Preparation method of PU putamina having various textures and color diversification

A technology of color change and film shell manufacturing method, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of expensive mold production, difficult processing, expensive production cost, etc., to achieve rich choices, easy production, and low cost. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

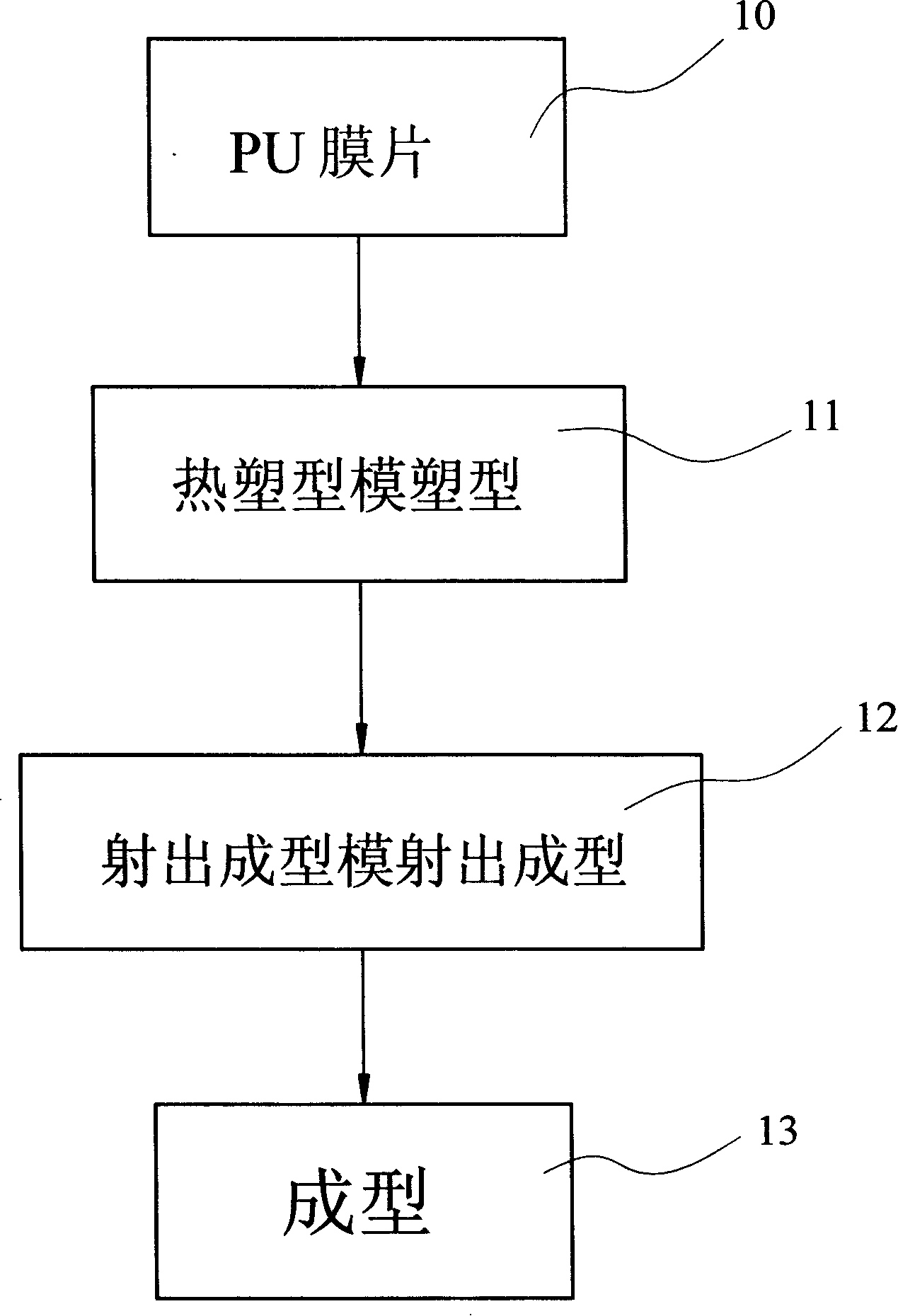

[0025] see figure 2 As shown, a kind of PU film shell manufacturing method with various textures and color changes, the manufacturing method of one embodiment is:

[0026] (a) PU film 10: it is a PU film with patterns and colors on the surface;

[0027] (b) Thermoplastic molding type 11: use a PU film with patterns and colors to be placed in a thermoplastic mold with a flat concave-convex mold with a shell surface shape, and then thermoplastically molded into a shell surface shape and a PU moldings with patterns and colors;

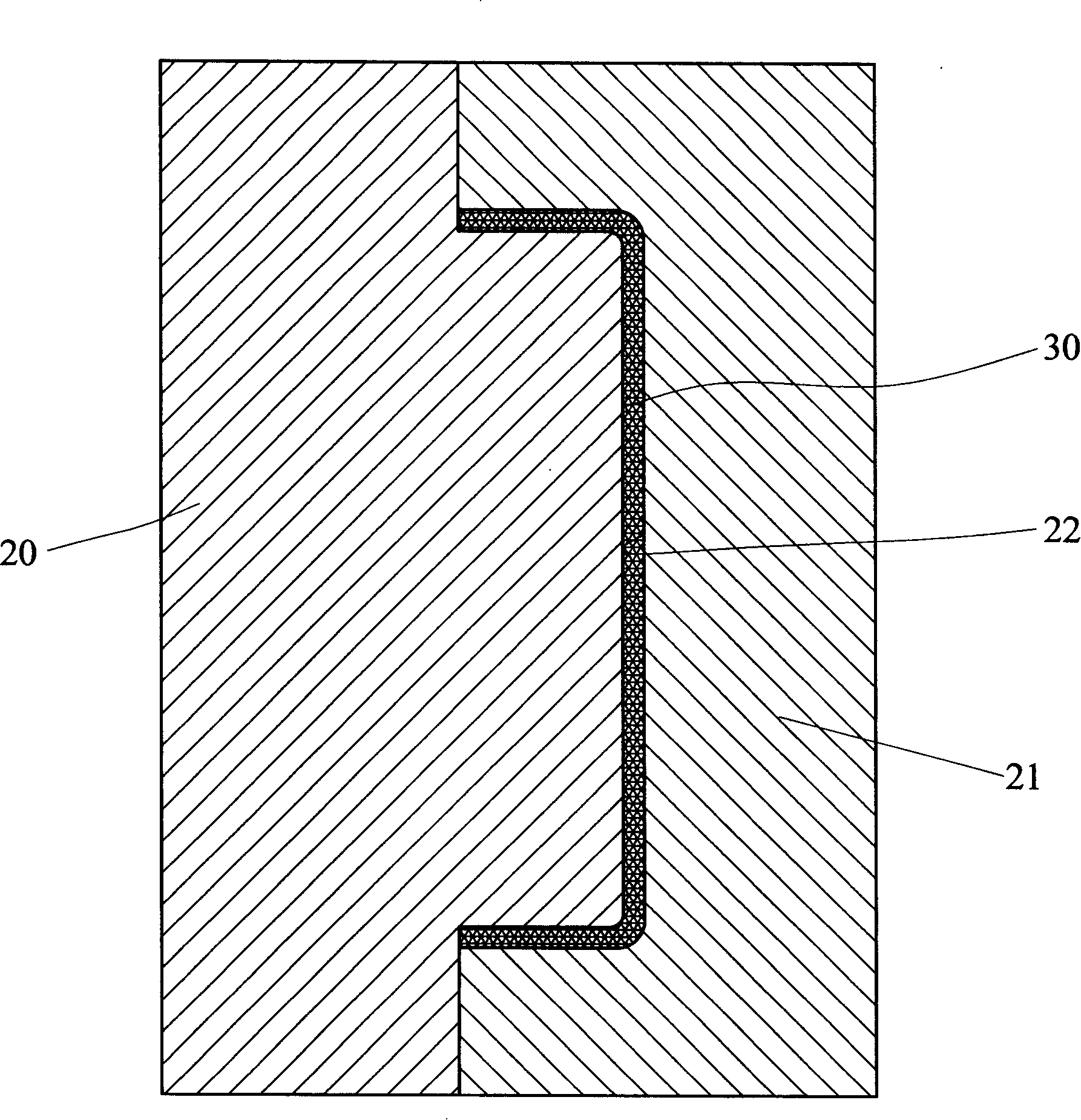

[0028] (c) Injection molding 12: The PU molded body with the shell surface pattern and the pattern and color is then placed in the cavity of the injection molding die, and the plastic material is injected into the mold to combine the plastic material and the PU molded body. cooling out;

[0029] (d) Molding 13: Molding into a shell with patterns and colors on the surface.

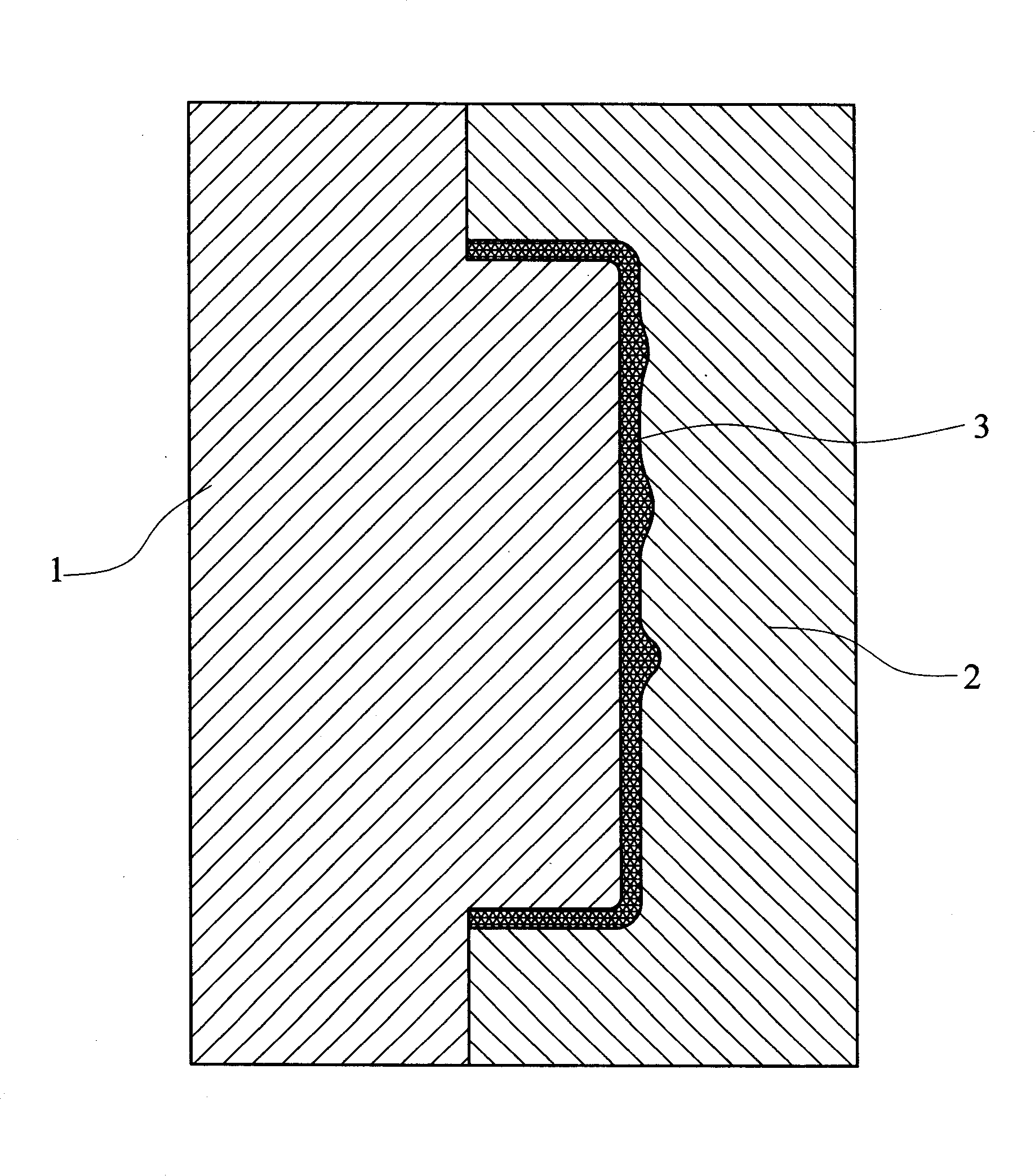

[0030] see image 3 As shown, it is an embodiment of the thermoplastic mold....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com