Multi-material part 3D printing device and printing method thereof

A 3D printing and multi-material technology, applied in the field of 3D printing, can solve the problems of lack of 3D printing devices for multi-material parts, the inability to realize the formation of metal and ceramic gradient parts, and the inability to prepare metal and ceramic multi-material gradient parts, etc., to achieve simple process , low cost, material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

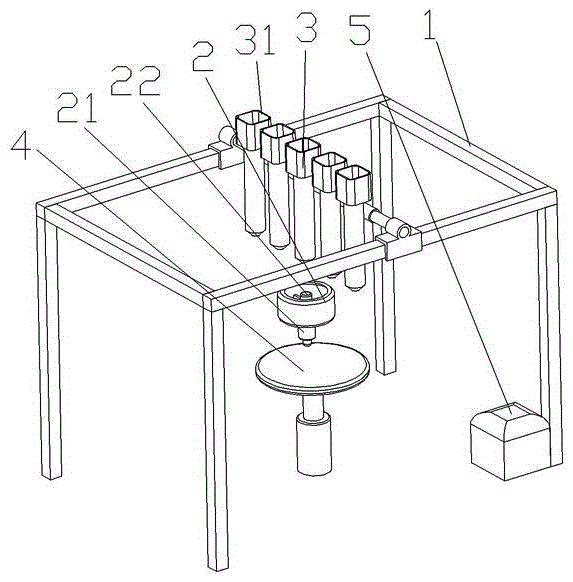

[0021] see figure 1 , figure 2 , image 3 and Figure 4 As shown, the multi-material parts 3D printing device of the present invention is composed of a support device 1, a controllable stirring extrusion head device 2, several digital material supply systems 3, a working platform 4 and a controller 5. The controllable stirring extrusion head 2 and the controller 5 are fixedly arranged on the support device 1, the digital material supply system 3 is fixedly arranged under several controllable stirring extrusion heads 2, and the working platform 4 is arranged in the support device 1; the controllable stirring extrusion head device 2 There is a print head 21 and an agitator 22 on it, and several digital material supply systems 3 have a discharge controller 31 .

[0022] The printing method of the multi-material part 3D printing device of the present invention is as follows:

[0023] 1: Preparation of mixed slurry, uniformly mix metal or ceramic powder with polymer binder and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com