Lithium ion battery thermal runaway product collection and test method

A technology of lithium ion battery and testing method, which is applied in the field of collection and testing of thermal runaway products of lithium ion batteries, and can solve problems such as thermal runaway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Samsung brand 18650 lithium-ion battery is used, the initial power is 0, and it is charged to 100SOC by the blue electric test system.

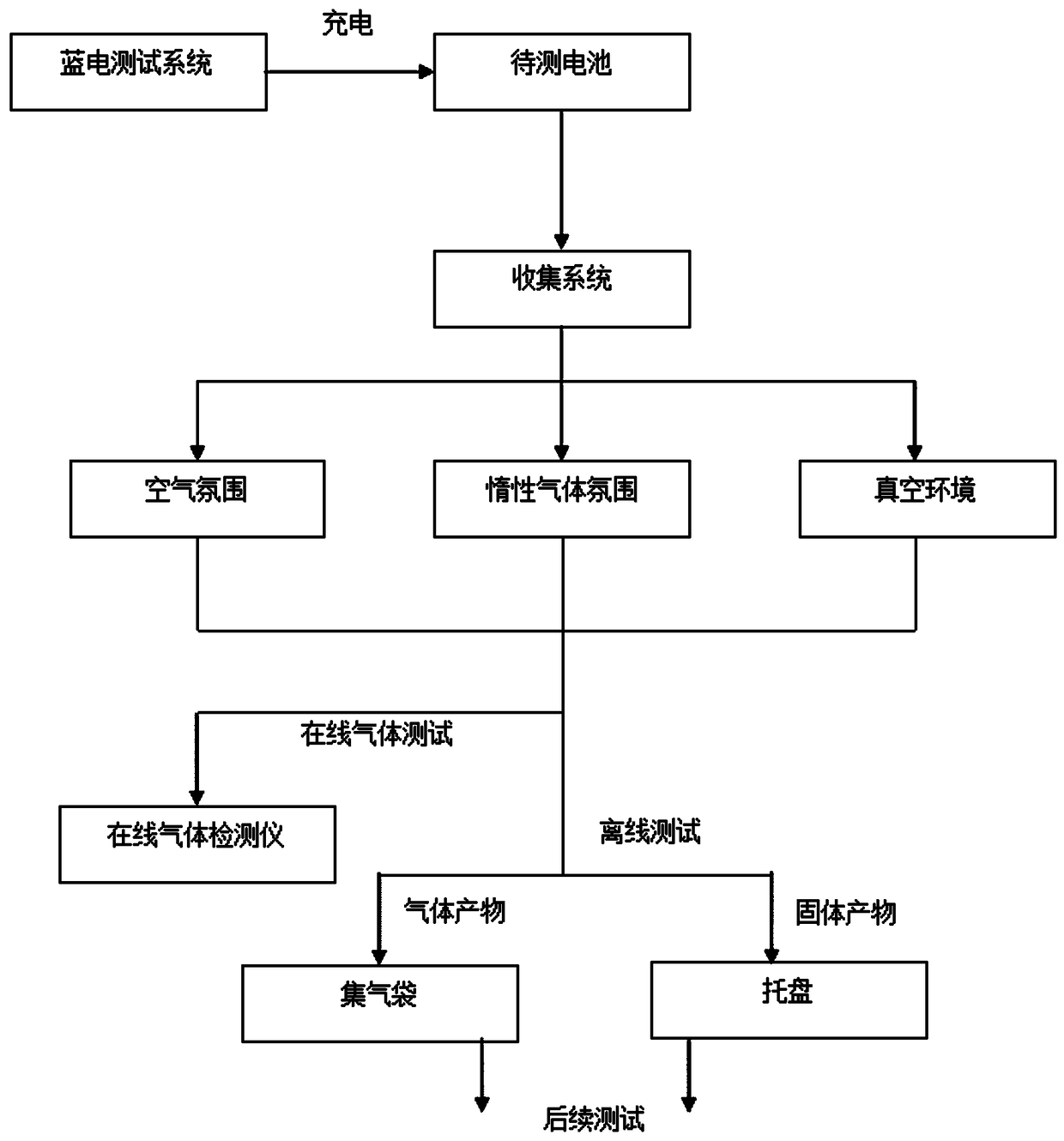

[0066] refer to figure 1 Under the parameter conditions shown in the lithium ion battery thermal runaway gas, solid product collection and online offline test method, the gas product concentration of the lithium ion battery to be tested in the air atmosphere is tested for the concentration of the gas product thermal runaway, including the following steps:

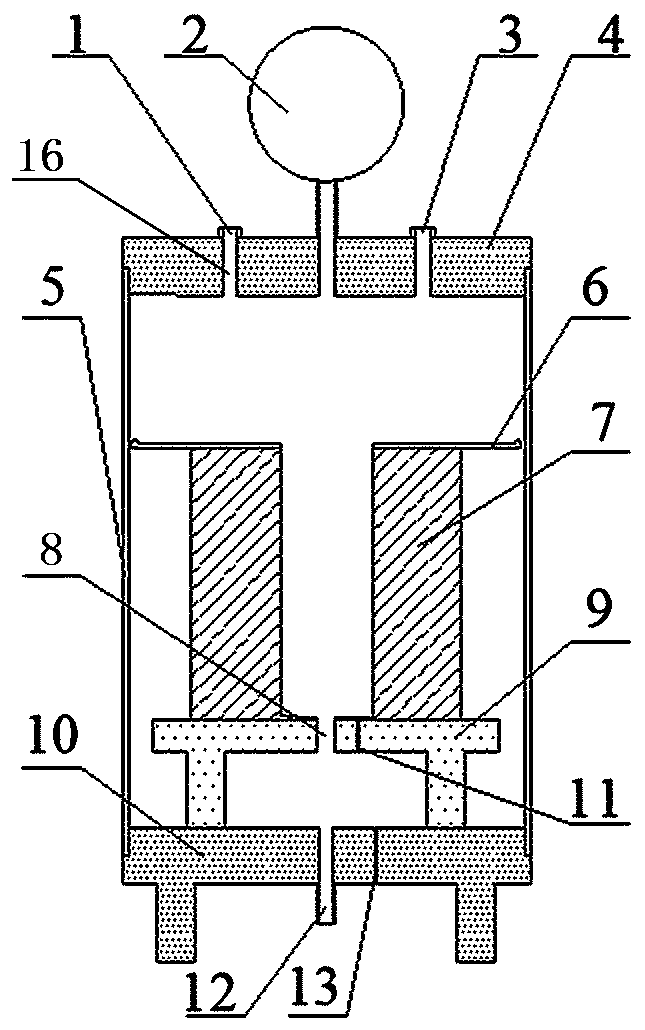

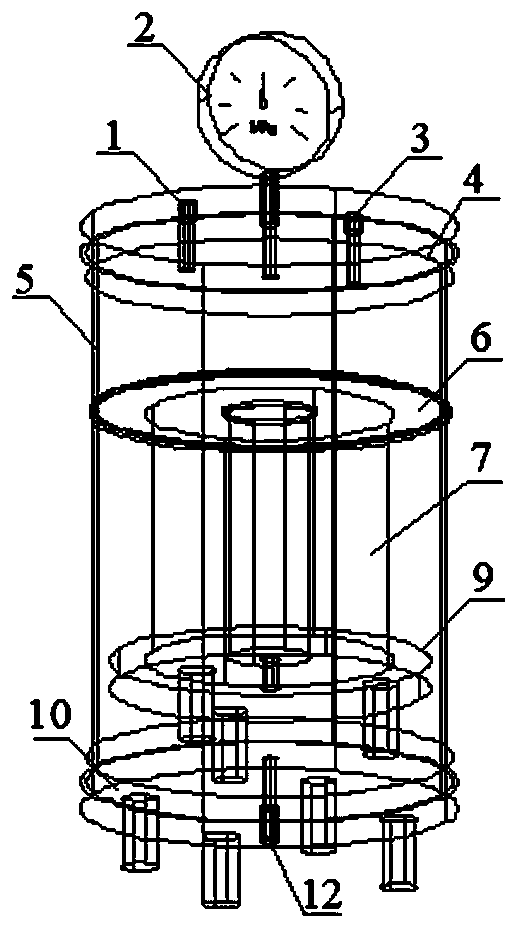

[0067] (1) Use the lithium-ion battery thermal runaway gas, solid product collection and testing system to heat the lithium-ion battery. The operation method is: before the experiment, put the lithium-ion battery to be tested into the blue electric brand test system, charge it to 100SOC, and then put it Into the battery heating pool of the lithium-ion battery thermal runaway gas and solid product collection and testing system, and attach the temperature thermocouple of the temperatu...

Embodiment 2

[0072] Samsung brand 18650 lithium-ion battery is used, the initial power is 0, and it is charged to 100SOC by the blue electric brand test system.

[0073] refer to figure 1 Under the parameter conditions shown in the lithium ion battery thermal runaway gas, solid product collection and online offline test method, after collecting the gas product of thermal runaway of the lithium ion battery to be tested in the air atmosphere in this embodiment, test its lower explosion limit, and the solid product After collection, their thermal stability was tested, including the following steps:

[0074] (1) Use the lithium-ion battery thermal runaway gas, solid product collection and testing system to heat the lithium-ion battery. The operation method is: before the experiment, put the lithium-ion battery to be tested into the blue electric brand test system, charge it to 100SOC, and then put it Into the battery heating pool of the lithium-ion battery thermal runaway gas and solid produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com