Blended yarn of cotton fibers, hemp fibers and bamboo fibers and production process thereof

A technology of blended yarn and production process, which is applied in yarn, textiles and papermaking, etc. It can solve the problems of not crisp and beautiful, easy to shrink, easy to wrinkle, etc., and achieve the effect of simple process, high added value and soft texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Present embodiment is a kind of cotton, fiber crops, bamboo fiber blended yarn and production technology thereof, comprises following process step:

[0018] Step 1: Prepare materials: Prepare corresponding materials according to production needs, including good Xinjiang long-staple cotton 129a, high-quality flax fiber, and natural bamboo fiber; the cotton, hemp, and bamboo fibers are respectively by weight fraction, and cotton fiber 40 30 parts of hemp fiber, 30 parts of bamboo fiber, set aside.

[0019] Step 2: Making cotton and linen yarn strands: firstly, the hemp fiber is pretreated to improve the spinnability. The flax fiber raw material can be fully separated by mechanical separation to make the splitting degree exceed 2000, and then mixed evenly to reduce the color difference between the fibers; then evenly spray 3% emulsion and 2.5% on the mixed hemp fiber Softening agent, and pile tank processing 24h, this step can be finished before material preparation, wher...

Embodiment 2

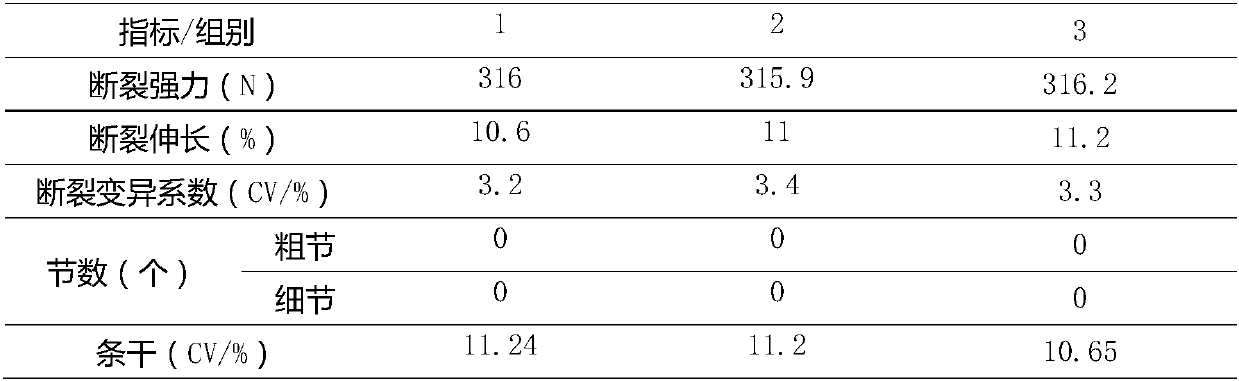

[0023] This embodiment is to check the properties such as the breaking strength, breaking elongation and breaking coefficient of variation of the cotton, hemp and bamboo fiber blended yarns prepared in Example 1.

[0024] Three groups of cotton, hemp, and bamboo fiber blended yarns obtained in Example 1 were tested for properties such as breaking strength, breaking elongation, and breaking coefficient of variation, and the results are shown in Table 1.

[0025] Table 1. Cotton, fiber crops, bamboo fiber blended yarn performance that embodiment 1 makes

[0026]

Embodiment 3

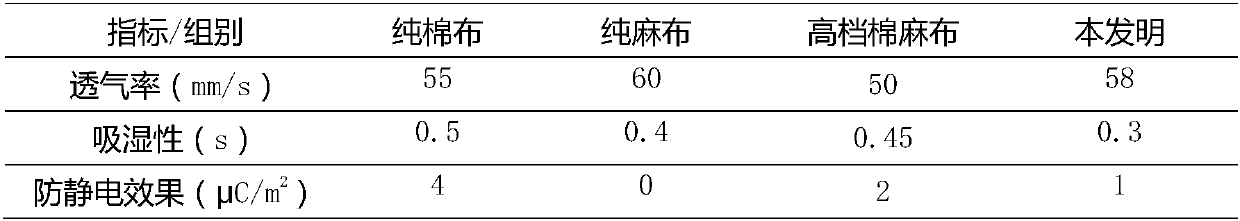

[0028] In this embodiment, the cotton, hemp, and bamboo fiber blended yarns prepared in Example 1 are anti-woven into cloth, and then its related properties are tested.

[0029] Get the cotton, hemp and bamboo fiber blended yarns obtained in Example 1 to make cotton, hemp and bamboo fiber blended cloth, the warp of the cloth is 50S, and the weft is 60S. Conduct a comparative test with high-grade cotton and linen fabrics, pure linen and pure cotton fabrics bought in the market, and measure their air permeability, moisture absorption and antistatic effects. Among them, air permeability is tested by water vapor transmission method, 25±0.5℃, relative humidity is 90±0.2; hygroscopicity is tested by water drop diffusion method, that is, the instantaneous diffusion time of water droplets on the fabric, and the antistatic effect is based on GB / T 12703- 1991 The surface charge density method of textile electrostatic testing. The results are shown in Table 2.

[0030] Table 2. Test re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com