Quick-charging polymer lithium ion battery based on carbon-based nanometer materials

A technology of carbon-based nanomaterials and lithium-ion batteries, which is applied in the direction of carbon nanotubes, nanocarbons, battery electrodes, etc., to achieve the effects of shortening the batching time, increasing flexibility, and improving fast charging and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

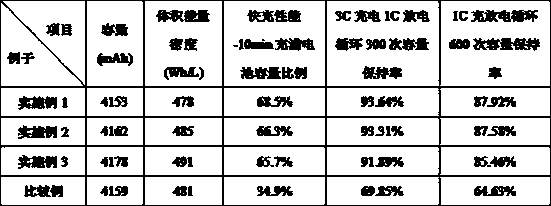

Embodiment 1

[0039] A kind of fast charging polymer lithium-ion battery based on carbon-based nanomaterials of the present embodiment, its preparation comprises the following steps:

[0040] (1) Preparation of positive electrode sheet:

[0041] The solid mass percentage of each component of the positive electrode is lithium cobaltate: graphene / carbon nanotube composite conductive agent: KS-6: PVDF=95.2:1.1:1.2:2.5, as follows:

[0042] A. Add polyvinylidene fluoride and N-methylpyrrolidone into the high-speed shear disperser according to the ratio of 0.05:0.95, stir in vacuum at high speed for 120min, and prepare the adhesive glue;

[0043] B. Add graphene / carbon nanotube composite conductive liquid and micron-sized conductive graphite KS-6 into a sand mill with zirconium beads for grinding and ultra-fine dispersion for 1.0h, the speed is 2600 rpm, and the size of the zirconia grinding beads is 1.1mm, turn on the cooling circulating water to cool down during the grinding process, and obta...

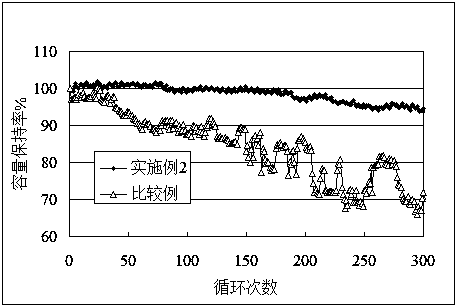

Embodiment 2

[0065] A kind of fast charging polymer lithium-ion battery based on carbon-based nanomaterials of the present embodiment, its preparation comprises the following steps:

[0066] (1) Preparation of positive electrode sheet:

[0067] The solid mass percentage of each component of the positive electrode is lithium cobaltate: graphene / carbon nanotube composite conductive agent: KS-6: PVDF=96.0:0.9:1.0:2.1, as follows:

[0068] A. Add polyvinylidene fluoride and N-methylpyrrolidone into the high-speed shear disperser according to the ratio of 0.05:0.95, stir in vacuum at high speed for 150min, and prepare the adhesive glue;

[0069] B. Add graphene / carbon nanotube composite conductive liquid and micron-sized conductive graphite KS-6 into a sand mill with zirconium beads for grinding and ultrafine dispersion for 1.2h, with a speed of 2800 rpm, and the size of the zirconia grinding beads is 1.1mm, turn on the cooling circulating water to cool down during the grinding process, and ob...

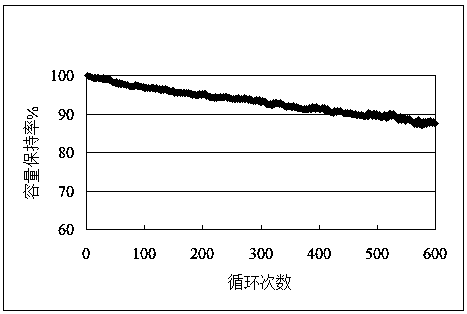

Embodiment 3

[0091] A kind of fast charging polymer lithium-ion battery based on carbon-based nanomaterials of the present embodiment, its preparation comprises the following steps:

[0092] (1) Preparation of positive electrode sheet:

[0093] The solid mass percentage of each component of the positive electrode is lithium cobaltate: graphene / carbon nanotube composite conductive agent: KS-6: PVDF=96.7:0.7:0.8:1.8, as follows:

[0094] A. Add polyvinylidene fluoride and N-methylpyrrolidone into the high-speed shear disperser according to the ratio of 0.05:0.95, stir at high speed in vacuum for 180min, and prepare the adhesive glue;

[0095] B. Add graphene / carbon nanotube composite conductive liquid and micron-sized conductive graphite KS-6 into a sand mill with zirconium beads for grinding and ultrafine dispersion for 1.5 hours, with a speed of 3000 rpm, and the size of the zirconia grinding beads is 1.1mm, turn on the cooling circulating water to cool down during the grinding process, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com