Combined structure of lower support double-runway conical ring and steel wire ring

A combined structure and traveler technology, applied in textiles and papermaking, can solve the problems of limited contact length between the steel ring and the traveler, high temperature of the traveler, and affecting spinning quality, so as to improve spinning quality without damaging fibers , the effect of improving spinning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

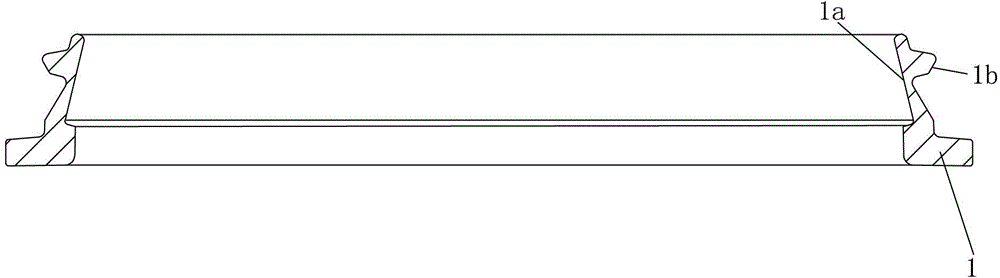

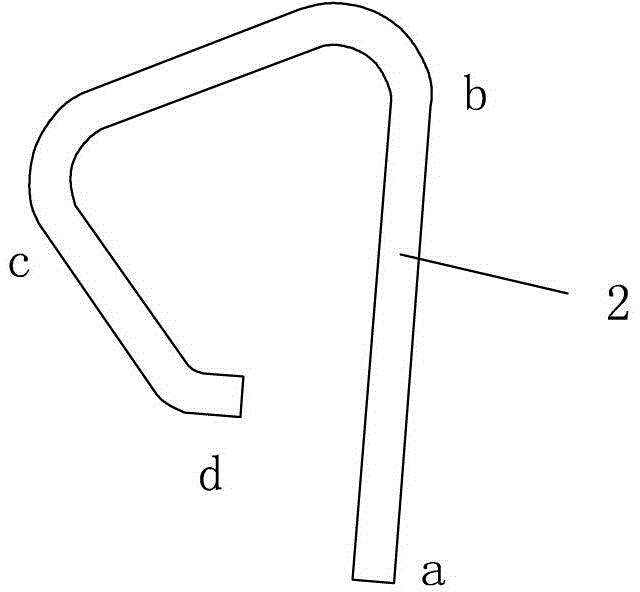

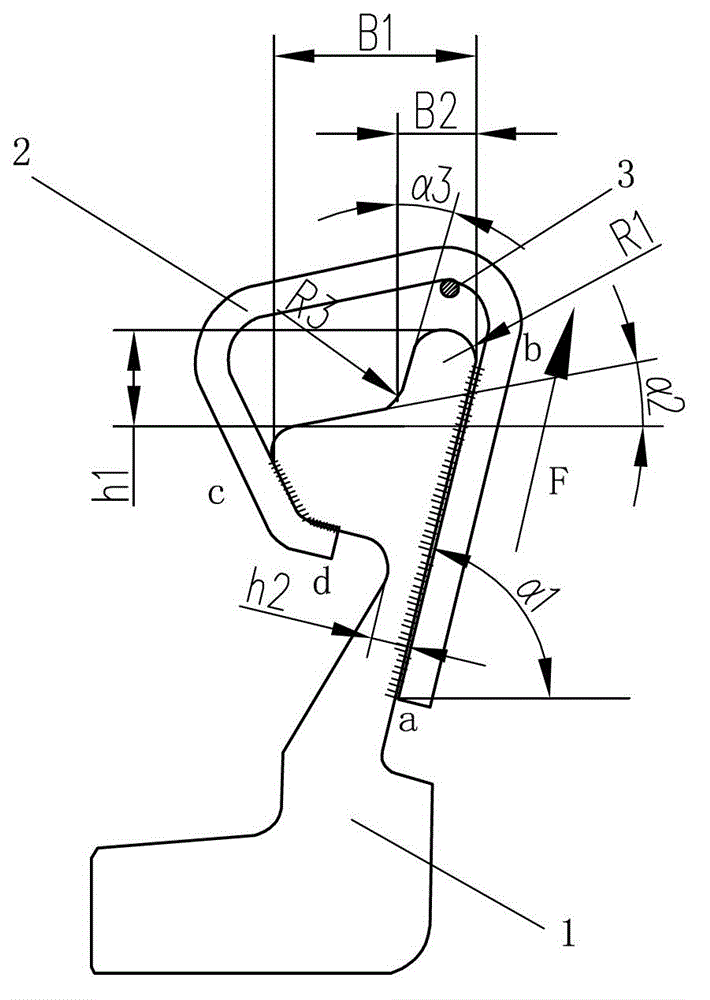

[0025] like figure 1 The lower supporting ring 1 shown is provided with an inner runway 1a and an outer runway 1b, the angle between the inner runway 1a and the horizontal coordinate axis is α1, and α1=65~89°, which constitutes the lower supporting tapered steel ring , in the cone ring, when the angle between the inner runway 1a and the horizontal coordinate axis is less than 65°, it is the upper support cone ring; when the angle between the inner runway 1a and the horizontal coordinate axis is greater than 65°, it is the lower support For the support cone ring, 65° is the dividing point between the upper and lower support cone rings. As the lower supporting ring, during normal spinning, the matching lower supporting traveler is under the upward force F and is in the lifting operation state; on the contrary, when the upper supporting ring is normally spinning, the supporting upper supporting traveler is under the upward force F The downward force F is in the pull-down operat...

Embodiment 2

[0031] like Figure 4-6 As shown, the lower support ring 1 and the lower support traveler 2 are basically similar to the embodiment 1, and the difference from the embodiment 1 is that the inner track 1a is an arc surface, and the radius of the arc is R2, R2=4~20mm, The angle between the inner runway 1a and the horizontal coordinate axis is α1, which is the angle between the chord of the arc and the horizontal coordinate axis.

[0032] like image 3 , in the size design of the lower support ring 1, the side width B1=2.4~4mm, preferably 3.2mm; the width of the top protrusion B2=0.5~2mm, preferably 1.2mm; the radius of the top protrusion R1=0.2~1mm , preferably 0.5mm; the depth of the top outer depression h1=1~3mm, preferably 1.4mm; the inclination angle of the bottom slope of the top depression α2=5°~20°, preferably 10°; the inclination angle of the inner slope of the top depression α3=5° ~20°, preferably 10°; the minimum wall thickness of the ring h2=0.5~1.5mm, the inner trac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com