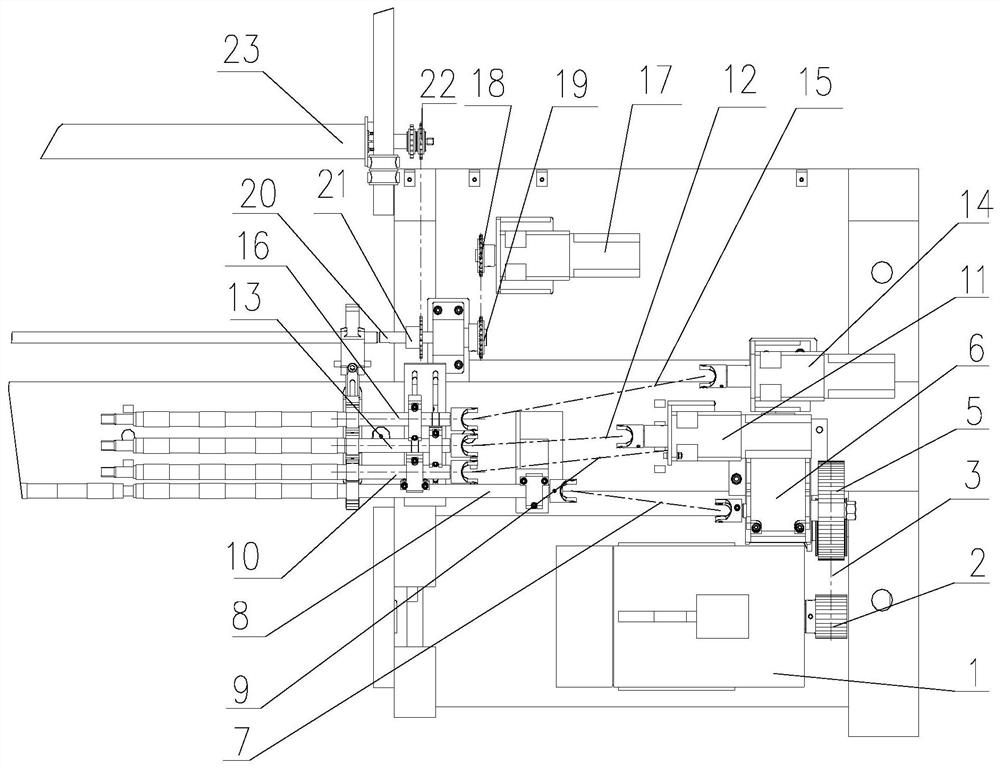

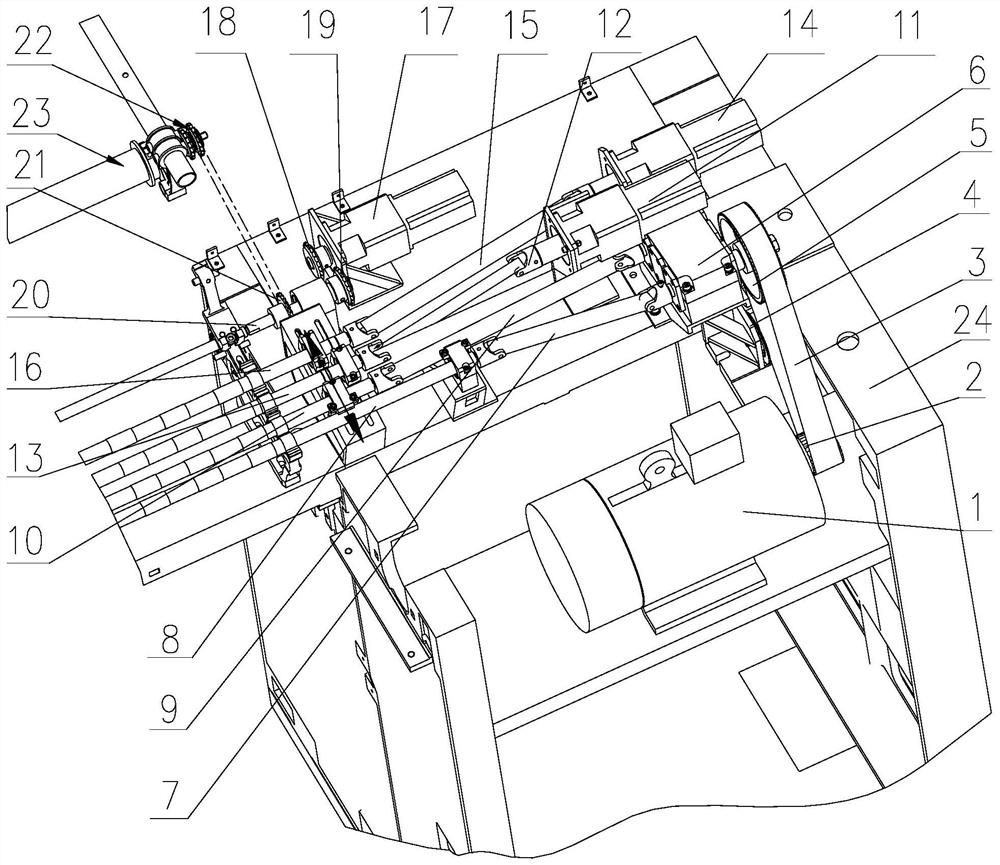

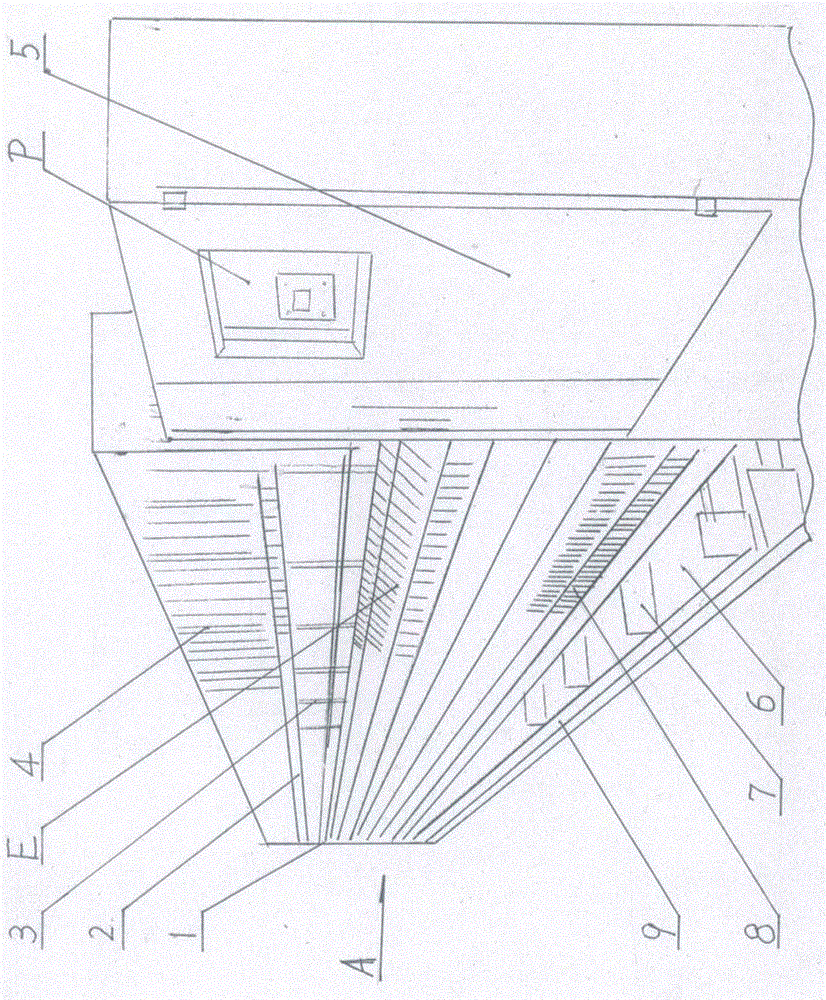

Spinning unit for producing low-twist yarn

InactiveCN102296388ATake advantage ofTo achieve the effect of false twistContinuous wound-up machinesYarnPhenanthrene

Spinning device for producing low-twist yarn, including a ring spinning machine and false twisting device, the false twisting device is placed between the output roller pair and the yarn guide hook of the ring spinning machine, and placed on the yarn guide hook Directly above. The present invention has the advantages that the existing spinning device can be fully utilized and the effect of false twisting can be achieved only by setting the false twisting device directly above the yarn guide hook and fixing it. Therefore, the structure of the whole spinning device is simple, and The existing ring spinning machine can be modified conveniently and at low cost, and the yarn produced is of good quality. It can be applied to Solo spinning, Siro spinning, Sirofi, compact spinning devices of ring spinning or a combination of these devices.

Owner:NINGBO DECHANG PRECISION TEXTILE MACHINERY +1

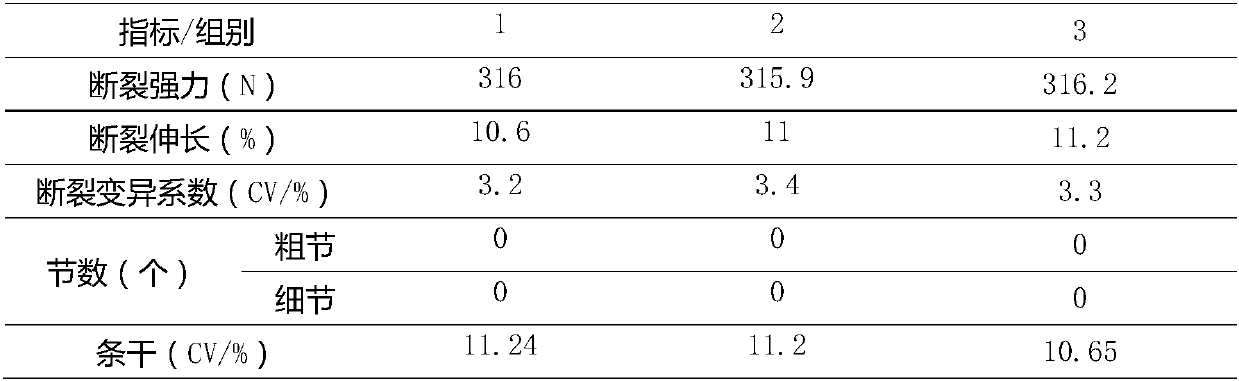

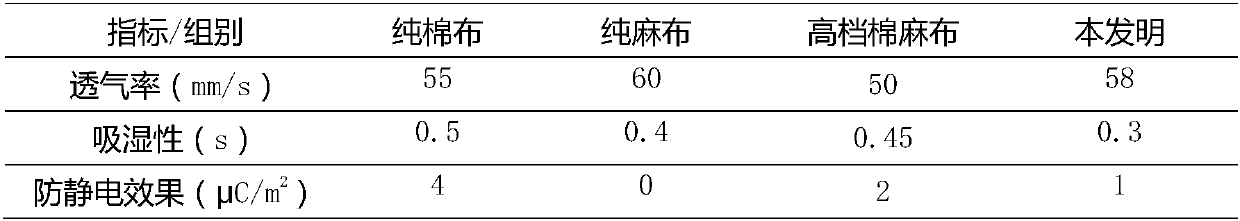

Blended yarn of cotton fibers, hemp fibers and bamboo fibers and production process thereof

The invention discloses a blended yarn of cotton fibers, hemp fibers and bamboo fibers and a production process thereof. The production process comprises the steps of material preparation, ramie cotton yarn strand preparation, bamboo cotton yarn strand preparation and blending doubling, wherein the cotton fibers, the hemp fibers and the bamboo fibers which are used by the blended yarn are all carefully selected from superior fiber materials. By blending the bamboo fibers with the cotton fibers and the hemp fibers, the cotton fibers, the hemp fibers and the bamboo fibers give full play to theirfiber advantages, the textile yarn with better hygroscopicity, higher air permeability and good drapability is obtained, and the yarn is used for spinning cloth and making clothing, is soft in texture and cool and comfortable when worn, has the advantages such as softness of cotton, the antistatic property of hemp and smoothness of bamboos, has a high additional value, meets the demands of high-end fabrics, and has good economic benefits.

Owner:张家港市华益纺织有限公司

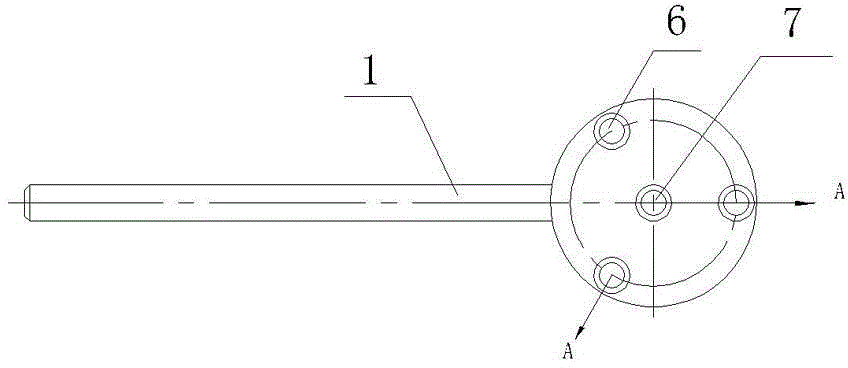

Yarn guiding device

The invention relates to textile machinery components, particularly to a yarn guiding device, which comprises an upper fixed plate and a lower fixed plate arranged in parallel, wherein center holes are both formed in the centers of the upper fixed plate and the lower fixed plate; more than three upper edge holes and lower edge holes are formed on the upper fixed plate and the lower fixed plate; a distance from the upper center hole to the upper edge holes on the upper fixed plate is larger than that from the lower center hole to the lower edge holes on the lower fixed plate; and yarn guides are arranged in the upper and lower center holes and the upper and lower edge holes. The yarn guiding device has the advantages that the structure is simple, silk yarns can be threaded conveniently, and compound yarn ballooning check twisting points can be directly formed on silk outlets of thermotropic silk and multistrand sewing threads. The yarn guiding device can precisely cover thermotropic silk quilt covers among the multistrand sewing threads, and therefore, the yarn guiding device solves the technical problems that in the prior art, the thermotropic silk quilt covers can not be covered among the ultistrand sewing threads precisely, the silk outlets can not directly form the compound yarn ballooning check twisting points, assembled structures are complex, the operation is difficult, and raw material and labor force are wasted, so that finished products of the yarns have poor quality.

Owner:单水甫

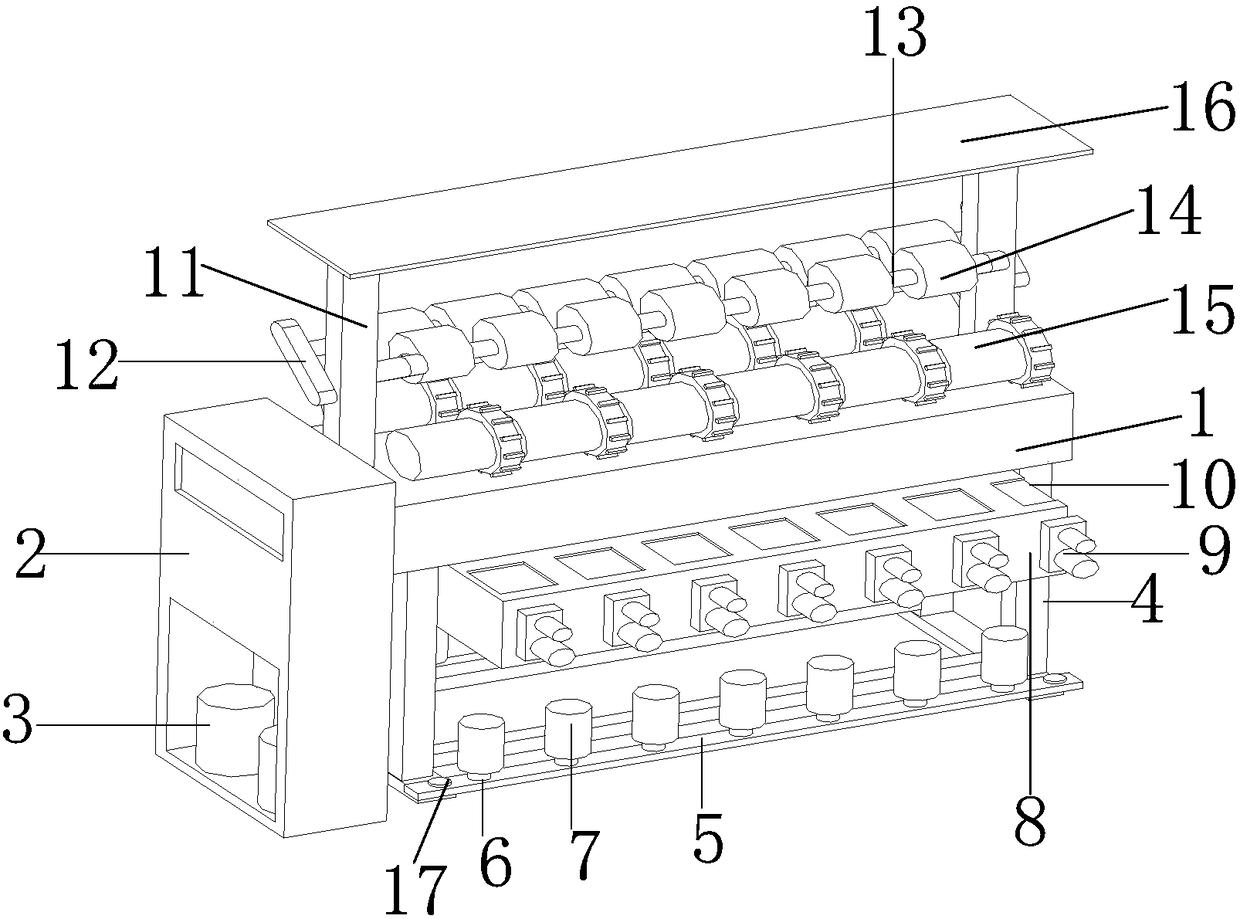

Grooved drum winder

The invention discloses a grooved drum winder which comprises a workbench and the like. A supporting table is connected with a plurality of supporting legs and located between the workbench and a cross beam. A plurality of yarn cleaners are fixed to the supporting table, and a plurality of supporting columns are all arranged on the workbench. A plurality of fixed plates are all fixed to the multiple supporting columns, and a plurality of driving rockers are connected with the multiple fixed plates. A plurality of drums are all arranged on the multiple driving rockers, and a plurality of groovedrums are all arranged on the workbench and located between the multiple supporting columns. According to the grooved drum winder, a plurality of cops carry out spooling at the same time, work efficiency is improved, and the grooved drum winder is easier to maintain and mount due to a one-to-one correspondence independent manner; and yarn passing through the yarn clears is higher in quality and cleaner.

Owner:SUZHOU RUIRI TEXTILE SCI & TECH

A spinning device for producing low-twist yarn

A spinning device for producing low-twisted yarn, comprising a ring spinning machine and a false twist device, the false twist device is placed between the output roller pair and the yarn guide hook of the ring spinning machine, and the false twist device is arranged on Directly above the yarn guide hook, the yarn guide angle between the output roller pair and the false twist device is at a fixed angle. The invention has the advantages of simple structure of the spinning device, convenient and low-cost transformation of the existing ring spinning machine and good quality of the prepared yarn.

Owner:NINGBO DECHANG PRECISION TEXTILE MACHINERY +1

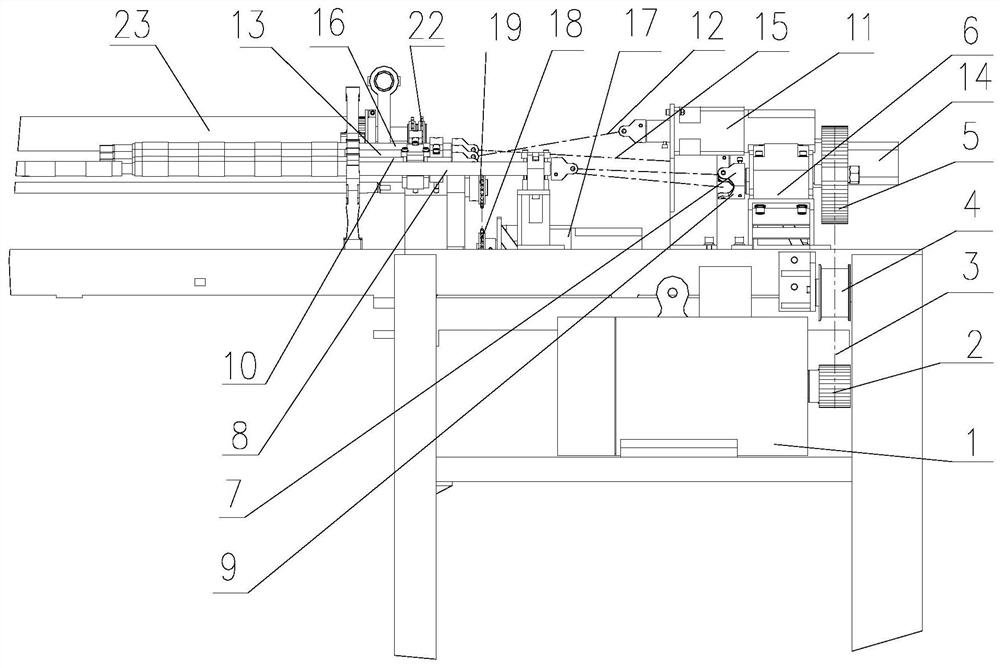

Drafting transmission device for roving frame

The invention discloses a drafting transmission device for a roving frame. Four shaft seats are arranged on a rack and are used for respectively supporting a first roller head section shaft, a secondroller head section shaft, a third roller head section shaft and a fourth roller head section shaft side by side; the positions of the shaft seats relative to the rack are adjustable, the first rollerhead section shaft, the third roller head section shaft and the fourth roller head section shaft are driven by independent power sources through universal couplings respectively, and the second roller head section shaft is in linkage with the first roller head section shaft through a transmission mechanism and universal couplings. Independent power sources are adopted for transmission of all thedrafting areas; the draft multiple set for spinning is more accurate, and the quality of yarns is better; meanwhile, the roller head sections are connected with the upstream transmission mechanism through universal couplings, so that when the center distance of the rollers needs to be adjusted in the spinning process, only the center distance of the rollers of the drafting part needs to be adjusted, and the drafting transmission device is simple in structure, convenient to adjust and stable and reliable to operate; the draft multiple is more accurate, and yarns with better quality can be obtained.

Owner:天津宏大纺织科技有限公司

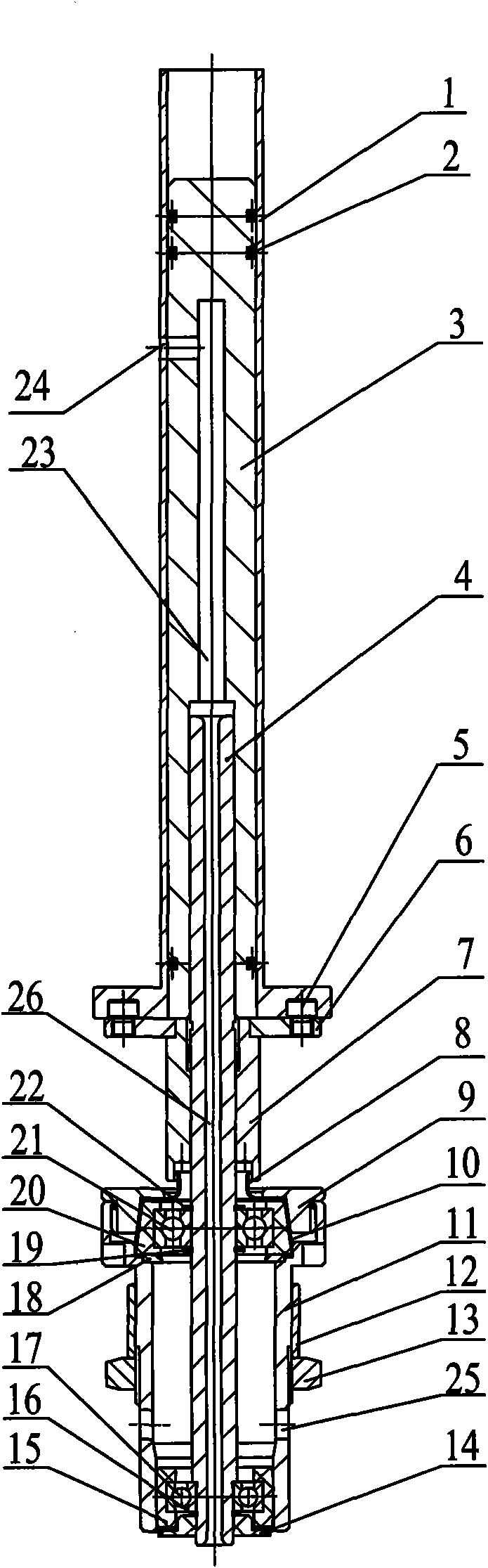

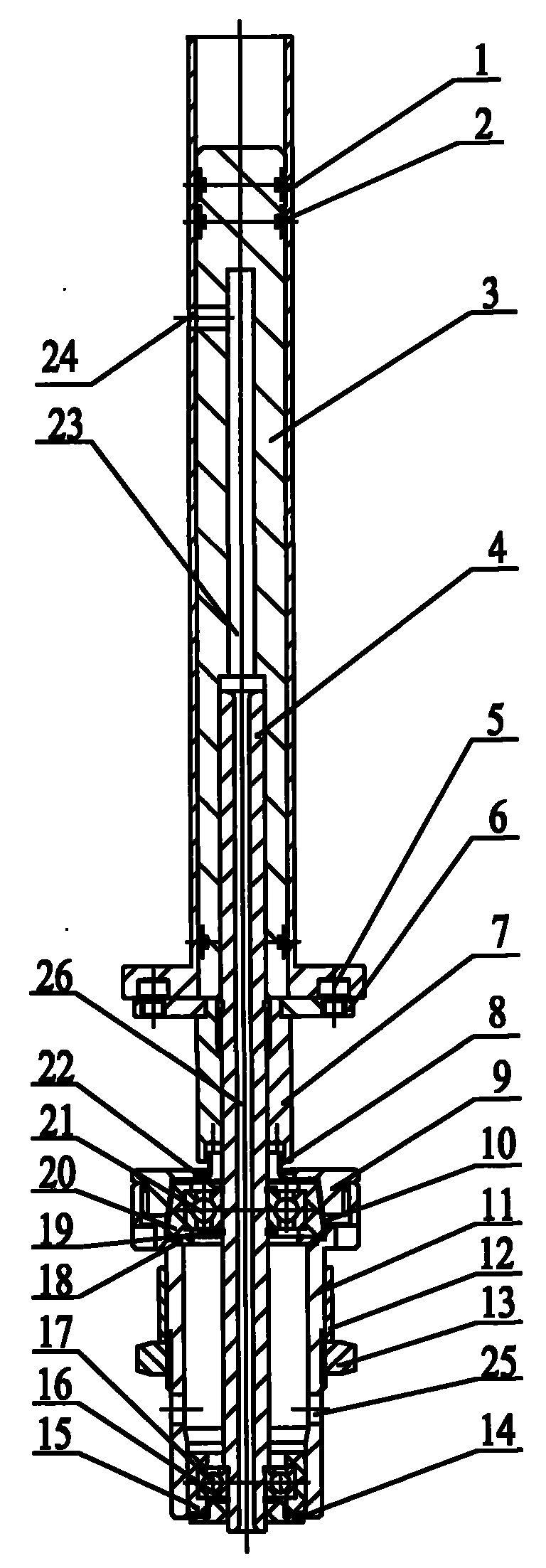

High-speed wire twisting spindle

The invention relates to a high-speed wire twisting spindle, in particular to a high-speed wire twisting spindle, belonging to the technical field of textile machinery. According to the technical scheme provided by the invention, the high-speed wire twisting spindle comprises a bobbin; a sleeve is fixedly connected with the inner part of the bobbin; one end of the bobbin is fixedly connected witha transmission ring, the bobbin is provided with a wharve, corresponding to the end provided with the transmission ring, the wharve is fixed with the bobbin through the transmission ring; a spindle rod is arranged in the sleeve; one end of the spindle rod penetrates through the wharve and then extends into the sleeve to be fixedly connected with the wharve and the sleeve; the other end of the spindle rod is provided with a spindle base, the spindle rod penetrates through the spindle base, and the spindle rod can rotate relative to the spindle base. The spindle of the invention has large package capacity, high rotation speed, small vibration and high automation without stopping or maintaining.

Owner:WUXI HONGDA TEXTILE MACHINERY SPECIAL PARTS

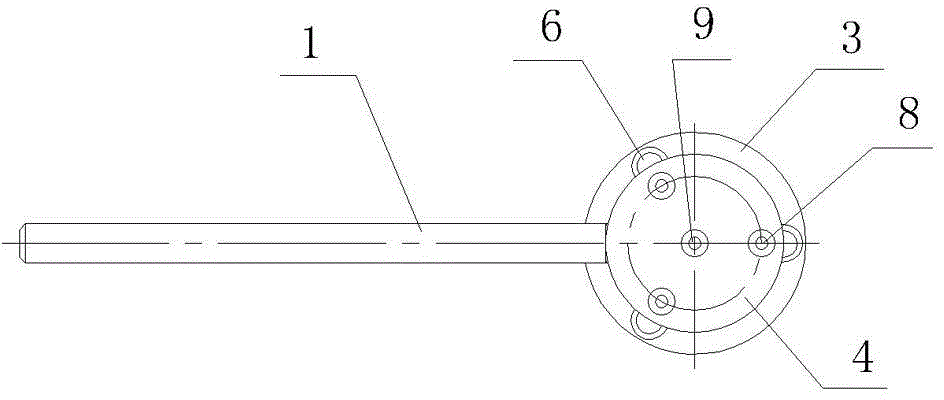

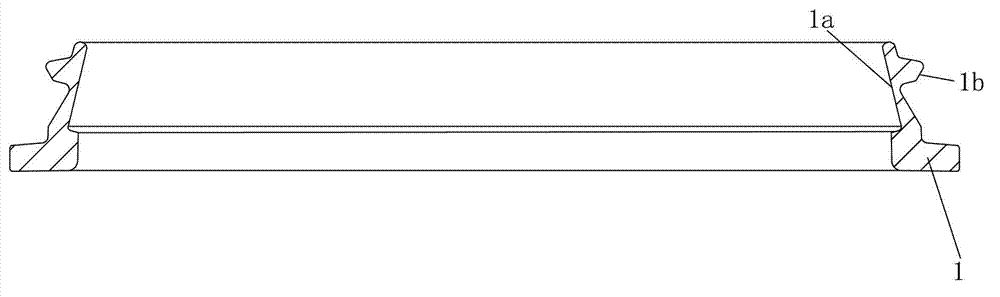

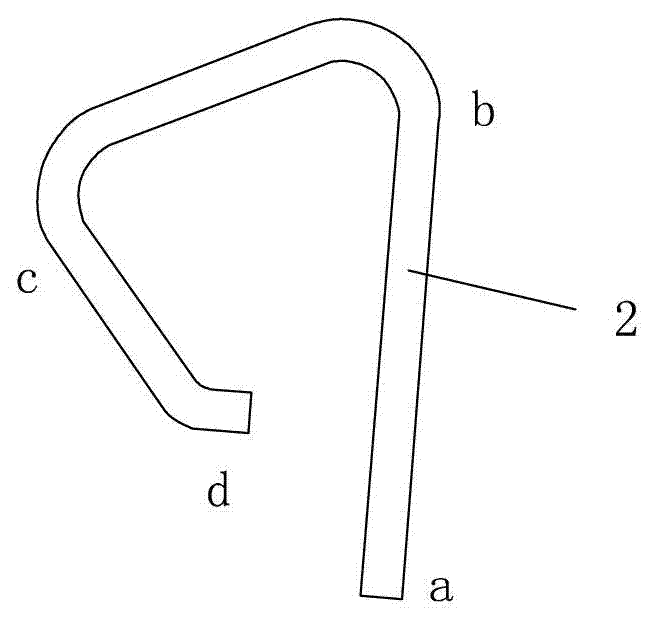

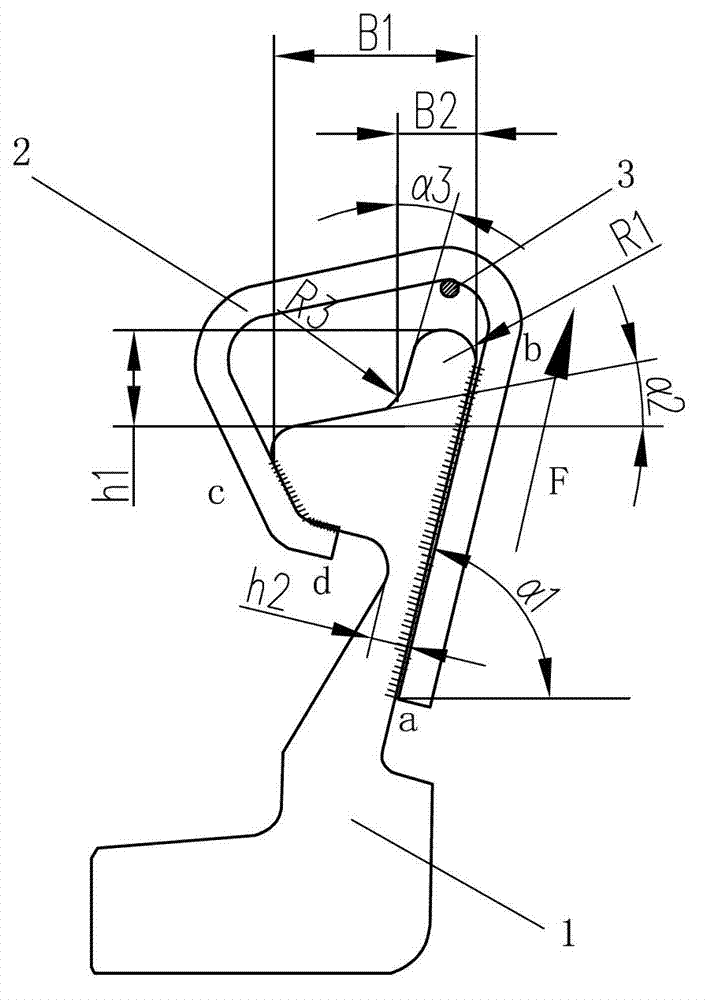

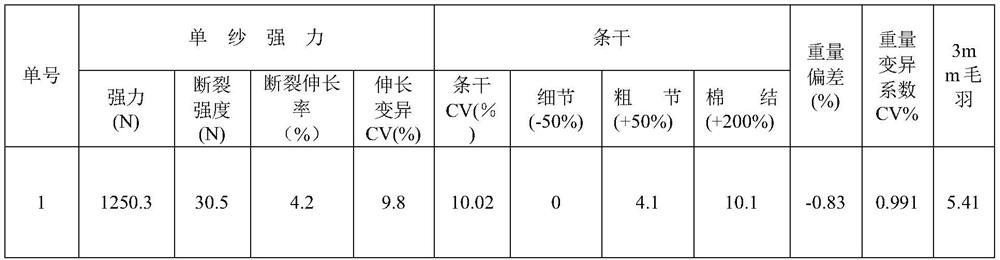

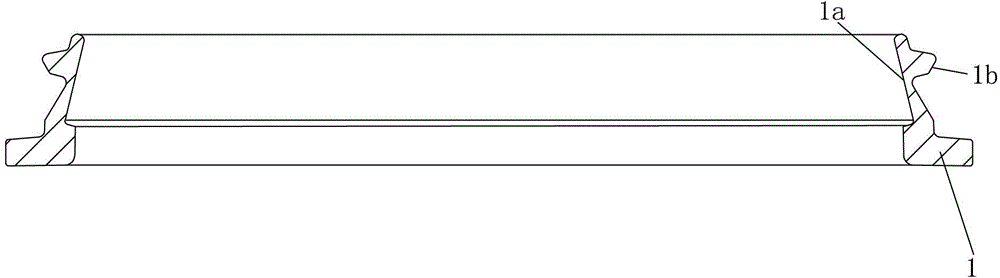

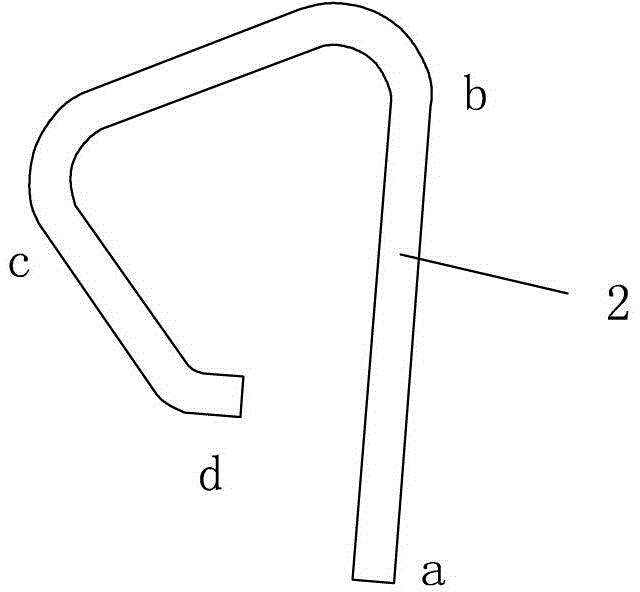

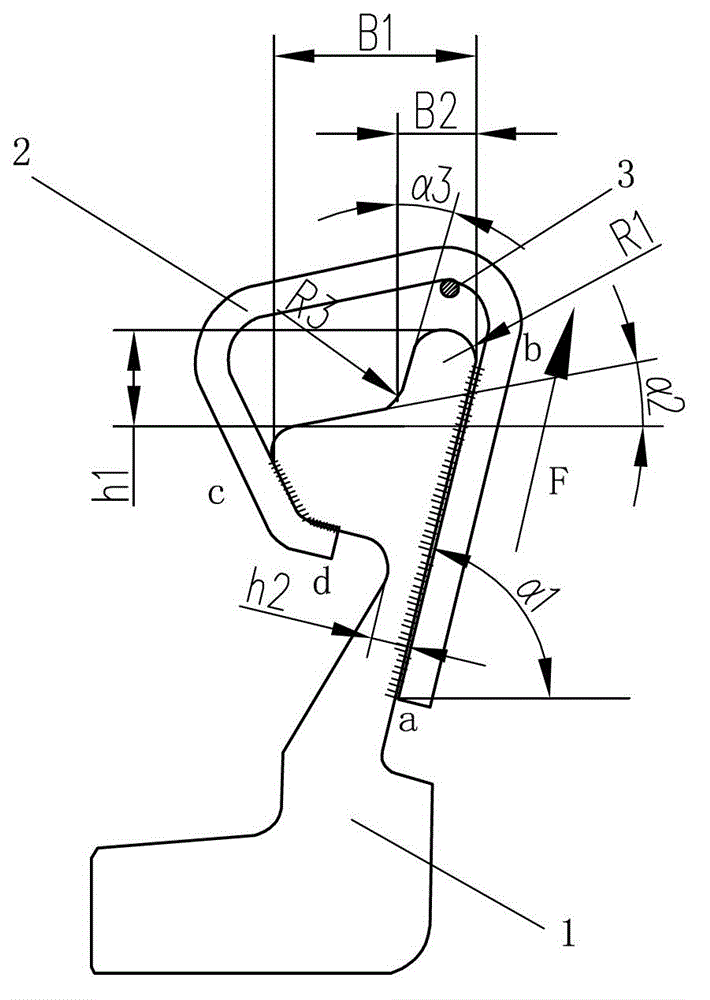

Combined structure of lower support double-runway conical ring and steel wire ring

The invention discloses a combined structure of a lower support double-runway conical ring and a steel wire ring, wherein an included angle alpha 1 between the inner runway (1a) of a lower support ring (1) and a horizontal coordinate axis is equal to 65-89 degrees; a dent with a depth of h1 is arranged on the outer side of the top of the lower support ring (1); the outer end of the dent is lower than the inner end of the dent so that an inclined surface with an inclined angle alpha 2 is formed; when yarns (3) run normally on the lower support ring (1) along with a lower support steel wire ring (2), the lower support steel wire ring (2) is at a lifting running state by means of an acting force of F; and simultaneously, the ab segment inner leg of the lower support steel wire ring (2) is tightly attached to the inner runway (1a) of the lower support ring (1) together, and the cd segment outer leg of the lower support steel wire ring (2) is tightly attached to the outer runway (1b) of the lower support ring (1) together. Through the structure, the contact area between the ring and the steel wire ring is increased, stable movement of the steel wire ring on the ring is ensured, the service life of the steel wire ring is prolonged, broken ends are reduced, and the spinning quality is improved.

Owner:CHONGQING JINMAO TEXTILE ACCESSORIES

Antimicrobial blended yarn

InactiveCN107326498AGood quality yarnYarn structure optimizationBiochemical fibre treatmentYarnIonBiguanide

The invention relates to antimicrobial blended yarn. The antimicrobial blended yarn comprises an antimicrobial layer and an antimicrobial blended yarn body, and the antimicrobial layer is manufactured by conducting finishing liquid padding treatment on antimicrobial blended yarn body and is prepared from 1-2 parts of fatty amine polyoxyethylene ether, 1-2 parts of polyacrylic acid, 2-3 parts of sorbic acid, 0.9-1.2 parts of sodium chloride, 0.9-1.2 parts of diethylenetriamine, 0.6-0.8 part of hawthorn kernel extracting liquid, 0.4-0.6 part of decamethylene biguanide dihydrochloride and 20-30 parts of deionized water. The antimicrobial blended yarn has the advantages that by conducting complementary optimization on bamboo fiber, polyester fiber and viscose, and through the finishing liquid padding treatment, the antimicrobial layer is formed to integrate the advantages of the bamboo fiber of resisting bacteria, conducting deodorization, absorbing moisture and being breathable, soft, draped, cool and comfortable and the function of the polyester fiber of inhibiting the bacteria, resisting the bacteria and preventing ultraviolet, so that the antimicrobial blended yarn gives play to the respective advantages, and the structure of resultant yarn is optimized.

Owner:NANTONG GUANZHOU INT TRADE CO LTD

A high-strength flame-retardant anti-melt drop wear-resistant anti-static blended wrapping core-spun yarn and its preparation method

ActiveCN109629060BHigh strengthAnti-droplet hasFibre typesUltrasonic/sonic fibre treatmentYarnPolymer science

The invention discloses a high-strength flame-retardant anti-dripping wear-resistant antistatic blending wrapping core-spun yarn and a preparation method thereof. The preparation method comprises thesteps of mixing an aramid fiber, a flame-retardant viscose fiber and an antistatic fiber, and conducting combing, drawing and roving to obtain rove; for the rove, using a non-flame-resistant nylon filament as a core, controlling a flame-retardant nylon filament to be wound on an outer layer, spinning a spun yarn, and spooling to obtain the blending wrapping core-spun yarn. The yarn adopts the aramid fiber, the flame-retardant viscose fiber, the flame-retardant nylon filament, the high-strength non-flame-resistant nylon filament and a conductive fiber as main components, a flame-retardant anti-dripping fabric is prepared by blending spinning and weaving process, the fabric has the advantages of flame retardant, anti-dripping performance, high strength, easy dyeing, antistatic performance, abrasion resistance, low cost, simple process, excellent yarn quality and the like, and the yarn can be used not only for requirements of special operations but also for requirements of other aspects such as work clothes and the like.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA

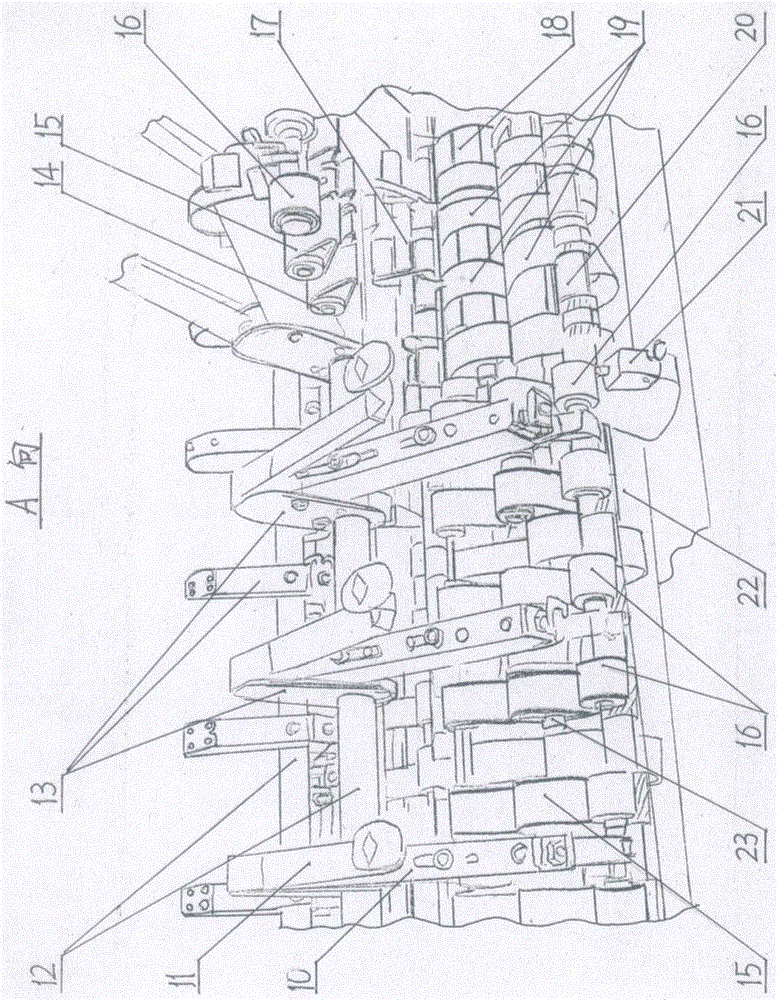

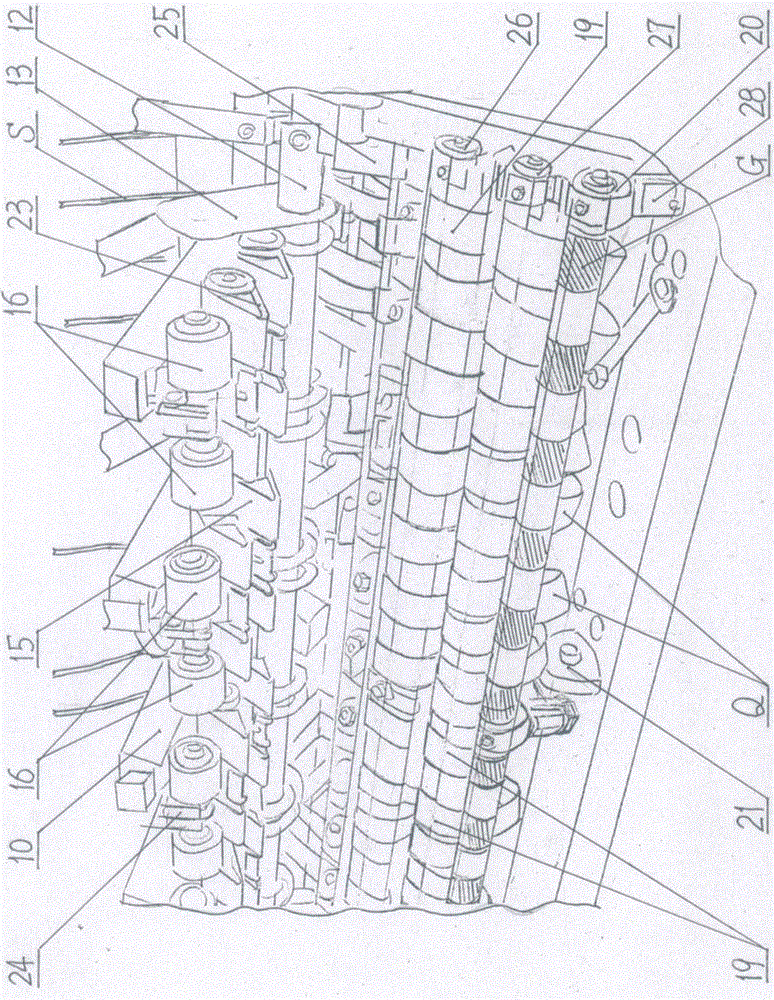

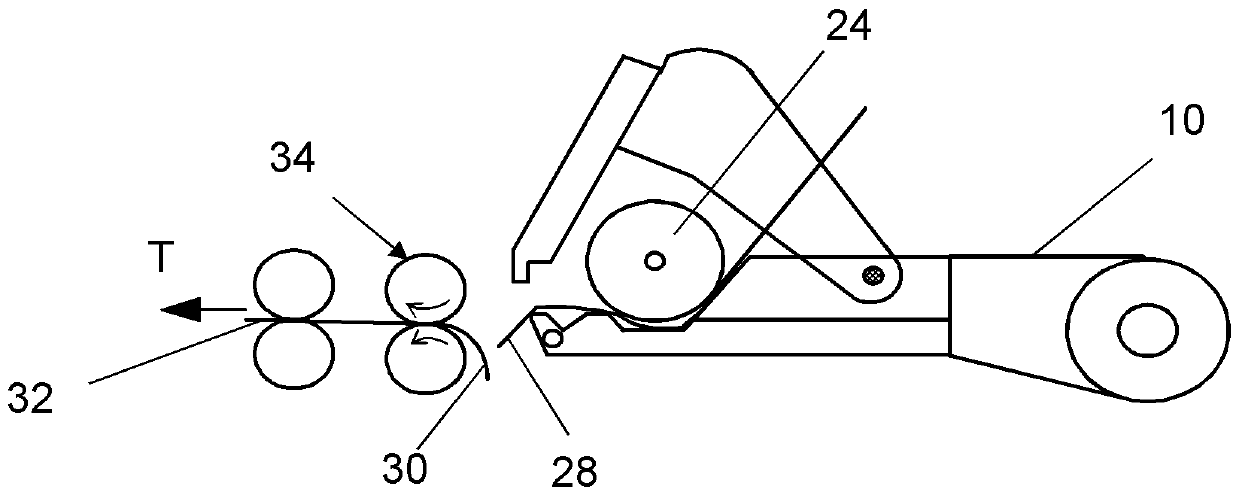

Double-region elastic drafting device of spinning frame

InactiveCN105463637AChanging the back zone drafting processPrevent early shiftingDrafting machinesFiberYarn

A double-region elastic drafting device of a spinning frame comprises a cradle body (10), a cradle rod (12), a rear upper roller (14), a front leather roller (16), a torsional spring frame (17), a lower pin (18), a front roller (20), an upper pin (23), a leather roller clamp (24), a roller slide base (25), a roller base (28), an upper middle roller (31) and a lower rear roller (33). A long leather ring (19) is arranged on the lower rear roller (33), the lower pin (18) and the torsional spring frame (17) in a sleeving mode. A short leather ring (15) is arranged on the rear upper roller (14) and the upper pin (23) in a sleeving mode, makes friction contact with the portion, on the lower rear roller (33), of the long leather ring (19) and is matched with the long leather ring (19) to form a rear region mechanism of the drafting device (E), the rear region mechanism is connected and matched with a front region mechanism of the drafting device (E), and the double-region elastic drafting device is formed. The upper pin (23) is a spring swing pin. The elastic drafting mode of the leather ring arranged on the rear region mechanism of the drafting device (E) improves rear-region guiding force, speed changing points of fibers become normal, stress of fiber silvers is uniform, slubs of yarn are reduced, spinning quality is good, and production efficiency is high.

Owner:SHANDONG ZHIDE TEXTILES CO LTD

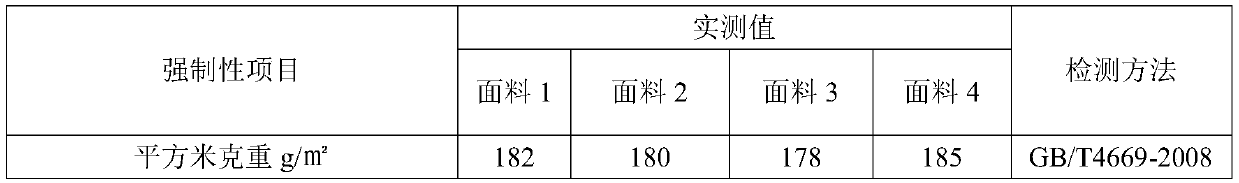

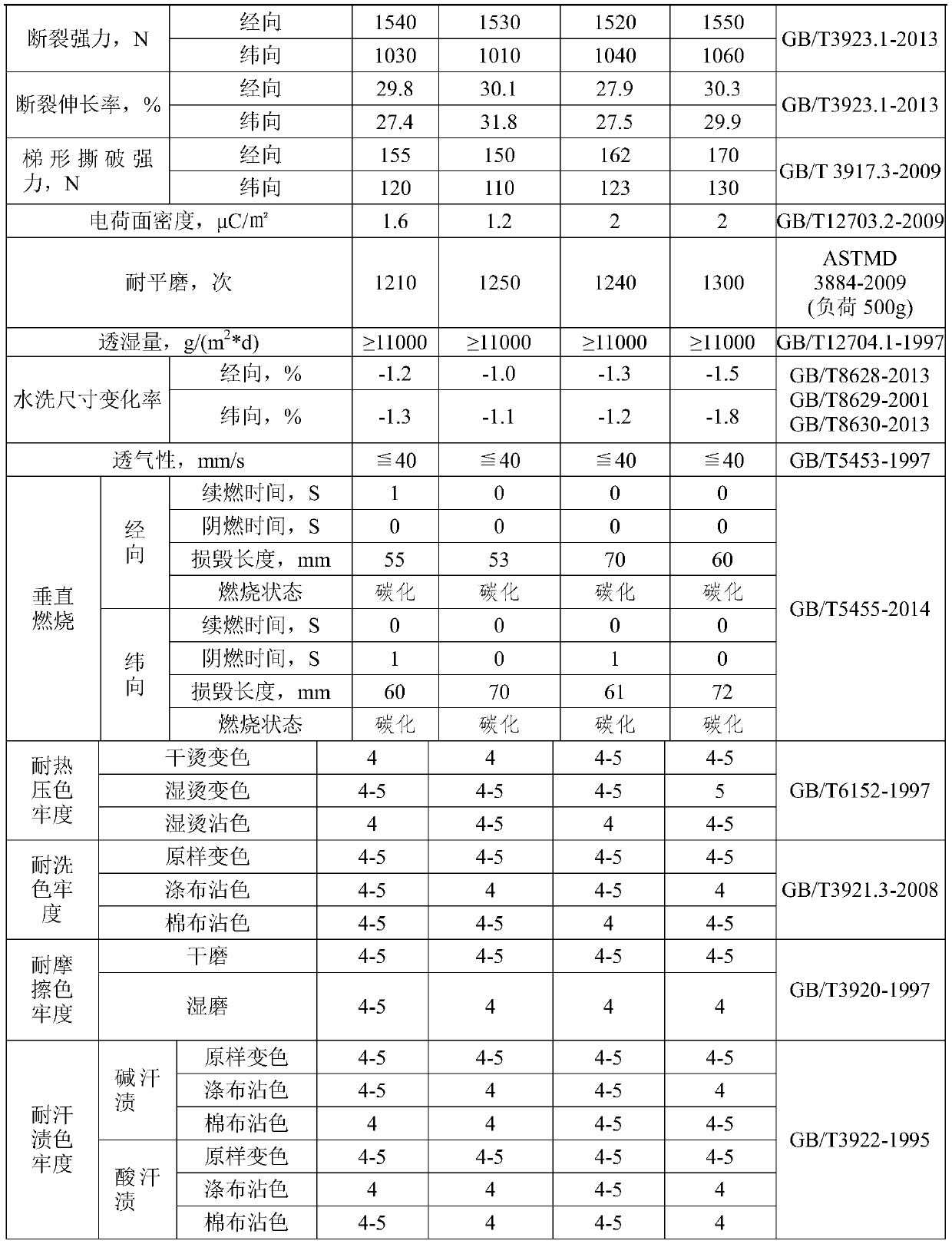

Weaving method of judo clothing fabric

The invention discloses a judo uniform fabric weaving method. It includes the steps of yarn doubling, twisting, diameter adjustment, hedging and weaving. The judo clothing fabric weaving method provided by the invention is to use strands with more strands than ordinary fabrics as raw materials, and simultaneously transform the three rows of heald curtains on the existing GA615 loom into five rows of heald curtains to produce the judo clothing fabric. Because the yarn quality selected by the present invention is good, and the weaving process and equipment design are reasonable, it can produce judo suit fabrics that can meet the requirements of international standards in terms of thickness, density and other indicators. After testing the tensile strength of the judo suit fabrics The strength is as high as 2000 Newtons, which fills the gap in the production of judo clothing fabrics in my country.

Owner:天津振宇服装有限公司

A kind of flame-retardant anti-droplet anti-static core-spun yarn and preparation method thereof

The invention discloses flame-retardant anti-molten-drop antistatic core-spun yarn and a preparation method thereof. The preparation method of the flame-retardant anti-molten-drop antistatic core-spunyarn comprises the following steps that aramid fibers, flame-retardant viscose fibers and antistatic fibers are mixed and then subjected to combing, drawing and roving in sequence, and the mixture and mixed nylon filaments are subjected to core spun yarn spinning; spooling is carried out, and the core-spun yarn is obtained, wherein the nylon filaments are a mixture obtained through drawing and mixing of flame-retardant nylon filaments and non-flame-retardant nylon filaments. According to the method, the aramid fibers, the flame-retardant viscose fibers, the flame-retardant nylon filaments, the high-strength non-flame-retardant nylon filaments and conductive fibers serve as main components, and a flame-retardant anti-molten-drop fabric is prepared through blending spinning and weaving technologies. The fabric has the advantages of being retardant to flame, resistant to molten drops, high in strength, antistatic, easy to dye, low in cost, simple in process, good in yarn quality and thelike, can be used for meeting requirements in the aspect of special operations and can also meet requirements in the aspects of uniforms and the like.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA

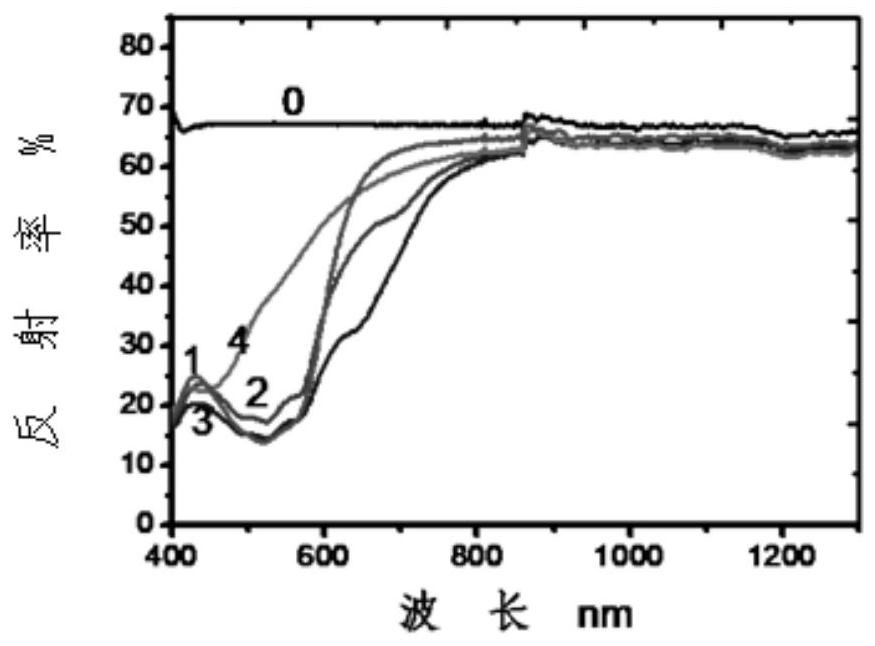

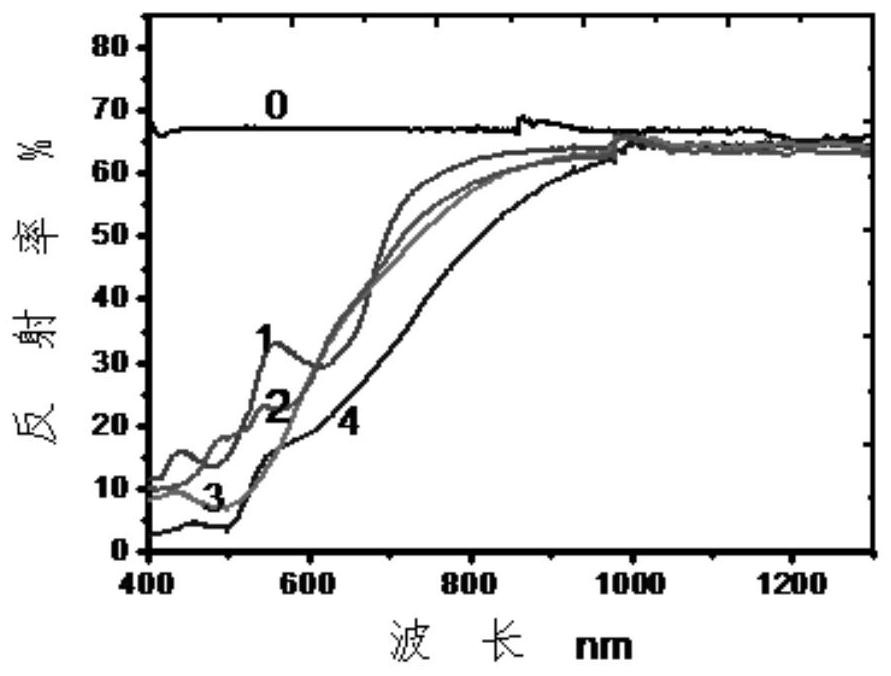

Anti-droplet, wear-resistant, anti-static and flame-resistant nylon blended camouflage cloth and preparation method thereof

ActiveCN109750409BHigh strengthImprove wear resistanceDyeing processWoven fabricsYarnTextile printer

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA

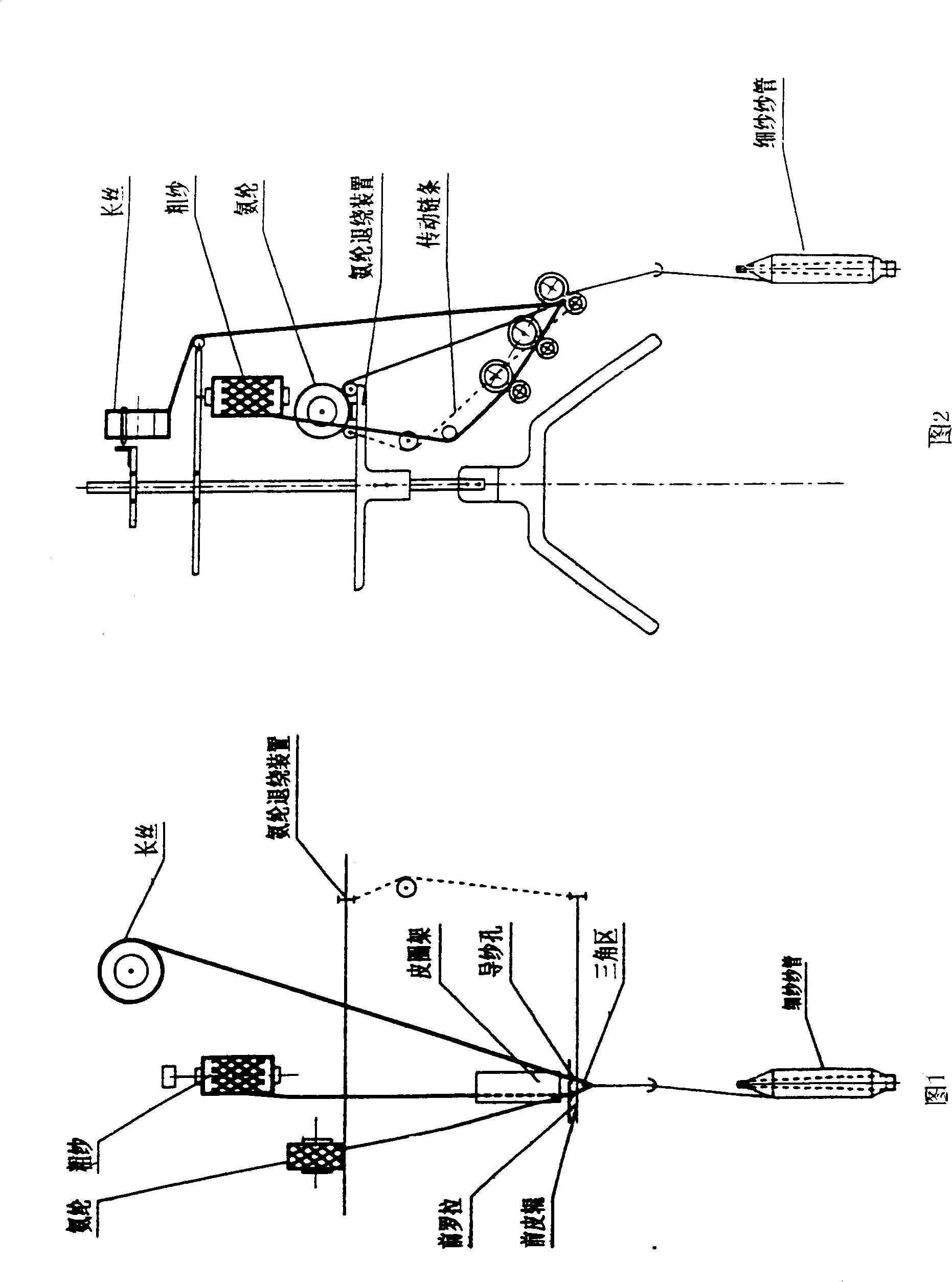

Process for spinning three-in-one stretch yarn of wool, filament and urethane elastic fiber

The invention relates to a process for spinning three-in-one stretch yarn of wool, filament and urethane elastic fiber, is characterised in that: at first, a continuous yarn feed device and a spandex feed device is mounted on a spinning machine, spandex is applied with a certain pre-tension, then the spandex is positioned by a guide yarn, and fed in a roving strand which is performed with normal drafting at a front roller tongs mouth, the continuous yarn is also directly fed to the front roller tongs mouth via a yarn guide hole and is held with a certain distance from the strand, the continuous yarn and the strand in which spandex is envelopped are twisted together under the tongs mouth to form a twisting trigonum, and the twisted yarn is winded on a yarn tube to form a three-in-one stretch yarn of wool, continuous yarn and spandex. The invention has a low spinning cost, good quality yarns, simple production and less difficulty.

Owner:JIANGSU SUNSHINE

Cheese fiber removal method for producing hemp/cotton and linen/ high count cotton yarns

InactiveCN102051724BShort processReduce energy consumptionDry-cleaning apparatus for textilesYarnFiberYarn

The invention provides a cheese fiber removal method for producing hemp / cotton and linen / high count cotton yarns, which comprises the following steps of: (1) winding blended spinning single yarns or blended spinning compound yarns on a loose type cheese winder into cheese; (2) controlling the following production conditions on a cheese dyeing machine: a temperature of between 60 and 100 DEG C, aliquor ratio of between 1:10 and 1:30, water exchange times of 1 to 6, a specific discharge of 50 to 70L / kg.min, and fiber removal time of 1 to 6 hours; and (3) removing water soluble PVA fibers fromthe cheese to obtain high count single yarns or high count compound yarns of hemp / cotton or linen / cotton. The single yarns or the compound yarns obtained after fiber removal by the method have the advantages of uniform fiber removal, capability of realizing high-speed unwinding without winding, and capability of being directly used in post processing of weaving and knitting, thereby laying the foundation for revealing the superior performances of the hemp / cotton and the linen / cotton, widening the application scope of hemp / cotton and linen / cotton products, and producing thin hemp / cotton and linen / cotton products with high quality.

Owner:DONGHUA UNIV +1

Combined structure of lower support double-runway conical ring and steel wire ring

ActiveCN102899755BIncrease contact areaExtended service lifeTextiles and paperYarnStructural engineering

The invention discloses a combined structure of a lower support double-runway conical ring and a steel wire ring, wherein an included angle alpha 1 between the inner runway (1a) of a lower support ring (1) and a horizontal coordinate axis is equal to 65-89 degrees; a dent with a depth of h1 is arranged on the outer side of the top of the lower support ring (1); the outer end of the dent is lower than the inner end of the dent so that an inclined surface with an inclined angle alpha 2 is formed; when yarns (3) run normally on the lower support ring (1) along with a lower support steel wire ring (2), the lower support steel wire ring (2) is at a lifting running state by means of an acting force of F; and simultaneously, the ab segment inner leg of the lower support steel wire ring (2) is tightly attached to the inner runway (1a) of the lower support ring (1) together, and the cd segment outer leg of the lower support steel wire ring (2) is tightly attached to the outer runway (1b) of the lower support ring (1) together. Through the structure, the contact area between the ring and the steel wire ring is increased, stable movement of the steel wire ring on the ring is ensured, the service life of the steel wire ring is prolonged, broken ends are reduced, and the spinning quality is improved.

Owner:CHONGQING JINMAO TEXTILE ACCESSORIES

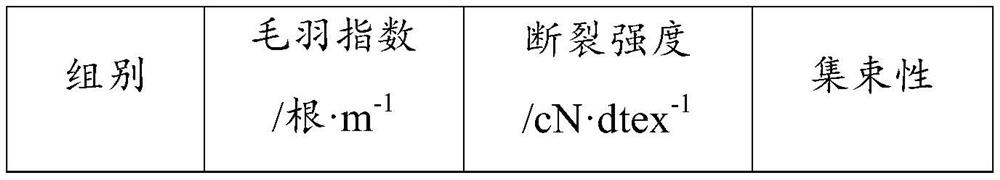

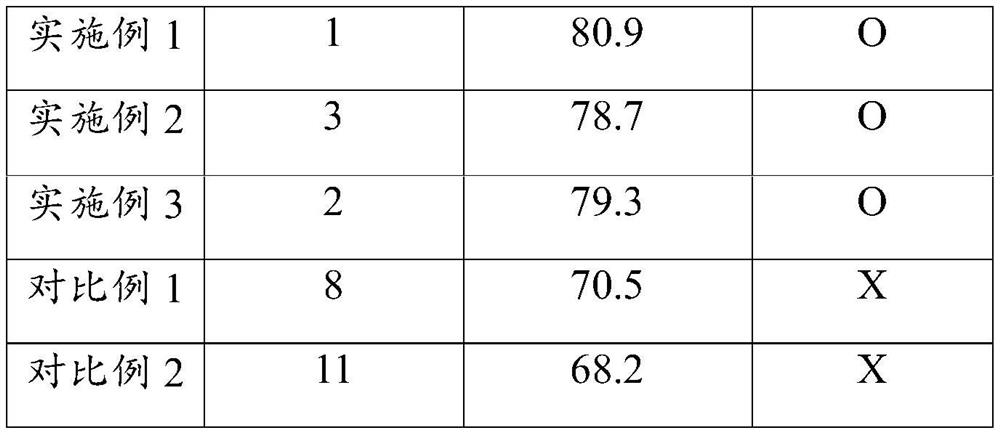

Impregnating compound for low-dielectric glass fiber direct yarn and preparation method of impregnating compound

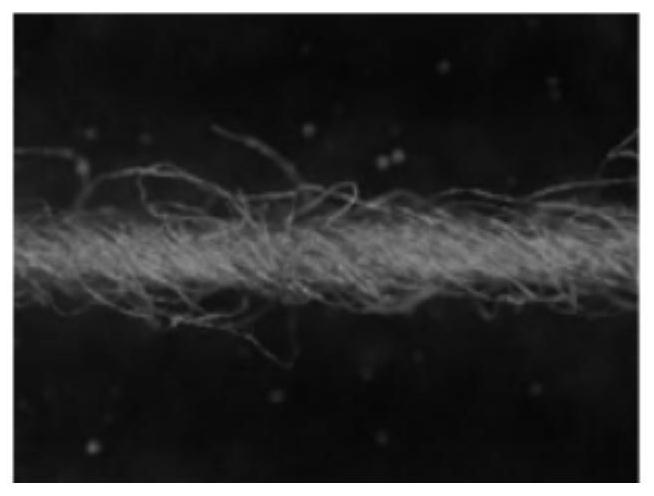

The invention relates to the technical field of glass fiber impregnating compounds, in particular to an impregnating compound for low-dielectric glass fiber direct yarn and a preparation method of the impregnating compound. Theimpregnating compound comprises the following components: a film-forming agent, a lubricant, a coupling agent, a pH regulator and deionized water.The film-forming agent is composed of low molecular weight bisphenol A type epoxy resin emulsion and medium molecular weight bisphenol A type epoxy resin emulsion, the molecular weight range of bisphenol A type epoxy resin in the low molecular weight bisphenol A type epoxy resin emulsion is 300-450, and the molecular weight range of bisphenol A type epoxy resin in the medium molecular weight bisphenol A type epoxy resin emulsion is 1000-1400. The hairiness of the low-dielectric glass fiber direct yarn can be reduced, the yarn quality is improved, sanding is not easy to generate in the weaving process, the yarn quality is improved, the yarn bundling property is improved, the yarn flexibility is increased, the tensile strength and the bending strength of the yarn are improved, and the interface bonding force with resin is enhanced.

Owner:LINZHOU GUANGYUAN NEW MATERIAL TECH

Blended core-spun yarn for gauze and manufacture method thereof

The invention relates to a blended core-spun yarn for gauze and a manufacture method thereof. The blended core-spun yarn is made from, by mass, cellulose fibers 45-65%, spandex fibers 10-20% and cashmere fibers 20-30%. The manufacture method includes the following steps: S1, raw material mixing: artificially mixing the cellulose fibers and the cashmere fibers; S2, spinning: carding blended raw materials obtained in the step S1, drawing, performing secondary drawing, sterilizing, processing to obtain roving, and conducting core spinning together with the spandex fibers; spooling to obtain the blended core-spun yarn for the gauze. The blended core-spun yarn has the advantages of low cost, simple process, excellent yarn quality and low microbial residue.

Owner:吕元伟

Anti-dripping wear-resistant anti-static flame-retardant nylon-blended camouflage cloth and preparation method thereof

The invention discloses an anti-dripping wear-resistant anti-static flame-retardant nylon-blended camouflage cloth and a preparation method thereof. The preparation method comprises the following steps that (1) after an aramid fiber, a flame-retardant viscose fiber and an anti-static fiber are mixed, carding, drawing and roving are carried out in sequence to obtain rough yarn, a non-flame-retardant nylon filament is adopted as a core of the rough yarn, a flame-retardant nylon filament winds around an outer layer of the rough yarn, spun yarn is spun out and subjected to spooling, and a blendedwrapped and cored yarn is obtained; and (2) the blended wrapping and cored yarn is woven to obtain a grey fabric, the grey fabric is subjected to boiling, oxygen bleaching, mercerization and camouflage printing treatment in sequence, a printed cloth is obtained, and the printed cloth is subjected to ageing treatment to obtain the camouflage cloth. Fabric prepared by the preparation method of the anti-dripping wear-resistant anti-static flame-retardant nylon-blended camouflage cloth has the advantage that the fabric retards flame, resists dripping, is high in strength, can be subjected to dyeing and camouflage printing easily, resists static, is low in cost, easy in procedures and superior in yarn quality and the like; and the fabric is especially suitable for requirements in the aspect ofspecial operations, and can further meet requirements in aspects such as other overall uniforms.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA

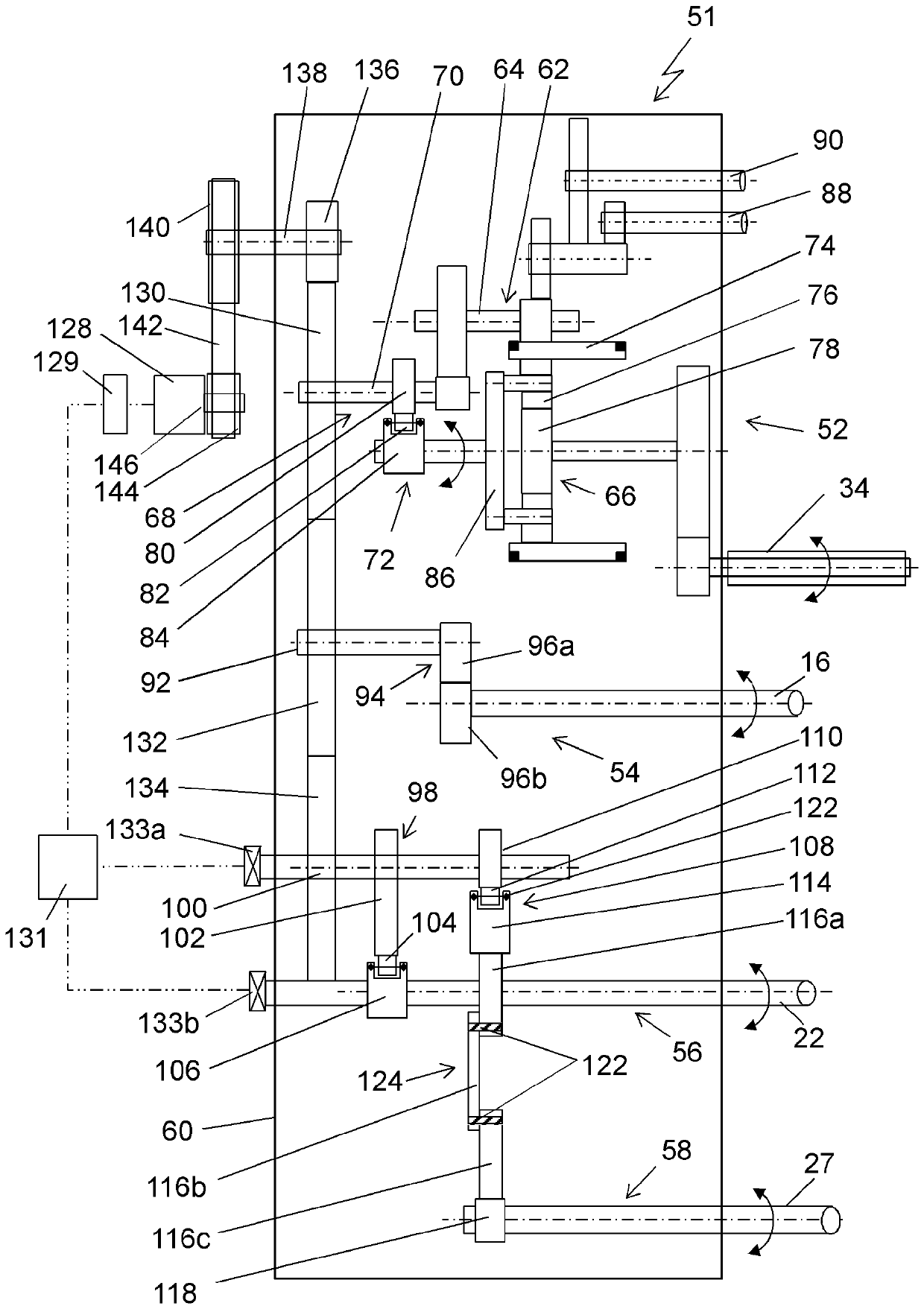

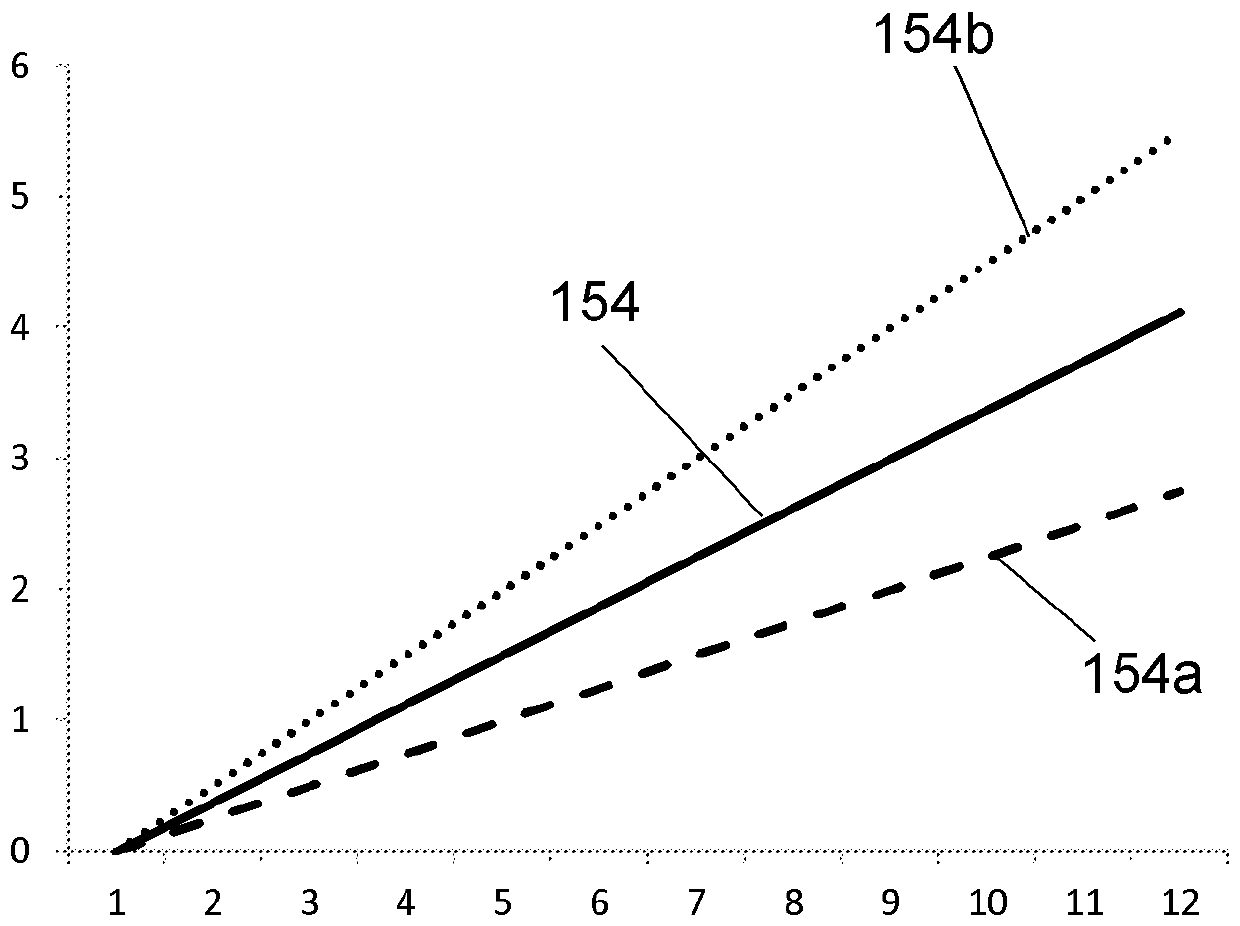

Drive device for detaching rollers of a comber

ActiveCN110067046AImprove uniformityBinding distance variableCombing machinesReciprocating motionDrive shaft

The invention relates to a drive device for a separating roller (34) of a comber (4), the drive device having a housing (60a) surrounding a gear device (51a). The gear device (51a) has a first drive train (62) of a drive shaft (64), the first drive shaft (64) transmits a continuous rotational motion to the separating roller (34) via a hollow wheel (74) of a differential gear device (66), and the gear unit (51a) has a second drive train (68) with a separation roller auxiliary shaft (70), and the separation roller cam disc device (72) is disposed on the separation roller auxiliary shaft (70) togenerate forward and backward movement. Through the continuous rotational movement of the hollow wheel (74) and the forward and backward movement of the separation cam disc device (72), the reciprocating motion is transmitted to a separating roller. According to the invention, an adjustment mechanism (158) is provided for adjusting the gear ratio between the continuous rational motion and the forward and backward movement.

Owner:MASCHINENFABRIK RIETER AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com