Printing ink powder raw material taking device

A powder and raw material technology, which is applied in the field of devices for taking ink powder raw materials, can solve problems such as increasing the time for ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

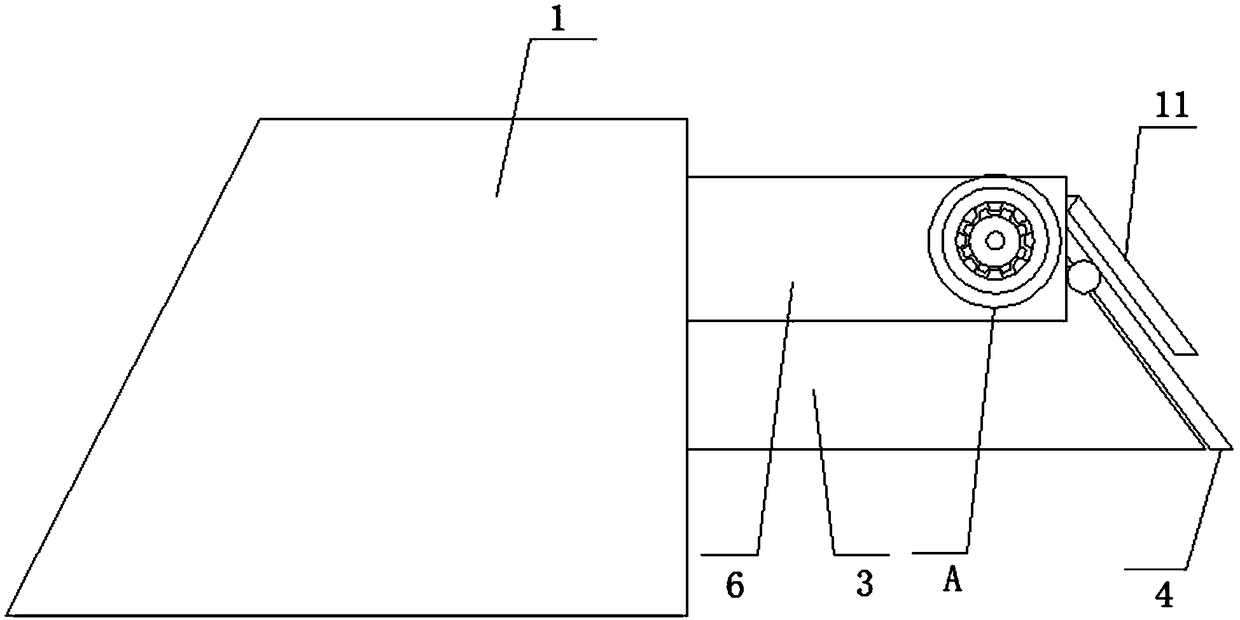

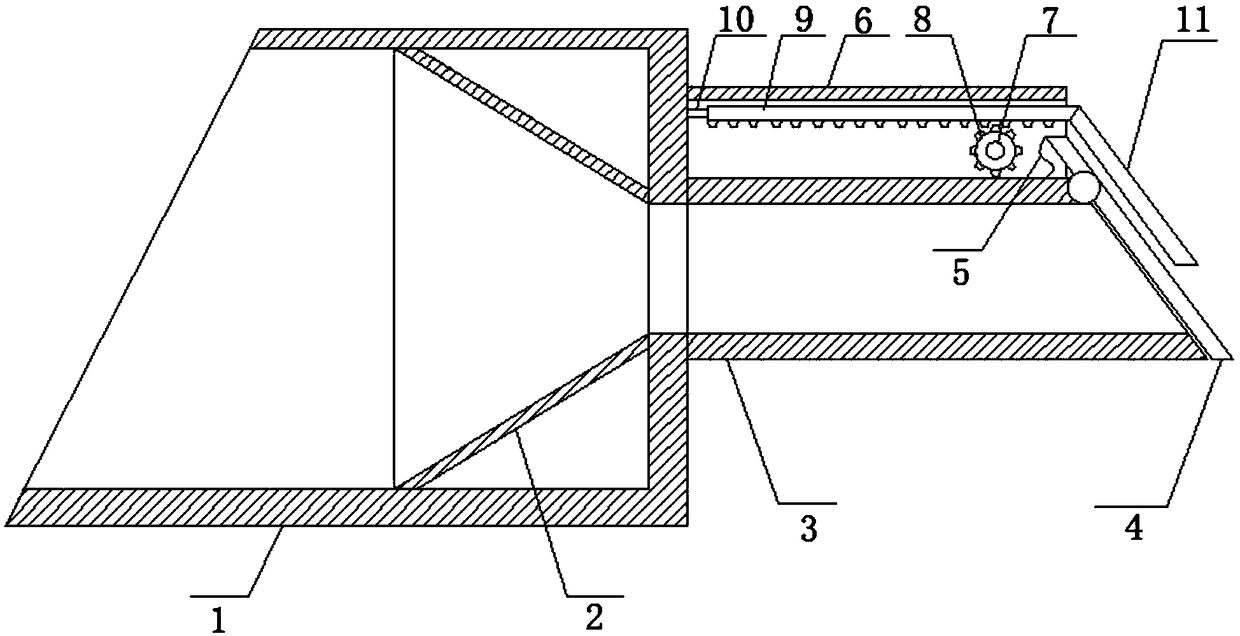

[0023] Such as Figure 1-3 As shown, a device for taking powdery ink raw materials includes a first cylinder 1, the first cylinder 1 is connected with a second cylinder 3, and the feed end of the first cylinder 1 and the second cylinder 3 away from each other, the longitudinal sections of the first cylinder 1 and the second cylinder 3 are right-angled trapezoids, the radius of the first cylinder 1 is twice the radius of the second cylinder 3, and the inner wall of the first cylinder 1 is connected with a material The bucket 2 and the right end of the hopper 2 are connected through the first cylinder 1 and the second cylinder 3 .

[0024] In this case, hold the second cylinder 3 in hand, insert the first cylinder 1 into the material storage device to take the material, when a large amount of raw materials need to be poured out, use the first cylinder 1 to dump, and when the weight of the raw materials needs to be poured out gradually When using the second cylinder body 3, the ...

Embodiment 2

[0026] Such as Figure 1-3 As shown, a device for taking powdery ink raw materials includes a first cylinder 1, the first cylinder 1 is connected with a second cylinder 3, and the feed end of the first cylinder 1 and the second cylinder 3 away from each other, the longitudinal sections of the first cylinder 1 and the second cylinder 3 are right-angled trapezoids, the radius of the first cylinder 1 is twice the radius of the second cylinder 3, and the inner wall of the first cylinder 1 is connected with a material Bucket 2, the right end of the hopper 2 passes through the first cylinder 1 and the second cylinder 3;

[0027] The upper end of the side wall of the second cylinder 3 away from the first cylinder 1 is hinged with a baffle 4, and a spring 5 is connected between the side wall of the baffle 4 close to the second cylinder 3 and the upper end surface of the second cylinder 3. A cylinder 1 is connected with a cover plate 6 near the side wall of the second cylinder 3, the ...

Embodiment 3

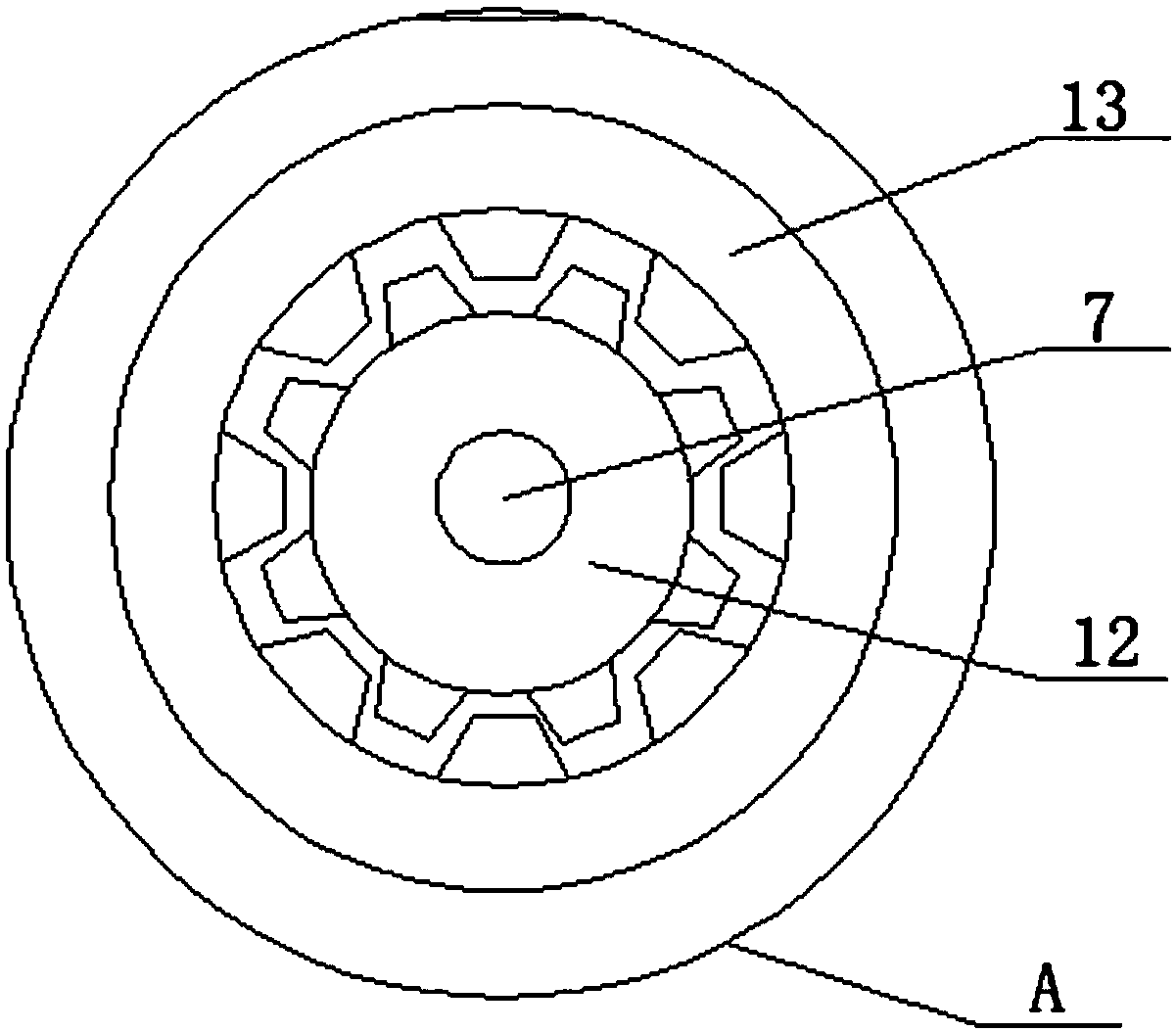

[0031] Such as Figure 1-4 As shown, a device for taking powdery ink raw materials includes a first cylinder 1, the first cylinder 1 is connected with a second cylinder 3, and the feed end of the first cylinder 1 and the second cylinder 3 away from each other, the longitudinal sections of the first cylinder 1 and the second cylinder 3 are right-angled trapezoids, the radius of the first cylinder 1 is twice the radius of the second cylinder 3, and the inner wall of the first cylinder 1 is connected with a material The bucket 2 and the right end of the hopper 2 are connected through the first cylinder 1 and the second cylinder 3 .

[0032] The upper end of the side wall of the second cylinder 3 away from the first cylinder 1 is hinged with a baffle 4, and a spring 5 is connected between the side wall of the baffle 4 close to the second cylinder 3 and the upper end surface of the second cylinder 3. A cylinder 1 is connected with a cover plate 6 near the side wall of the second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com