Capacitance type digital material-level sensor and its measurement method

A capacitive and sensor technology, applied in the direction of liquid level indicators for physical variable measurement, can solve the problems of large errors in the measurement of material levels, achieve the effects of simple, compact and reasonable structure, novel measurement methods, and enhanced anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

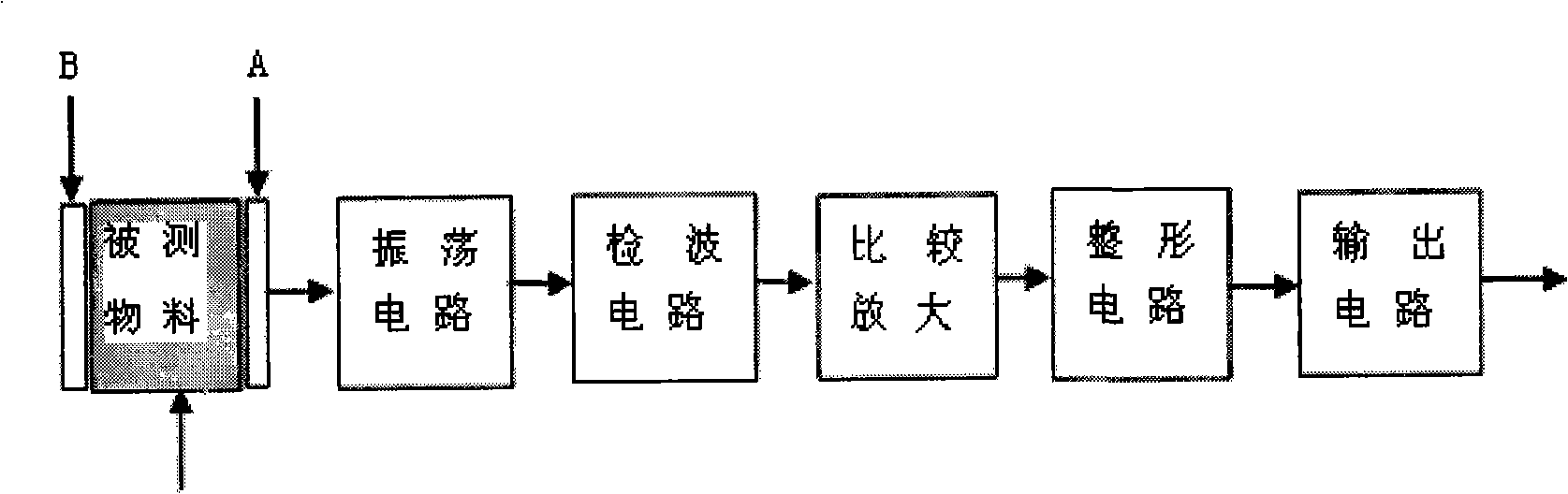

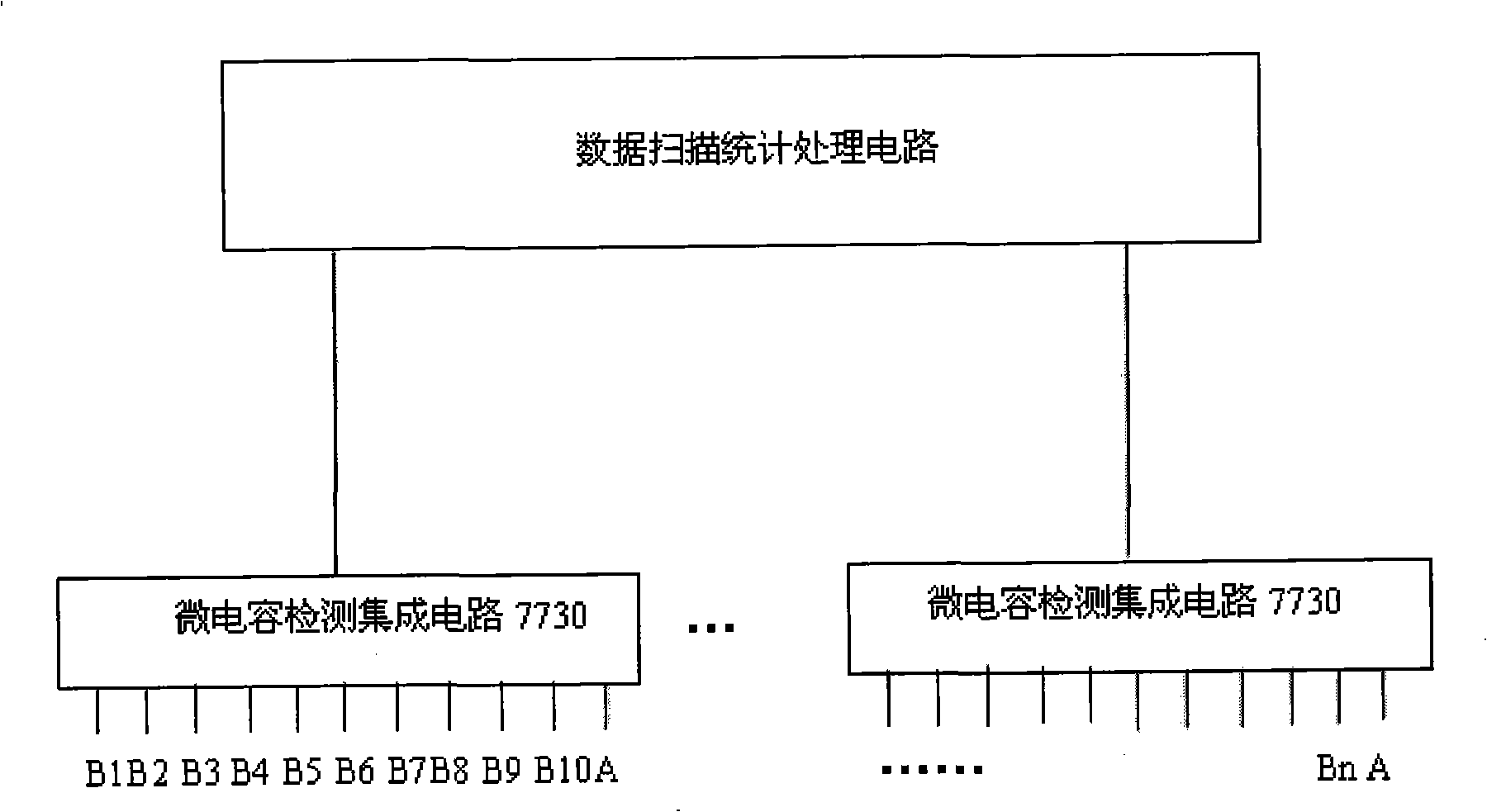

[0017] The technical solutions of the present invention can be further described in detail below in conjunction with the accompanying drawings. This embodiment is a further detailed description of the present invention and does not limit the present invention in any way.

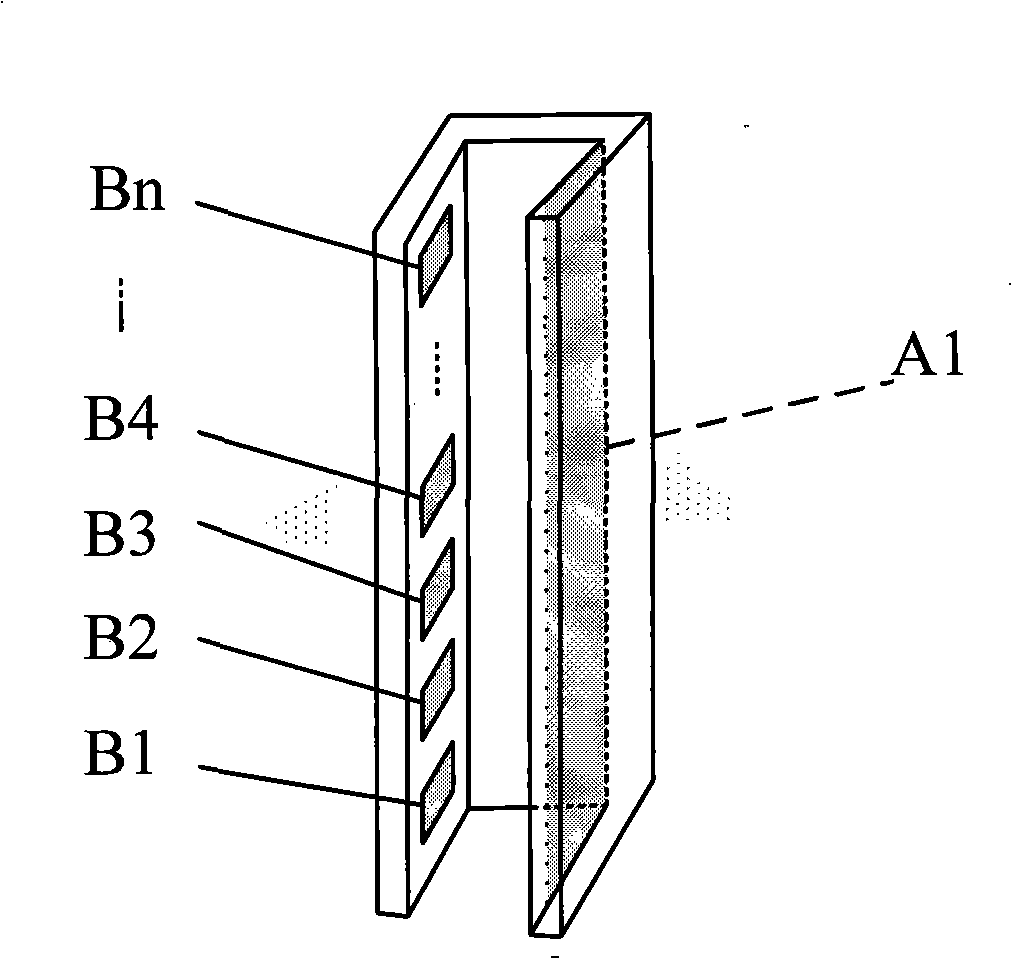

[0018] The structure of the capacitive digital level sensor of the present invention can be made into a variety of plate structures with inductive shapes, such as: flat plate structure, "V" shaped plate structure, "U" shaped plate structure and two parallel plate structure, etc. The sensing distance of the planar plate structure is 180 degrees, the sensing distance of the “V”-shaped plate structure is 0-180 degrees, and the sensing distance of the “U”-shaped plate structure and two parallel plate structures is two poles. The distance that the board can sense.

[0019] The setting of the pole plate of the capacitive digital level sensor of the present invention is a variety of settings that the two pole plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com