Spinning unit for producing low-twist yarn

A twisted yarn and spinning machine technology, which is applied in the field of low-torque ring-spun yarn spinning devices, can solve the problems of inconvenient manufacture and use, high cost, complex structure, etc., and achieve good false twist effect and low residual torque , good yarn quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

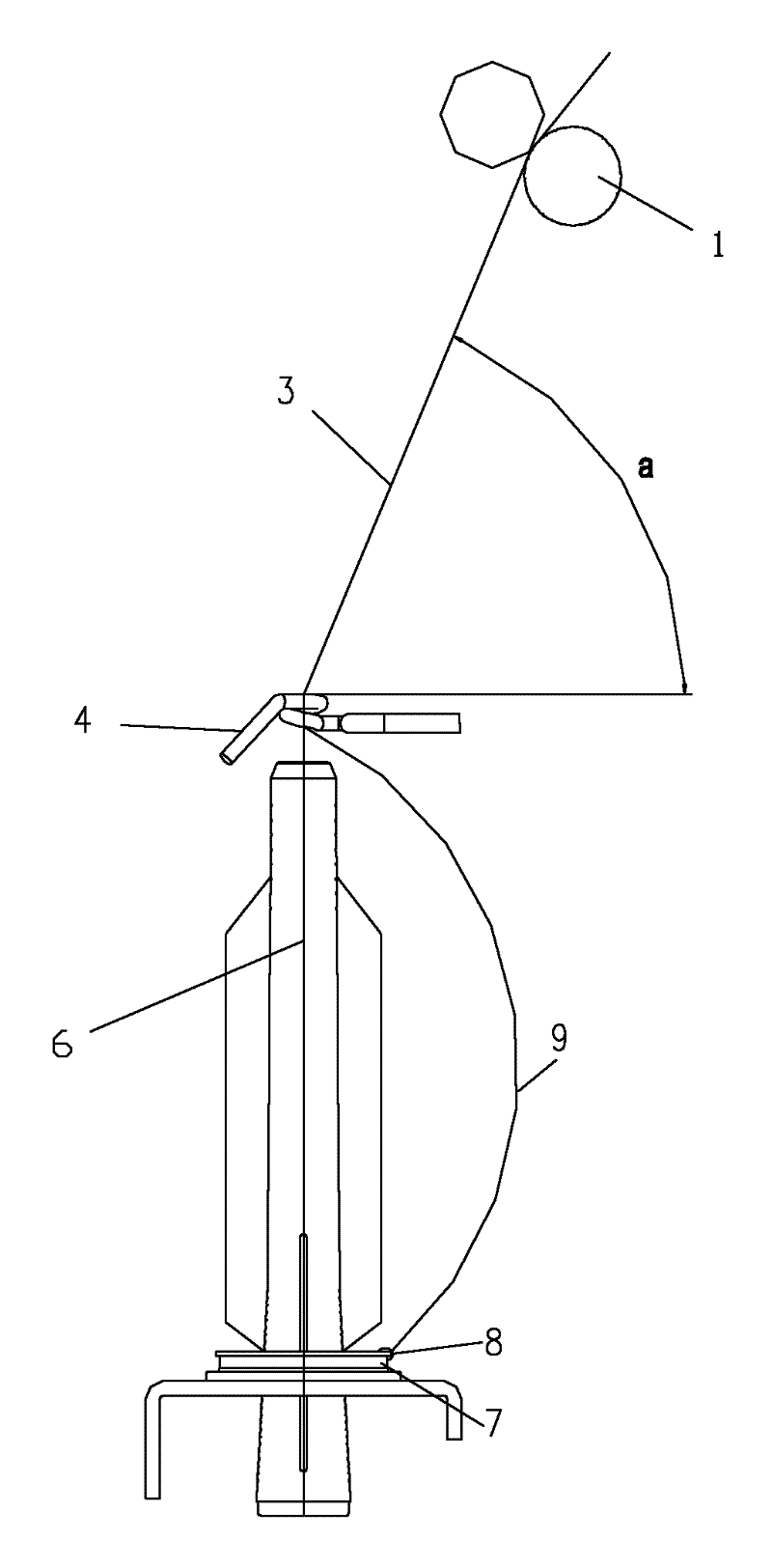

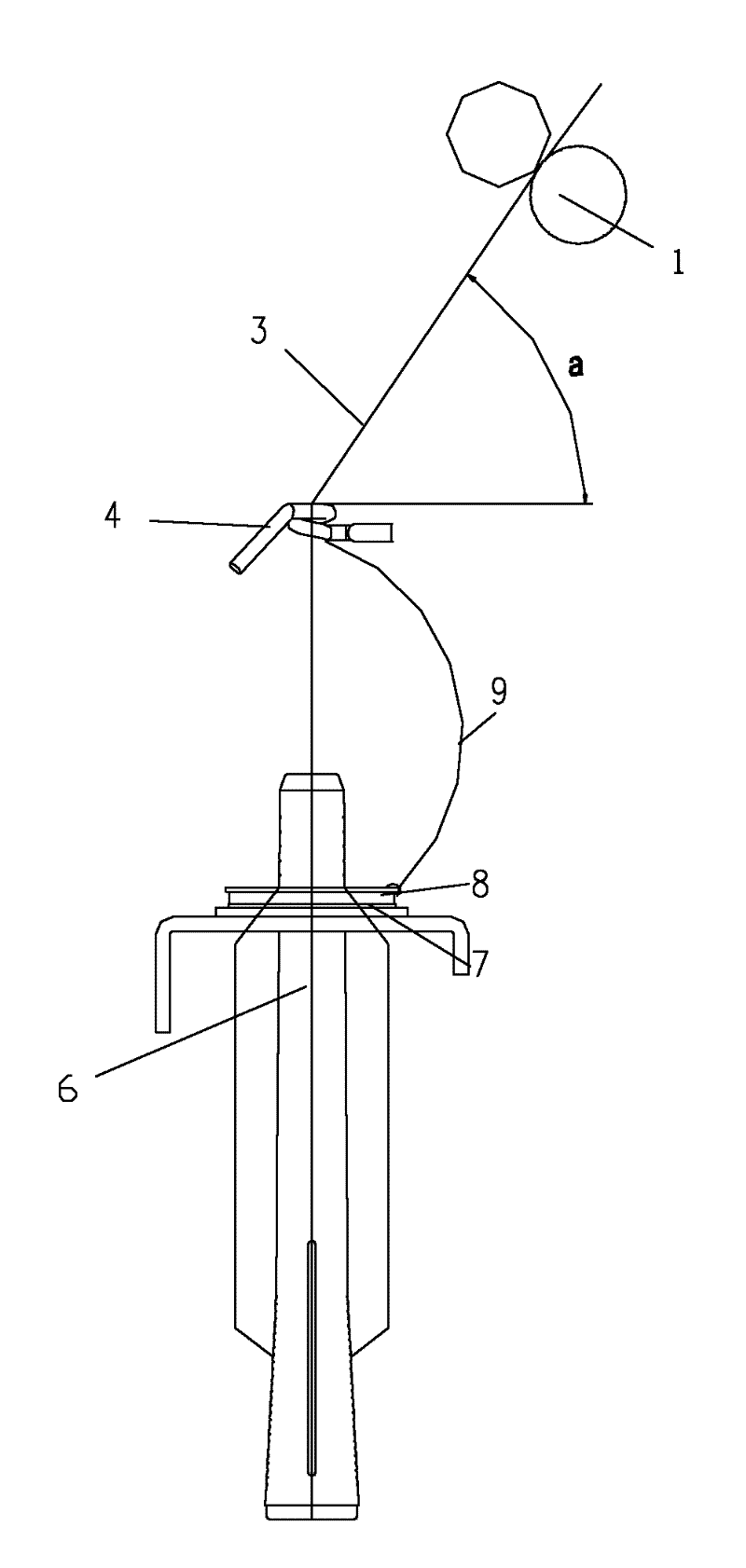

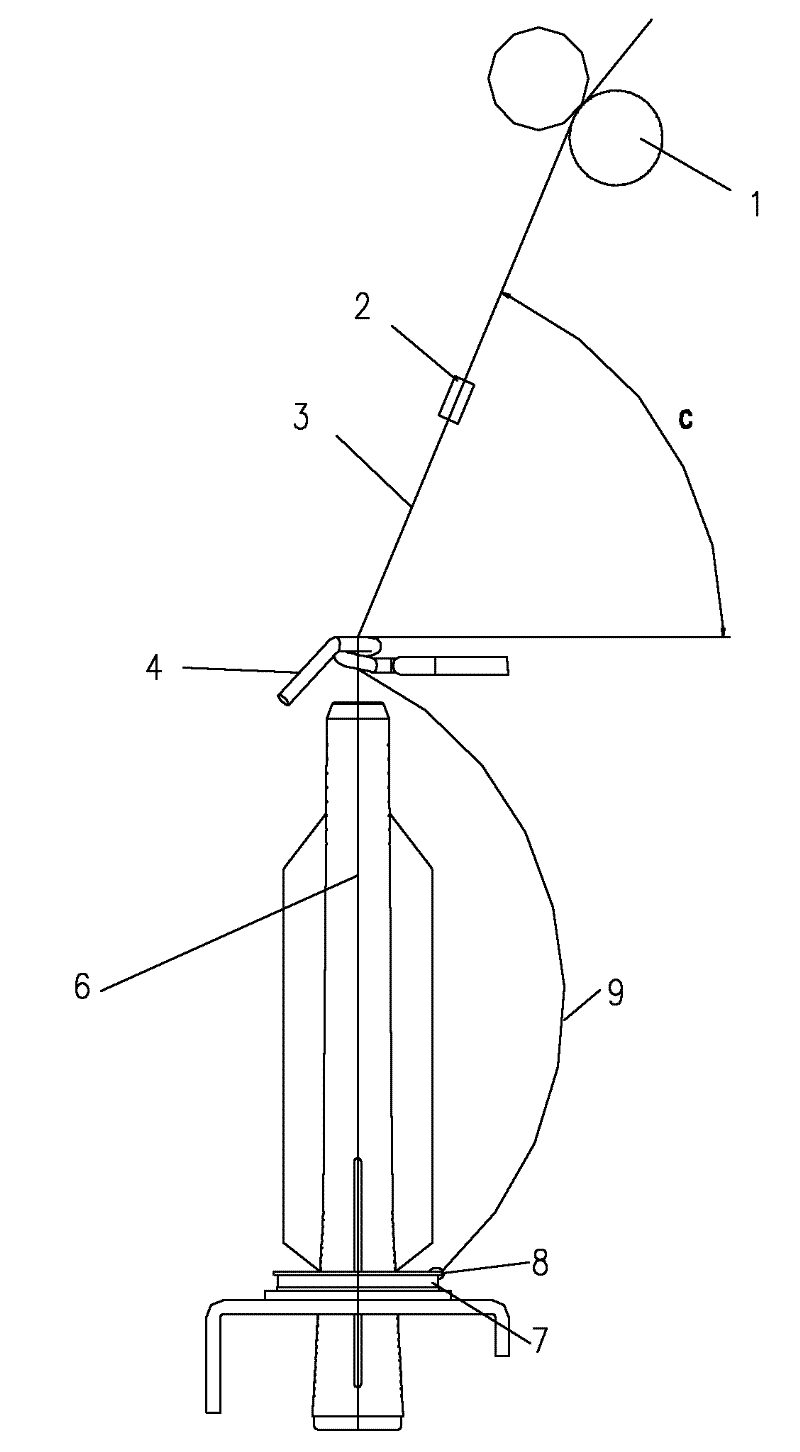

[0026] like Figure 5 , Image 6 Shown, a kind of spinning device of producing low torque yarn, it comprises existing ring spinning machine (see figure 1 and figure 2 ) and the false twist device 2, the false twist device 2 is placed between the output roller pair 1 and the guide hook 4 of the ring spinning machine.

[0027] When the yarn 3 enters the false twist device 2, the yarn 3 and the false twist device 2 form a fixed yarn guide angle b.

[0028] Above-mentioned false twist device 2 must be fixed, and it both can be fixed on the frame 12 of ring spinning machine, or be fixed to other places of machine, also can be fixed on the suitable position of spinning machine periphery.

[0029] The yarn twisting and winding device of the above-mentioned ring spinning machine is the same as the existing spinning machine, including bobbin 6, ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com