Drive device for detaching rollers of a comber

A technology for driving equipment and separating rollers, applied in combing machines, textiles and papermaking, fiber processing, etc., can solve problems such as large unevenness, fiber tip folding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

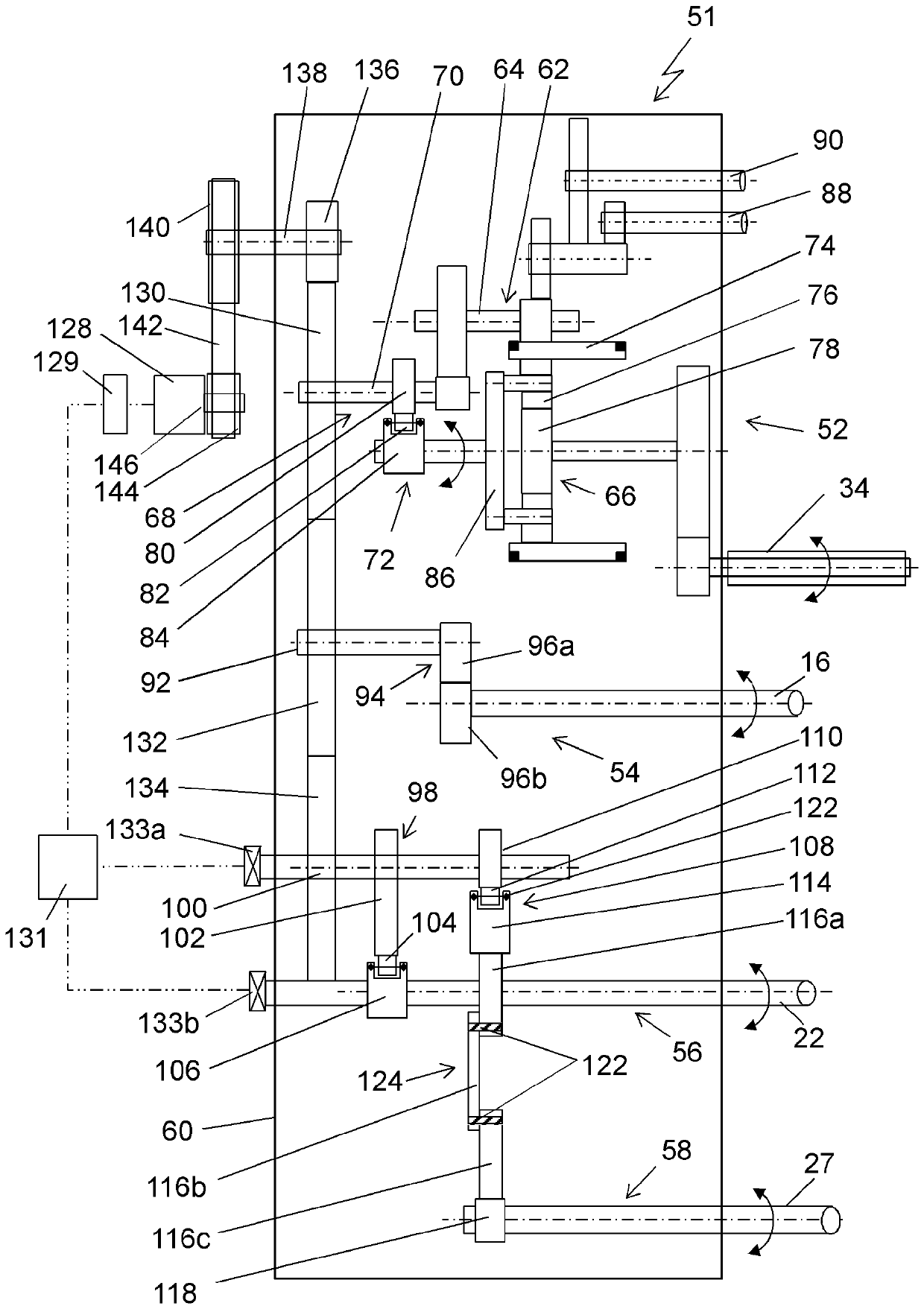

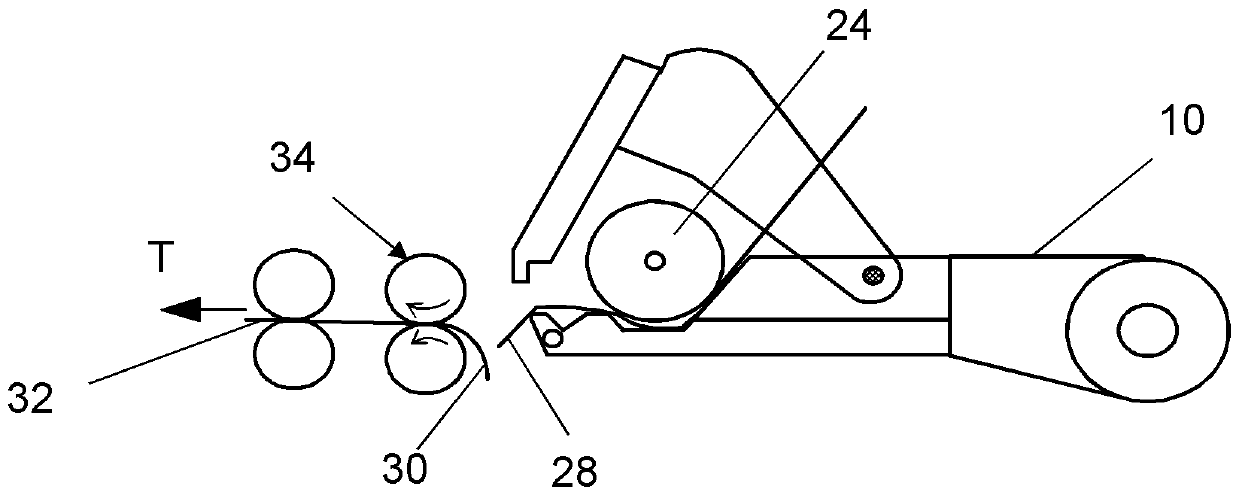

[0033] figure 1 A cross-section through the combing station 2 on the combing machine 4 is schematically shown. In practice, eight such combing stations 2 are arranged side by side. Each combing station 2 is made up of a nipper assembly 10 (referred to as nipper for short), and this nipper 10 executes the forward and backward movement of the nipper 10 by means of a front rocker 12 and a rear rocker 14 . Front rockers 12 (only one shown) are mounted in a rotationally movable manner on a circular comb shaft 16 and on a front nipper hub 18 of the nipper 10 . A rear rocker 14 mounted on a rear nipper axle 20 of the nipper 10 so that it can move rotationally is connected in a rotationally fixed manner to a driven nipper shaft 22 . The cotton filling 26 is fed to a feeding cylinder 24 installed inside the nipper 10 such that the cotton filling 26 can be rotationally moved. The filler material 26 is unwound from a folded roll (not shown) which rests on take-up rolls (also not shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com