Yarn guiding device

A yarn guide device and yarn guide technology, applied in the direction of textiles and papermaking, etc., can solve problems such as difficult operation, poor quality of yarn finished products, complex structure, etc., and achieve improved yield and yarn quality, good yarn quality, Even twist effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

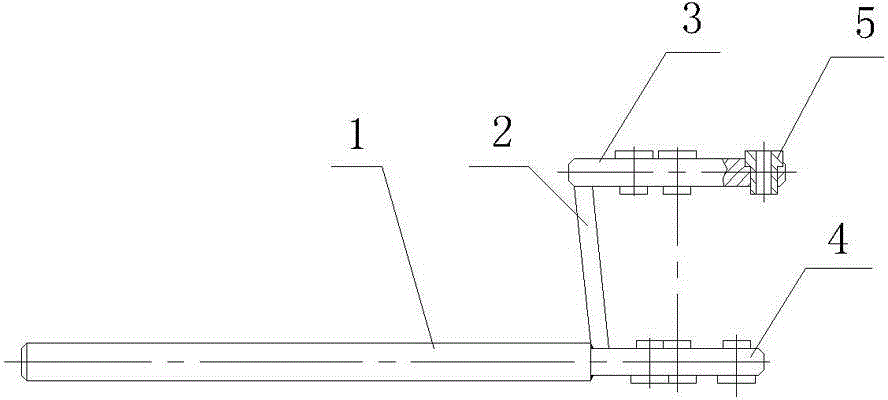

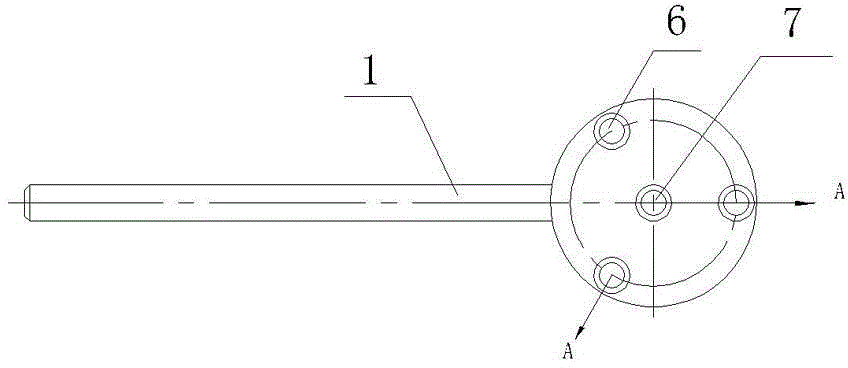

[0024] Such as figure 1Shown, a kind of yarn guiding device comprises circular upper fixed plate 3 and circular lower fixed plate 4, the upper and lower fixed plates are parallel to each other, the diameter of upper fixed plate 3 is greater than the diameter of lower fixed plate 4, and upper fixed plate 3 The distance with the lower fixing plate 4 is 33mm. The upper fixed plate 3 and the lower fixed plate 4 are connected to each other by a connecting rod 2, the width of the connecting rod 2 is only 1 / 8 of the side area of the circular platform space surrounded by the upper and lower fixed plates, and the upper and lower fixed plates and the connecting rod 2 are One piece. A fixed rod 1 is fixed on the outer edge of the lower fixed plate 4, and the end of the fixed rod 1 intersects with the connection point of the connecting rod 2 on the lower fixed plate 4, and the yarn guide is connected on the support part 21 of the frame by the fixed rod 1. Such as figure 2 As shown, ...

Embodiment 2

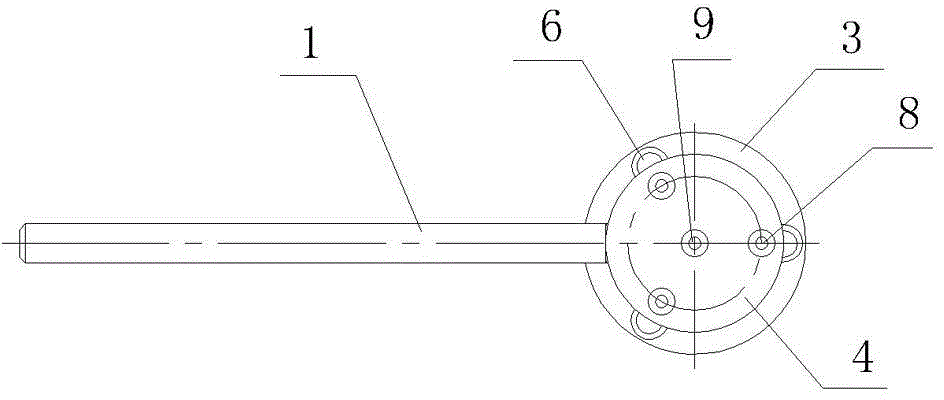

[0027] Such as Figure 5 As shown, the difference from Embodiment 1 is that the upper holes 6 on the upper fixing plate 3 and the lower holes 8 on the corresponding lower fixing plate 4 are alternately arranged, that is, the upper and lower fixing plates in Embodiment 1 are rotated by an angle. , the connection line between one of the lower hole 8 and the lower center hole 9 on the lower fixing plate 4 is projected onto the upper fixing plate 3, and the line between the projection line and the corresponding lower hole and the lower center hole on the upper fixing plate The angle θ between them is 8°. That is, the yarn passing through the upper hole and the lower hole produces an offset when going from the upper hole to the lower hole, forming a spiral-like rotating package. All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com