Continuous ultrafine grinder

An ultra-fine pulverizer and vertical plate technology, which is applied in grain processing and other directions, can solve the problems of reducing the working efficiency of the pulverizer, unfavorable formation of production lines, inconvenient connection, etc., so as to improve the pulverization processing capacity, reduce labor costs, and save operating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

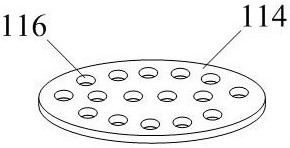

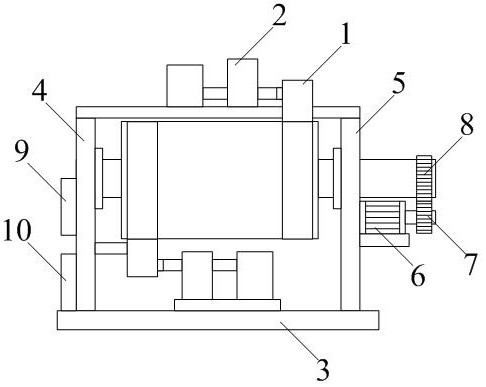

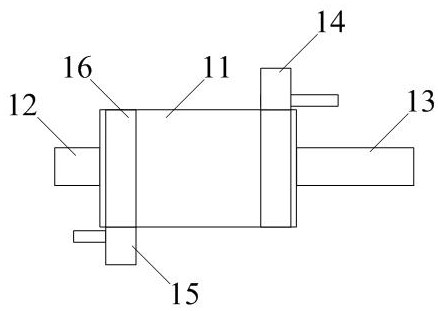

[0028] as attached figure 1 to attach Image 6 shown

[0029] The present invention provides a continuous ultrafine pulverizer, comprising a box assembly 1, a vacuum assembly 2, a bottom plate 3, a first vertical plate 4, a second vertical plate 5, a driving motor 6, a driving gear 7, a driven gear 8, The electric control cabinet 9 and the PLC controller 10, the first vertical plate 4 is installed on one side above the bottom plate 3; the second vertical plate 5 is installed on the other side above the bottom plate 3; the box assembly 1 is installed on the first Above between the vertical plate 4 and the second vertical plate 5, and the end of the box assembly 1 penetrates to the side of the second vertical plate 5 away from the first vertical plate 4; two vacuum components 2 are used, and the vacuum components 2 are respectively Installed on the base plate 3 and the first vertical plate 4; the driving motor 6 is installed on the middle position of the second vertical plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com