Batching apparatus for cultural medium book and periodical printing

A technology for media and books, applied in the field of batching devices for printing cultural media books and periodicals, can solve the problems of slow batching, time-consuming and labor-intensive, and low batching efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

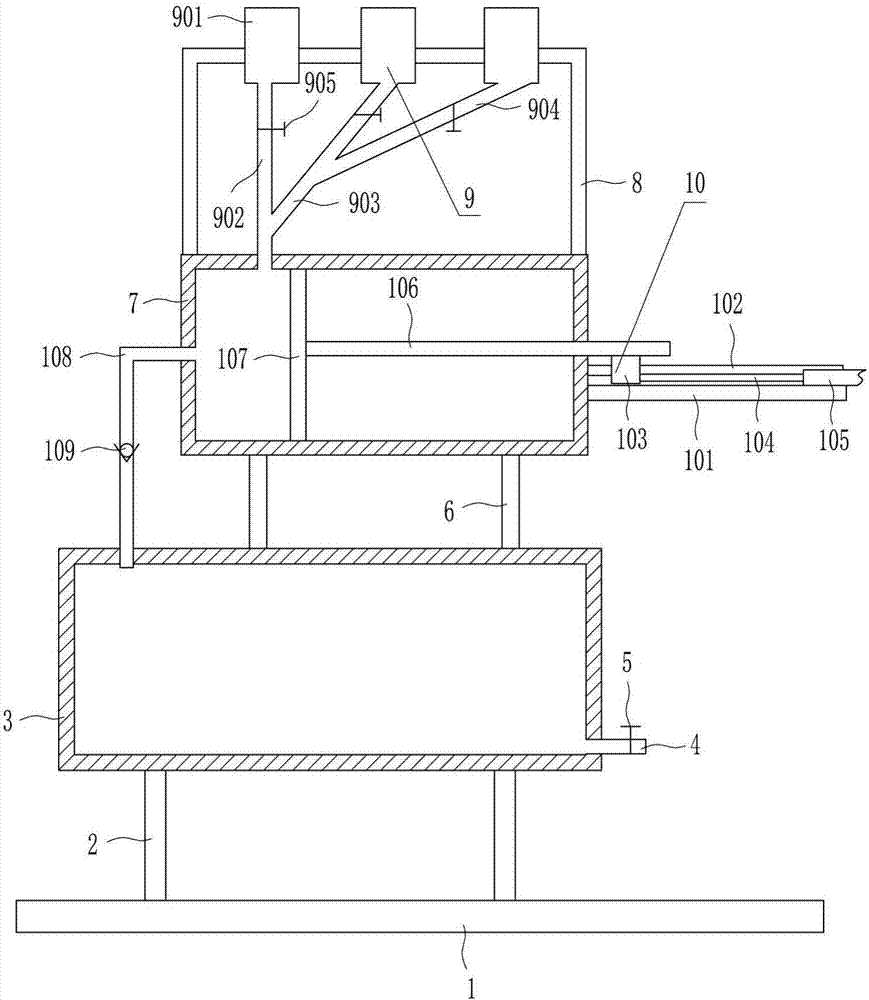

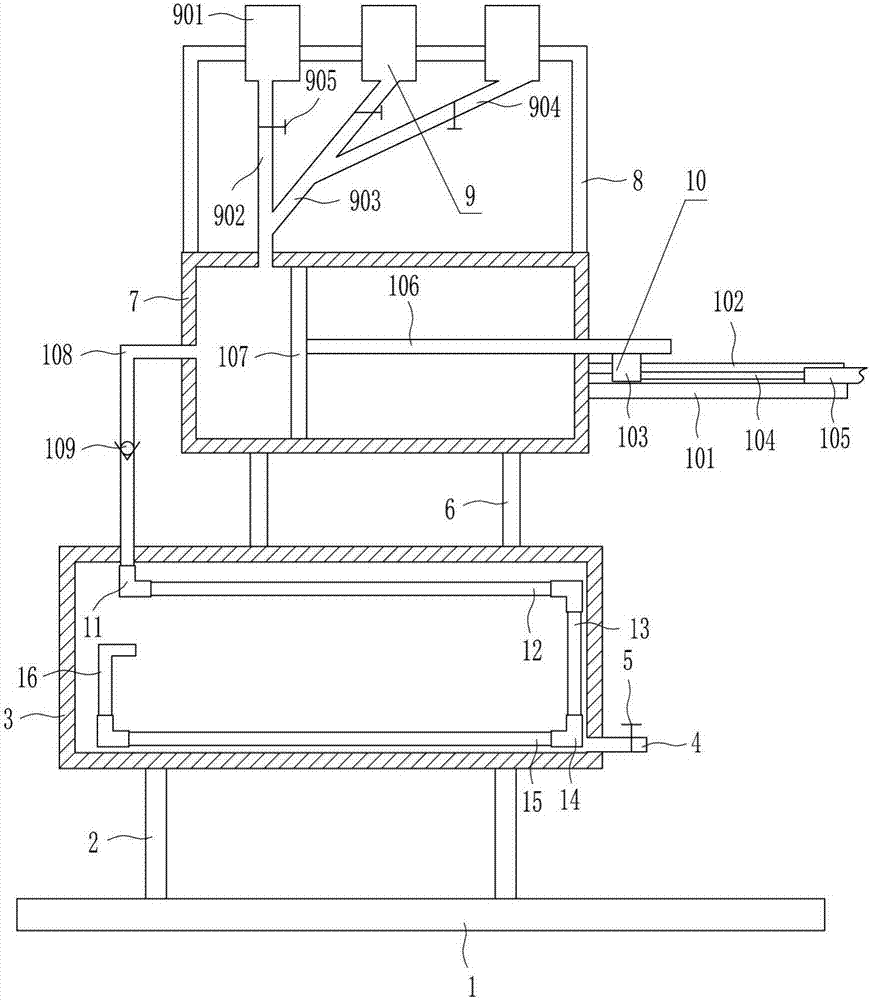

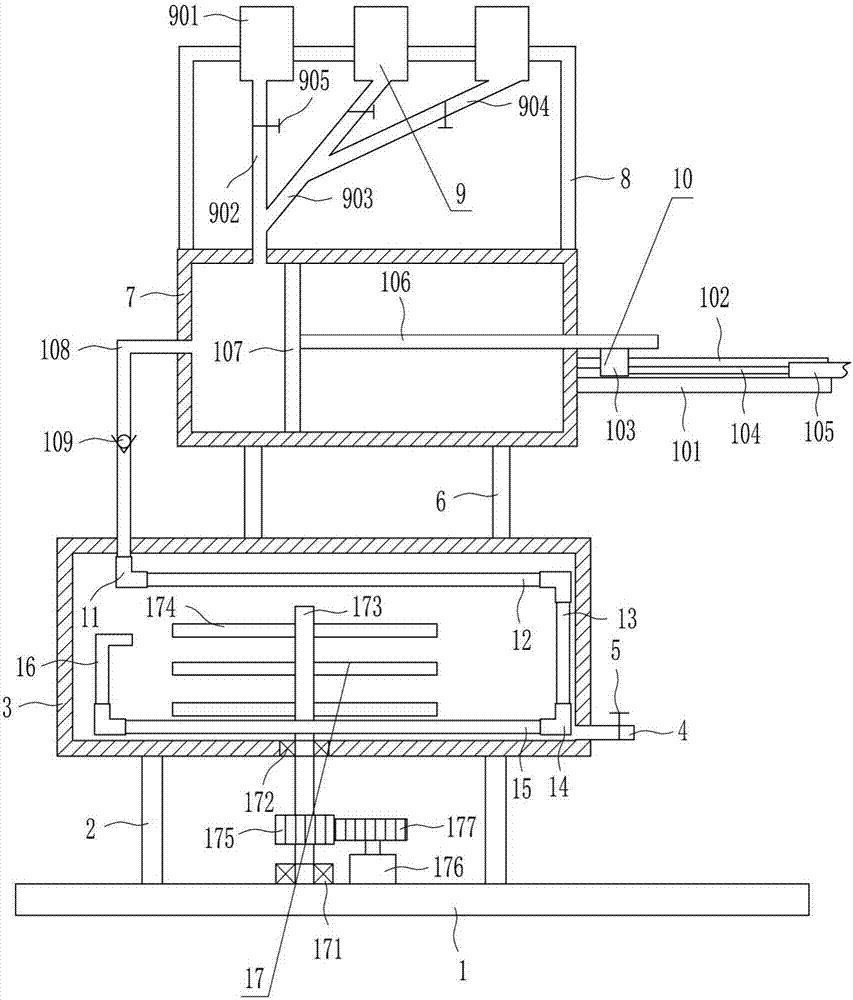

Embodiment 1

[0035] A batching device for printing cultural media books and periodicals, such as Figure 1-5 As shown, it includes bottom plate 1, first support plate 2, first box body 3, first liquid outlet pipe 4, first valve 5, second support plate 6, second box body 7, bracket 8, first lower The feeding device 9 and the second feeding device 10, the top of the bottom plate 1 is vertically connected with two first support plates 2 by bolts, the two first support plates 2 are left and right symmetrical, and the top of the two first support plates 2 Connected with the first box body 3, the lower right side of the first box body 3 is connected with the first liquid outlet pipe 4, the first liquid outlet pipe 4 is provided with the first valve 5, and the top of the first box body 3 is vertically connected by bolts. Two second support plates 6 are directly connected, and the two second support plates 6 are left and right symmetrical, and a second box body 7 is connected between the tops of t...

Embodiment 2

[0037] A batching device for printing cultural media books and periodicals, such as Figure 1-5 As shown, it includes bottom plate 1, first support plate 2, first box body 3, first liquid outlet pipe 4, first valve 5, second support plate 6, second box body 7, bracket 8, first lower The feeding device 9 and the second feeding device 10, the top of the bottom plate 1 is vertically connected with two first support plates 2 by bolts, the two first support plates 2 are left and right symmetrical, and the top of the two first support plates 2 Connected with the first box body 3, the lower right side of the first box body 3 is connected with the first liquid outlet pipe 4, the first liquid outlet pipe 4 is provided with the first valve 5, and the top of the first box body 3 is vertically connected by bolts. Two second support plates 6 are directly connected, and the two second support plates 6 are left and right symmetrical, and a second box body 7 is connected between the tops of t...

Embodiment 3

[0040] A batching device for printing cultural media books and periodicals, such as Figure 1-5 As shown, it includes bottom plate 1, first support plate 2, first box body 3, first liquid outlet pipe 4, first valve 5, second support plate 6, second box body 7, bracket 8, first lower The feeding device 9 and the second feeding device 10, the top of the bottom plate 1 is vertically connected with two first support plates 2 by bolts, the two first support plates 2 are left and right symmetrical, and the top of the two first support plates 2 Connected with the first box body 3, the lower right side of the first box body 3 is connected with the first liquid outlet pipe 4, the first liquid outlet pipe 4 is provided with the first valve 5, and the top of the first box body 3 is vertically connected by bolts. Two second support plates 6 are directly connected, and the two second support plates 6 are left and right symmetrical, and a second box body 7 is connected between the tops of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com