Impregnating compound for low-dielectric glass fiber direct yarn and preparation method of impregnating compound

A technology of glass fiber and sizing agent, which is applied in the field of sizing agent for low-dielectric glass fiber direct yarn and its preparation, which can solve the problems of poor resin interfacial bonding, poor yarn bundling, and more hairiness, etc., to increase softness and strengthen Excellent interfacial adhesion and softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

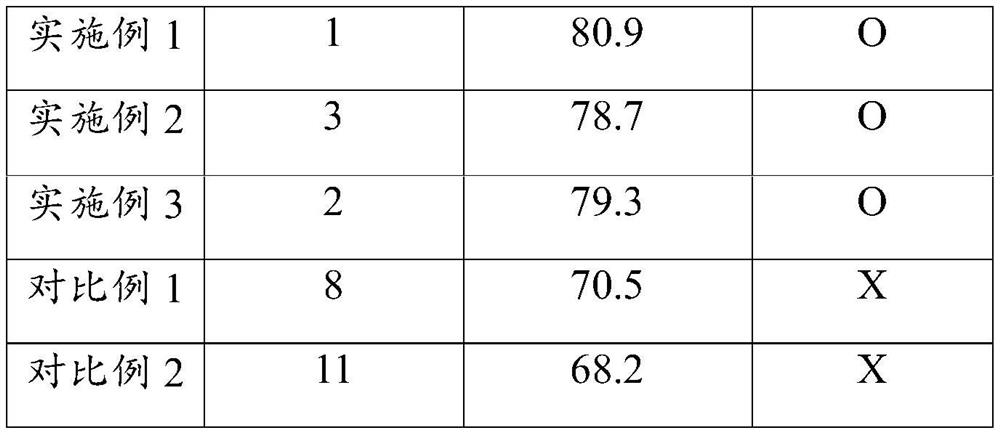

Embodiment 1

[0031] A sizing agent for low-dielectric glass fiber direct yarn, including the following components in mass percentage: film forming agent 10%, lubricant A 0.3%, silicone lubricant 0.8%, silane coupling agent OFS-603 20.6%, ice 0.05% acetic acid, and the rest is deionized water. The film-forming agent is composed of a low molecular weight bisphenol A epoxy resin emulsion with an average molecular weight of 420 and a medium molecular weight bisphenol A epoxy resin emulsion with an average molecular weight of 1200, wherein the low molecular weight bisphenol A epoxy resin The mass ratio of the emulsion to the medium molecular weight bisphenol A type epoxy resin emulsion is 1:1. Lubricant A is obtained by compounding imidazoline cationic lubricant and polyoxyethylene ether at a mass ratio of 1:2.1.

[0032]A preparation method of a sizing agent for low-dielectric glass fiber direct yarn, comprising the following steps:

[0033] (1) Use glacial acetic acid to adjust the pH value...

Embodiment 2

[0037] A sizing agent for low-dielectric glass fiber direct yarn, comprising the following components in mass percentage: 6% film-forming agent, 0.25% imidazoline cationic lubricant, 0.6% silicone lubricant, 0.6% silane coupling agent, 0.04% citric acid, and the rest is deionized water. Among them, the film-forming agent is composed of a low molecular weight bisphenol A epoxy resin emulsion with an average molecular weight of 430 and a medium molecular weight bisphenol A epoxy resin emulsion with an average molecular weight of 1400, wherein the low molecular weight bisphenol A ring The mass ratio of the epoxy resin emulsion to the medium molecular weight bisphenol A type epoxy resin emulsion is 1.8:1; the silane coupling agent is made by mixing the silane coupling agent KH570 and the silane coupling agent OFS-6032 in a mass ratio of 1:1 to make.

[0038] A preparation method of a sizing agent for low-dielectric glass fiber direct yarn, comprising the following steps:

[0039...

Embodiment 3

[0043] A sizing agent for low-dielectric glass fiber direct yarn, including the following components in mass percentage: 6% of film-forming agent, 0.25% of polyoxyethylene ether, 0.6% of silicone lubricant, 0.6% of silane coupling agent KH570, Oxalic acid 0.06%, the rest is deionized water.

[0044] The film-forming agent is composed of a low molecular weight bisphenol A epoxy resin emulsion with an average molecular weight of 410 and a medium molecular weight bisphenol A epoxy resin emulsion with an average molecular weight of 1100, wherein the low molecular weight bisphenol A epoxy resin The mass ratio of the emulsion to the medium molecular weight bisphenol A type epoxy resin emulsion is 1.5:1.

[0045] A preparation method of a sizing agent for low-dielectric glass fiber direct yarn, comprising the following steps:

[0046] (1) Use oxalic acid to adjust the pH value of the deionized water to 3.5, add the coupling agent and stir, the stirring speed is 70rmp, the stirring t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com