MTF test apparatus and method for small off-axis optical system

An optical system and testing device technology, applied in the field of optical measurement, can solve the problems of complex structure, large volume, off-axis optical system measurement, etc., and achieve the effect of simple structure, low cost and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

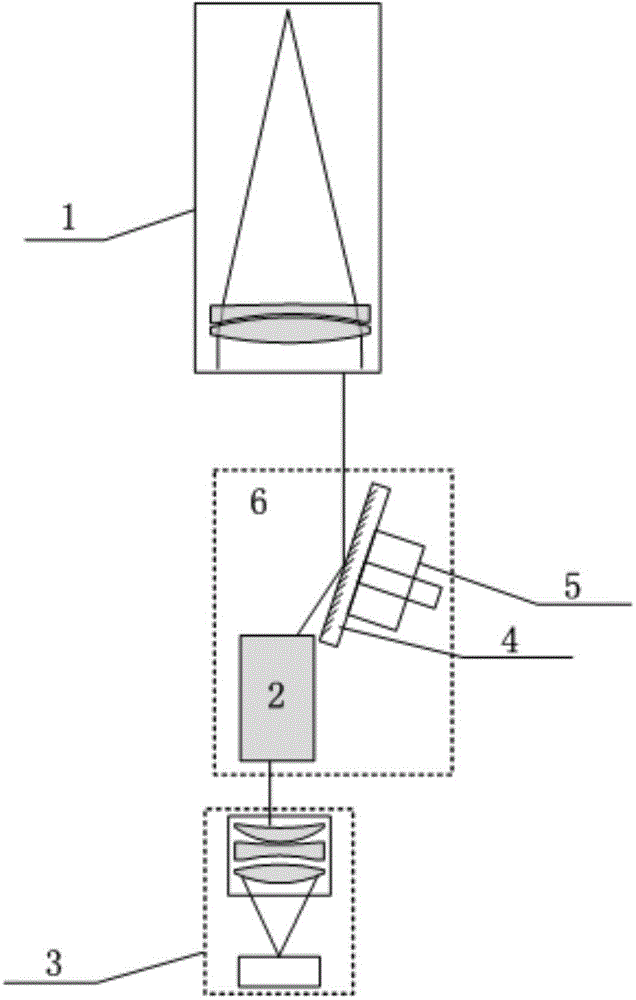

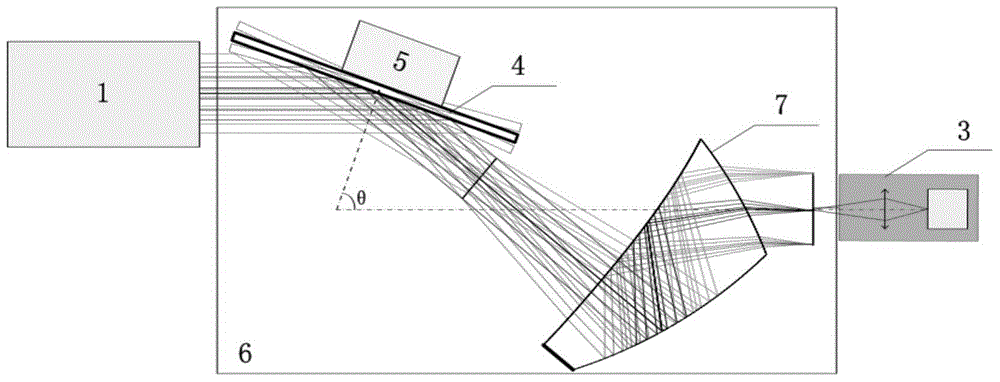

[0027] Example: The system under test is an asymmetric free-form surface prism,

[0028] Such as figure 2 As shown, the collimator 1 and the MTF detection system 3 are on the same optical axis, and the test module 6 is placed in the optical path between the two; the test module 6 is composed of an off-axis asymmetric free-form surface prism 7, a plane mirror to be tested 4 and a two-dimensional rotating mechanism 5; the two-dimensional rotating mechanism 5 and the plane mirror 4 are rigidly connected.

[0029] The angle between the exit optical axis and the incident optical axis of the off-axis asymmetric free-form surface prism 7 to be measured is 2θ, and the plane mirror 4 needs to be placed at an angle of θ between the normal direction and the horizontal direction, so that the measured The incident optical axis of the off-axis asymmetric free-form surface prism 7 is parallel to the exit optical axis; at the same time, the aperture of the plane mirror 4 should be large enough t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com