Blended core-spun yarn for gauze and manufacture method thereof

A production method and core-spun technology, applied in yarn, textile and papermaking, irradiation and other directions, can solve the problems of uneven yarn, microbial residue, etc., and achieve the effect of good yarn quality, light sliver quality and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

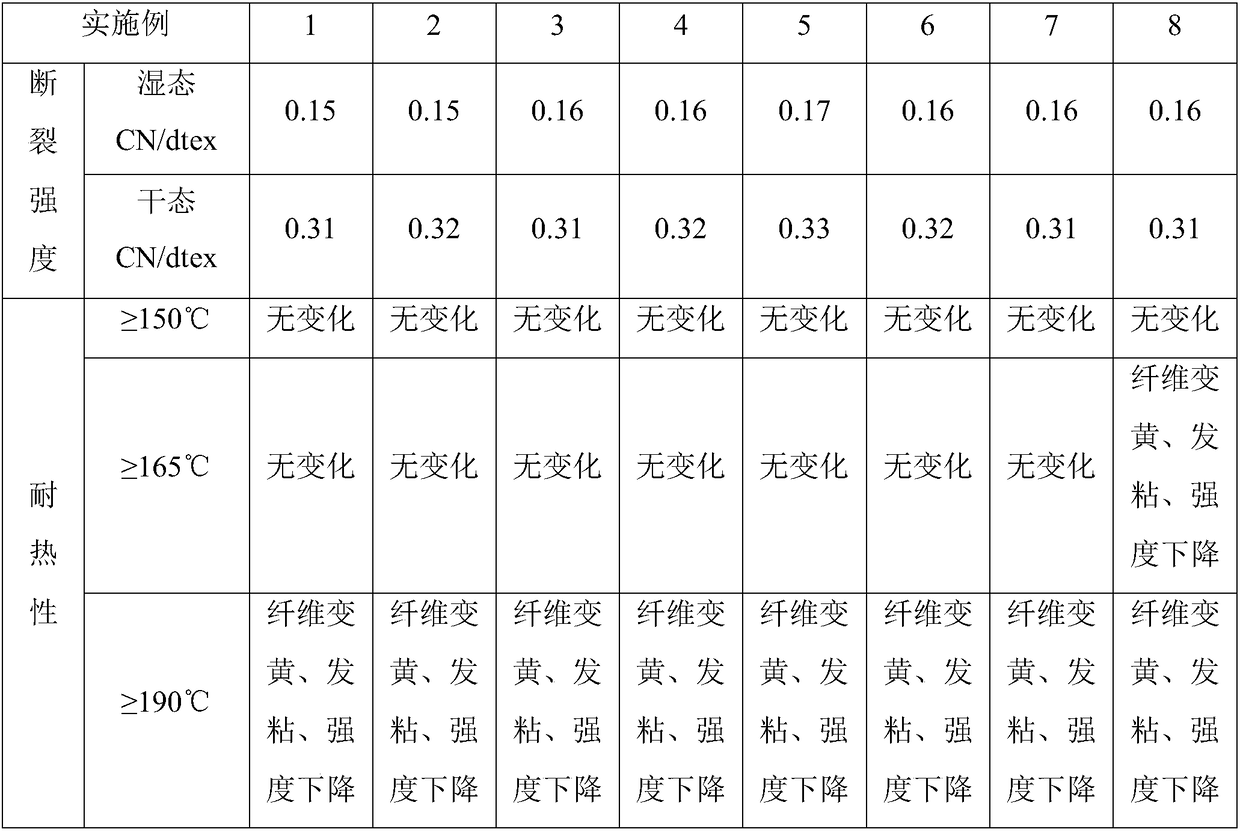

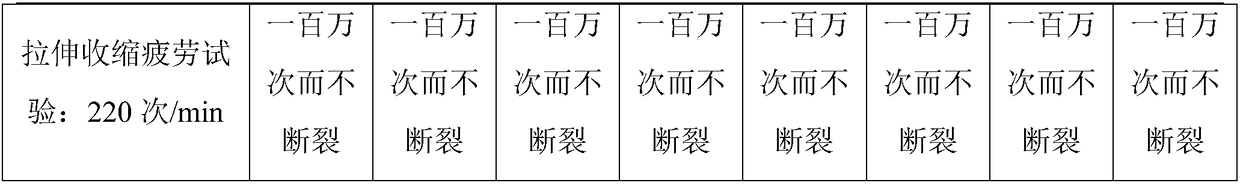

Examples

Embodiment 1

[0038] A blended core-spun yarn used for gauze is made of the following raw materials in terms of mass percentage:

[0040] Spandex 20%

[0041] Cashmere 25%.

[0042] The production method comprises the steps of:

[0043] S1 mixing of raw materials: manually mixing 55% cellulose fibers and 25% cashmere fibers;

[0044] S2 spinning: combing, drawing, secondary drawing, sterilizing, and roving the blended raw materials mixed in step S1, and then core-spun with 20% spandex fiber, and then through the winding process to obtain the blended bag used for gauze core yarn.

[0045] Specifically, the carding process is as follows: the sliver output speed during carding is 450m / min, and the sliver output weight is 5-7g / m.

[0046] Specifically, the drawing process is as follows: the drawing speed is 160m / min, and the drawing weight is 5-7g / m.

[0047] Specifically, the sterilization process is: irradiating with ultraviolet light for 30 minutes.

[004...

Embodiment 2

[0050] A blended core-spun yarn used for gauze is made of the following raw materials in terms of mass percentage:

[0052] Spandex 15%

[0053] Cashmere 30%.

[0054] The production method comprises the steps of:

[0055] S1 mixing of raw materials: manual mixing of 55% cellulose fibers and 30% cashmere fibers;

[0056] S2 spinning: combing, drawing, secondary drawing, sterilizing, and roving the blended raw materials mixed in step S1, and then core-spun with 15% spandex fiber, and then through the winding process to obtain the blended bag used for gauze core yarn.

[0057] Specifically, the carding process is as follows: the sliver output speed during carding is 500m / min, and the sliver output weight is 5-7g / m.

[0058] Specifically, the drawing process is as follows: the drawing speed is 200m / min, and the drawing weight is 5-7g / m.

[0059] Specifically, the sterilization process is: irradiating with ultraviolet light for 40 minutes.

[00...

Embodiment 3

[0062] A blended core-spun yarn used for gauze is made of the following raw materials in terms of mass percentage:

[0064] Spandex 20%

[0065] Cashmere 20%.

[0066] The production method comprises the steps of:

[0067] S1 mixing of raw materials: manual mixing of 60% cellulose fibers and 20% cashmere fibers;

[0068] S2 spinning: combing, drawing, secondary drawing, sterilizing, and roving the blended raw materials mixed in step S1, and then core-spun with 20% spandex fiber, and then through the winding process to obtain the blended bag used for gauze core yarn.

[0069] Specifically, the carding process is as follows: the sliver output speed during carding is 550m / min, and the sliver output weight is 5-7g / m.

[0070] Specifically, the drawing process is as follows: the drawing speed is 180m / min, and the drawing weight is 5-7g / m.

[0071] Specifically, the sterilization process is: irradiating with ultraviolet light for 40 minutes.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com