Burdening method based on electromagnetic chuck

An electromagnetic chuck and magnetic disk technology, which is applied in the direction of electrical program control, general control system, sequence/logic controller program control, etc., can solve the problems of poor control of manual feeding time, lower batching efficiency, and excessive feeding, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

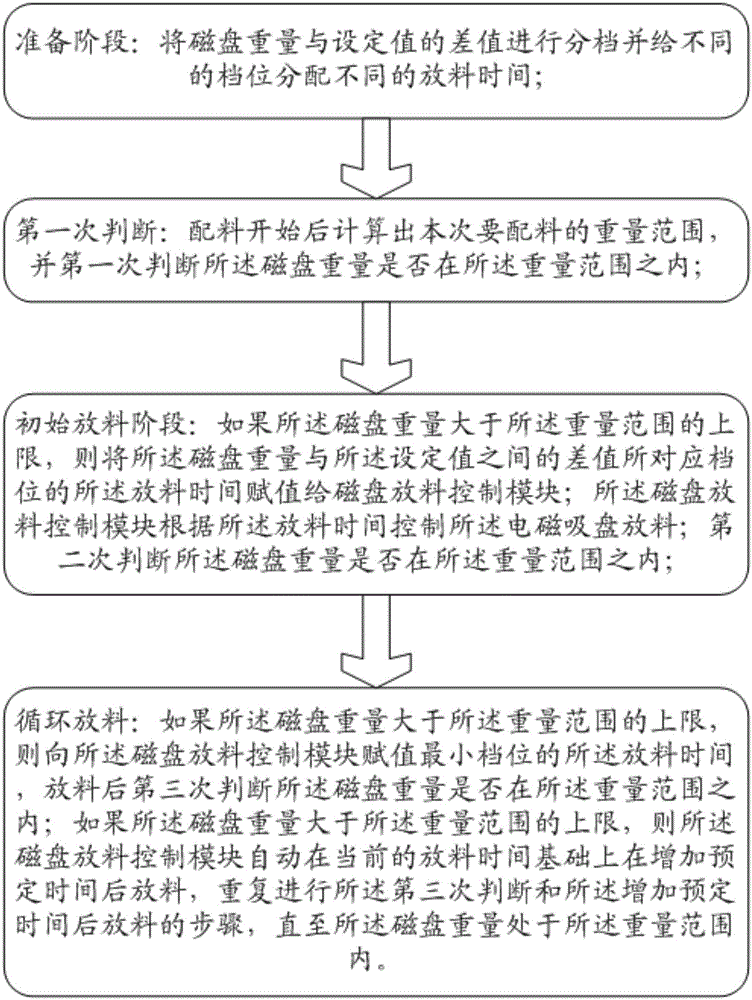

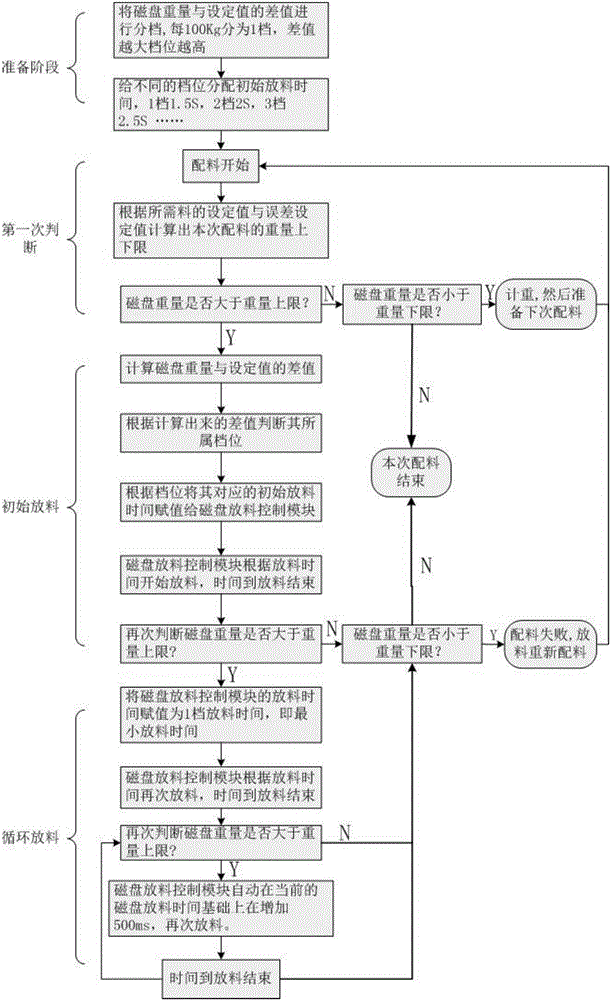

[0022] refer to figure 1 , the method for adopting electromagnetic chuck batching of the present invention, comprises the steps:

[0023] Preparation stage: classify the difference between the disk weight and the set value and assign different discharge times to different gears;

[0024] The first judgment: calculate the weight range of the secondary ingredients after the batching starts, and judge whether the disk weight is within the weight range for the first time;

[0025] Initial discharge: if the weight of the disk is greater than the upper limit of the weight range, assign the discharge time of the gear corresponding to the difference between the disk weight and the set value to the disk discharge control module; the disk discharge control module according to the discharge time Time control electromagnetic chuck feeding; the second time to judge whether the weight of the disk is within the weight range;

[0026] Circular discharge: if the weight of the disk is greater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com