Material preparing control method and material preparing control system

A control system and control method technology, applied in chemical instruments and methods, mixer accessories, dissolution, etc., can solve problems such as unfavorable automatic processing and production, slow batching speed, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

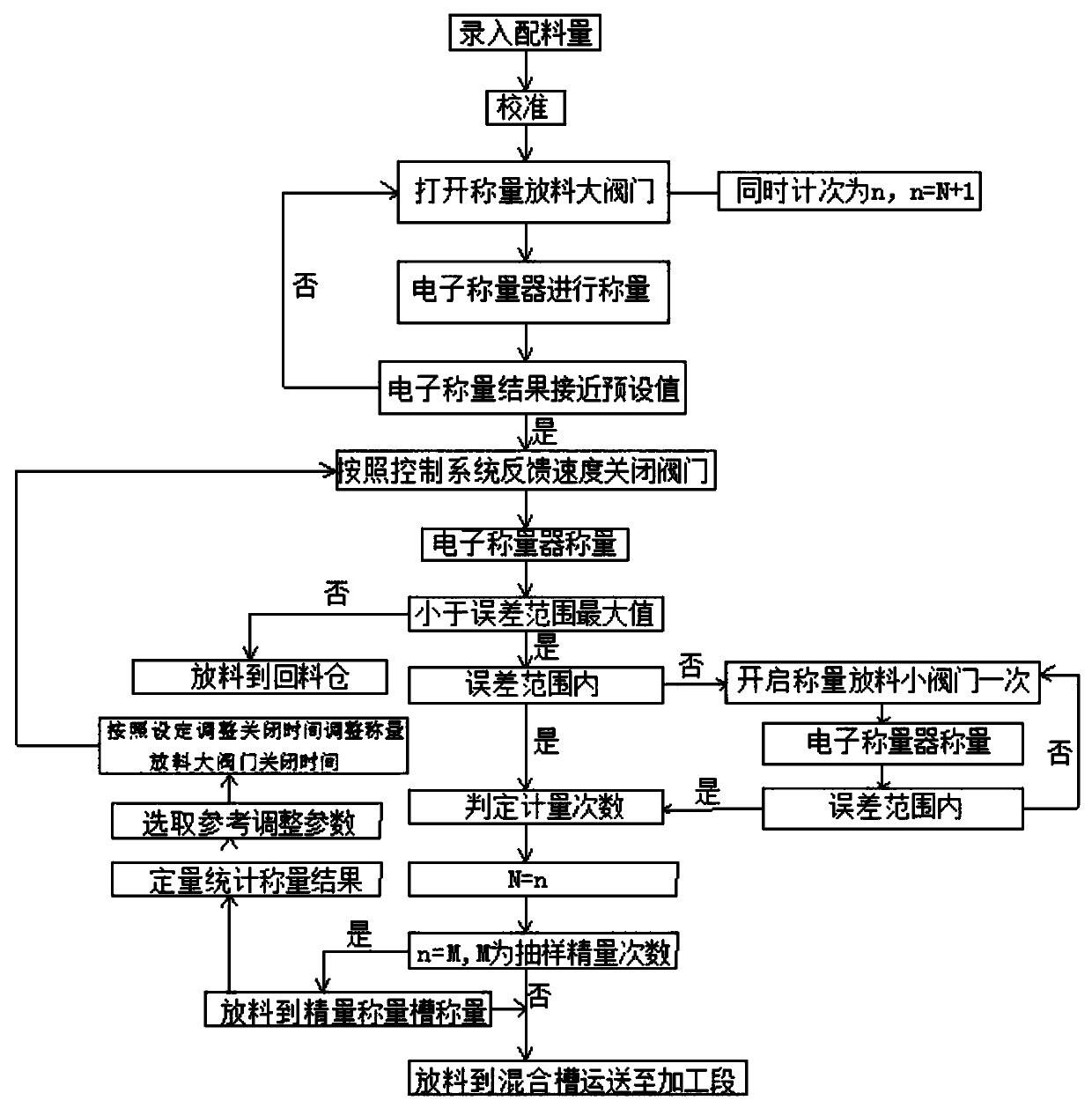

[0024] see figure 1 The flowchart of this specific embodiment discloses a batching control method, and the batching is controlled through the following steps:

[0025] Step 1. The input device on the control system inputs the batching amount of each material storage component for each storage tank of the material; feasible, for example, each storage tank may correspond to a setting component for setting the batching amount, including The adjustment button and the liquid crystal display screen have a controller for the entire control panel inside, which is connected with the control system, and the setting data is stored in the memory of the control system.

[0026] Step 2. Calibrate the electronic weighing device in the electronic weighing tank at the outlet of each storage tank and the electronic weighing device in the precise weighing tank. At this time, the calibration adopts the zero-return calibration in the electronic weighing device , Feasible, the electronic weighing ...

Embodiment 2

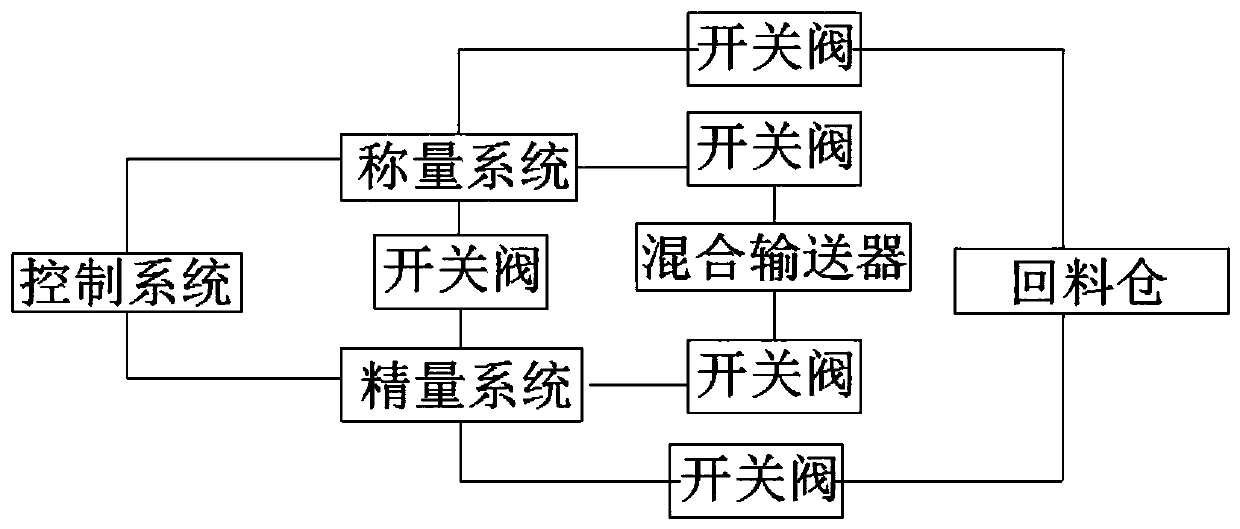

[0038] see figure 2 , this specific embodiment discloses a batching system applying the batching control method in Example 1, including a weighing system, a precision system, a control system and a mixing conveyor, and a switch is used between the weighing system and the precision system The valve is connected, the weighing system and the precision system are respectively connected to the mixing conveyor through the switch valve, the weighing system and the precision system are respectively electrically connected to and controlled by the control system, and the feeding part of the weighing system is respectively connected through the large and small The feeding valve feeds the material, and the switching speed of the large feeding valve is controlled by the control system. In addition, the weighing system and precision system can also be connected to the return bin through the switch valve, which is used to return the material whose weighing exceeds the range to the storage t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com