A high-strength flame-retardant anti-melt drop wear-resistant anti-static blended wrapping core-spun yarn and its preparation method

An anti-droplet and anti-static technology, applied in the textile field, can solve the problems of high glass transition temperature, poor durability and low strength of aramid fiber, and achieve the effect of excellent yarn quality, simple process and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

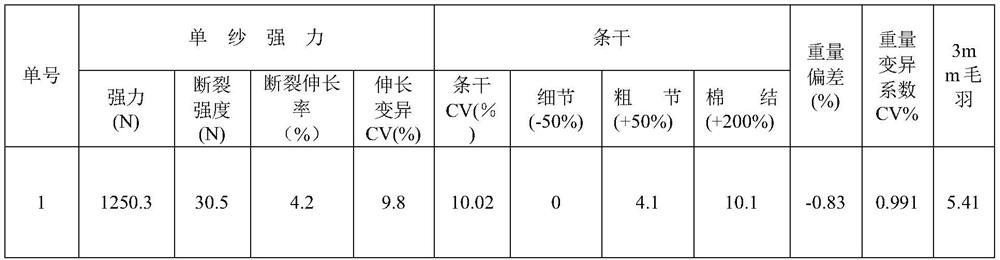

[0046] Example 1, Preparation of high-strength flame-retardant anti-droplet anti-static fabric 1

[0047] 1) 15% of aramid fiber (of which aramid 1414 fiber accounts for 60%), 55% of flame-retardant viscose fiber (FR fiber provided by Lenzing Company in Austria) and organic conductive fiber (conductive fiber provided by Japan China Textile Co., Ltd.) 2% is mixed evenly, and the uniformly mixed fibers are carded, drawn, drawn twice, drawn three times, and roved for use; wherein, the sliver speed during carding is 550m / min, and the sliver weight is 7g / m ; The drawing speed is 250m / min, and the drawing weight is 5g / m.

[0048] 2) Anti-droplet treatment: pad the flame-retardant nylon filament into the glycerin solution, the treatment temperature of the padding solution is 90°C, and the liquid-carrying amount of the flame-retardant fiber after the padding treatment is 50%; Beam irradiation grafting cross-linking reaction, the electron beam irradiation dose is 100kGy, washed, and f...

Embodiment 2

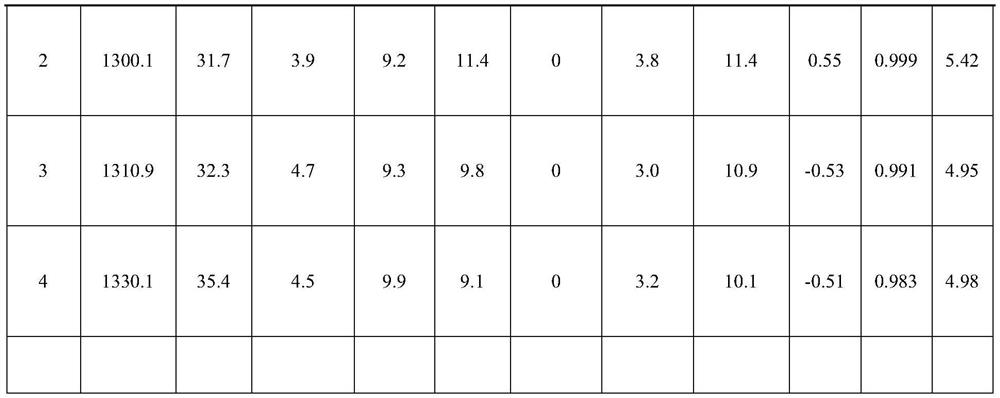

[0050] Embodiment 2, preparation of high-strength flame-retardant anti-droplet anti-static fabric 2

[0051]1) 17% of aramid fiber (wherein the proportion of aramid 1414 fiber is 80%), 45% of flame-retardant viscose fiber (FR fiber provided by Lenzing Company of Austria) and organic conductive fiber (conductive fiber provided by China Textile Company of Japan) ) 3% mixed evenly, carding, drawing, secondary drawing, third drawing, roving, stand-by; wherein, the sliver speed during carding is 650m / min, and the sliver weight is 5g / m; The stripping speed is 200m / min, and the stripping weight is 7g / m.

[0052] 2) Anti-droplet treatment: pad the flame-retardant nylon filament into the pentaerythritol solution, the treatment temperature of the padding solution is 55°C, and the liquid-carrying amount of the flame-retardant fiber after the padding treatment is 200%; carry out electron beam irradiation According to the graft cross-linking reaction, the electron beam irradiation dose is...

Embodiment 3

[0054] Embodiment 3, preparation of high-strength flame-retardant anti-droplet anti-static fabric 3

[0055] 1) 16.5% of aramid fiber (of which aramid 1414 fiber is 100%), 50% of flame-retardant viscose fiber (FR fiber provided by Lenzing Company of Austria) and organic conductive fiber (conductive fiber provided by Japan China Textile Co., Ltd.) 2.5% mix evenly, carry out carding, drawing, secondary drawing, third drawing, roving, stand-by; Wherein, the sliver speed when carding is 600m / min, the sliver weight 6g / m; The speed is 230m / min, and the delivery weight is 6g / m.

[0056] 2) Anti-melt droplet treatment: pad the flame-retardant nylon filament into a dipropylene glycol solution, the treatment temperature of the padding solution is 70°C, and the liquid-carrying amount of the flame-retardant fiber after the padding treatment is 100%; Electron beam irradiation grafting cross-linking reaction, the electron beam irradiation dose is 300kGy, washed clean, finally combed into s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Torsion | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com