High-speed wire twisting spindle

A twisting yarn and spindle technology, applied in textiles and papermaking, etc., can solve the problems of affecting production efficiency, large package speed, low speed, and high working speed, and achieve the effects of low labor intensity, large package capacity, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

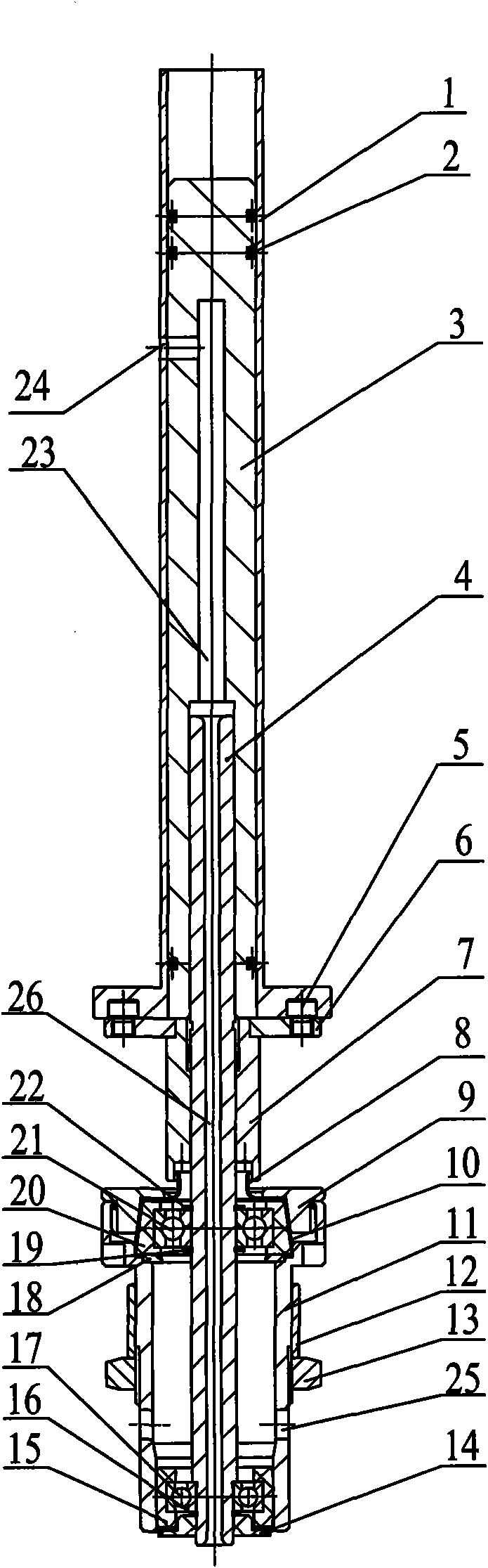

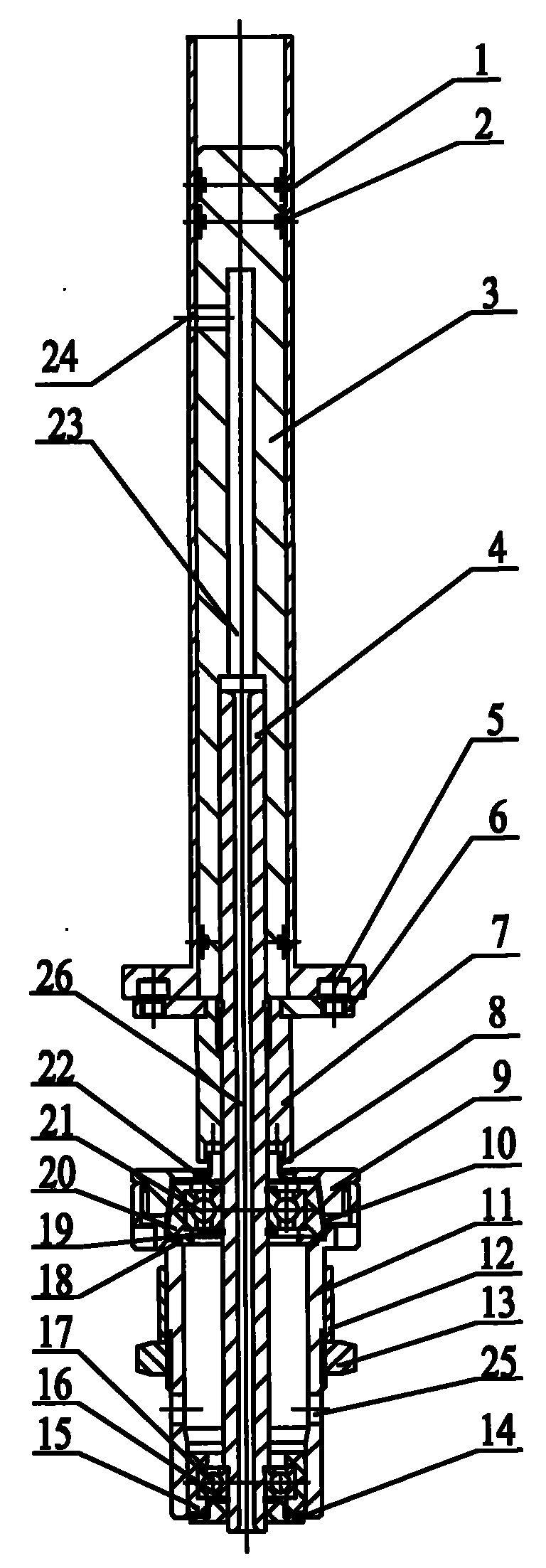

[0009] like figure 1 Shown: the present invention includes bobbin 1, O-ring 2, casing 3, spindle bar 4, pin 5, transmission ring 6, spindle disk 7, dustproof ring 8, spindle cover 9, protective cover 10, spindle seat 11 , lock sleeve 12, lock nut 13, bottom cover 14, lower vibration-absorbing rubber 15, first retaining ring 16, lower support bearing 17, gasket 18, second retaining ring 19, upper vibration-absorbing rubber 20, upper support bearing 21 , The third retaining ring 22 , the elongated hole 23 , the connection hole 24 , the convection hole 25 and the through hole 26 .

[0010] like figure 1 As shown: the sleeve 3 is arranged inside the bobbin 1, and the sleeve 3 is fixedly connected with the bobbin 1. The casing 3 is provided with an elongated hole 23 , and the elongated hole 23 communicates with the connecting hole 24 on the side wall of the bobbin 1 . An O-ring 2 is arranged between the bobbin 1 and the casing 3, the two O-rings 2 are located above the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com