Process for spinning three-in-one stretch yarn of wool, filament and urethane elastic fiber

An elastic yarn, three-in-one technology, applied in the spinning of filament and spandex three-in-one elastic yarn, and wool field, can solve the problems of complex production, multi-grain, high cost, and achieve simple production with low difficulty and high yarn quality. Good, low textile cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

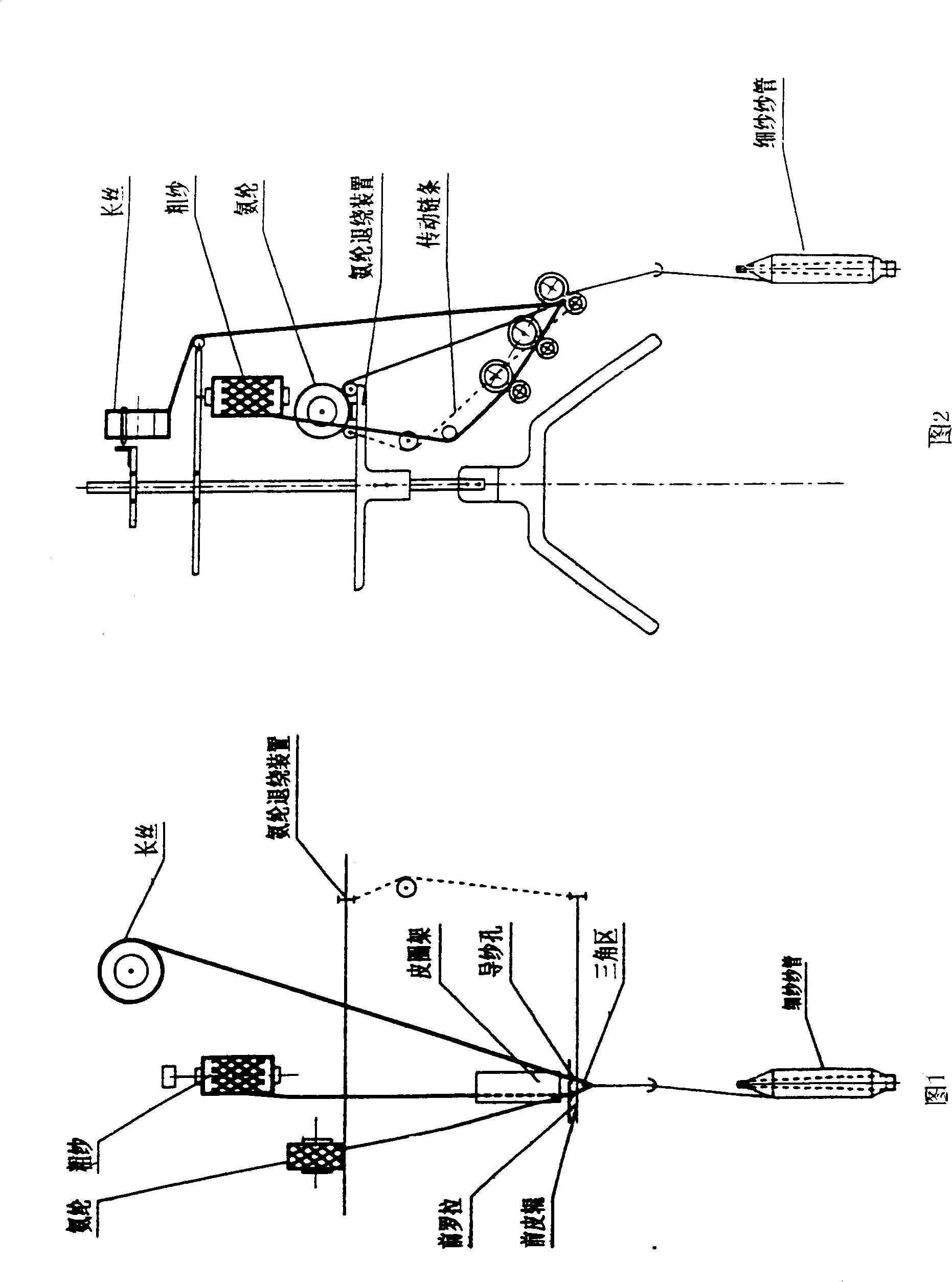

[0016] 1. Yarn forming mechanism

[0017] First, some modifications were made to the ring spinning frame, mainly adding a filament feeder and a spandex feeder. Due to the elasticity of spandex, a certain pre-stretch should be given, which can be realized by two unwinding rollers. The unwinding roller is connected to the front roller through a chain, and the speed ratio with the front roller can be changed by adjusting the sprocket to ensure uniform and stable elongation of the spandex. Spandex is positioned through the yarn guide hole installed on the ring spinning frame, and fed into the center of the roving sliver that has been normally drafted at the front roller nip of the spinning frame. The filament is also directly fed to the nip of the front roller of the spinning frame through the yarn guide hole installed on the spinning frame, but a certain distance should be kept from the beard, generally about 12mm. Under the jaws, the filament and the spandex-wrapped strands ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com