Batching device for seasoning powder bag production, and implementation method thereof

A technology for seasoning and powder packaging, which is used in transportation and packaging, chemical instruments and methods, mixers with rotary stirring devices, etc. The effect of batching interruption and improving batching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

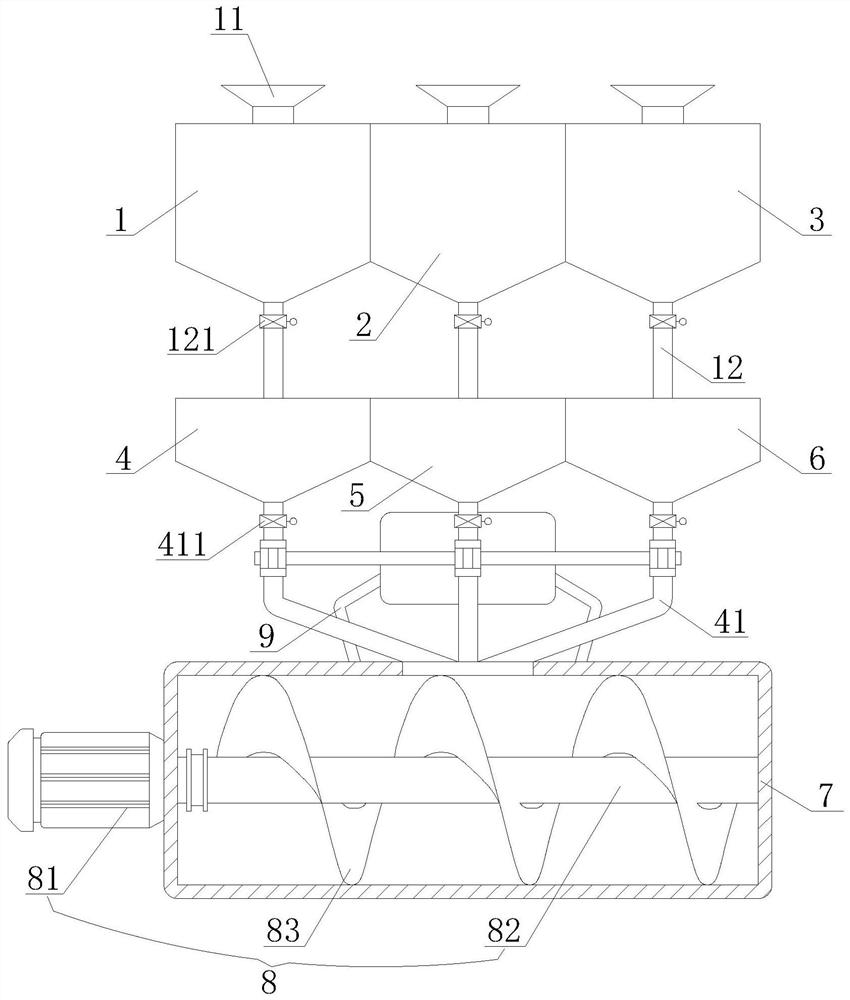

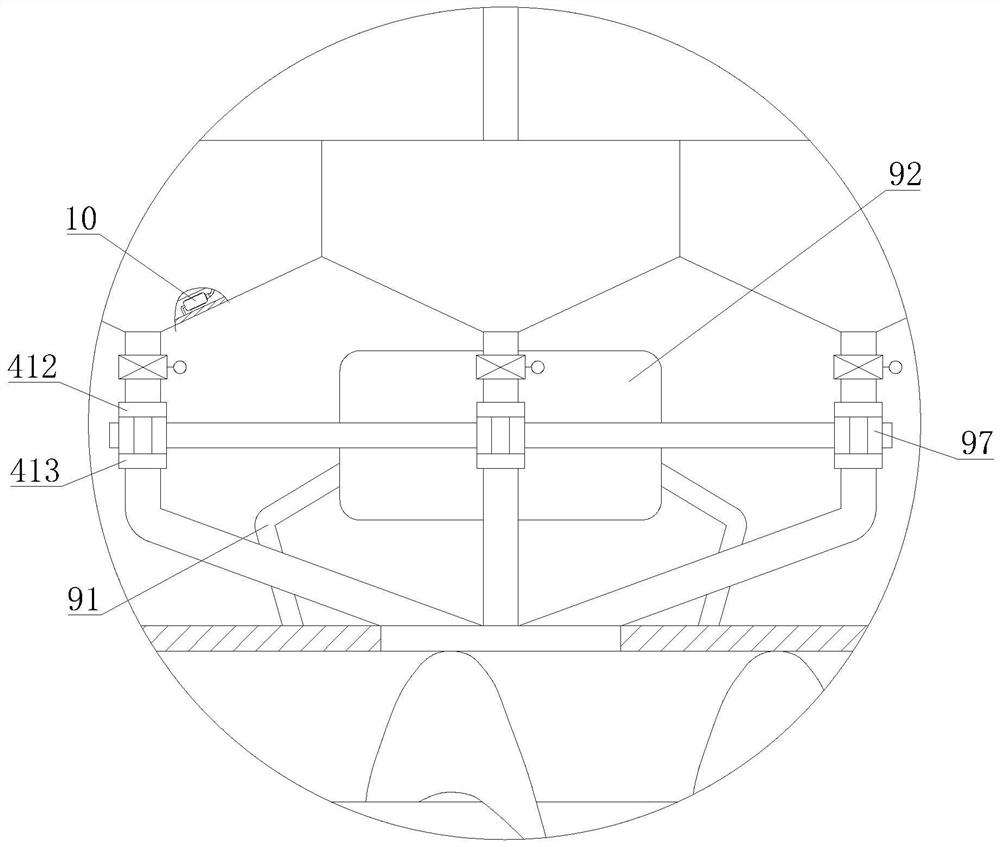

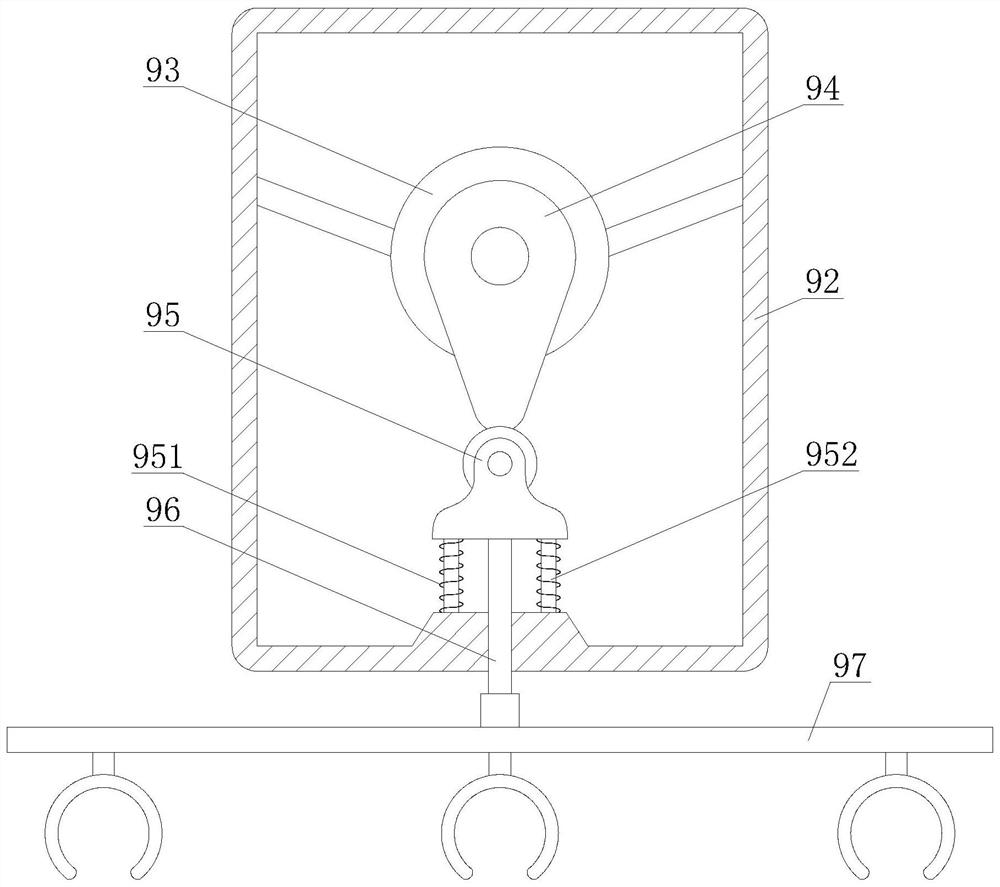

[0032] In order to better demonstrate the implementation process of the batching device for seasoning powder packet production, this embodiment now proposes an implementation method for the batching device for seasoning powder packet production, including the following steps:

[0033] S1: After different raw materials enter the storage tank A1, storage tank B2 and storage tank C3 respectively through the feed port 11, open the solenoid valve 121, close the discharge valve 411, the storage tank A1, storage tank B2 and the raw materials in the storage tank C3 respectively enter the weighing chamber A4, the weighing chamber B5 and the weighing chamber C6 through the feed pipe 12 for weighing;

[0034] S2: When the raw materials in weighing chamber A4, weighing chamber B5 and weighing chamber C6 reach the specified weight, close the solenoid valve 121 and open the discharge valve 411. At this time, weighing chamber A4, weighing chamber B5 and weighing chamber The raw materials in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com