Petroleum coke high polymer modified asphalt waterproof coiled material and preparation method thereof

A technology of bitumen waterproofing membrane and petroleum bitumen, which is applied in building construction, building insulation materials, textiles and papermaking, etc. The effect of consumption and reduction of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

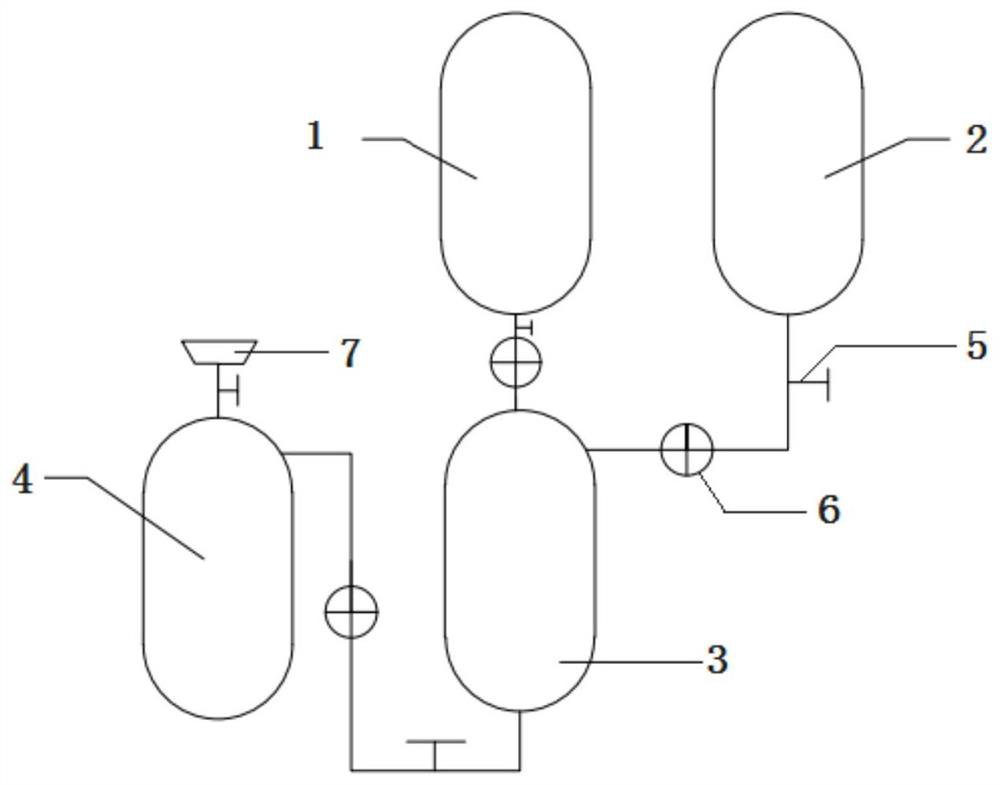

[0043] The following examples all adopt the following preparation method to prepare, comprising the following steps:

[0044] S1 Self-adhesive coating material preparation, specifically including the following steps:

[0045] A1 Add 70#-100# petroleum asphalt, base oil, and tackifier into the asphalt reactor 1 according to the proportion and mix them, stir at a low speed of 15-20Hz and heat until the temperature of the asphalt reaches 180°C, and add SBS thermoplastic elastomer according to the proportion Body rubber, SBR styrene-butadiene rubber powder and petroleum coke. When the temperature reaches 180°C, carry out high-speed stirring at a frequency of 45-50 Hz and keep warm for 1.5-3 hours until the SBS thermoplastic elastomer rubber and SBR styrene-butadiene rubber powder are melted. Disperse evenly to obtain petroleum coke modified material;

[0046] A2 Add 70#-100# petroleum asphalt into the rubber powder reactor 2 according to the proportion, stir at a low speed of 15-...

Embodiment 1

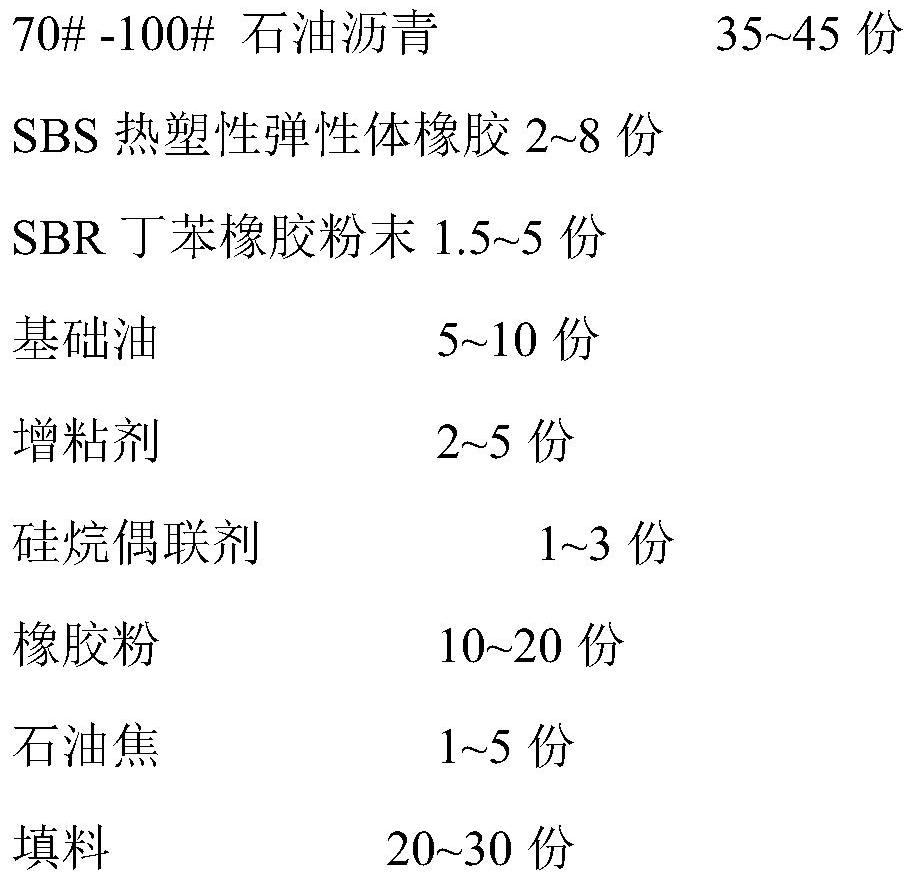

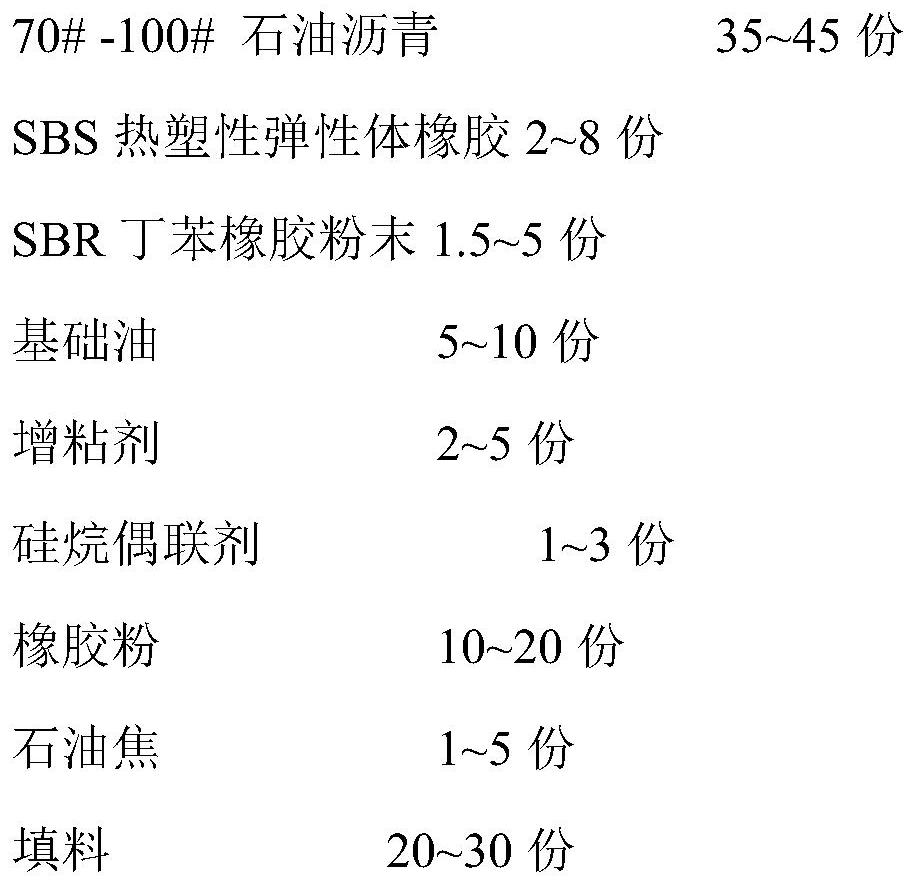

[0055] In this embodiment, an asphalt waterproof membrane with petroleum coke added as a modifier includes a base layer and a self-adhesive coating layer arranged on the upper and lower surfaces of the base base layer, and the self-adhesive coating layer on the upper surface of the base base layer An upper surface covering layer is arranged above the cover layer, and a lower surface covering layer is arranged below the self-adhesive coating layer on the lower surface of the base layer, and the self-adhesive coating layer includes the following components calculated in parts by weight:

[0056]

[0057] In the present embodiment, the 70#-100# petroleum asphalt adopts 70# petroleum asphalt, the tackifier adopts terpene resin, the rubber powder is 200 mesh tire rubber powder, and the petroleum coke is 200 mesh. The filler is 200 mesh talcum powder.

[0058] In this embodiment, the base layer is 200g / m 2 The long-fiber polyester tire, the upper surface covering layer is a PE f...

Embodiment 2

[0061] In this embodiment, an asphalt waterproof membrane with petroleum coke added as a modifier includes a base layer and a self-adhesive coating layer arranged on the upper and lower surfaces of the base base layer, and the self-adhesive coating layer on the upper surface of the base base layer An upper surface covering layer is arranged above the cover layer, and a lower surface covering layer is arranged below the self-adhesive coating layer on the lower surface of the base layer, and the self-adhesive coating layer includes the following components calculated in parts by weight:

[0062]

[0063] In the present embodiment, the 70#-100# petroleum asphalt adopts 70# petroleum asphalt, the tackifier adopts terpene resin, the rubber powder is 200 mesh tire rubber powder, and the petroleum coke is 200 mesh. The filler is 200 mesh talcum powder.

[0064] In this embodiment, the base layer is 200g / m 2 The long-fiber polyester tire, the upper surface covering layer is a PE f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com