Automatic batching technological process and automatic batching machine

A technology of automatic batching and process flow, which is applied in the field of automatic batching machine and automatic batching process, can solve the problems of limited types of ingredients, low degree of automation, troublesome batching operation, etc., and achieves many varieties, high degree of automation and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

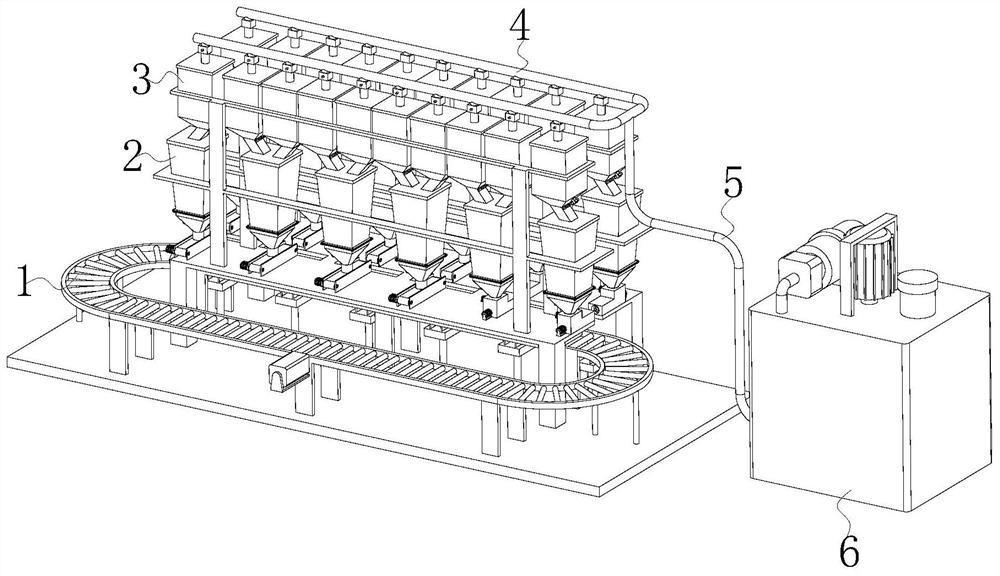

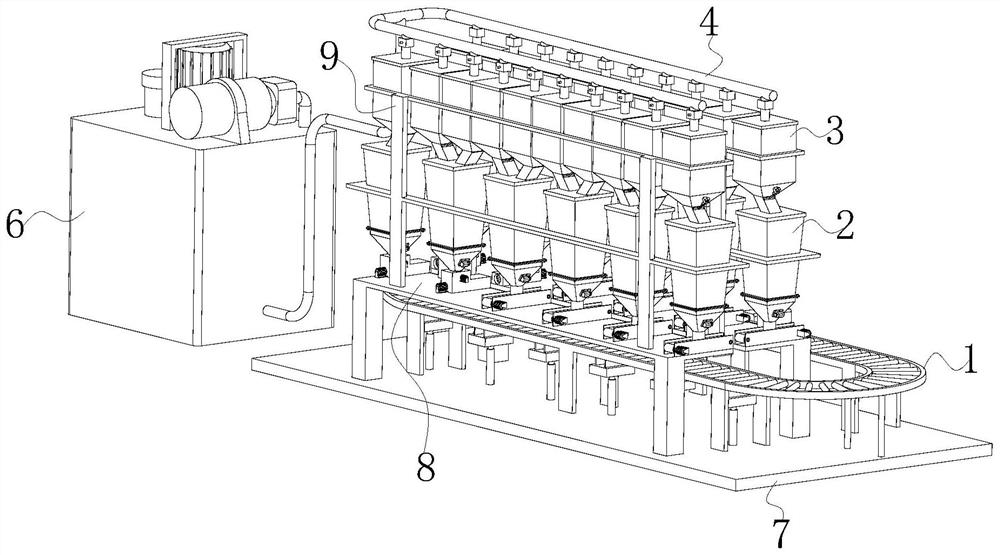

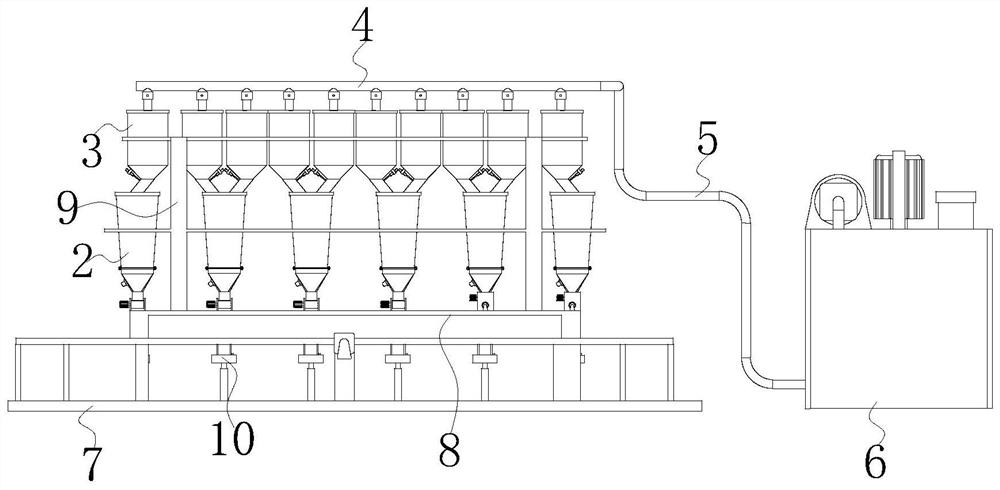

[0040]The technical solutions in the embodiments of the present invention will be apparent from the drawings in the embodiment of the present invention.

[0041]The present invention is an automatic ingredient process, and specifically includes the following steps:

[0042]1. Add the raw material for the production of a nitrile rubber foam, and in the negative pressure feed mechanism, and under the action of the negative pressure, the raw material in the negative pressure feed mechanism is delivered to the distribution tube; A feed tube is connected to each of the storage tubes and each of the storage valves, and is equipped with a switch valve on the feed tube. The switch of the feed tube is controlled by the PLC controller. The switch control of the switch valve, which is transported into the specified storage bucket in the designated storage bucket, and the raw material stored in the storage bucket is a powdered material and a particulate material.

[0043]2. Control the lower plate plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com