Drafting transmission device for roving frame

A technology of transmission device and roving frame, applied in the field of drafting system, which can solve the problems affecting the production efficiency of textile operations, time-consuming and laborious, etc., and achieve the effects of good yarn quality, convenient adjustment, and accurate draft ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

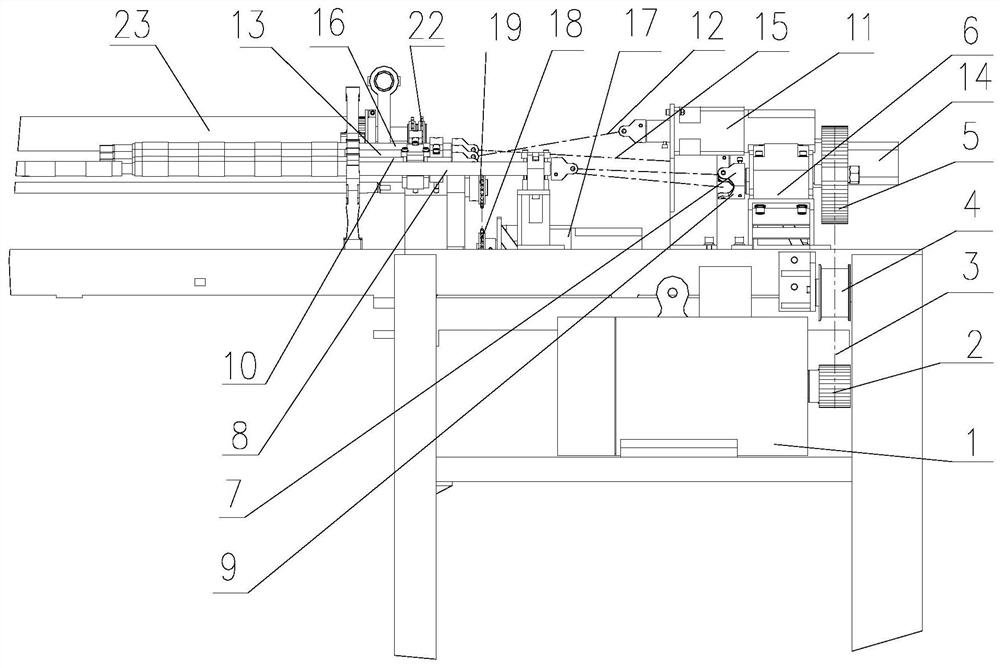

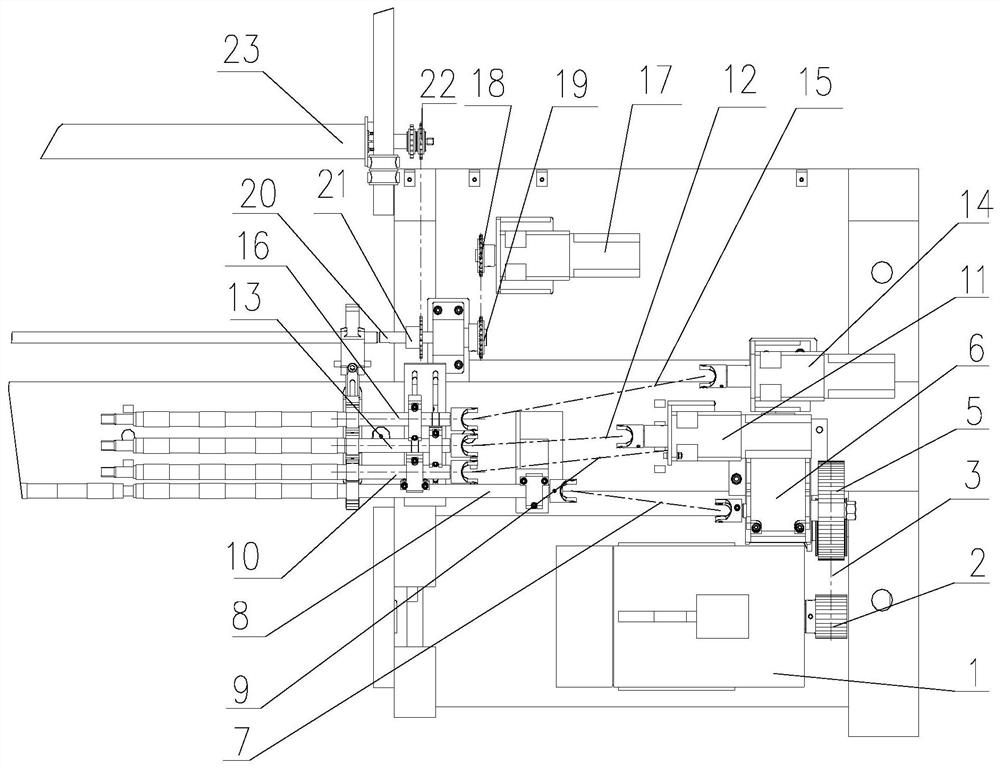

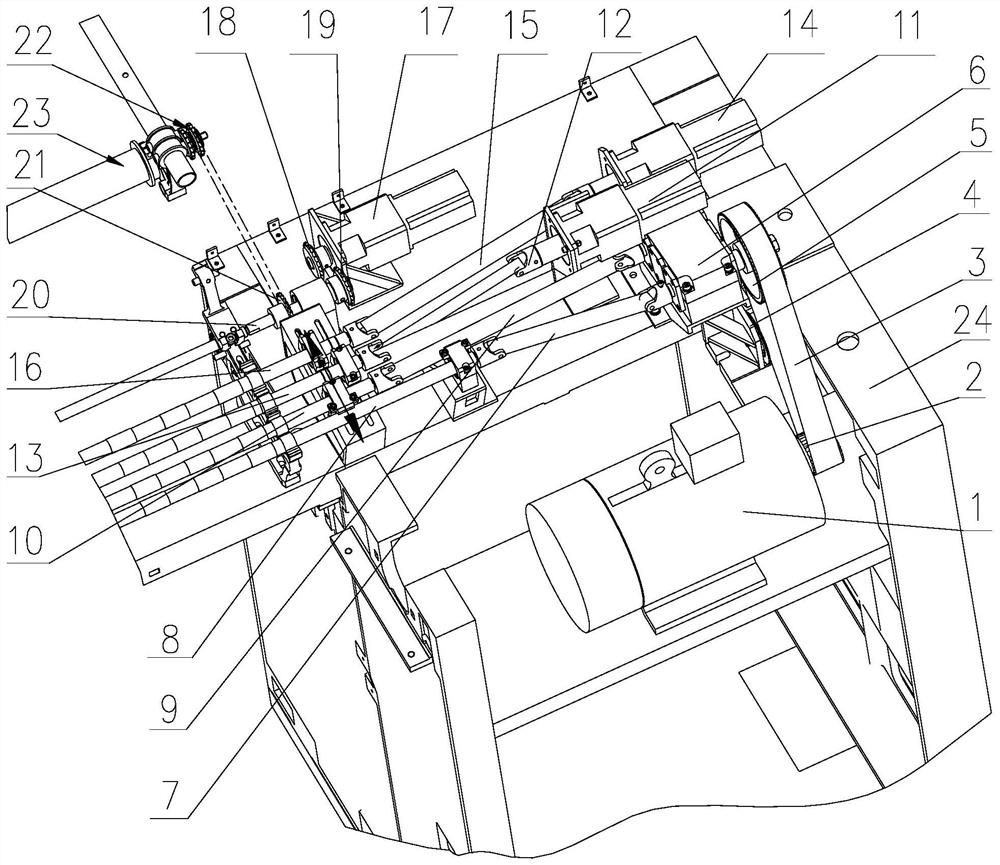

[0028] Such as figure 1 , figure 2 and image 3 As shown, a draft transmission device for a roving frame proposed by the present invention includes a first shaft seat arranged on a frame 24, and a roller head section shaft 8 and two roller heads are arranged side by side on the first shaft seat. Roller head shaft 10, three-roller head shaft 13 and four-roller head shaft 16, the one-roller head shaft 8, three-roller head shaft 13 and four-roller head shaft 16 are respectively passed through the universal joint by Driven by independent power sources; the two roller head shafts 10 are linked with the first roller head shaft 8 through a transmission mechanism; in order to realize convenient and quick adjustment of the center distance of each row of rollers, the first shaft in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com