Spun yarn collector

A concentrator and spinning technology, applied to the concentrator. It can solve the problems affecting the yarn quality and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing.

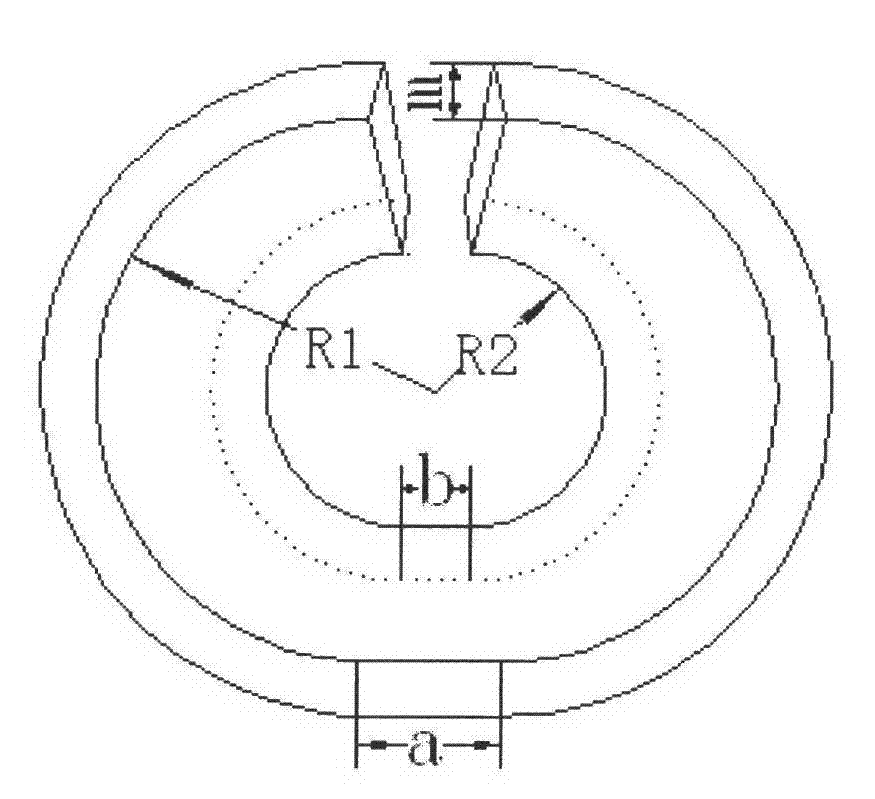

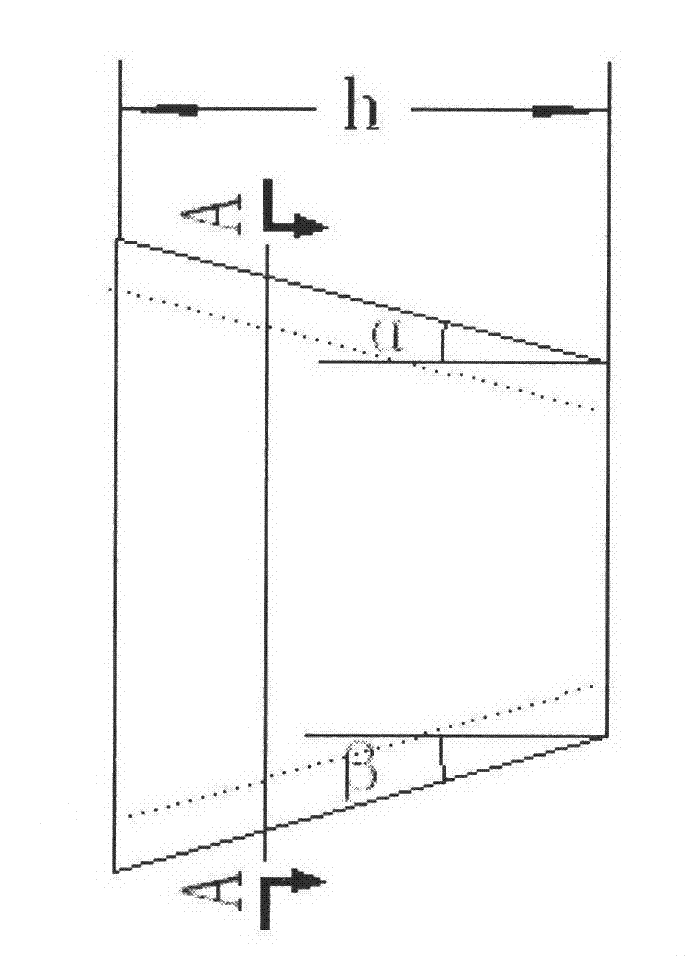

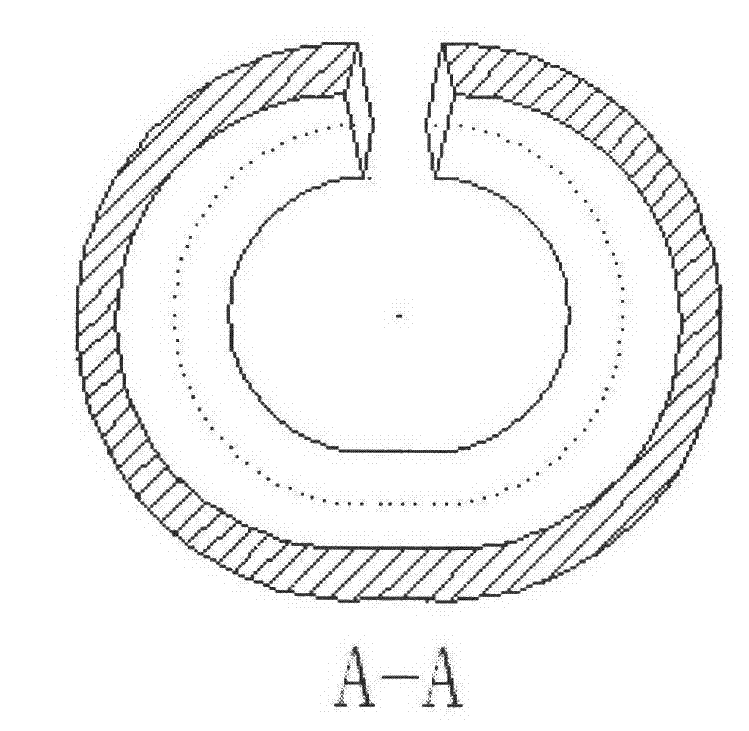

[0010] The appearance of the concentrator is tubular, and the contour line of the section at the entrance is composed of arc R1, line segment a, and arc R2. The contour line of the cross-section at the exit is composed of circular arc R3, line segment b, and circular arc R4, which are smoothly and seamlessly connected. The length of the collector is 2 mm in thickness. The radius of the arcs R1, R2 is 5 mm, and the radius of the arcs R3, R4 is 2.5 mm. The inclination angles α and β are 8°, and the total length h is 1.5 mm. Spun yarn collectors are different from traditional collectors in terms of shape, size and quality. The section shape of the collector is similar to a circle, and the radian of the contact between the collector and the surface of the top roller is appropriately increased, and the two-point contact of the original collector is changed to a circular arc c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com