Method and apparatus for spinning staple fibres on ring-spinning machines

A technology of ring spinning machine and short fiber, which is applied in the field of short fiber spinning, which can solve the problems of increasing yarn ball resistance, power increase, increasing energy demand, etc., and achieves the effect of energy saving and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

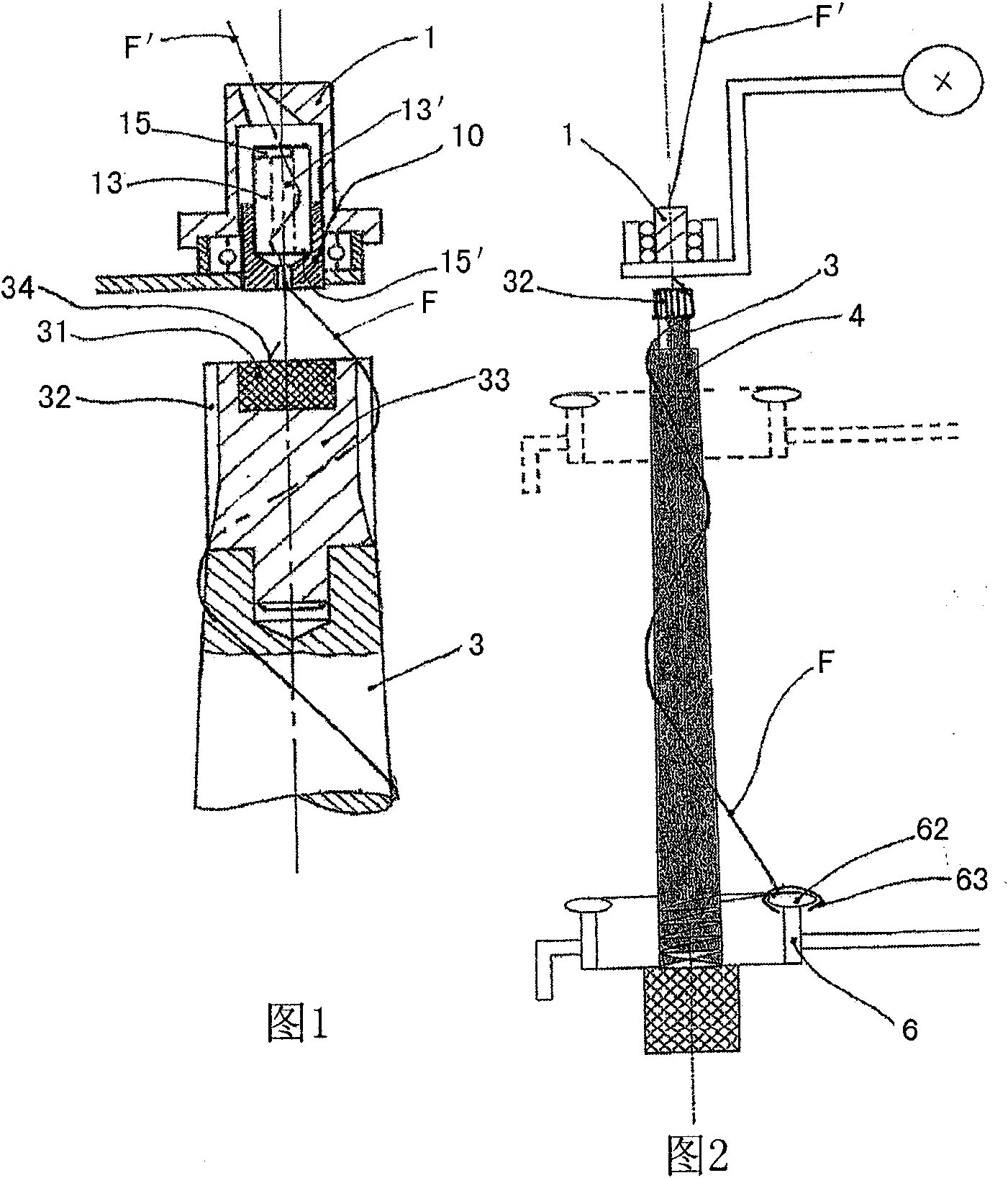

[0022] The yarn guiding device consists of a yarn guiding device 1 arranged above the spindle, which has a twisting part 10, which contains a braking mechanism. The braking mechanism consists of a tappet 13 which has a core 13' extending coaxially with the axis of rotation around which the upper unfinished yarn F coming out from the spindle 3 to the outlet of the draw frame surrounds. On the core member 13', there are an upper edge 15 and a lower edge 15' on which the yarn F passed through the yarn-guiding device 1 rests and is brought into rotation when the twisting member 10 turns.

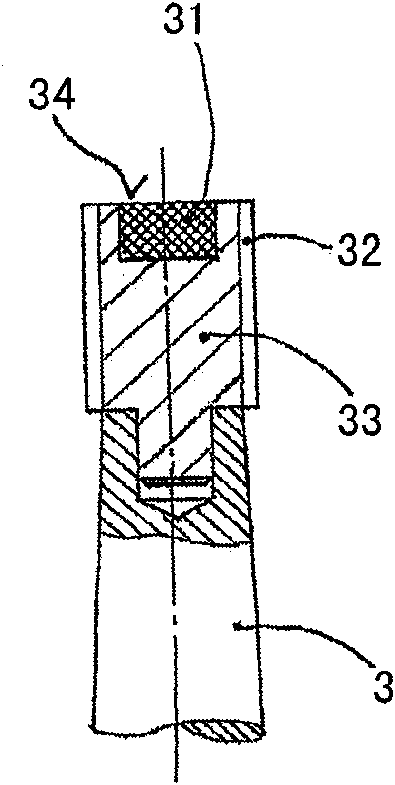

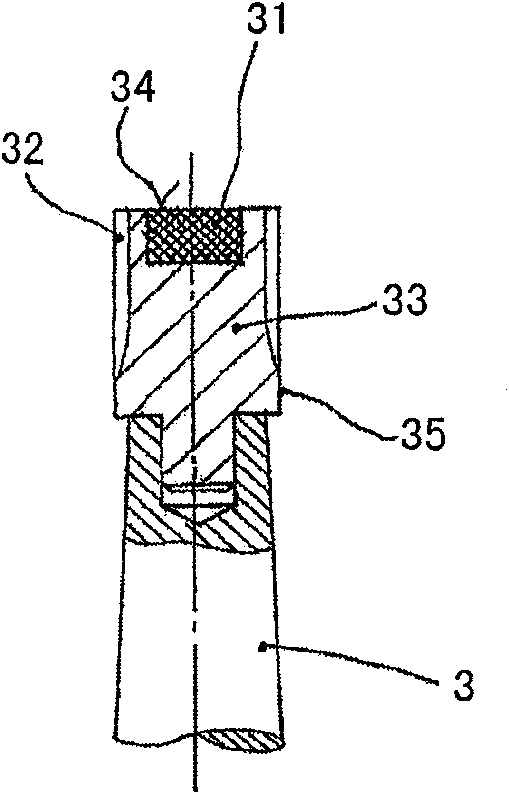

[0023] The part facing the spindle 3 on the twisting member 10 is used as a magnet, and forms a coupling magnet with the accessory 33 on the spindle 3 that is also equipped with a permanent magnet 31, so that the twisting member 10 rotates at the same speed as the spindle 3. The distance between the spindle fitting 33 and the twisting element 10 is determined by the necessary magnetic field to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com