Color masterbatch automatic feeding equipment and feeding process

A technology of batching equipment and color masterbatch, which is applied in the direction of conveying bulk materials, conveyors, containers, etc., can solve the problems of low degree of automation of the batching system, low efficiency of automatic batching, and difficulty in tracing the production process. Continuity and reliability, reduced manual involvement, improved batching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to be able to understand the technical means of the present invention more clearly and implement it according to the contents of the description, the specific implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

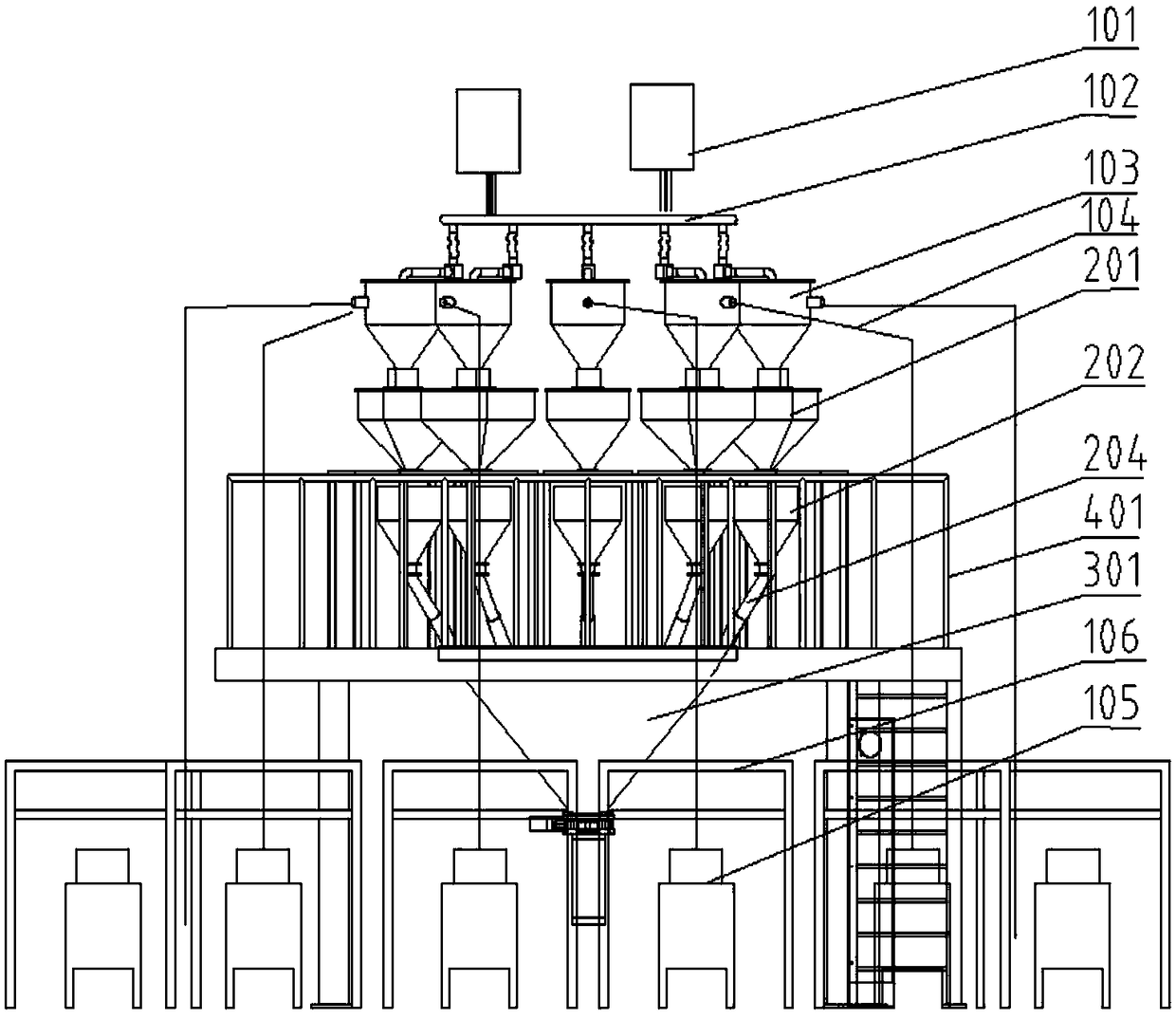

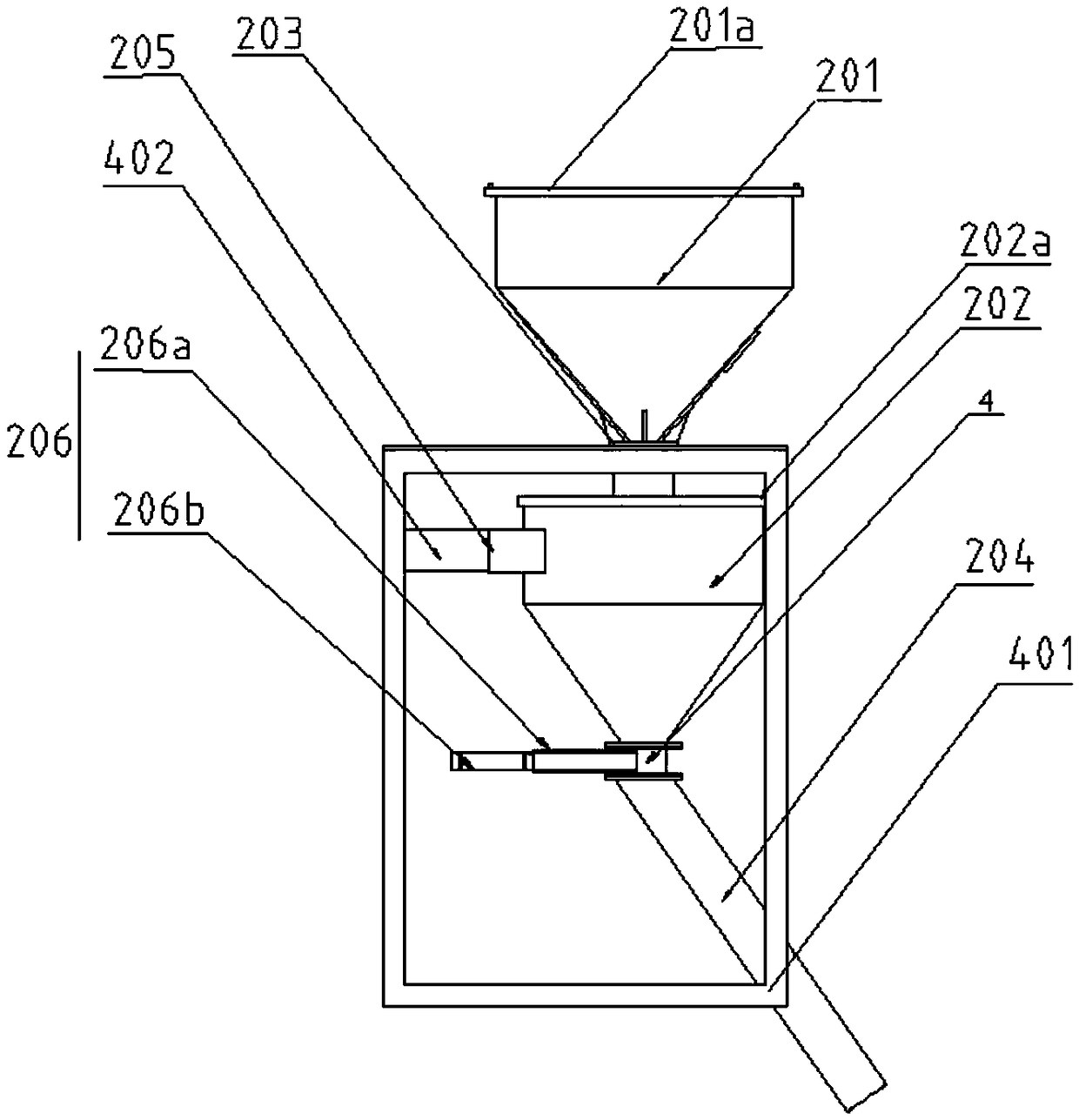

[0037] The invention discloses an automatic batching equipment for color masterbatch, which comprises a raw material feeding device, a weight-increasing batching device, a material collecting device and a control device. In this specific embodiment, there are ten stations arranged in circles.

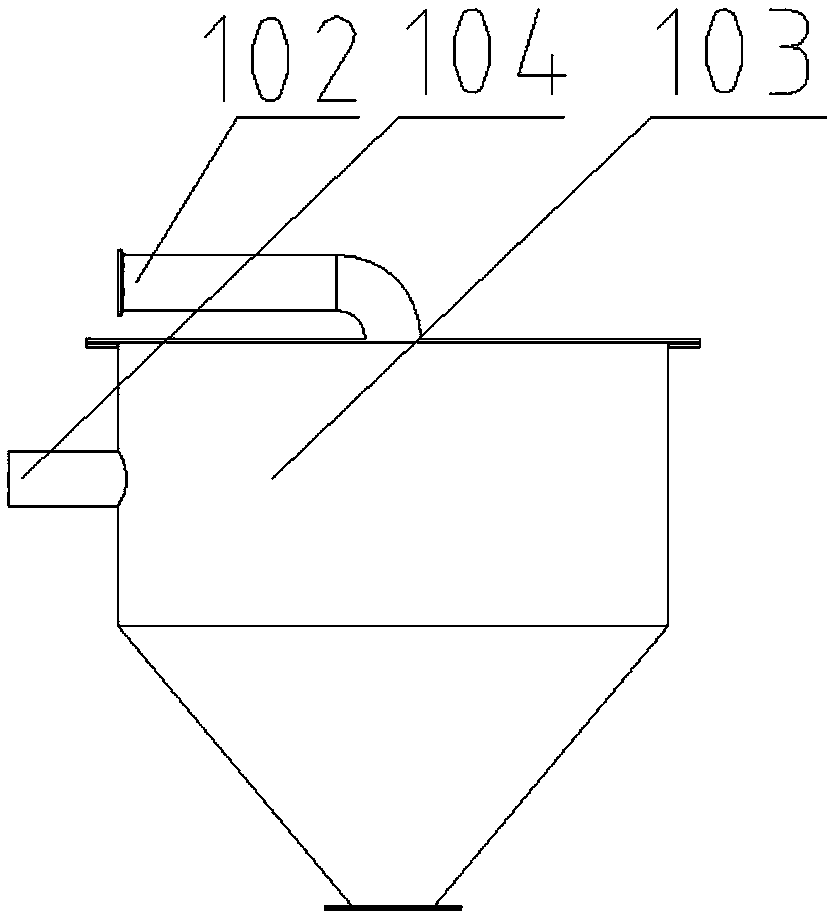

[0038] The raw material feeding device includes several blowers 101 located on the top floor of the working area, and each blower communicates with several vacuum hoppers 103 through vacuum pipes 102 . In this specific embodiment, the working area is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com