Wireless digital terminal based real-time monitoring system and method for machined work-in-process parts

A digital terminal and real-time monitoring technology, applied in the direction of manufacturing computing systems, transmission systems, electrical components, etc., can solve problems such as no good solutions, achieve the effect of reducing backlogs and improving circulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

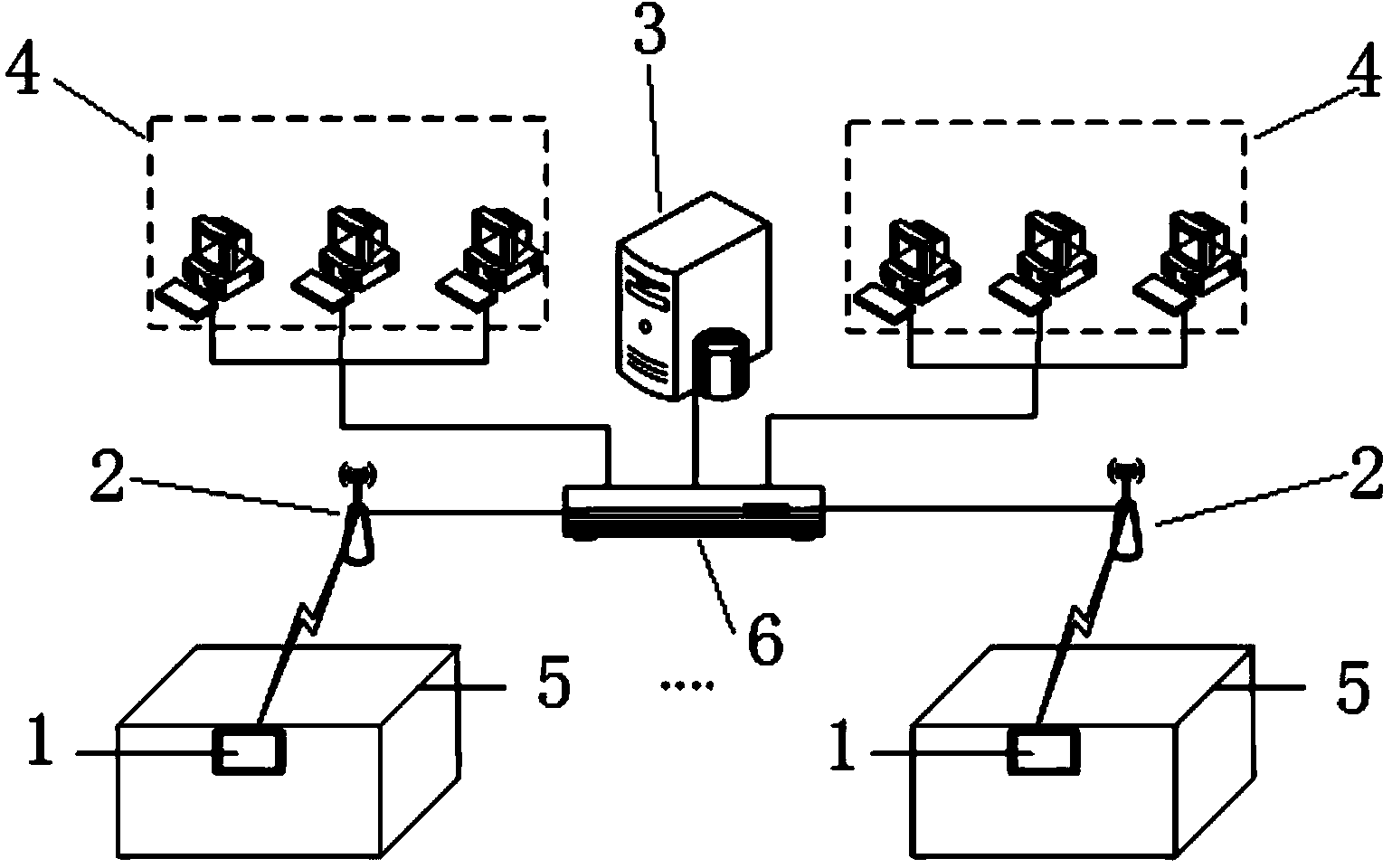

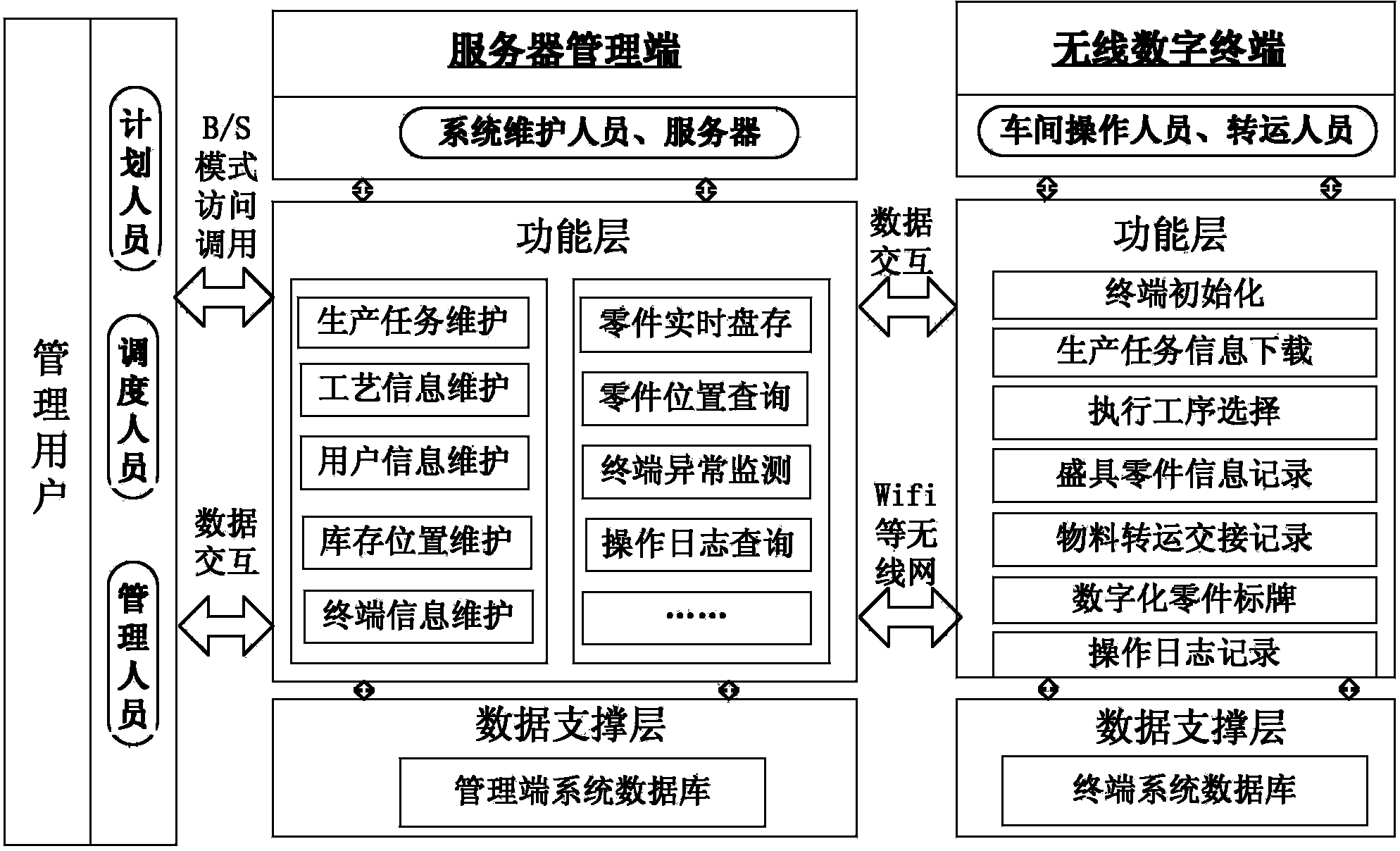

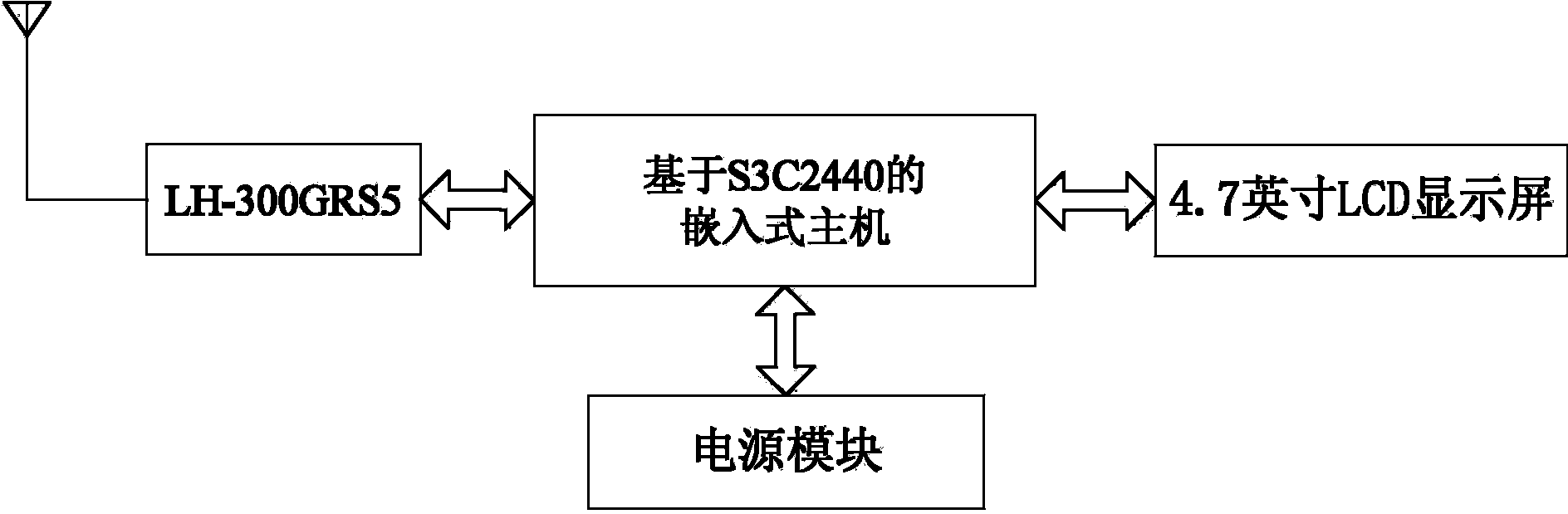

[0073] figure 1 The overall structure diagram of the real-time monitoring system for the machine-added WIP parts of the wireless digital terminal provided by the embodiment of the present invention, figure 2 It is a functional structural diagram of the real-time monitoring system for machine-in-process parts based on the Android wireless digital terminal of the present invention, image 3 For the present invention based on Android wireless digital terminal hardware block diagram, Figure 4 It is the terminal initialization flowchart of the real-time monitoring system for machine-added WIP parts based on the Android wireless digital terminal of the present invention, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com