Fully polished glazed ceramic tile with a real stone effect and production process thereof

A manufacturing process and technology for ceramic tiles, applied in the field of ceramic tile manufacturing, can solve the problems of less texture change, unreachable contrast between green body and surface texture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

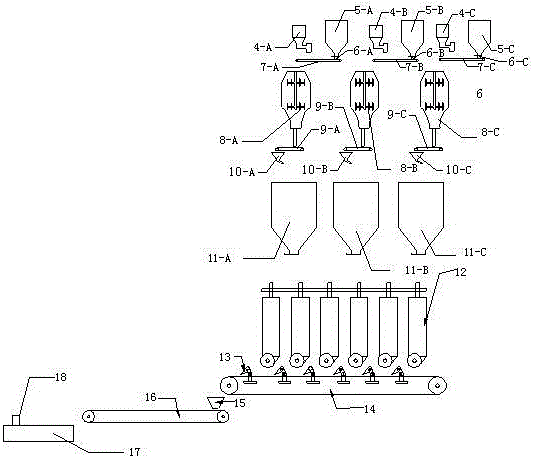

[0080] The first color matching device transports the pure yellow material and the orange material to the first mixer through the first color matching belt in a mass ratio of 7:5, and after mixing evenly, transports it to the color material bin 4-A for storage.

[0081] The second color matching device transports the pure yellow material, orange material and coffee color material to the second mixer through the second color matching belt according to the mass ratio of 13:28:7, and transports them to the color material bin 4-B for storage after mixing evenly.

[0082] The third color matching device transports the orange material, coffee color material and black color material to the third mixer through the third color matching belt according to the mass ratio of 8:33:56, and transports them to the color material bin 4-C for storage after stirring evenly.

[0083] The base material bin 5-A transports the base body powder to the batching belt 7-A through the transition hopper 6-A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com