Patents

Literature

34results about How to "Realize drying operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

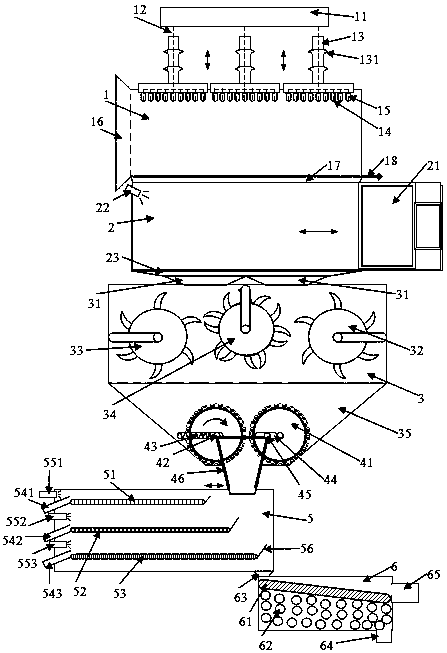

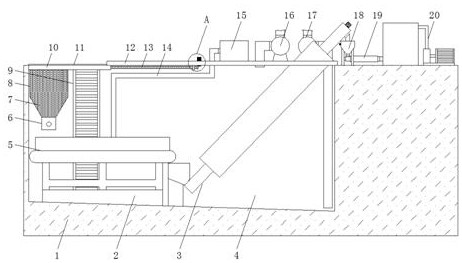

Multi-function waste pile classified treatment recycling device for garment processing plant

InactiveCN111472118AAchieve recyclingKeep dryLiquid/gas/vapor removal by squeezing rollersTreatment involving filtrationSprayerEnvironmental engineering

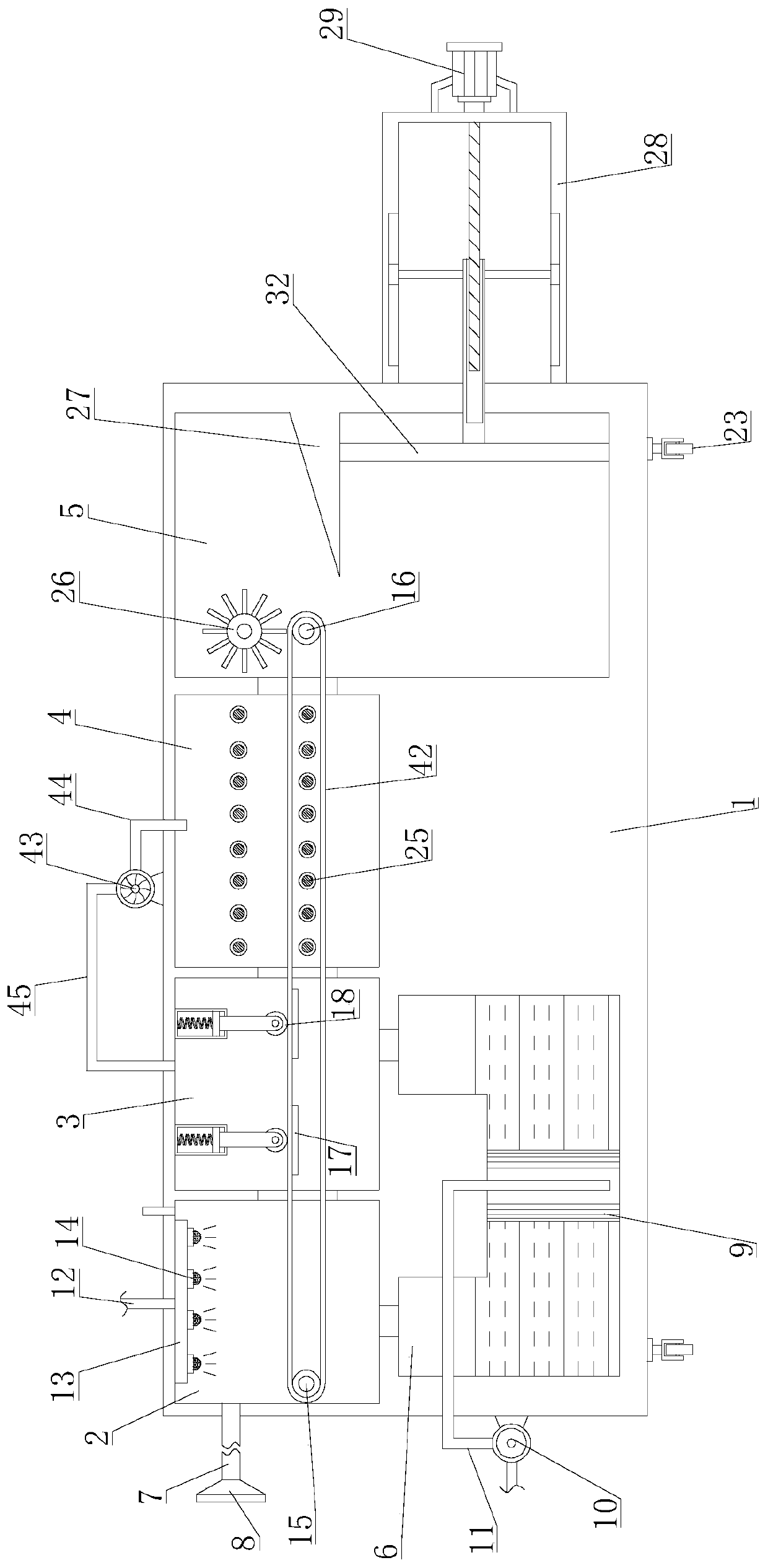

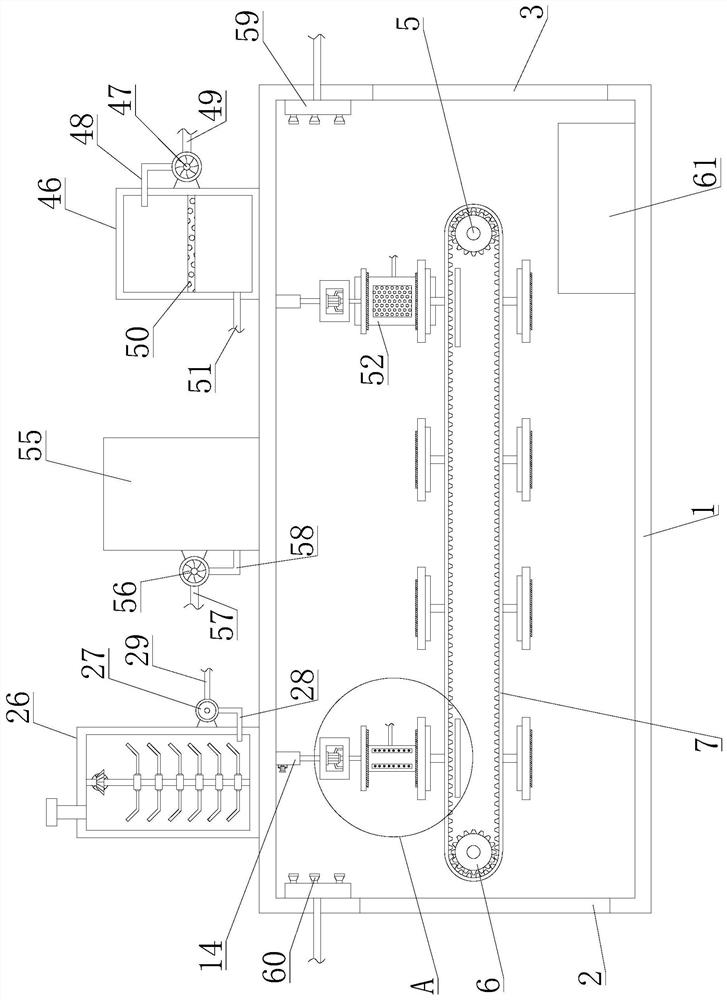

A multi-function waste pile classified treatment recycling device for a garment processing plant comprises a treatment recycling device body. The treatment recycling device body is internally providedwith a spray cleaning chamber, a water squeezing chamber, a drying chamber and a recycling chamber. A driving roller is longitudinally arranged in the spray cleaning chamber, a driven roller is longitudinally arranged in the recycling chamber, and a conveying belt is in transmission connection with the driving roller and the driven roller. A water storage chamber is arranged in the treatment recycling device body. A conveying pipe is arranged on the treatment recycling device body and communicates with the spray cleaning chamber, and sprayers are arranged at the bottom of a water collecting part. A water pumping pipe and a water conveying pipe are arranged on a water pump, the water pumping pipe is vertically inserted into a filtering device, and the water conveying pipe communicates withthe water collecting part. The water squeezing device comprises a water squeezing roller, movable rods, connecting cylinders, elastic parts and limiting blocks, and electric heating pipes are arranged in the drying chamber. The device integrates spray cleaning, water squeezing, drying, recycling and compression functions, has various functions, is simple to operate, saves time and labor in the operation process, can realize effective recycling of waste pile, and is excellent in use effect.

Owner:JIHUA 3536 PROFESSIONAL CLOTHING

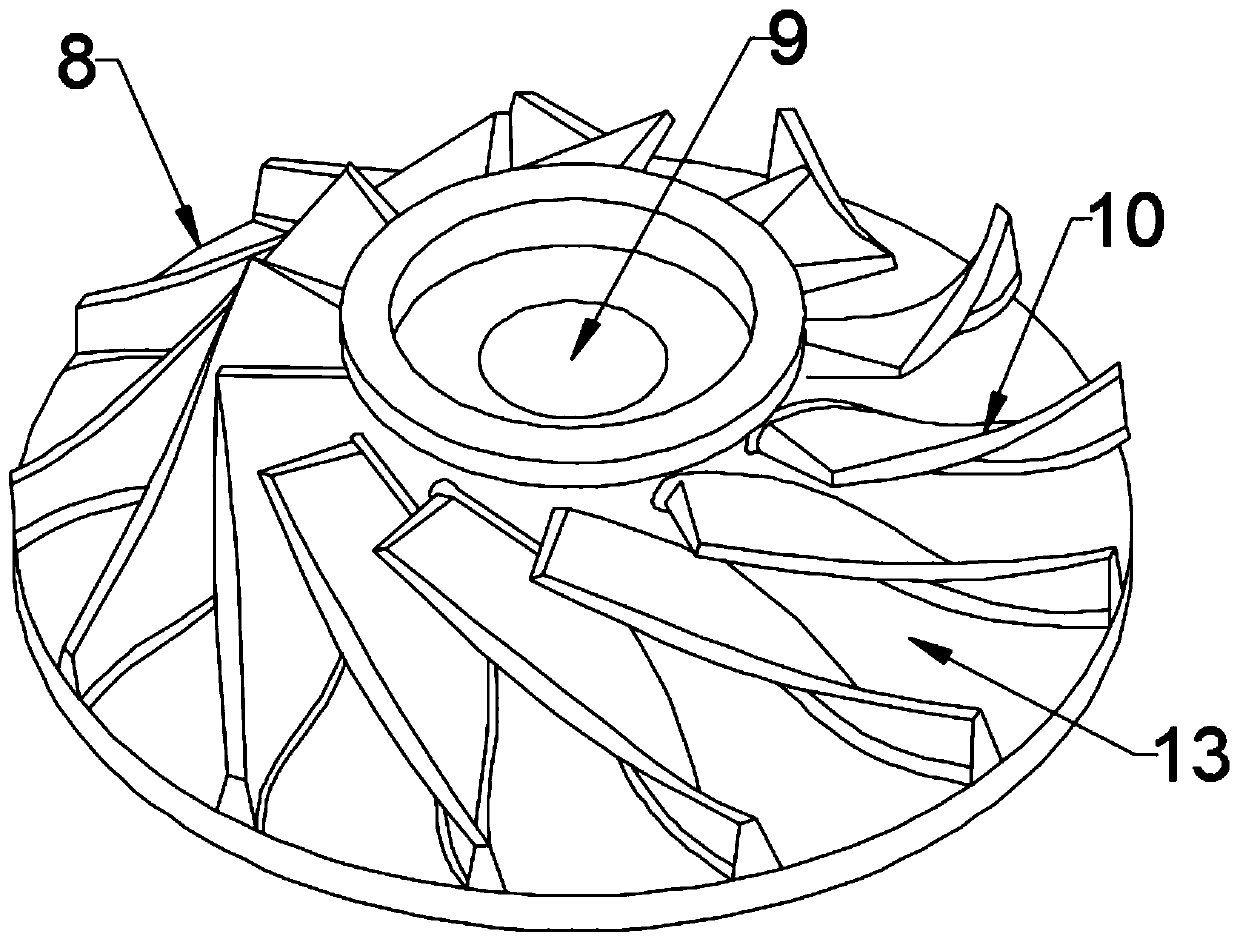

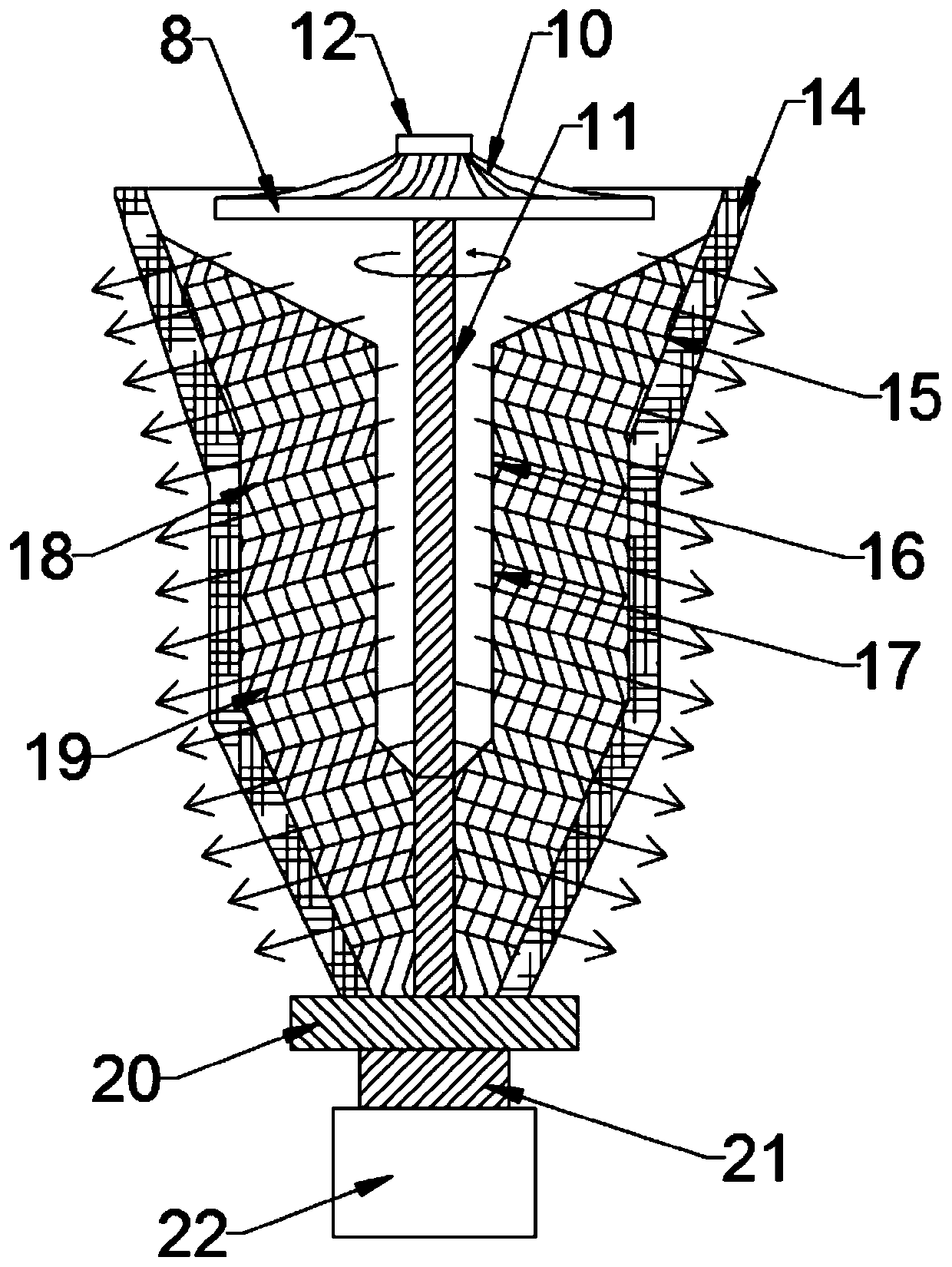

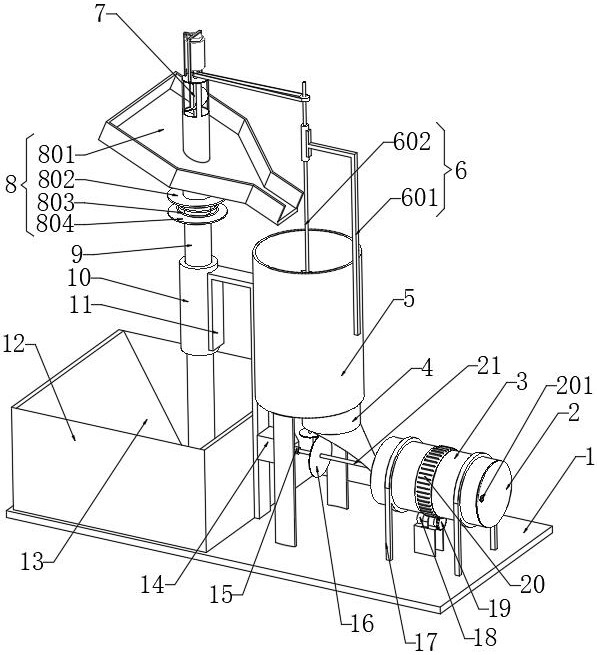

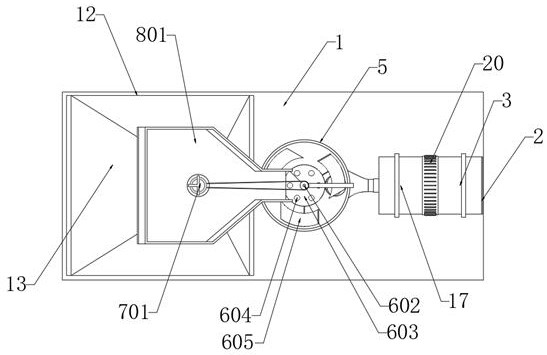

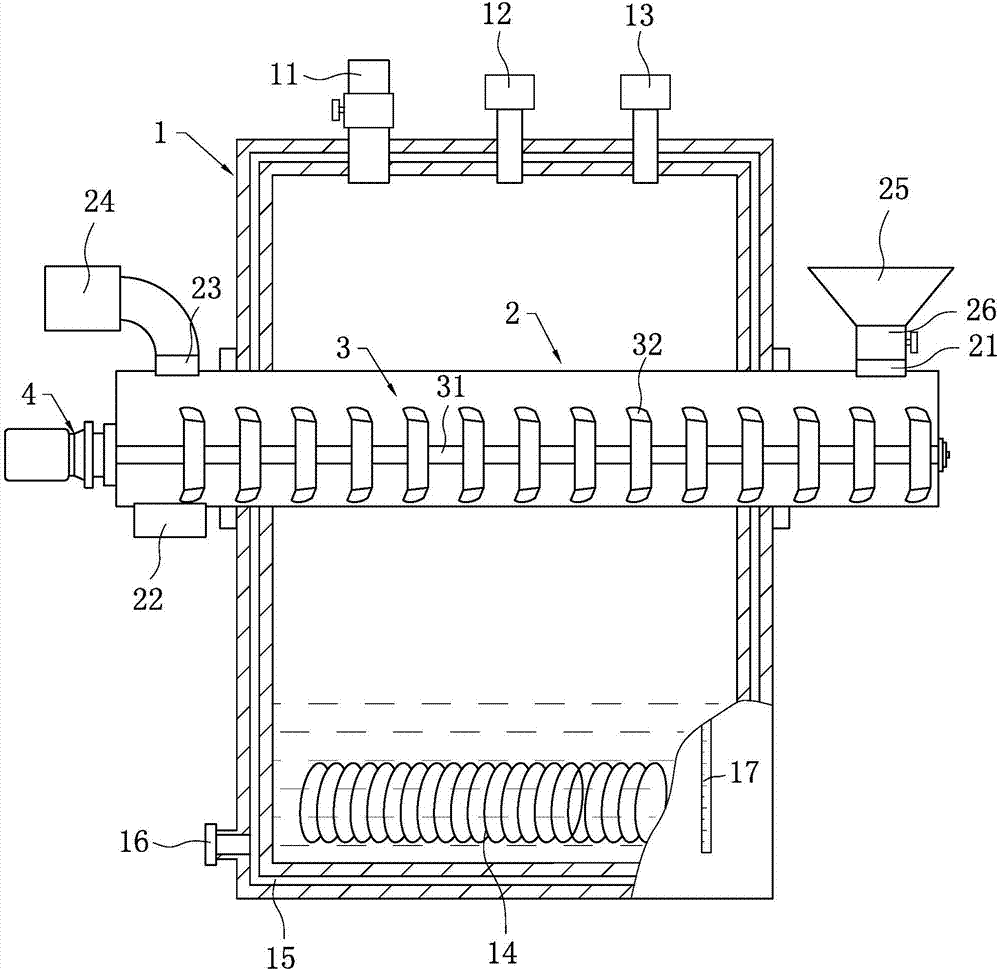

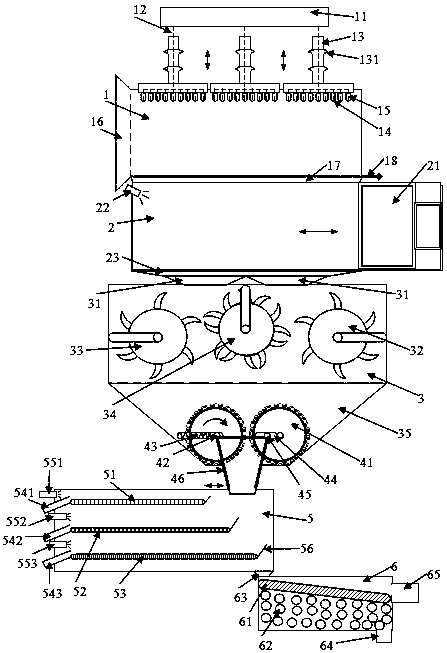

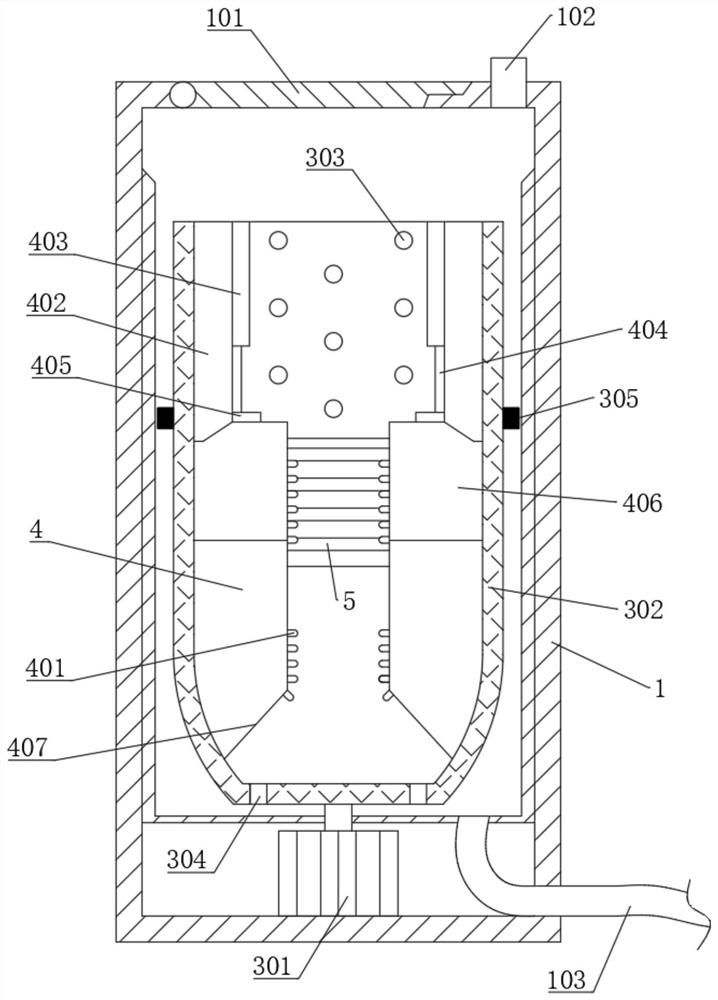

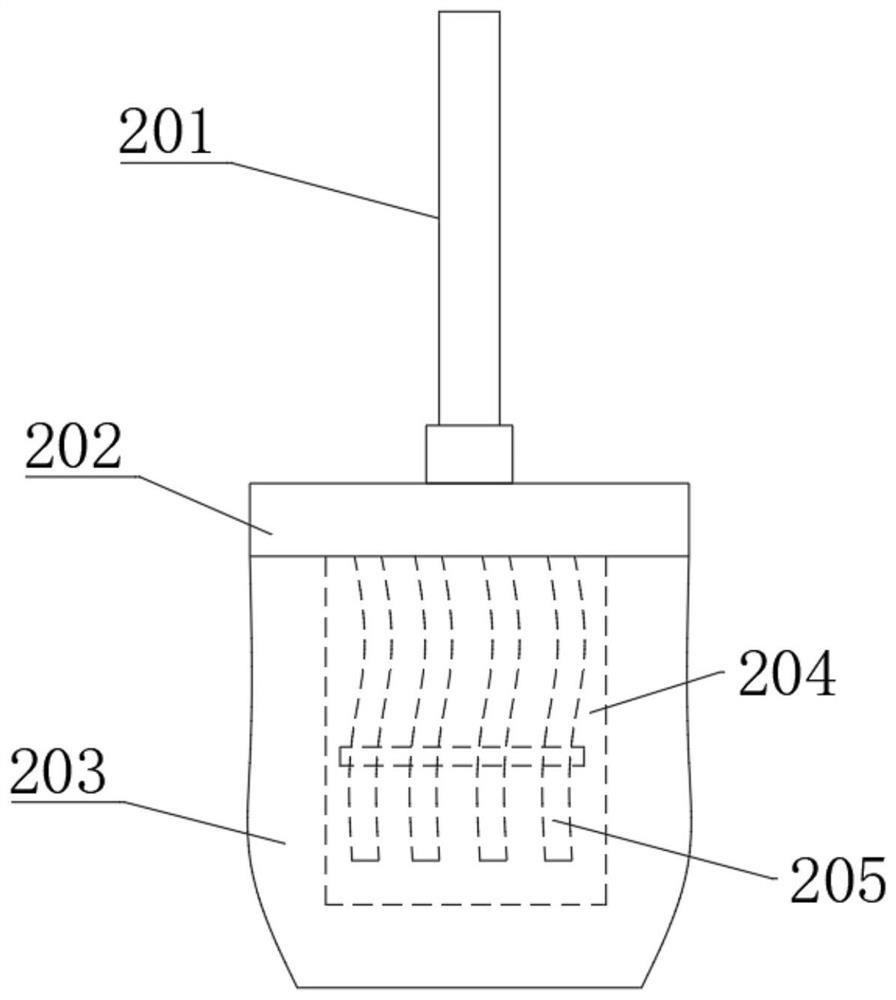

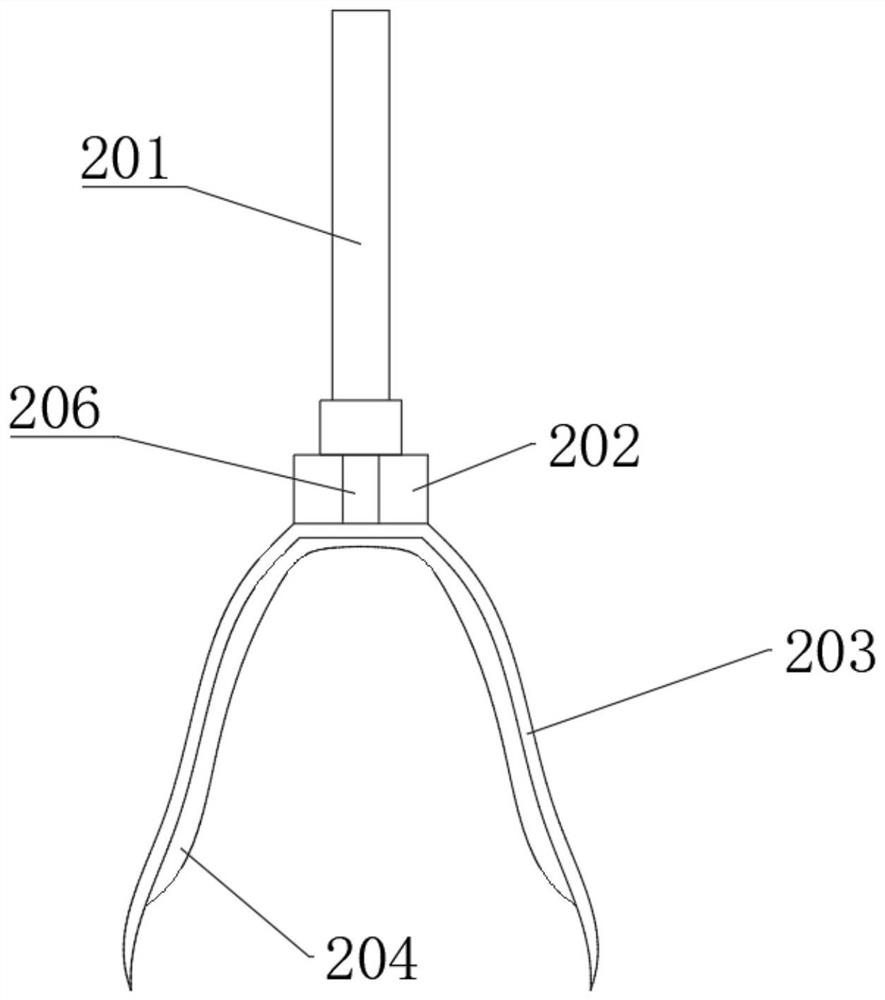

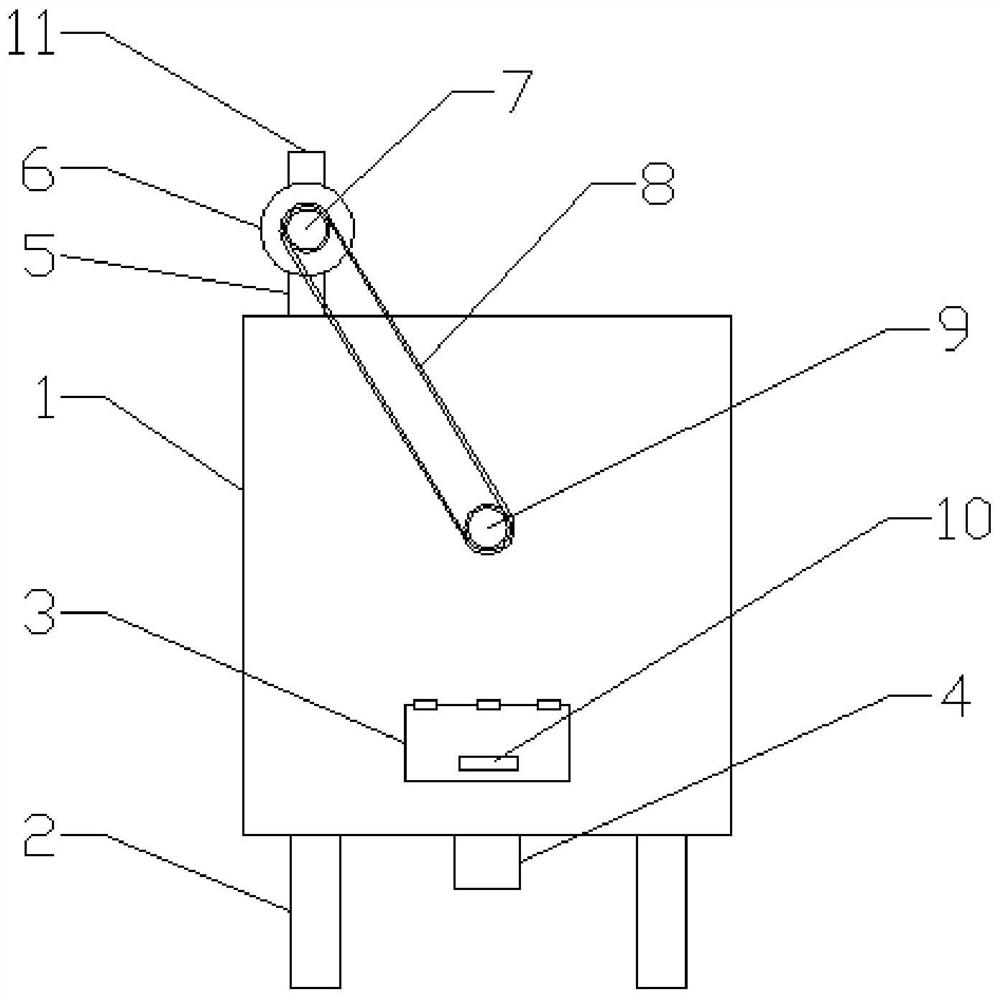

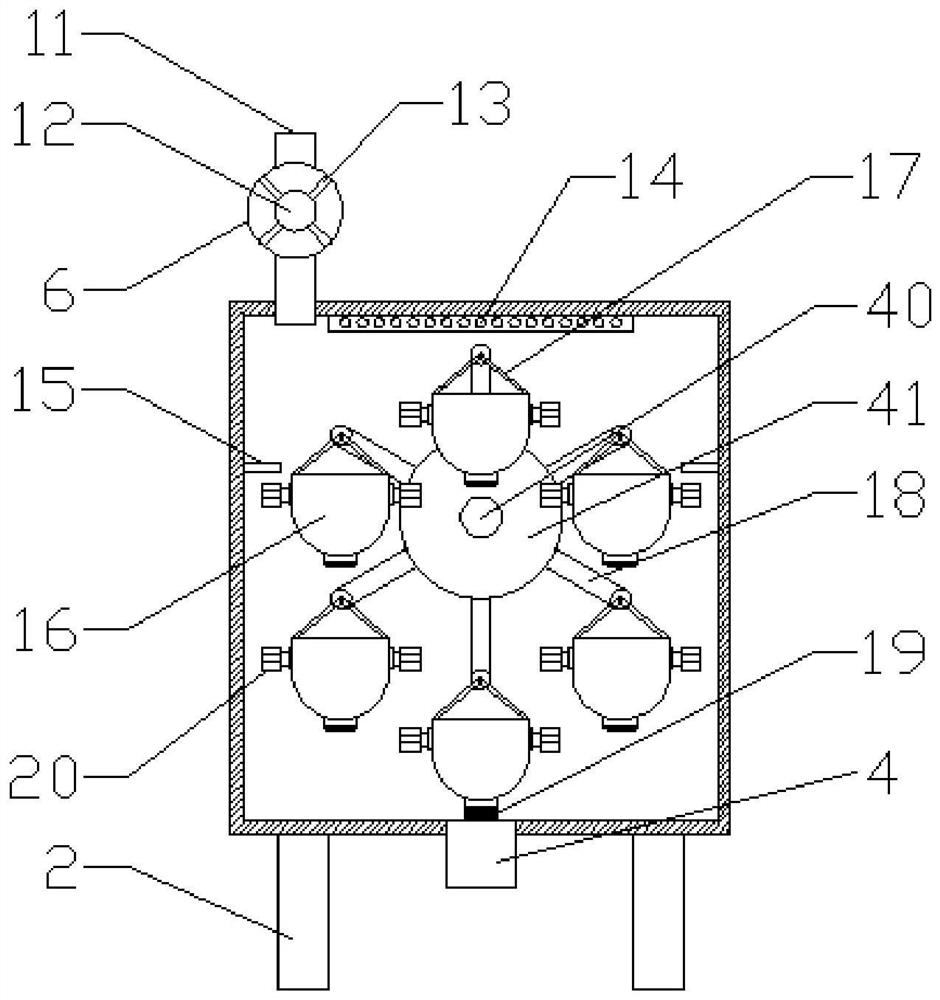

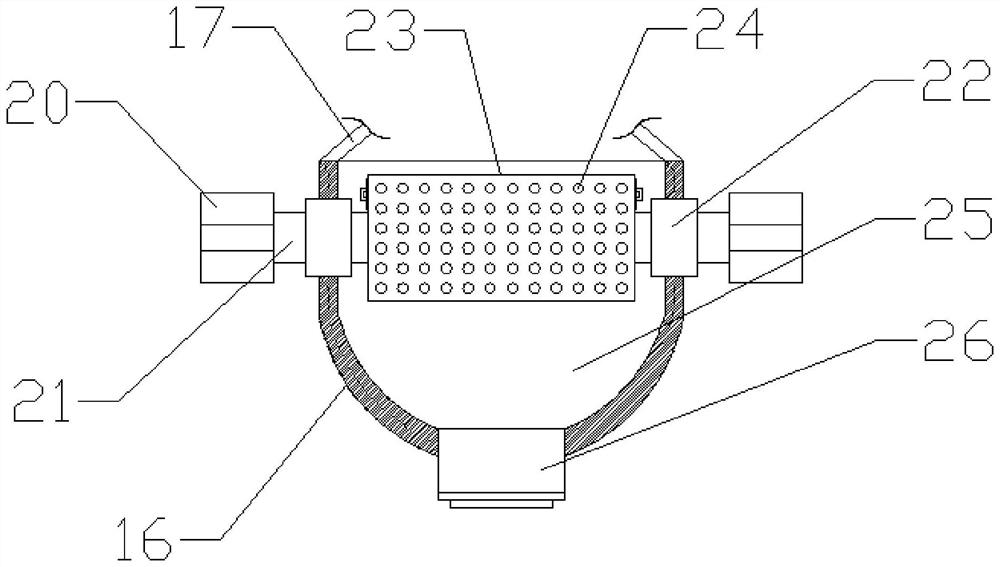

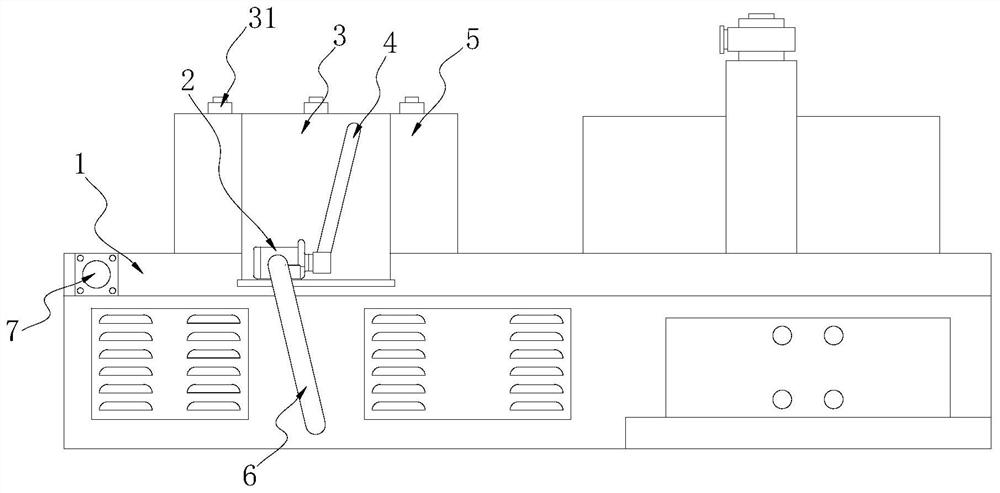

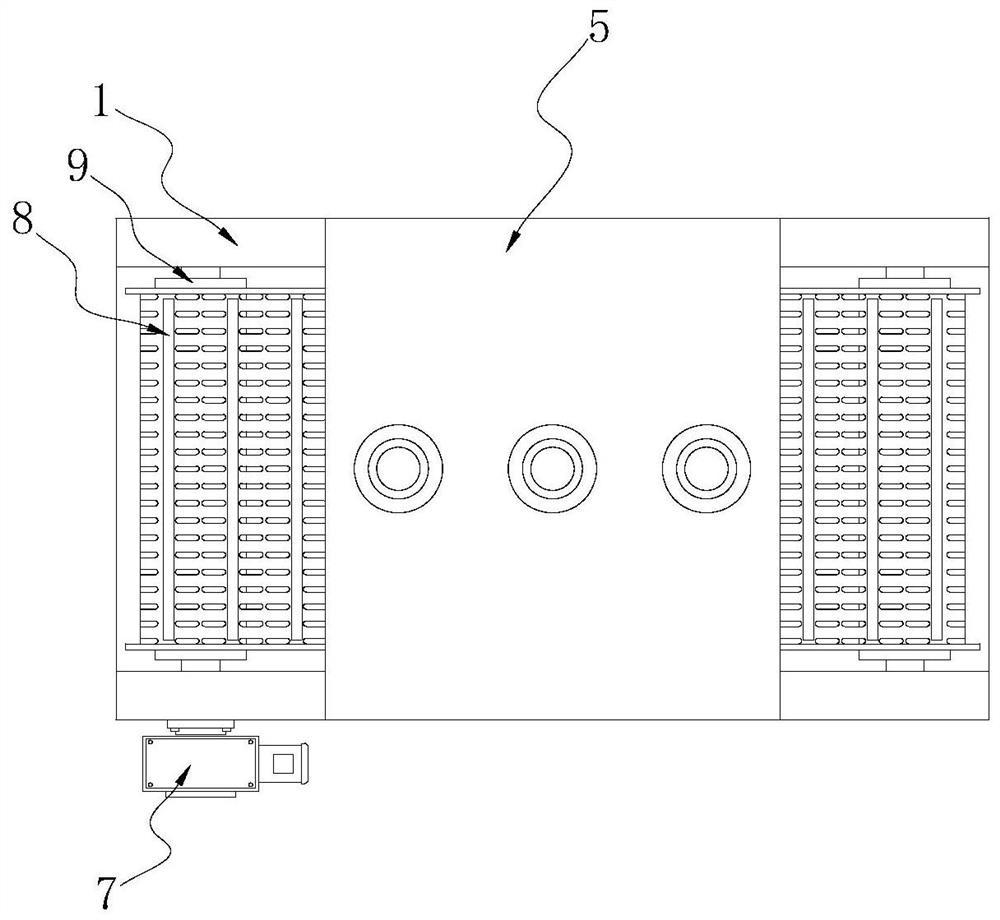

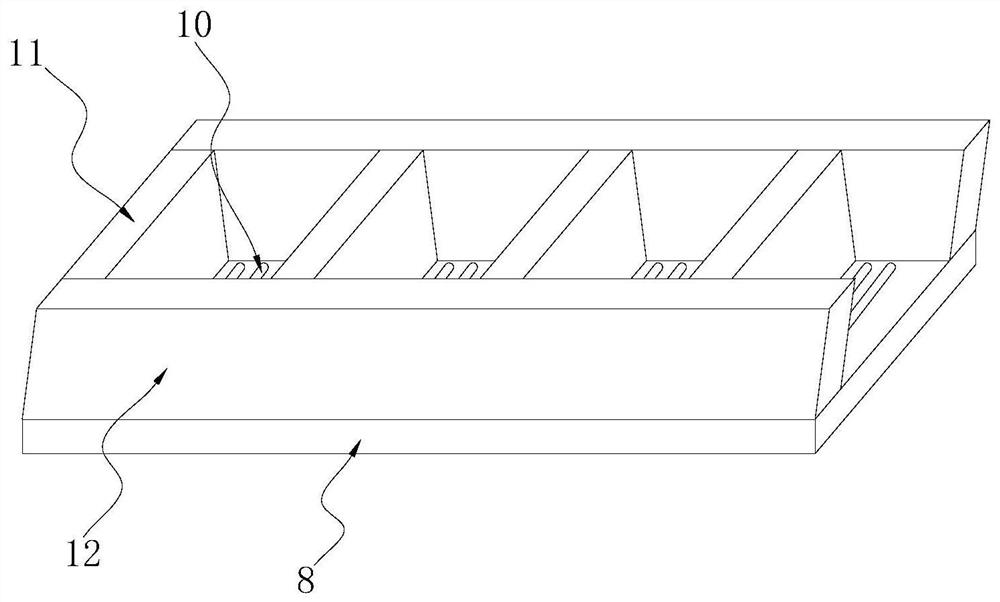

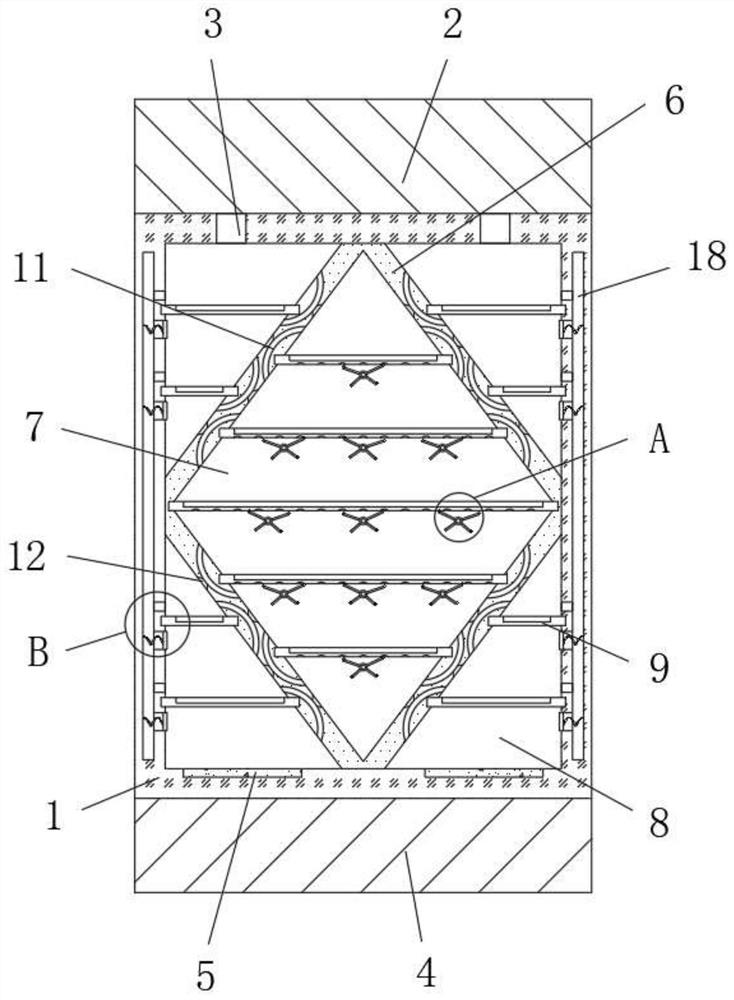

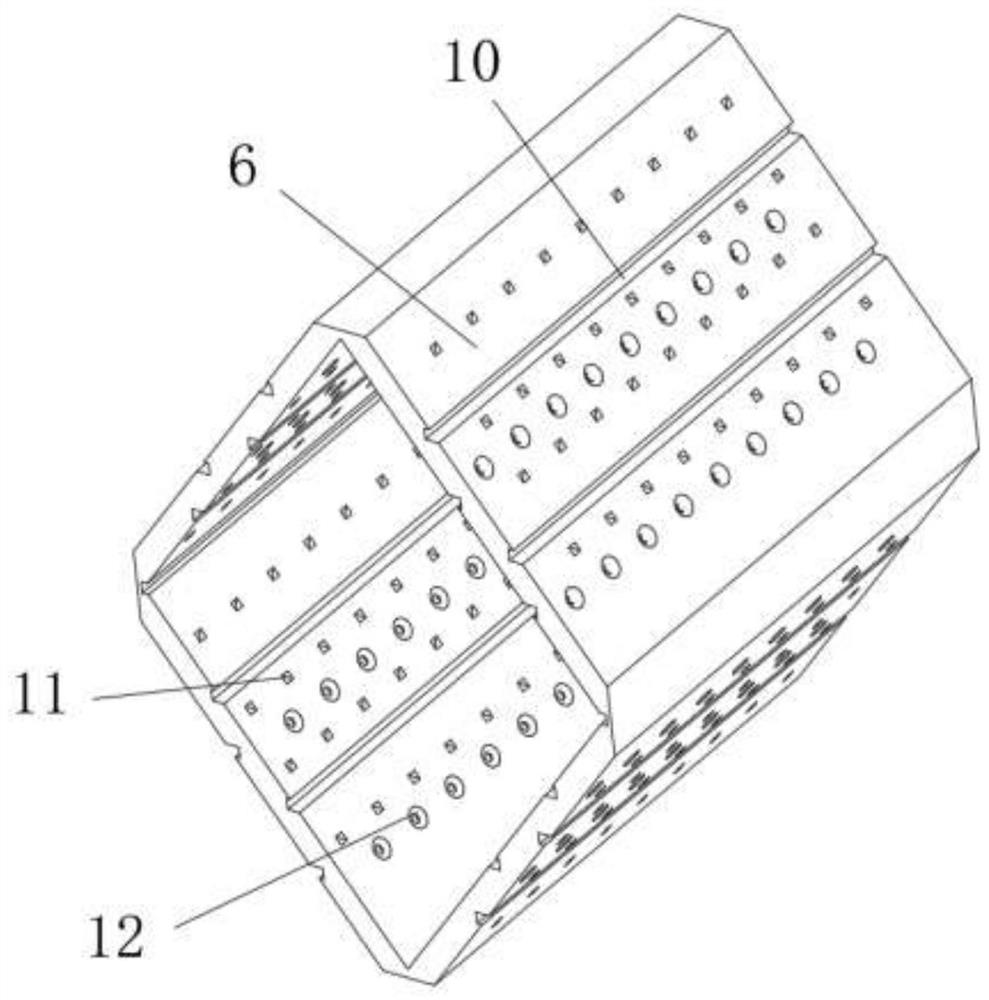

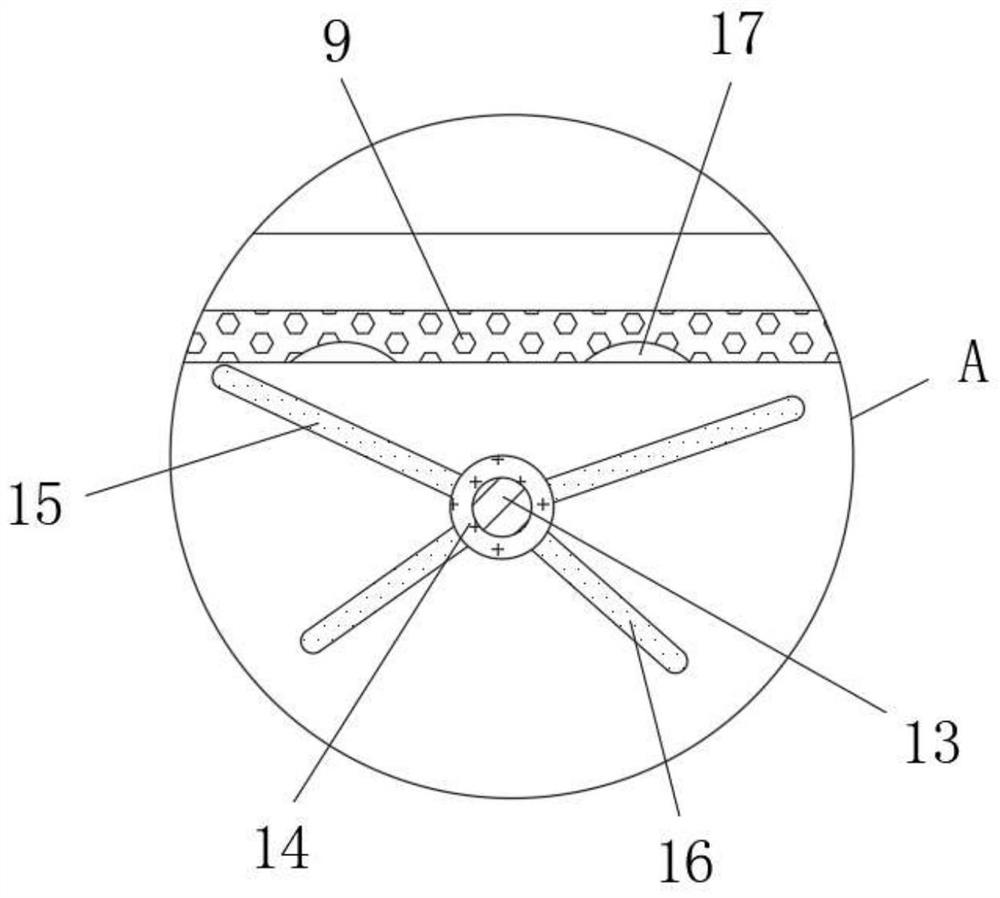

Drying equipment for grains and drying method thereof

ActiveCN111442608ARealize drying operationEasy to operateDrying solid materials with heatDrying gas arrangementsProcess engineeringIndustrial engineering

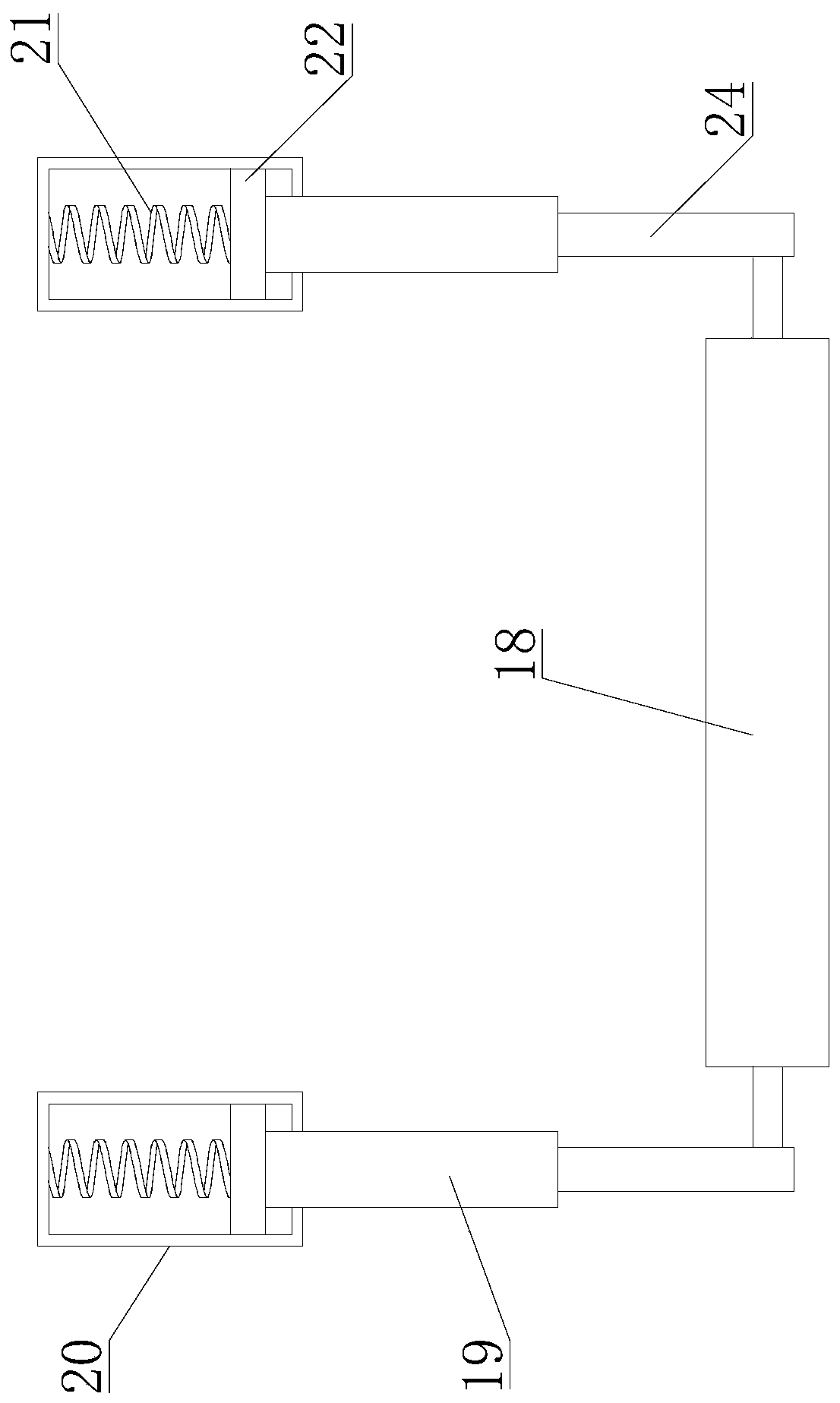

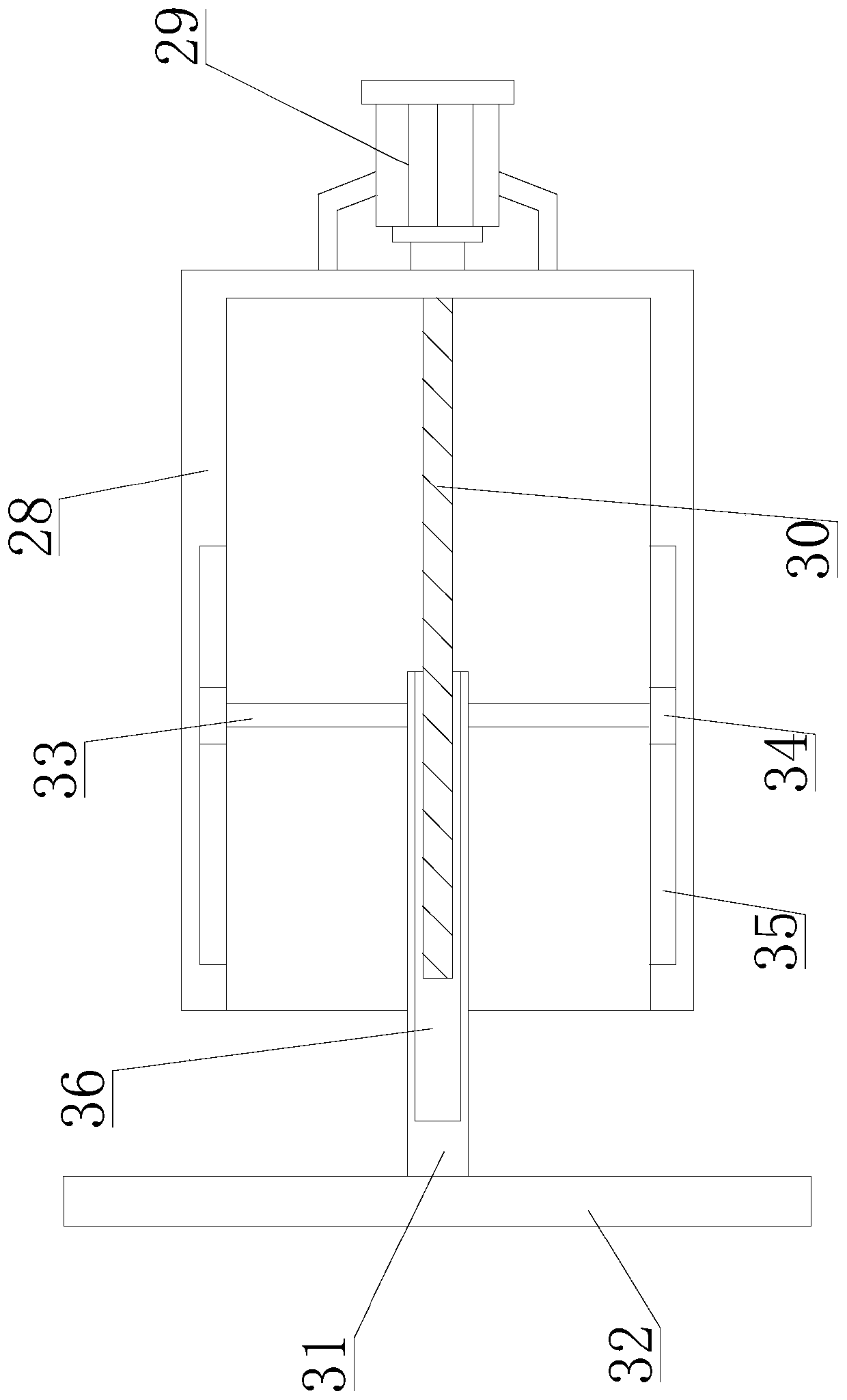

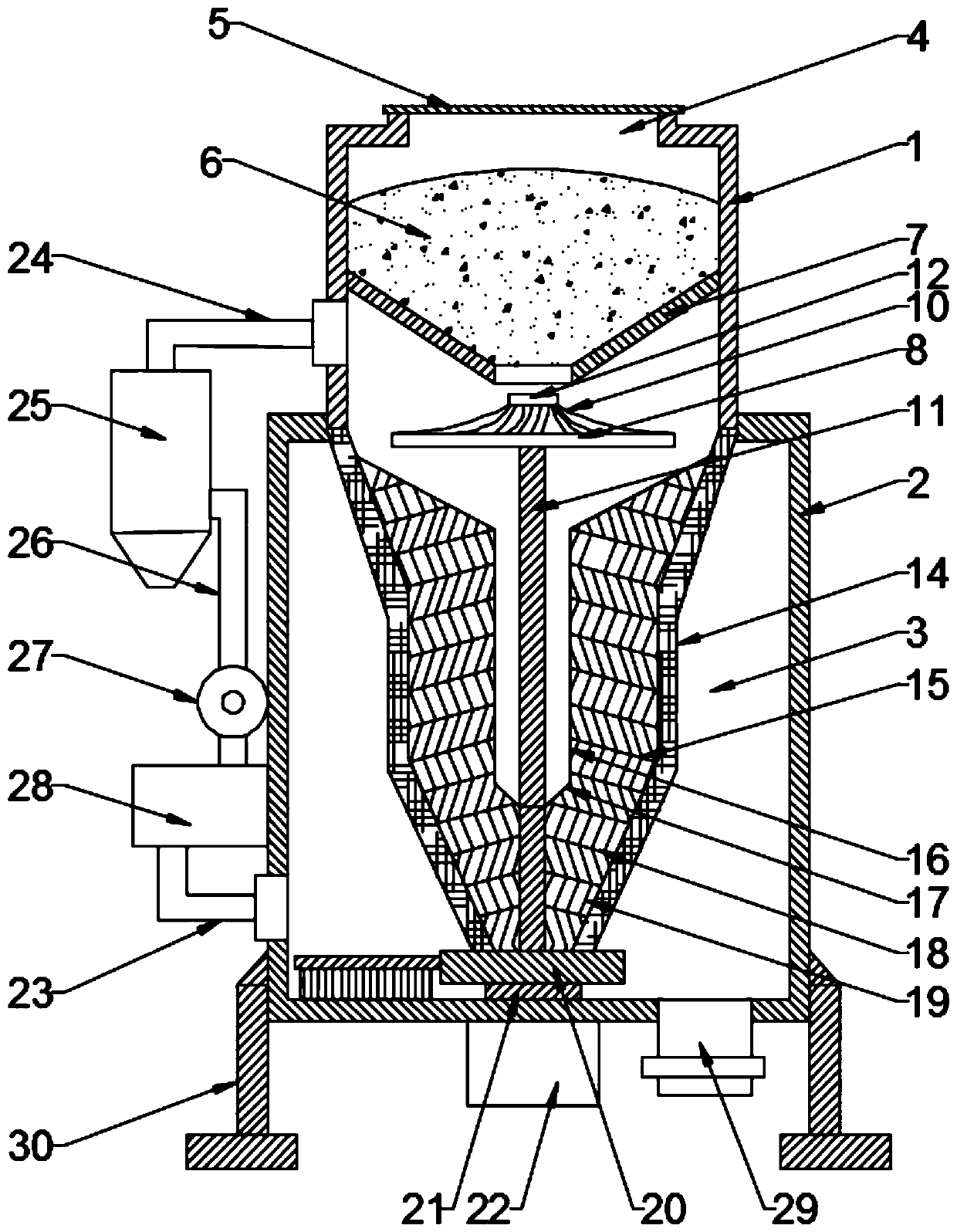

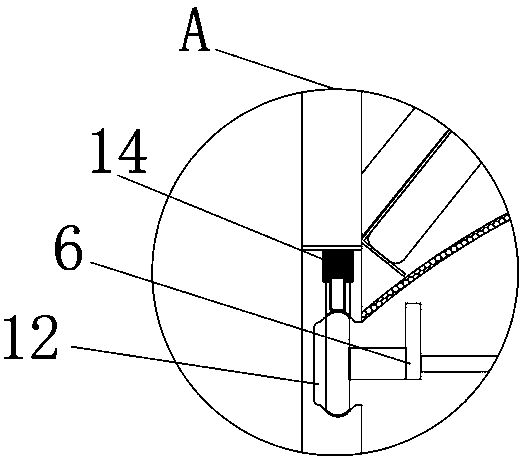

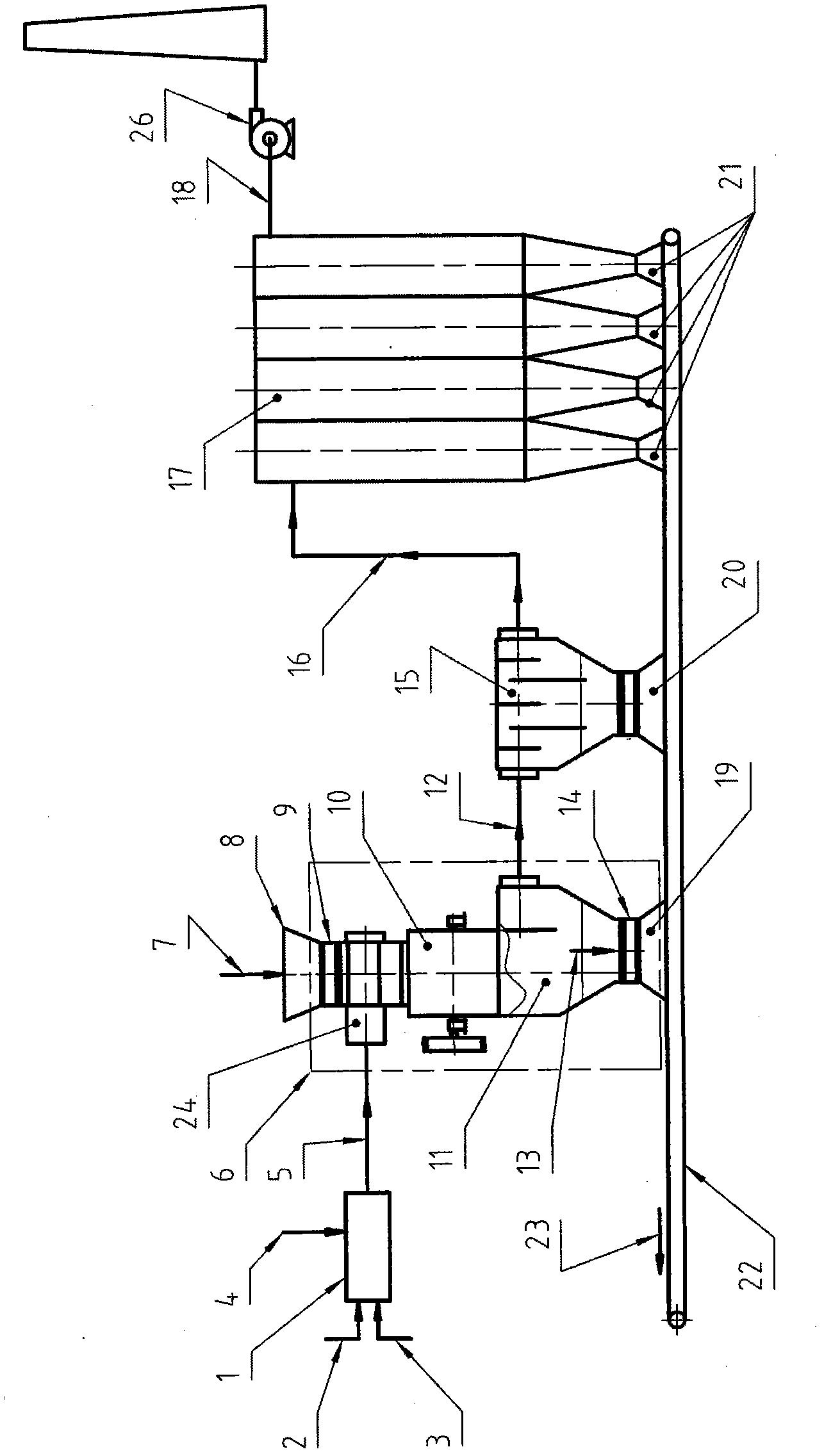

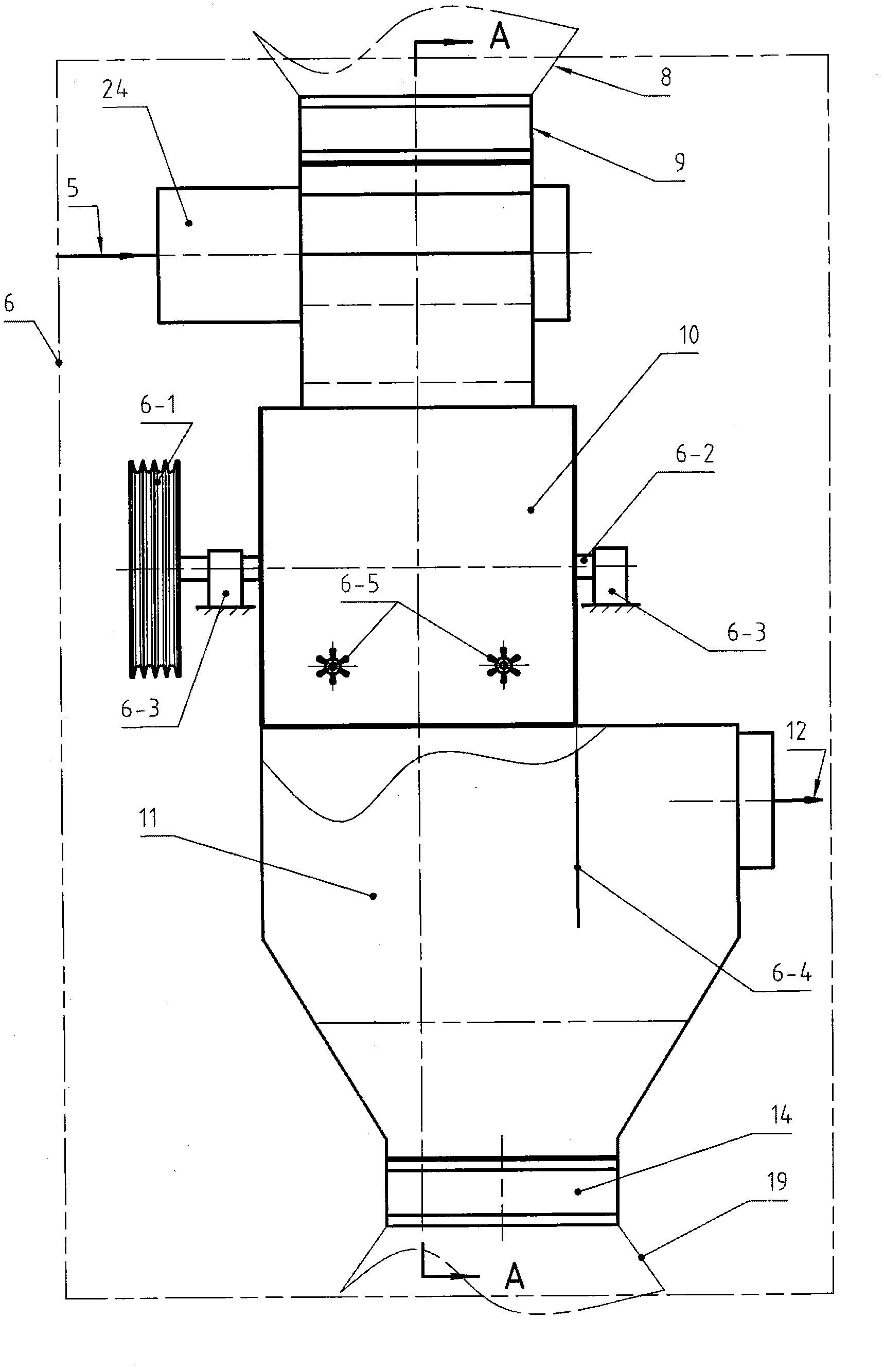

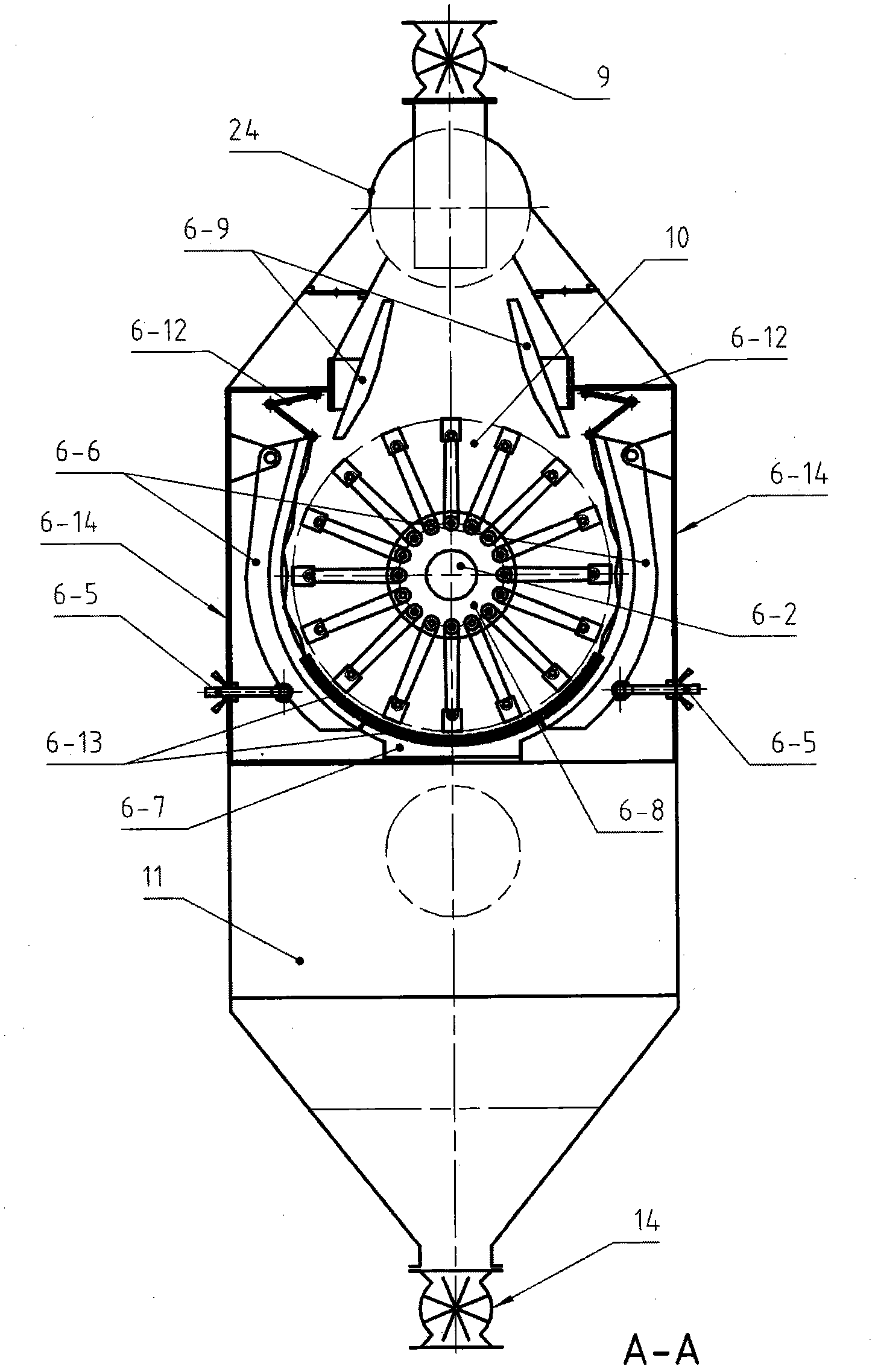

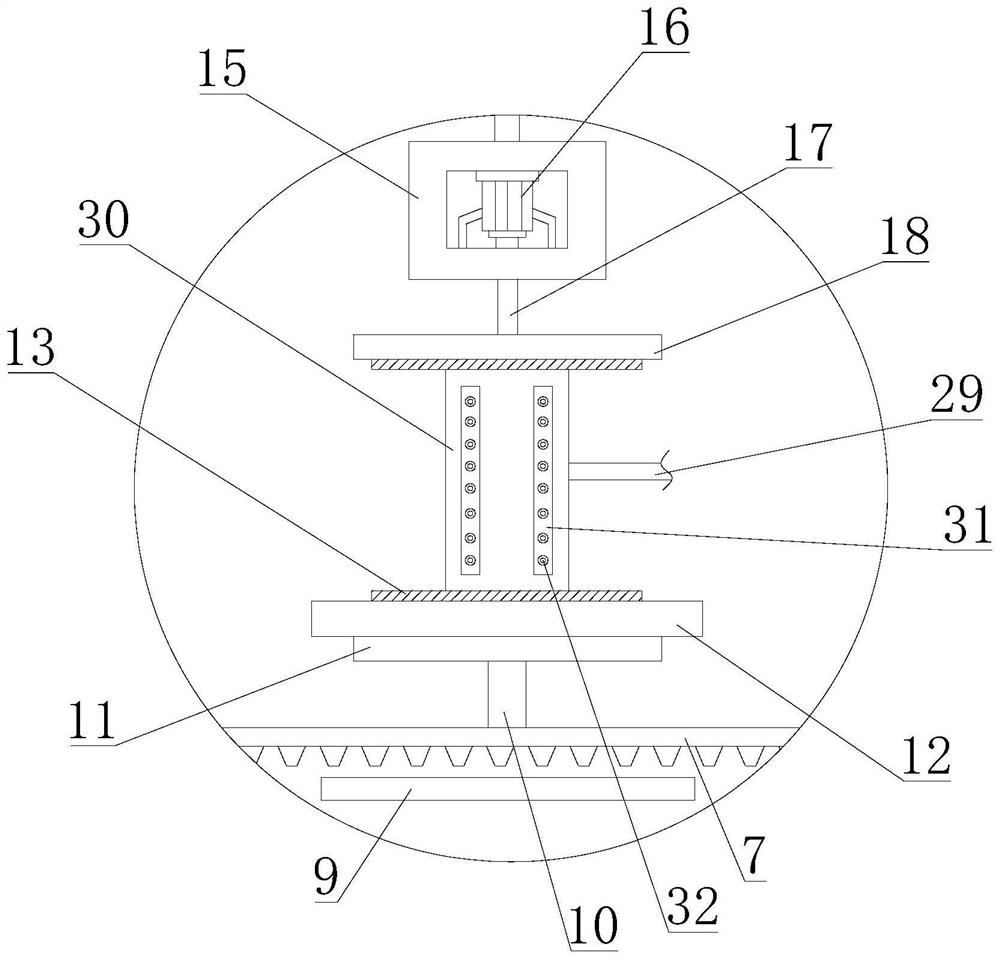

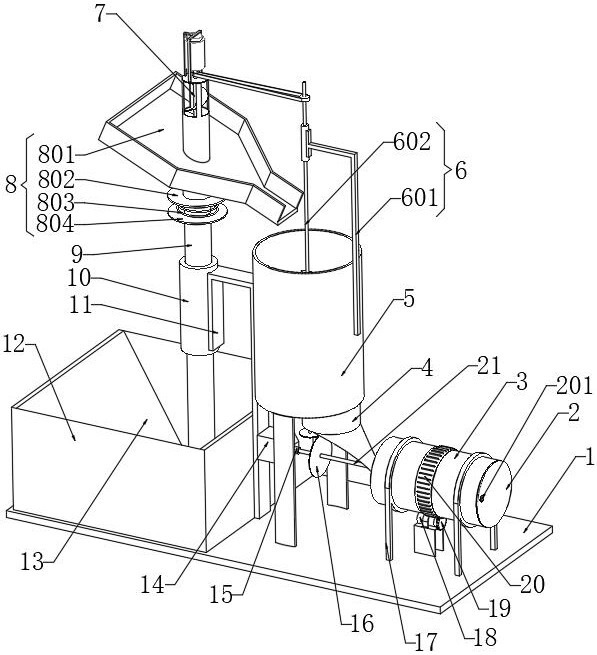

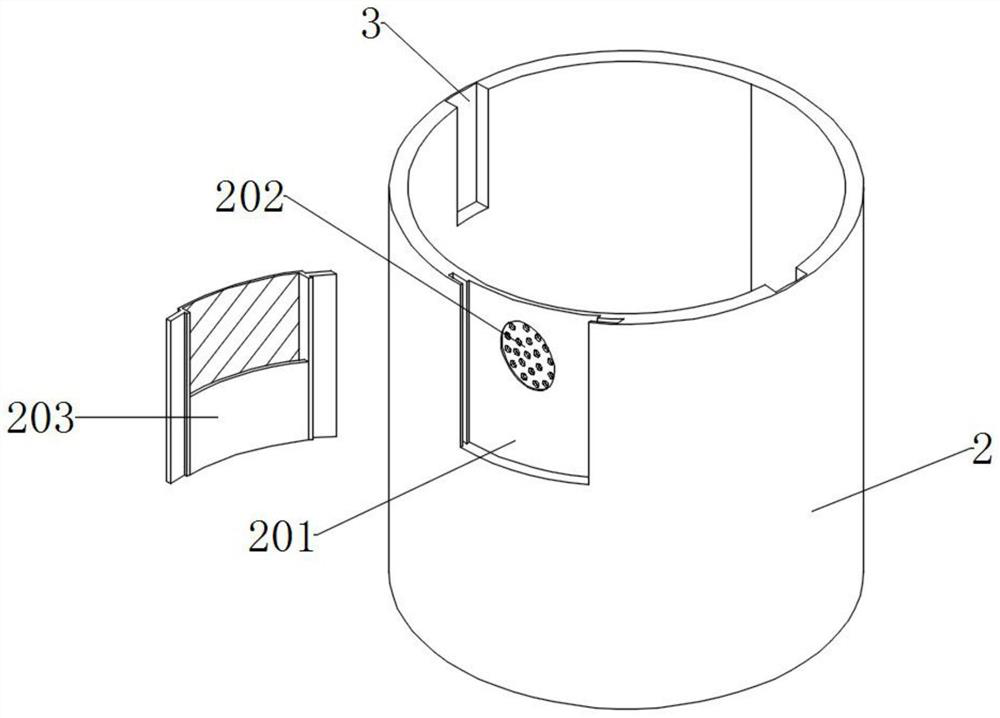

The invention discloses drying equipment for grains, belongs to the technical field of grain processing equipment and solves the problem that grains are prone to stacking and therefore are insufficiently dried in the process of drying. Key technical points of the equipment include: the equipment comprises a material storage tank body, a drying tank body, and a rotary drying assembly; the materialstorage tank body is installed above the drying tank body; and the rotary drying assembly is installed inside the drying tank body. The invention further comprises a drying method of the drying equipment for grains. The drying equipment is composed of the material storage tank body, the drying tank body and the rotary drying assembly and is for sufficiently dispersing the grains; and in the process of falling, grain granules are in sufficient contact with hot air which circulates and flows from up to down, so the grain granules are sufficiently dried. Grain drying operation is realized in a way that the rotary drying assembly is initiated to disperse the grains and the grains are dried in the drying tank body, the operation is convenient and rapid, and the equipment is applicable to graindrying.

Owner:合肥喜由米农业科技有限公司

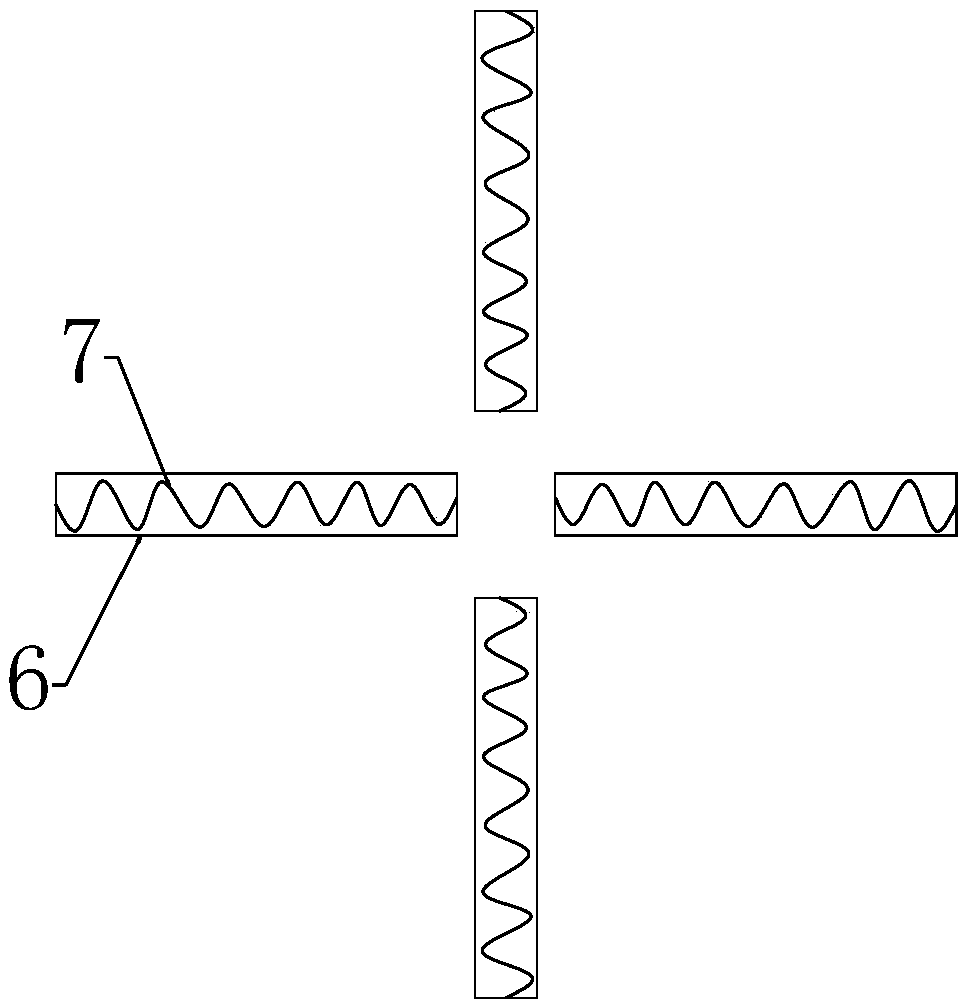

High efficient draining-drying device for vegetable dehydration

PendingCN109527618AAvoid damage to internal partsRealize drying operationFood treatmentDehydrationPulp and paper industry

The invention relates to the technical field of vegetable draining-drying devices, and discloses a high efficient draining-drying device for vegetable dehydration. The device comprises a draining-baking apparatus, a bin gate, a handle, a first chute, a suction pipe, an exhaust fan, a second chute, and a residue collecting box. The bin gate is arranged on the right surface of the draining-baking apparatus; the handle is fixedly connected to the right surface of the bin gate; the exhaust fan is fixedly connected to the left side of the top of the draining-baking apparatus; the suction opening ofthe exhaust fan is fixedly connected to the suction pipe; and the end, which is far away from the suction opening of the exhaust fan, is communicated with the interior of the draining-baking apparatus. The provided high efficient draining-drying device has the advantages that through the vibration of a pneumatic vibrator and a structure with crossed first baking lamp and second baking lamp, vegetables can be dried from all directions, all parts of vegetables are fully dried, and repeated drying is avoided.

Owner:JIANGSU NATURAL FOOD

Coking coal moisture control method and hammer crusher for realizing same

ActiveCN102911688AImprove effectivenessImprove uniformityCoke ovensGrain treatmentsPretreatment methodGranularity

The invention relates to a coking coal moisture control method and a hammer crusher for realizing the same and belongs to the technical field of coking coal pretreatment methods and equipment of coking plants. In order to solve the main technical problems, the characteristic that the moisture content and the granularity of coking coal are in inverse proportion approximately is bound to be mastered and used fully, and after rough distribution of the coking coal according to the granularity of the coking coal, drying of thin portions of the coking coal is continued, so that drying effectiveness is improved. The coking coal moisture control method is characterized by including: adopting the hammer crusher, wherein hot air is fed into the hammer crusher; performing distributing operation for crushed coking coal; and mixing the distributed coking coal and then conveying the mixed coking coal to a coke oven. The hammer crusher is characterized in that the hammer crusher is provided with a second outlet for the coking coal. The coking coal moisture control method and the hammer crusher for realizing the same are applicable to moisture control of the coking coal and have the advantages of simplicity, feasibility, energy and investment saving and the like.

Owner:SHANDONG PROVINCE METALLURGICAL ENG CO LTD

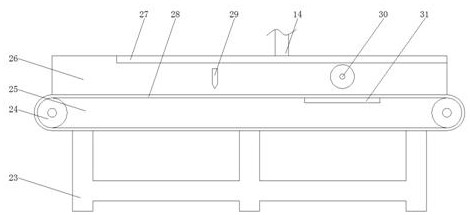

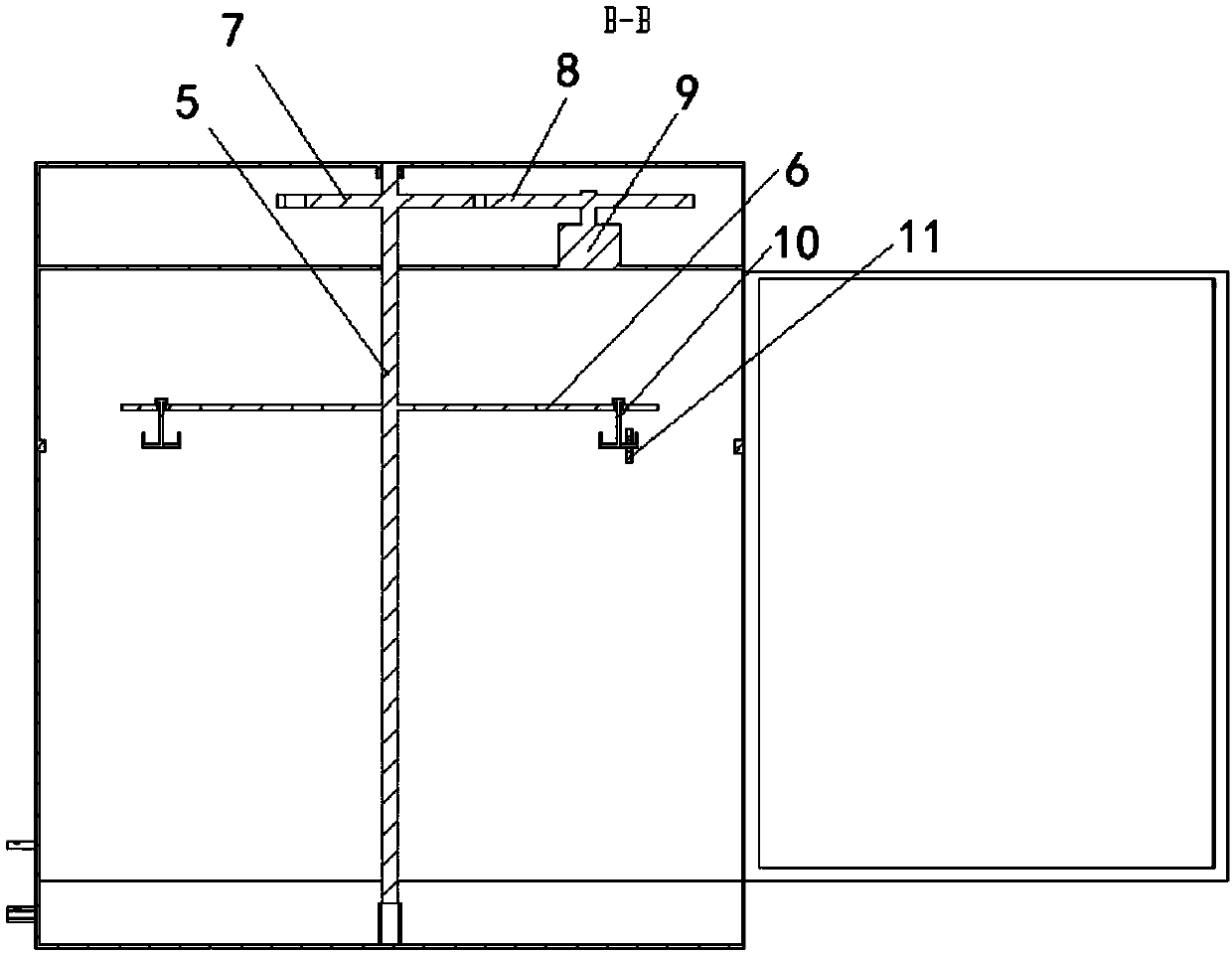

Paint spraying and drying integrated machine for hardware processing

InactiveCN112295818AEvenly paintedGood paint effectPretreated surfacesCoatingsConveyor beltHot blast

The invention discloses a paint spraying and drying integrated machine for hardware processing. The paint spraying and drying integrated machine comprises a processing box, wherein a first connectingpiece is longitudinally arranged in the processing box; a paint collection box is vertically arranged on the first connecting piece, and the paint collection box and an input port are positioned on the same side; a paint dividing pipe is arranged on one side, facing a conveyor belt, of the paint collection box; a paint spraying head is arranged on the paint dividing pipe; an oil paint pump is arranged on an oil paint storage box; a paint extracting pipe and a paint delivery hose are arranged on the oil paint pump; the other end of the paint extracting pipe communicates with the oil paint storage box while the other end of the paint delivery hose communicates with the paint collection box; a hot air box is arranged in the processing box, the hot air box and an output port are positioned onthe same side; a gas delivery hose is arranged on an air feeder, and the other end of the gas delivery hose communicates with the hot air box; an electric heating net is arranged in the hot air box; and a grid plate is arranged on one side, facing the conveyor belt, of the hot air box. The paint spraying and drying integrated machine disclosed by the invention integrates a paint spraying functionand a drying function, operation is simple, and the time and the labor are saved, and thus, a paint spraying effect is obviously improved, the processing efficiency is also improved; and moreover, theoil paint also can be stirred so as to prevent precipitation or unevenness of thickness, and thus, using of the machine is facilitated.

Owner:深圳市励东科技发展有限公司

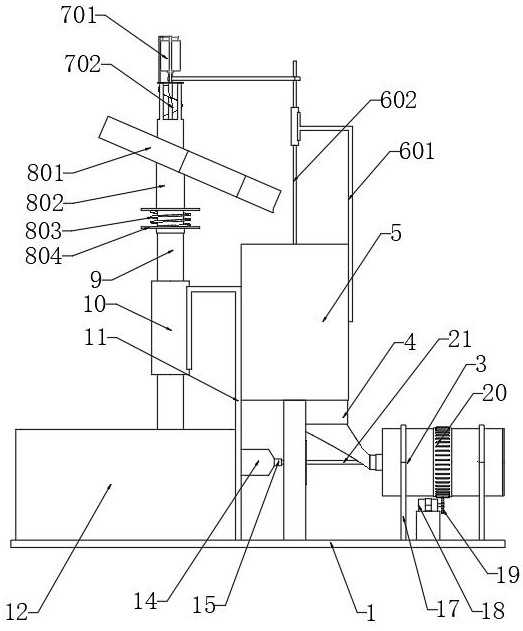

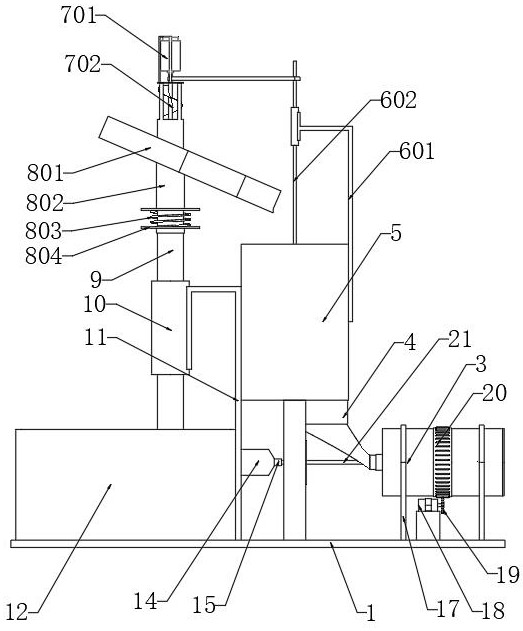

Distiller's yeast drying device for distiller's yeast processing

ActiveCN114294937AImprove drying qualityEfficient crushingDrying gas arrangementsDrying chambers/containersBiotechnologyEngineering

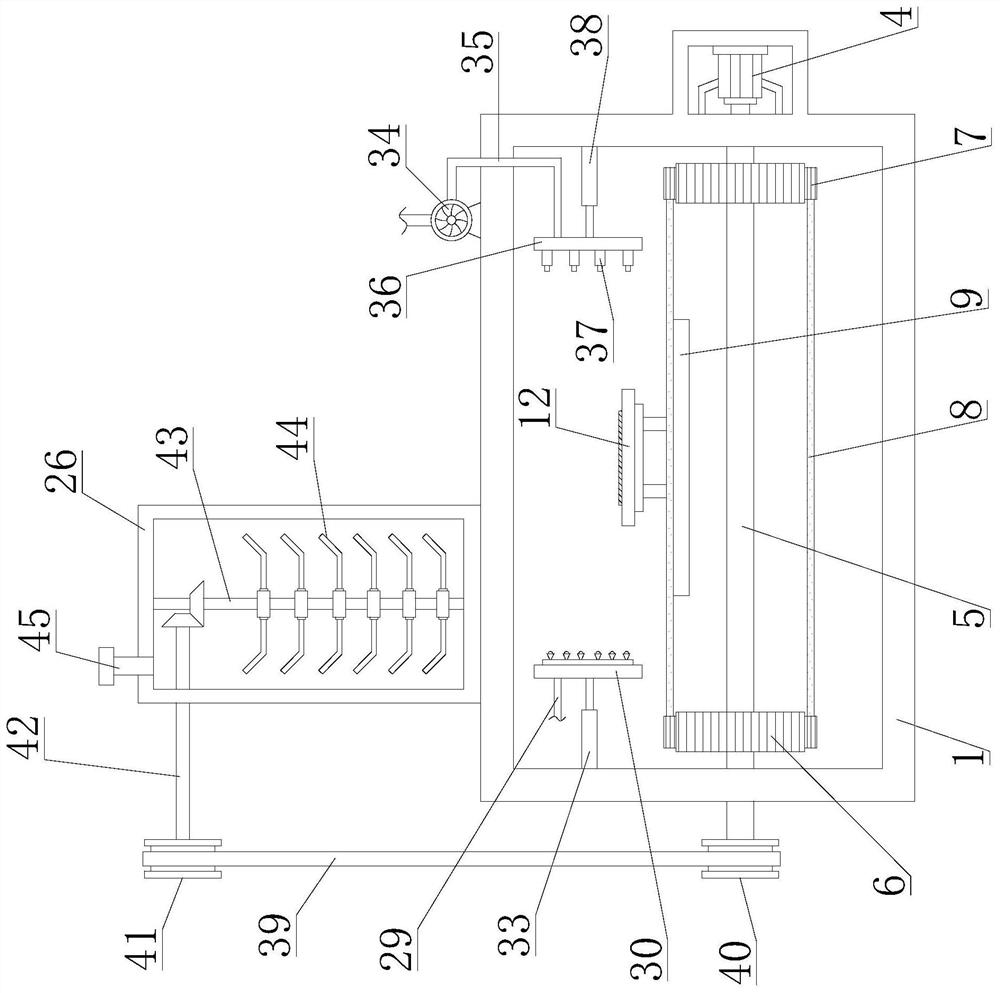

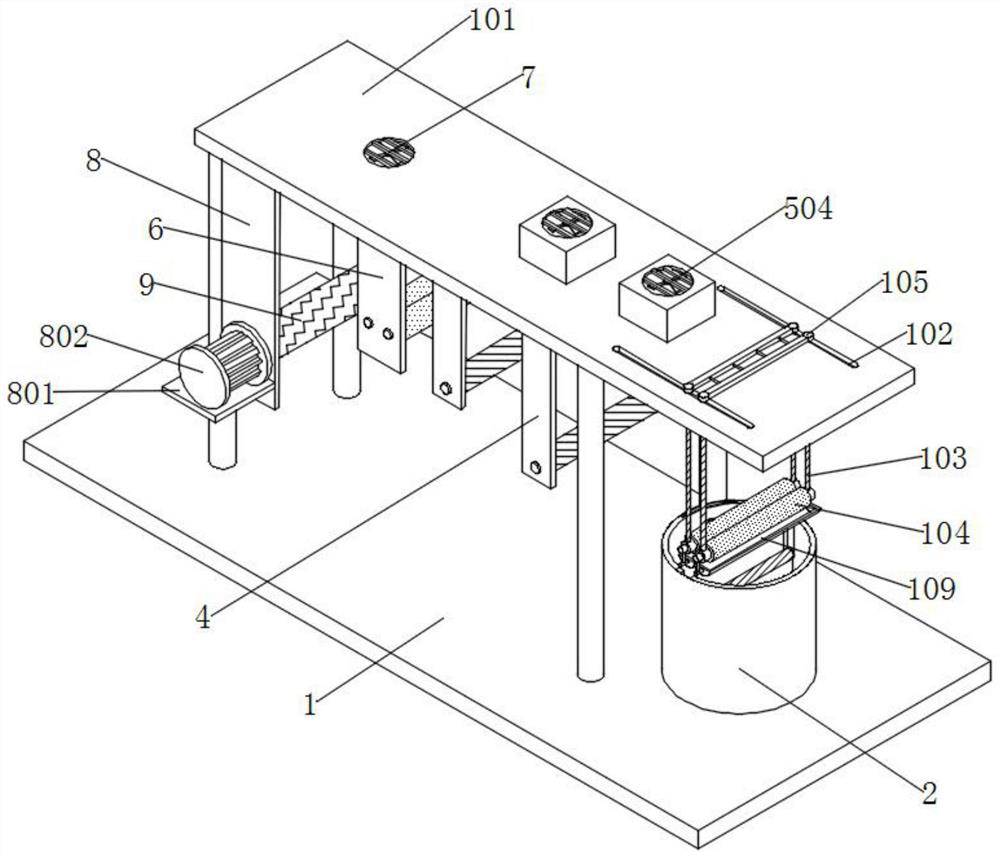

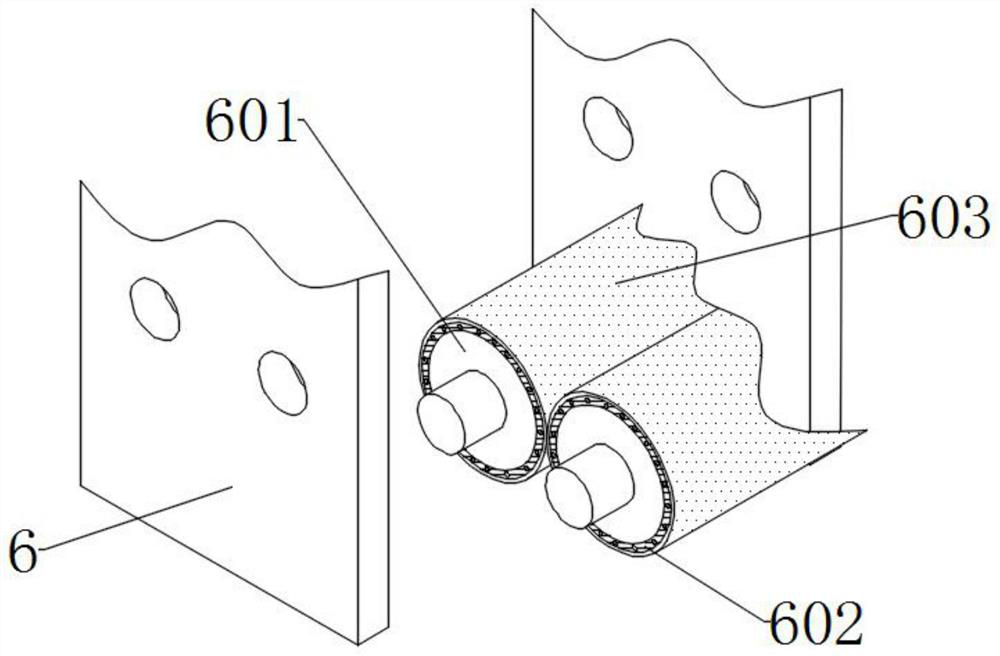

The invention discloses a distiller's yeast drying device for distiller's yeast processing, and relates to the technical field of distiller's yeast processing, the distiller's yeast drying device comprises a mounting plate, a raw material box, a material drying tank and a drying tank are mounted on the mounting plate, a lifting assembly is mounted on the raw material box, a material overturning assembly is mounted on the material drying tank, and the drying tank is connected with a material overturning and drying mechanism. A supporting vertical frame is fixedly mounted on the outer wall of one side of the raw material box; according to the distiller's yeast drying device, the arranged lifting assembly is matched with the material barrel, distiller's yeast to be dried can fall into the material drying tank through the guiding effect of the vibration material guiding assembly after being lifted from the raw material box at a constant speed, in the process, a heating wire is started, the material barrel and the material drying tank have the high temperature, and the distiller's yeast can be heated and dried when passing through the surface walls of the material barrel and the material drying tank; and finally, the distiller's yeast is fed into the drying tank through the material receiving assembly, multi-stage and efficient drying treatment of the distiller's yeast is achieved, the drying quality of the distiller's yeast is improved, and the uniformity and dryness are well guaranteed.

Owner:济南趵突泉酿酒有限责任公司

Building stone breaking and sorting device

The invention relates to a building stone breaking and sorting device, which comprises an ultrasonic treatment chamber, an impact chamber, a breaking chamber, a sorting device, a drying and conveyingchamber and a water treatment device. An ultrasonic device is utilized to crack stone in the ultrasonic treatment chamber, then the stone is broken by a pneumatic impact hammer according to cracks, the stone is broken in the breaking chamber, the stone is sent into the sorting device after being broken according to the size of the stone, the stone is sorted to different conveying belts to be driedand stored, and water in a process is regenerated and recycled by the water treatment device. Therefore, an effect that the stone is broken in a construction site and sorted according to granularityis achieved.

Owner:中铁十八局集团北京工程有限公司

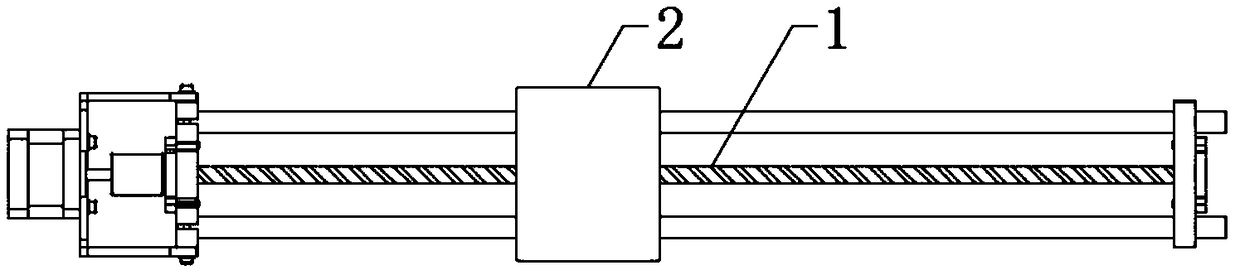

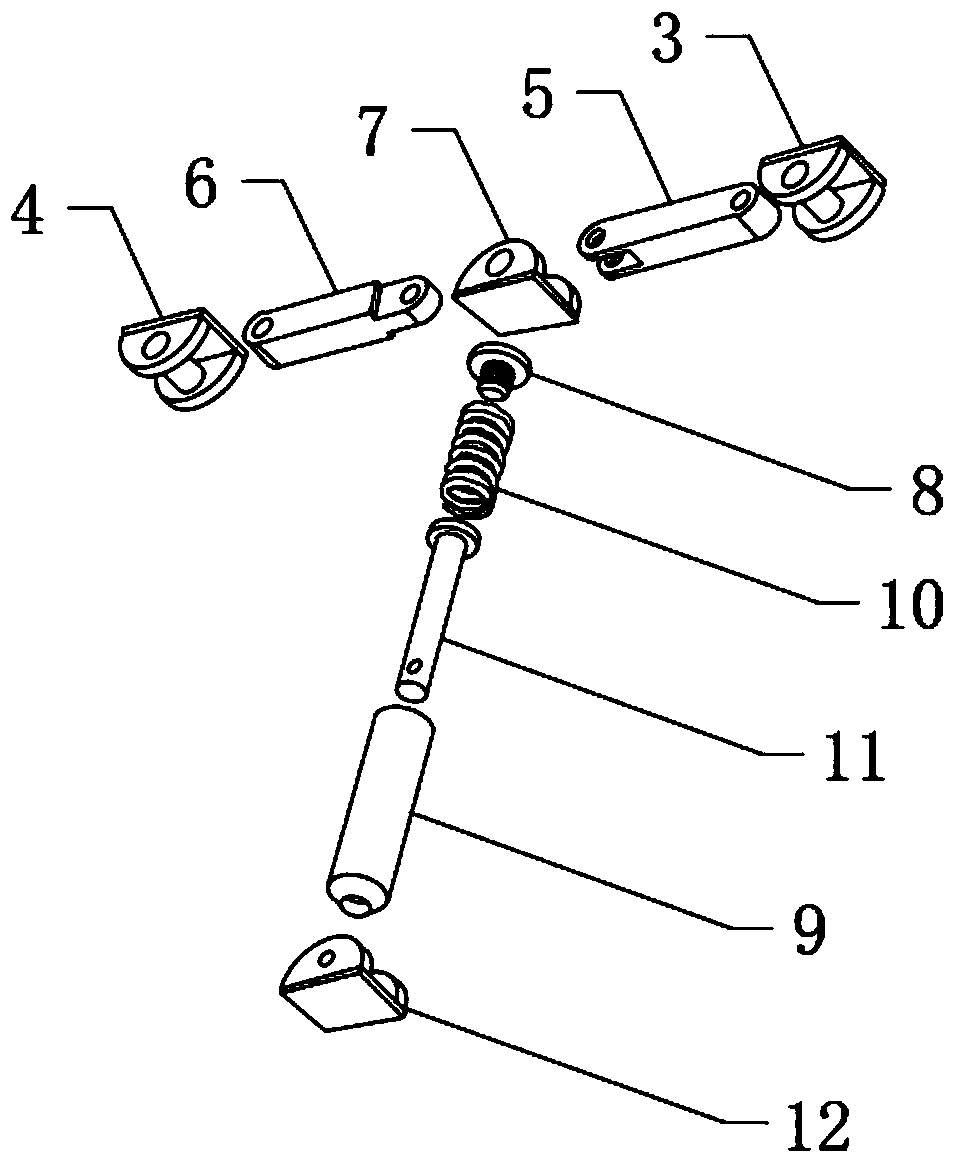

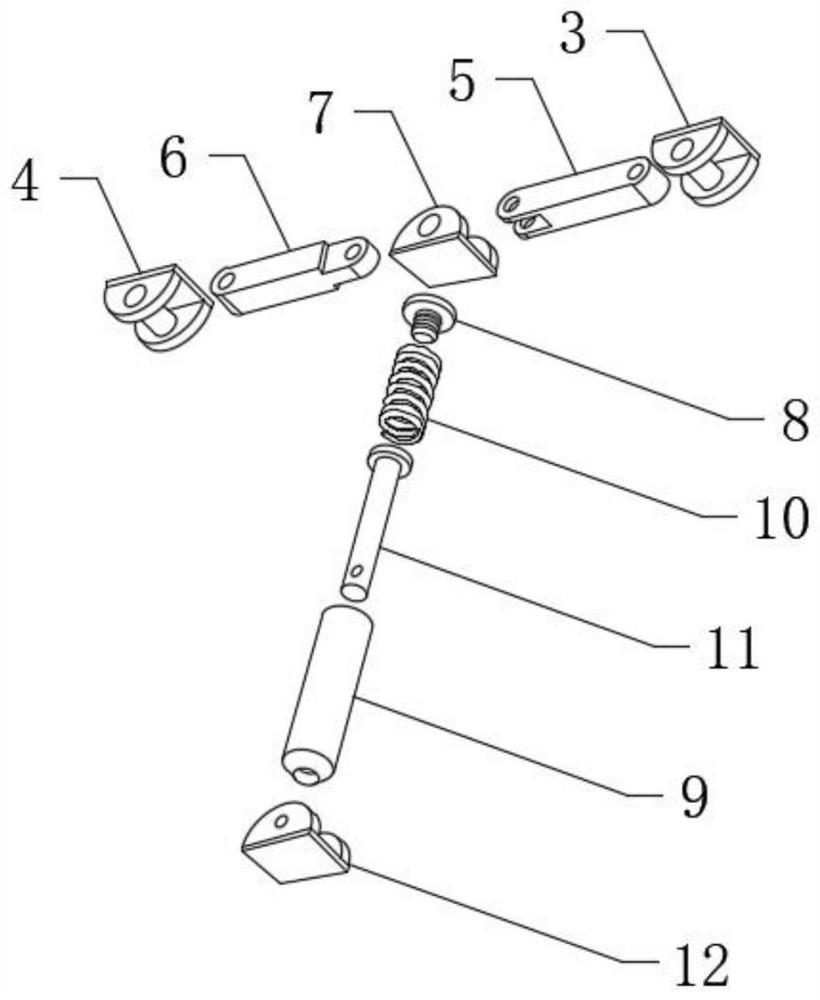

Anti-rust processing device after hardware workpiece ultrasonic cleaning

The invention discloses an anti-rust processing device after hardware workpiece ultrasonic cleaning. The anti-rust processing device comprises an oil immersing groove, and a ball screw, a sliding railand a material cage which are hung above the oil immersing groove. A nut of the ball screw is fixedly connected with an upper base block. The bottom of the upper base block is fixedly connected witha first hinging supporting seat and a second hinging supporting seat. A first connecting rod and a second connecting rod are respectively hinged to the first hinging supporting seat and the second hinging supporting seat. The first connecting rod and the second connecting rod are hinged to a third hinging supporting seat. The third hinging supporting seat is fixedly connected with a fastening piece. The fastening piece is connected with a sleeve in a threaded mode. The sleeve is internally provided with an elastic element. The elastic element abuts against a sleeving rod. The sleeving rod penetrates through the sleeve, and is hinged to a fourth hinging supporting seat. The fourth hinging supporting seat is fixedly connected with a lower base block. The anti-rust processing device moves inthe direction of the sliding rail by the lower base block, and immersing and taking out operation is well conducted. The material cage is driven to rotate by driving a stepping motor, and spin-dryingis well achieved. Traditional manual oil immersing and spin-drying procedures are replaced, and mechanical and automatic operation is achieved.

Owner:深圳市博思创环保设备有限公司

A distiller's yeast drying device for distiller's yeast processing

ActiveCN114294937BImprove drying qualityEfficient crushingDrying gas arrangementsDrying chambers/containersThermodynamicsProcess engineering

The invention discloses a distiller's yeast drying device for distiller's yeast processing, which relates to the technical field of distiller's yeast processing, and comprises a mounting plate, on which a raw material box, a drying tank and a drying tank are installed, and a lifting assembly is installed on the raw material box. In addition, a material turning assembly is installed on the drying tank, and the drying tank is connected with a turning drying mechanism, and a support stand is fixedly installed on one side of the outer wall of the raw material box; the present invention utilizes the provided lifting assembly to cooperate with the material cylinder, and can The koji to be dried is lifted from the raw material box at a uniform speed, and then falls into the drying tank through the guidance of the vibrating material guide assembly. During this process, the heating wire is turned on, so that the material cylinder and the drying tank have a higher temperature. The distiller's yeast can be heated and dried when it passes through its surface wall, and finally sent into the drying tank through the material receiving component to realize multi-stage and efficient drying treatment of the distiller's yeast, which is conducive to improving the drying quality of the distiller's yeast, in terms of uniformity and dryness All are well guaranteed.

Owner:济南趵突泉酿酒有限责任公司

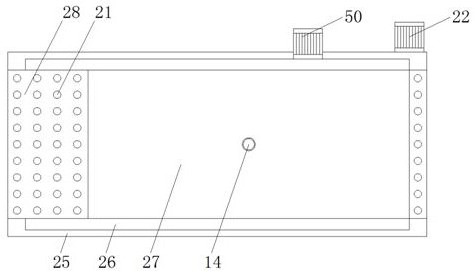

Raw material drying machine for organic silicone production

PendingCN106871624ARealize drying operationControl heating temperatureDrying gas arrangementsProcess engineeringSilicone

The invention discloses a raw material drying machine for organic silicon production. The raw material drying machine comprises a drying cylinder, a conveying pipe transversely penetrating the drying cylinder and a stirring conveying device arranged in the conveying pipe. The upper portion of the drying cylinder is provided with a water adding opening, a pressure meter head and a one-way valve, and the bottom of the drying cylinder is provided with a heating pipe which is spirally arranged. A vacuum interlayer is arranged in the cylinder wall of the drying cylinder. A feeding port is arranged at one end of the conveying pipe, a discharging port and a suction opening are arranged at the other end of the conveying pipe, and the suction opening is located on the upper portion of the conveying pipe. The stirring conveying device comprises a rotating shaft and blades arranged on the rotating shaft. The raw material drying machine for organic silicon production can quickly dry raw materials for organic silicon production, is high in heat exchanging efficiency and environmentally friendly, saves energy and has the beneficial effects of being simple in structure, low in manufacturing cost and the like.

Owner:RUIJIN RAGU TECH DEV

Garbage incineration power generation system for harmless treatment of garbage

InactiveCN112032729ARealize water filtration operationAvoid dropping large batches at onceMachines/enginesIncinerator apparatusElectric machineryProcess engineering

The invention discloses a garbage incineration power generation system for harmless treatment of garbage. The garbage incineration power generation system comprises a cement floor and a mounting groove formed in the cement floor, wherein a garbage can is fixedly connected to one side of the interior of the mounting groove. According to the garbage incineration power generation system for harmlesstreatment of garbage, through cooperative use of a crushing structure, a second feeding mechanism, a driving motor IV, crushing rollers and a crushing box, garbage entering the crushing box is crushed, small pieces of garbage are dried again through the second feeding mechanism, and large pieces of garbage are crushed into small pieces one by one, so that the contact area between the garbage and heat is further increased, and the garbage drying uniformity is further improved. Multiple drying measures are adopted for heating and drying the garbage, so that the garbage is dried more sufficientlyand thoroughly, and the garbage drying effect is good. The sufficiently-dried small pieces of garbage can be sufficiently combusted, so that smoke generated during garbage combustion can be reduced,and the garbage incineration power generation system is relatively environment-friendly.

Owner:(LONGYAN XINDONGYANG) SHENZHEN ENERGY ENVIRONMENT PURIFICATION CO LTD

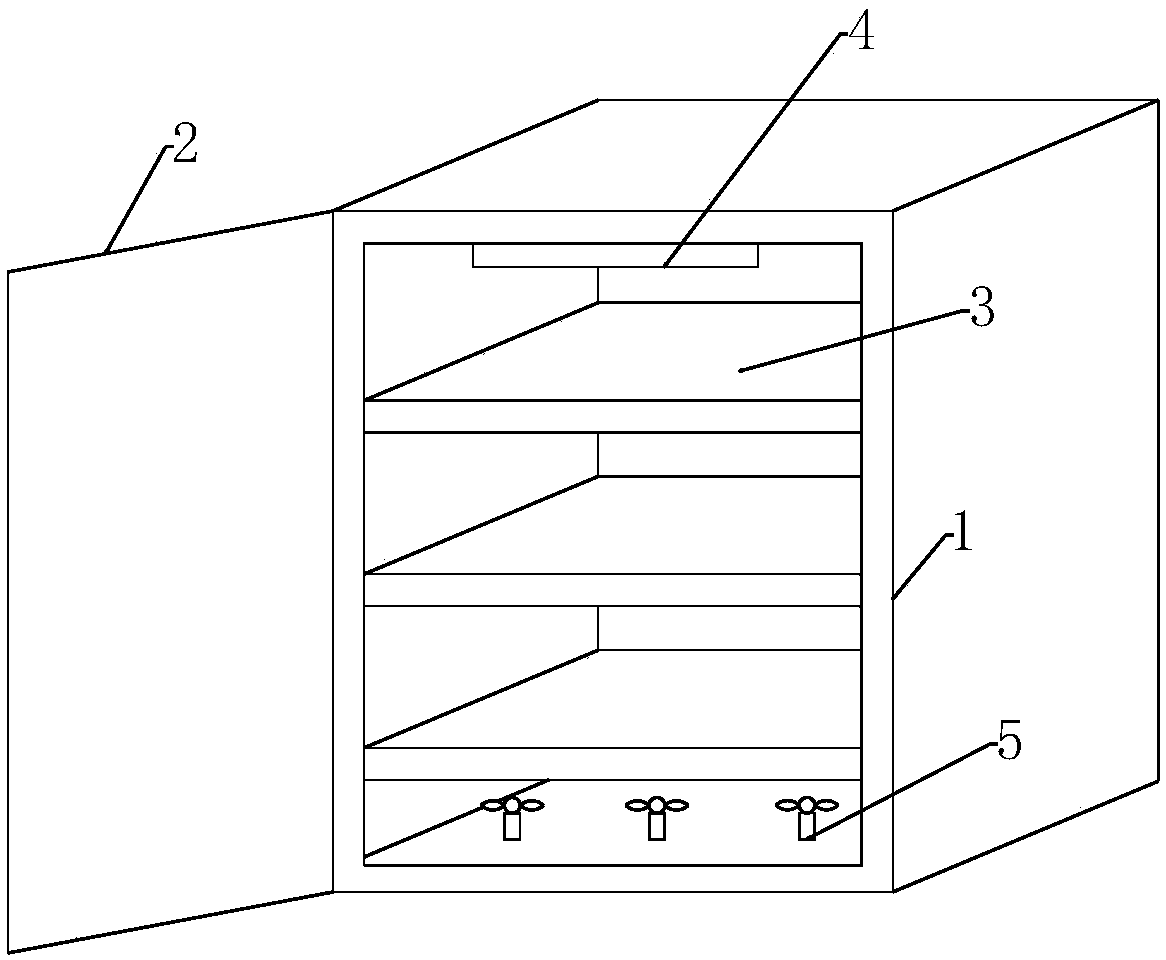

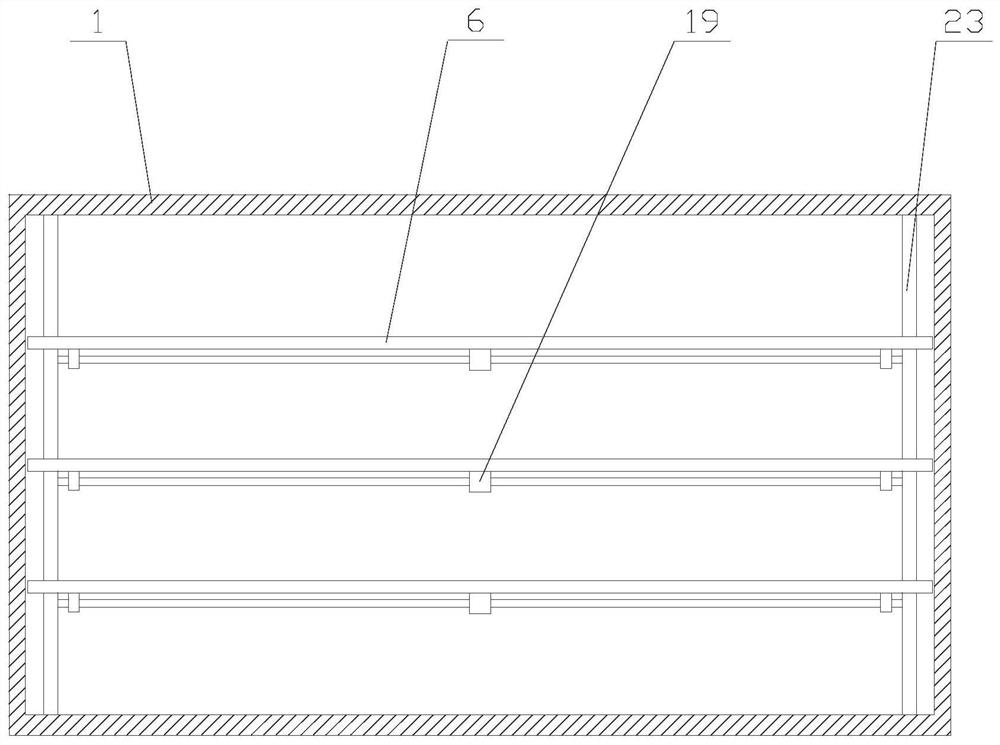

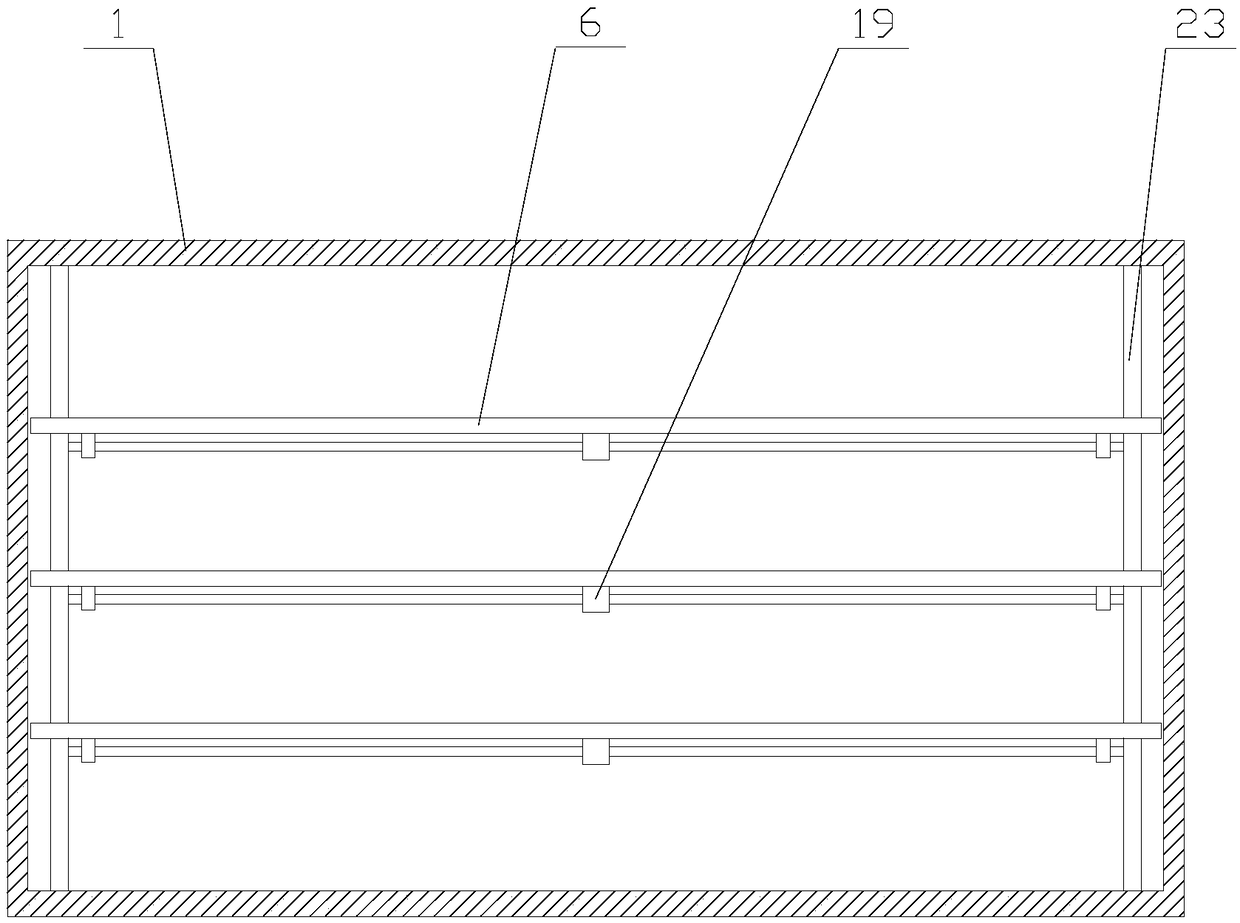

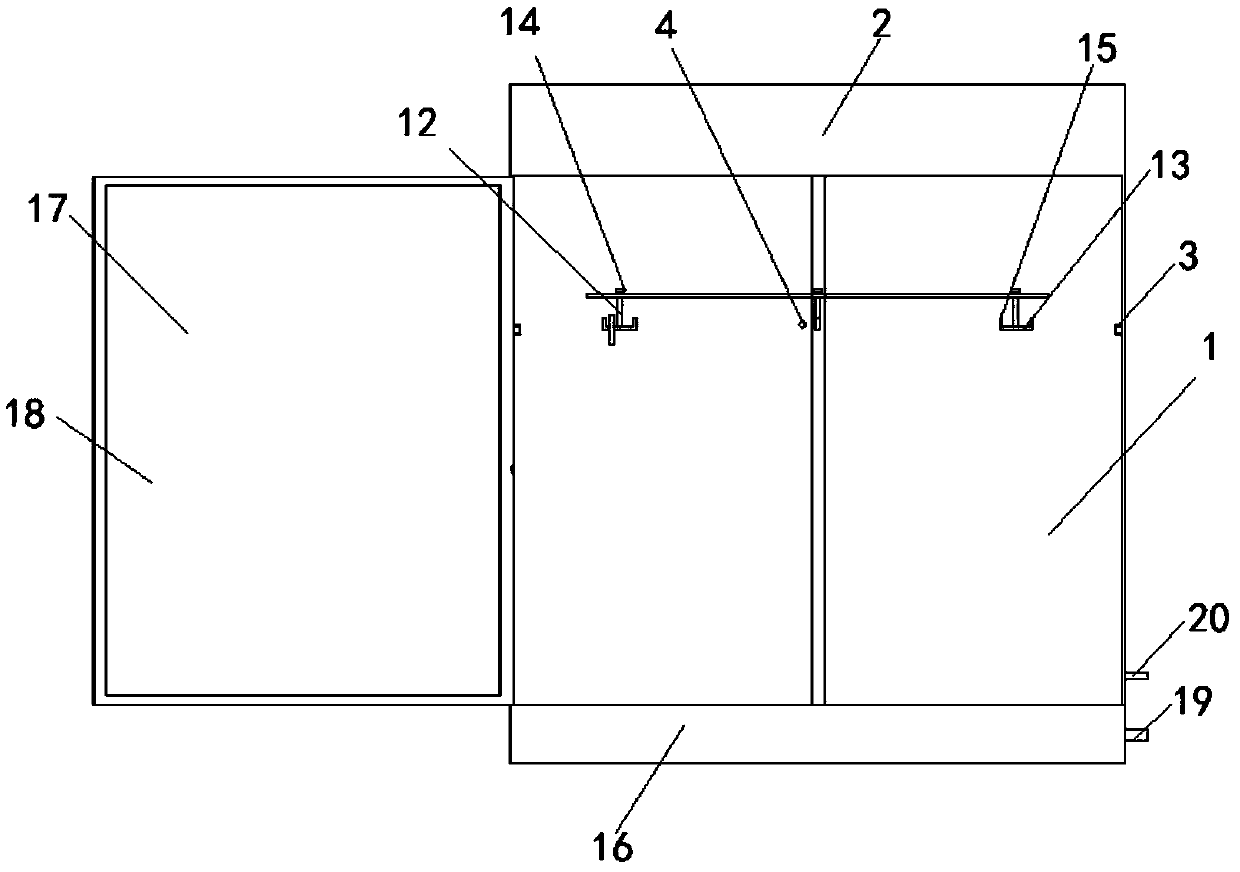

Drying device used for processing of new material

InactiveCN109780829ARealize drying operationSimple structureDrying chambers/containersDrying solid materialsEngineeringNew materials

The invention particularly relates to a drying device used for processing of a new material. The drying device comprises a drying oven. An oven door is rotatably arranged on the drying oven. A plurality of storage plates are arranged in the drying oven and are of a netty structure. A heating device is arranged at the top of the inner side of the drying oven. Air stirring devices are arranged at the bottom of the inner side of the drying oven. The drying device can be used for drying the new material, is simple in structure, high in drying efficiency, and has high practicability and market promotional value.

Owner:四川鑫涂盾新材料科技有限公司

A stone crushing and sorting device for construction

ActiveCN108374303BRealize sortingIncrease productivityRoads maintainenceArchitectural engineeringStructural engineering

The invention relates to a building stone breaking and sorting device, which comprises an ultrasonic treatment chamber, an impact chamber, a breaking chamber, a sorting device, a drying and conveyingchamber and a water treatment device. An ultrasonic device is utilized to crack stone in the ultrasonic treatment chamber, then the stone is broken by a pneumatic impact hammer according to cracks, the stone is broken in the breaking chamber, the stone is sent into the sorting device after being broken according to the size of the stone, the stone is sorted to different conveying belts to be driedand stored, and water in a process is regenerated and recycled by the water treatment device. Therefore, an effect that the stone is broken in a construction site and sorted according to granularityis achieved.

Owner:中铁十八局集团北京工程有限公司

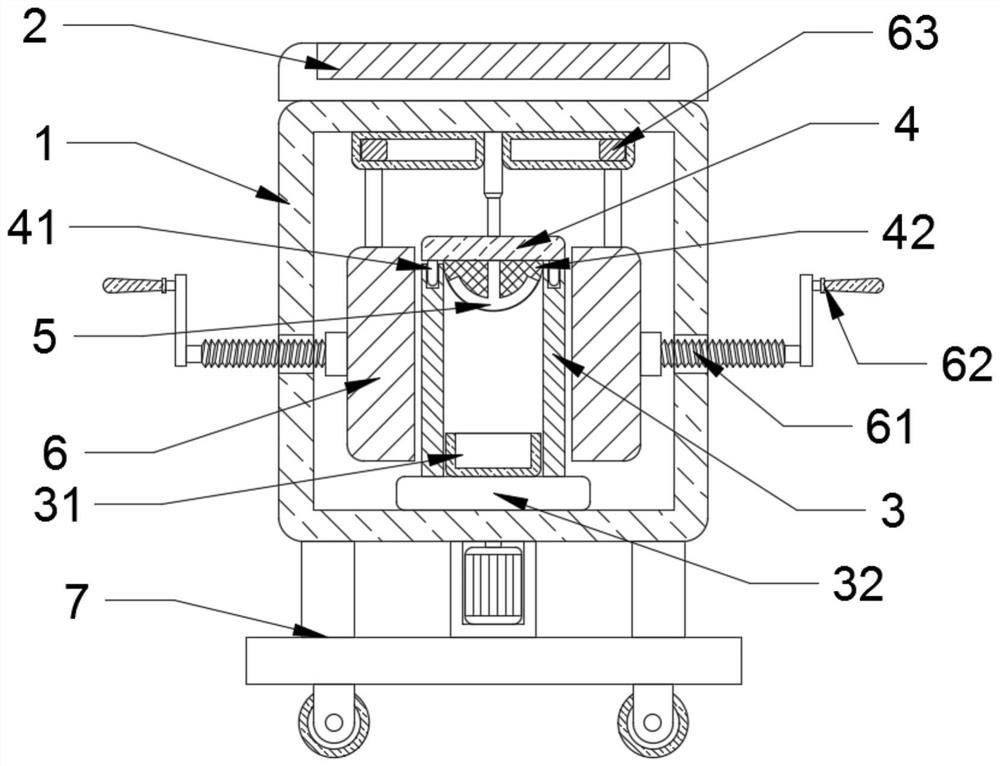

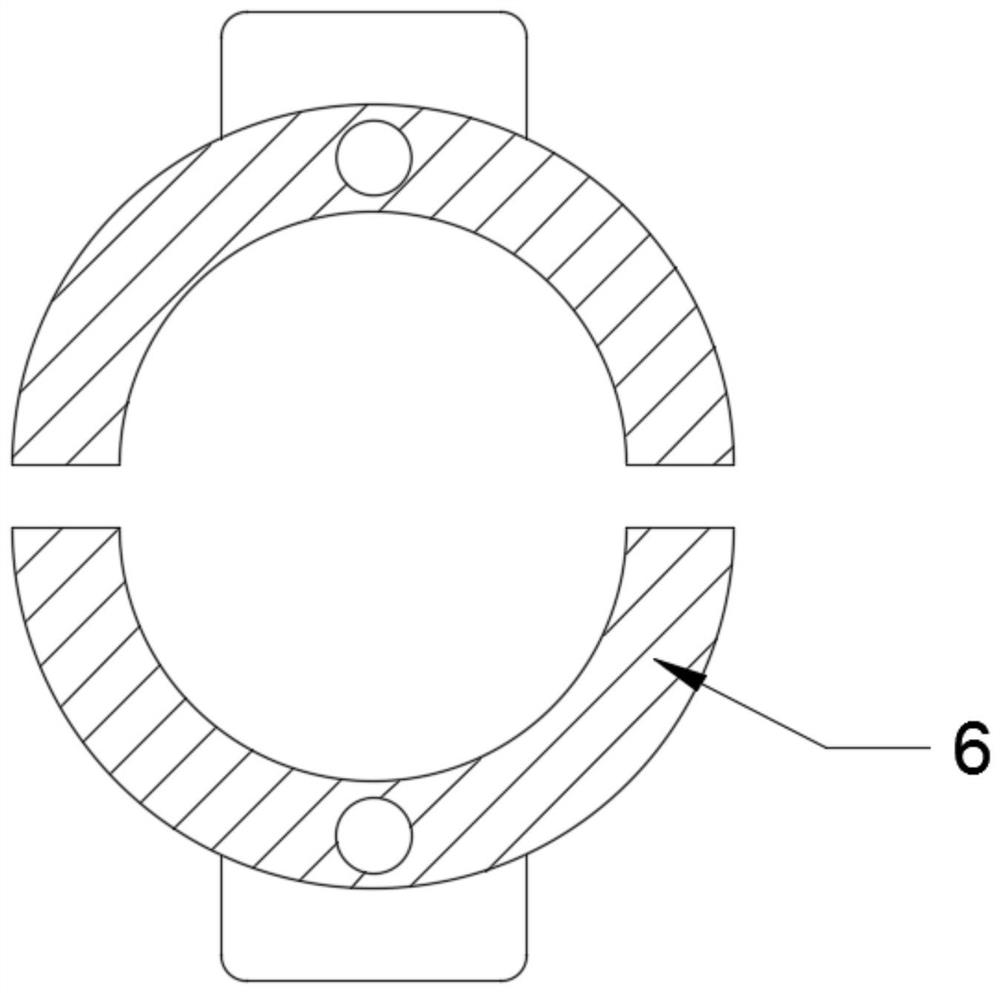

Gas bottle dryer with temperature control device

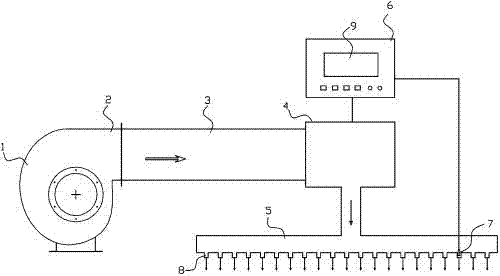

InactiveCN107514897AHigh measurement accuracyRealize drying operationDrying gas arrangementsTemperature controlGas cylinder

The invention relates to a gas cylinder dryer, and discloses a gas cylinder dryer with a temperature control device, which includes: a blower, a ventilation pipe connected to the air outlet of the blower, a heating device connected to the ventilation pipe, and a heating A gas cylinder drying unit connected to the device, wherein the heating device is connected to a thermostat, and the gas cylinder drying unit is provided with a temperature sensor connected to the thermostat. The beneficial effect is that the air blower passes the air from the ventilation pipe into the heating device, the air blown in by the blower is heated by the heating device, and then the heated air is led to the cylinder drying unit, and the heating is achieved by hot air. Drying of cylinders. During the whole drying process, the temperature of the gas cylinder drying unit is monitored in real time through the temperature sensor. The temperature sensor has high measurement accuracy. The temperature sensor transmits the temperature signal back to the thermostat, and the heating device is controlled by the thermostat. work.

Owner:倪飞

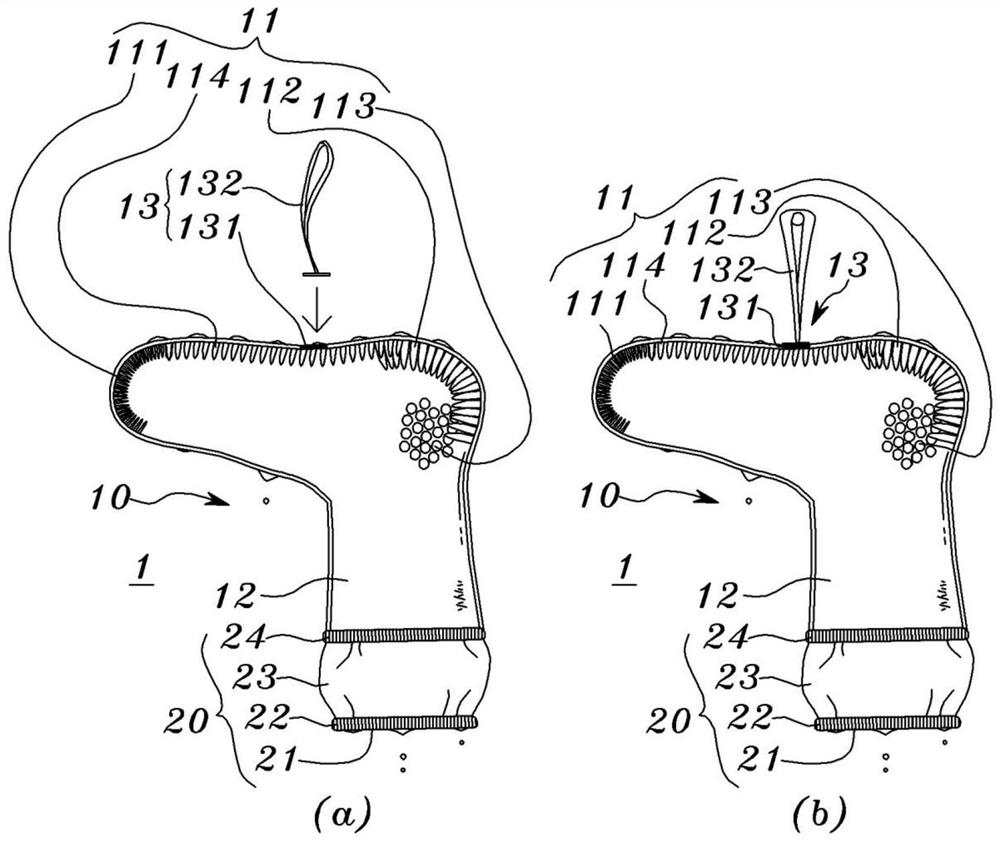

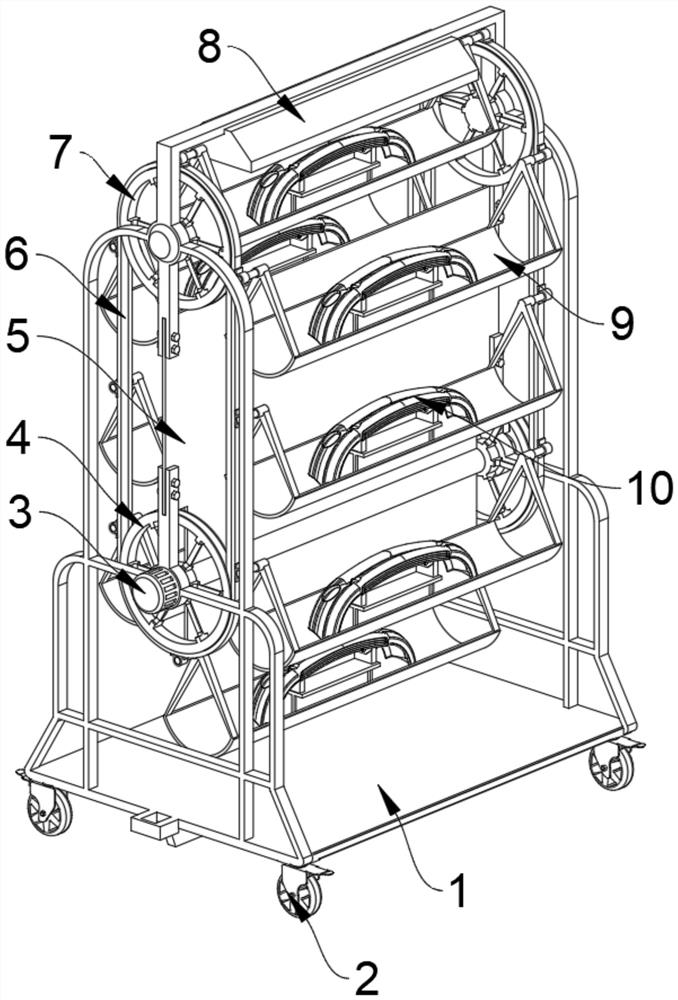

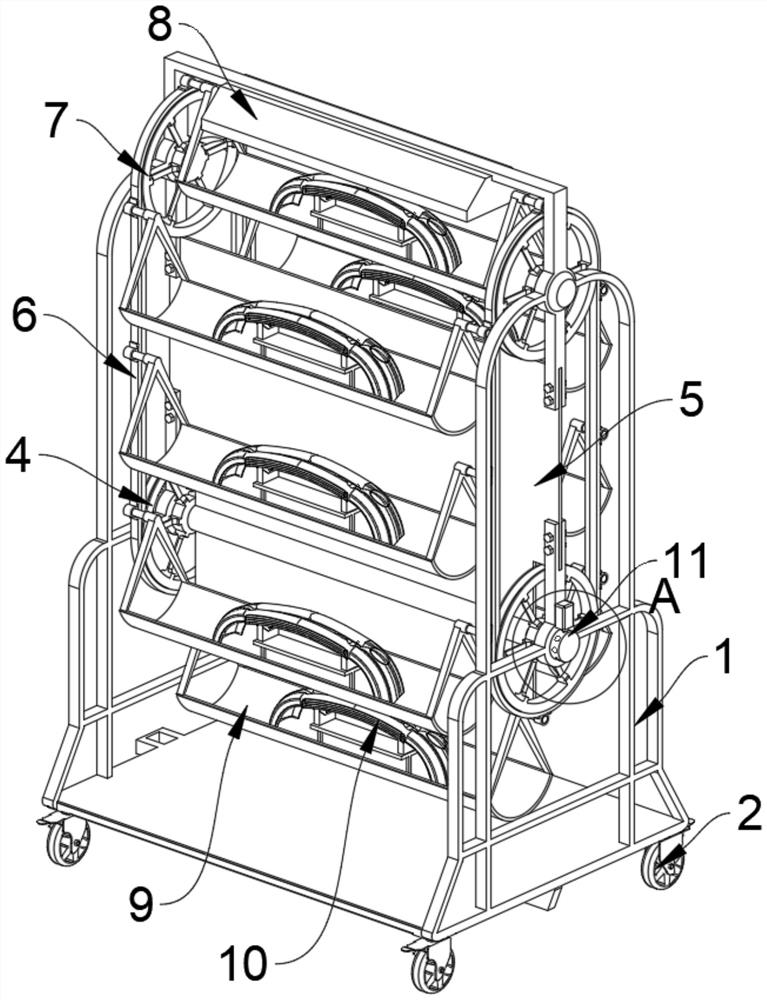

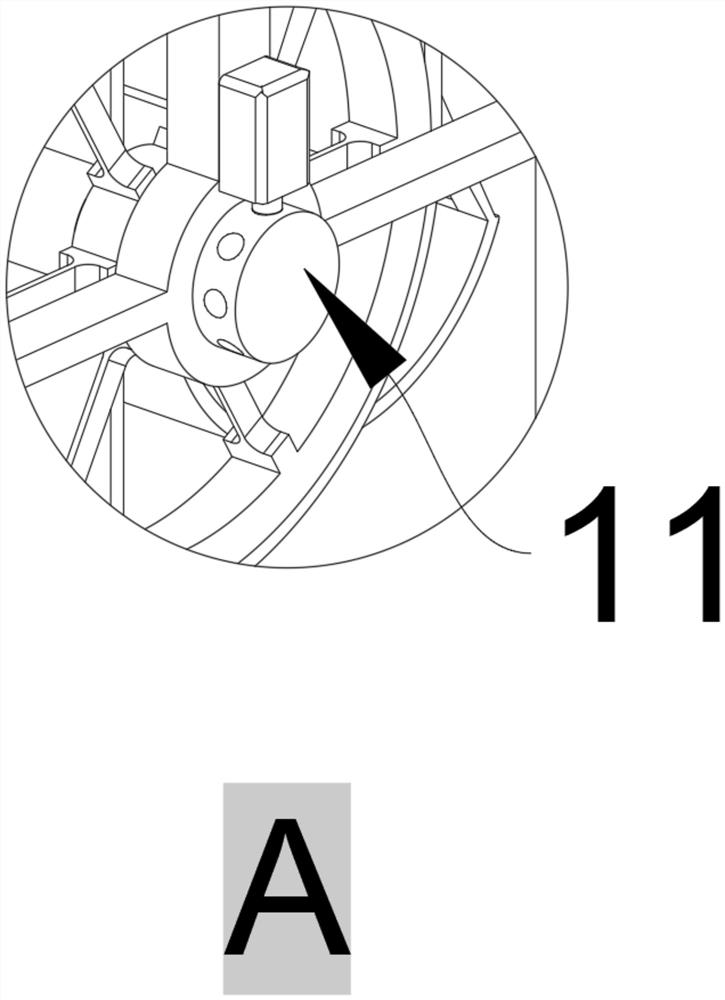

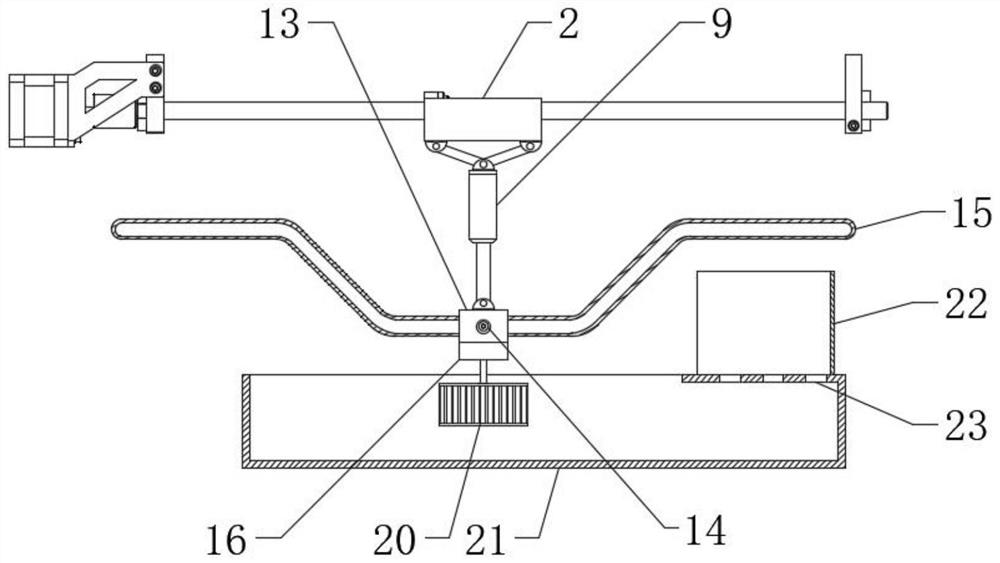

Mop washing machine and T-shaped mop matched with same

PendingCN113180561AEasy to cleanClean thoroughlyCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention relates to the technical field of life cleaning, in particular to a mop washing machine and a T-shaped mop matched with the same. The mop can be cleaned and spin-dried. According to the mop, the existing design of scattered cloth strip heads is abandoned, mop cloth made of superfine fibers is adopted through improvement, and the cleaning power is high; a slope is arranged at the lower part of a washboard and forms a big-end-down cavity with the bottom of a cleaning barrel, so that the space of the bottom is increased, and the mop cloth can be conveniently stored when moving downwards; the washboard and rubbing strips are matched, so that the mop cloth can be effectively cleaned when the mop moves up and down; and the washboard also serves as a support when the mop is spin-dried, the mop cloth is distributed in an inverted V shape through the guidance of the slope surface at the upper part, and the mop is spin-dried conveniently in cooperation with the detachable design of a mop head and a mop rod.

Owner:江涛

Vegetable pre-packaged food drying device

PendingCN113175798ARealize drying operationPrevent re-dryingDrying chambers/containersDrying solid materialsDryingProcess engineering

The invention relates to the technical field of food drying devices, in particular to a vegetable pre-packaged food drying device. The drying device comprises a box body, supporting legs are fixedly installed at the bottom ends of the two sides of the box body, a material taking door is fixedly connected to the bottom of the front end face of the box body through hinges, a handle is fixedly installed on the surface of the material taking door, a drainage pipe is fixedly installed in the middle of the bottom end of the box body and communicates with the box body, an air outlet pipe is fixedly installed at the top end of the left side of the box body and communicates with the box body, a rotating cylinder is fixedly installed at the upper end of the air outlet pipe and communicates with the air outlet pipe, and an air outlet is fixedly installed at the upper end of the rotating cylinder and communicates with the rotating cylinder. According to the vegetable pre-packaged food drying device, drying automation is achieved, the dewatering and drying efficiency of vegetables is improved, the uniform drying efficiency of the vegetables is ensured, and the drying quality is improved.

Owner:鲁晓军

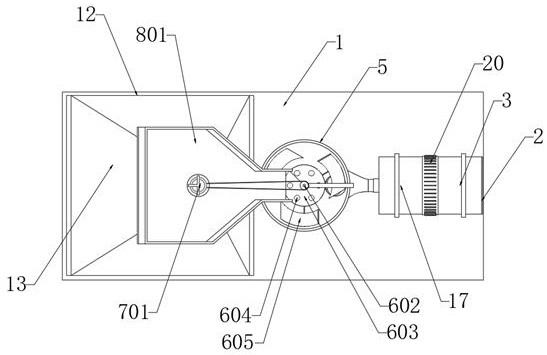

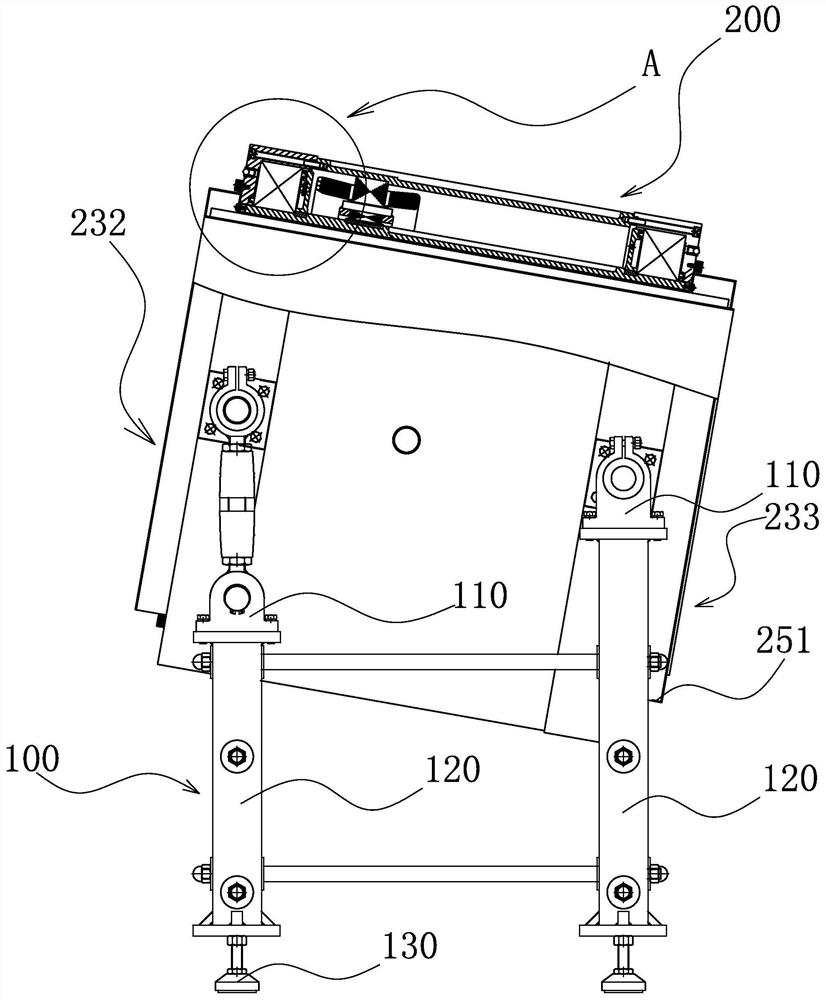

Centrifugal spin dryer

InactiveCN112503864ARealize drying operationEasy to operateDrying solid materials without heatDrying chambers/containersElectric machineryEngineering

The invention provides a centrifugal spin dryer, and belongs to the technical field of food processing. The centrifugal spin dryer comprises: a machine frame and a motor, wherein the machine frame serves as a support, the motor is obliquely arranged on the machine frame and comprises a stator and a rotor, a rotary drum is arranged in the rotor in an embedded mode, a through hole is formed in the rotary drum in the axis direction, and a feeding port and a discharging port are formed in the two ends of the through hole correspondingly. According to the centrifugal spin dryer, the whole motor serves as an integrated body of power and a spin-drying function, the rotor and the rotary drum rotate synchronously, spin-drying operation of food materials is realized, in addition, the motor is obliquely arranged on the machine frame, the two ends of the rotary drum communicate with each other, the food materials can automatically slide down along the drum wall of the rotary drum after spin-dryingof the food materials is completed, automatic discharging of the food materials is completed, and the operation is convenient and reliable.

Owner:ZHEJIANG XIANGYING CENT KITCHEN EQUIP CO LTD

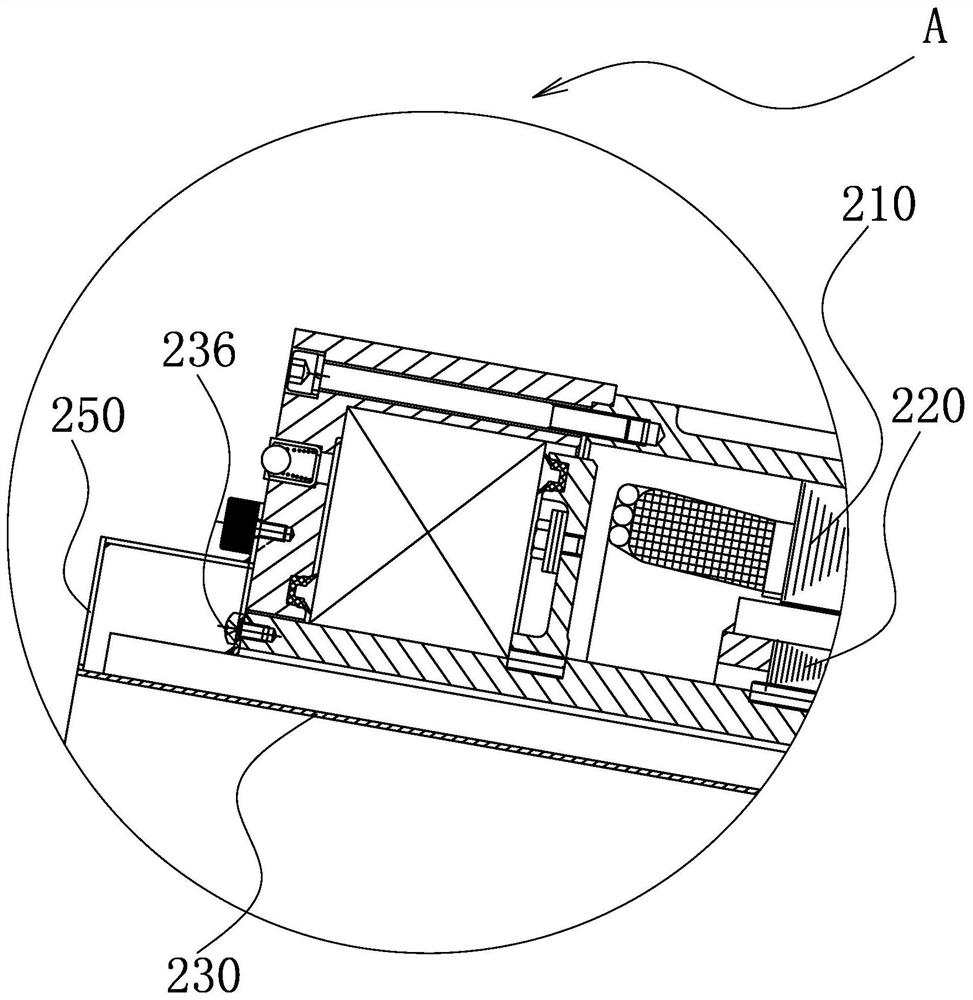

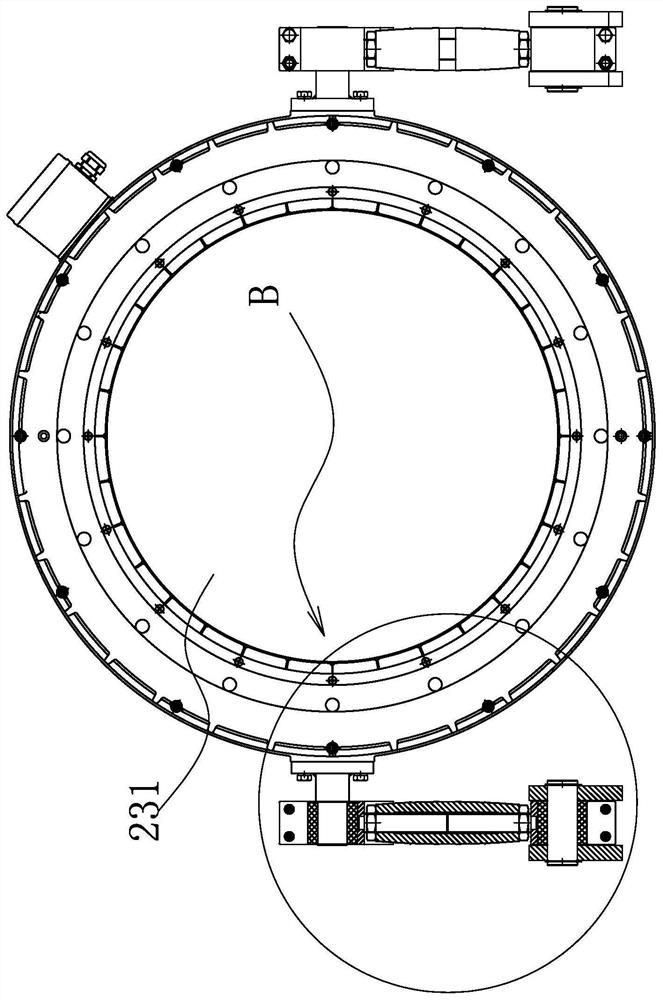

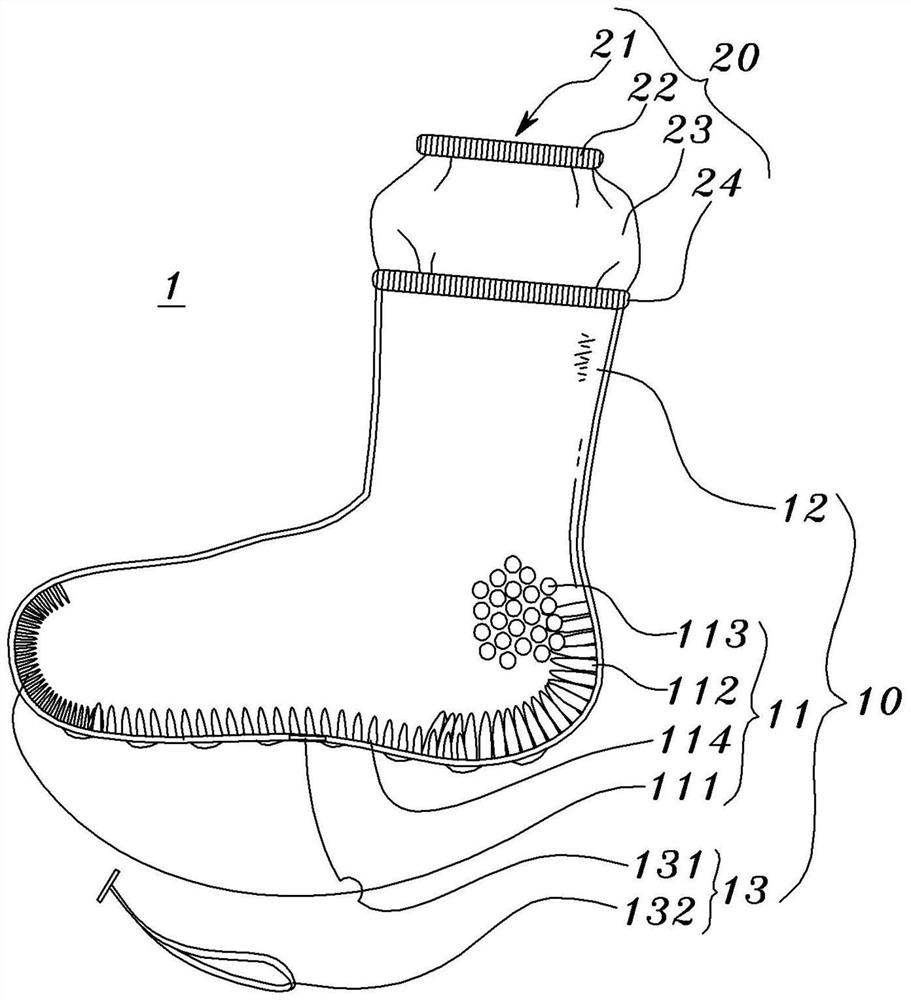

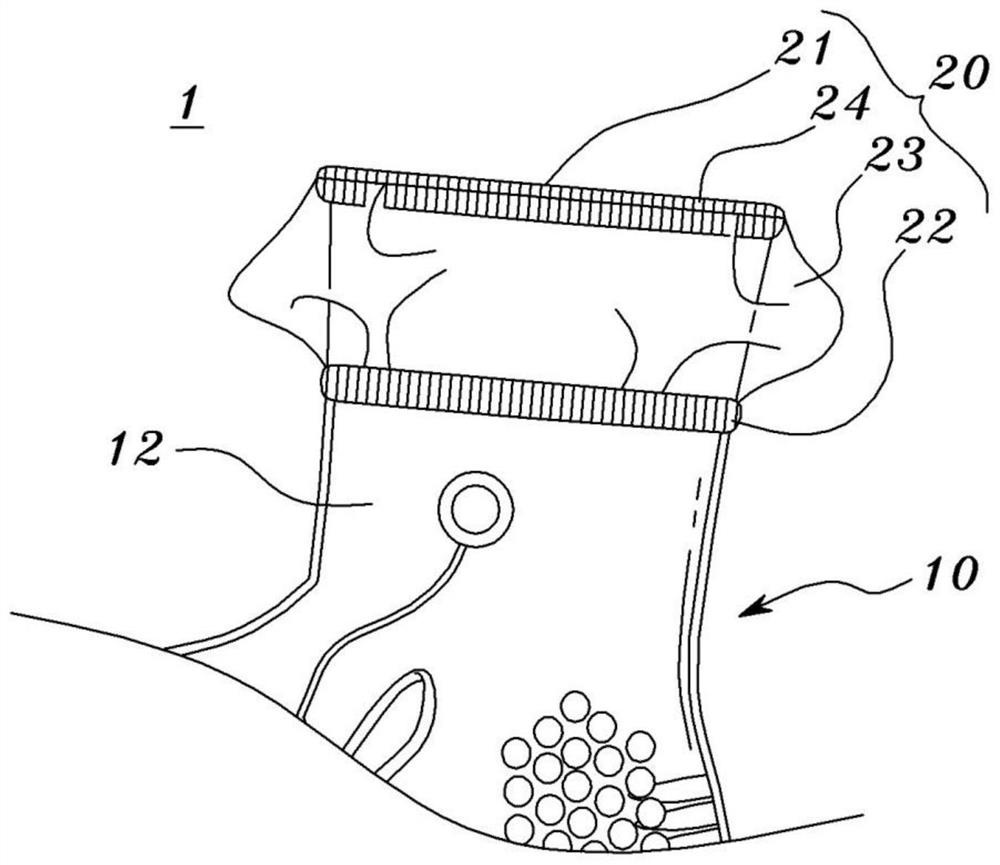

Shoe for foot-washing

InactiveCN112218565AGuaranteed cleanlinessRealize the effect of foot bathBathsDouchesPhysical medicine and rehabilitationPhysical therapy

The present invention relates to a shoe for foot-washing and, more specifically, to a shoe for foot-washing, wherein the shoe: enables a user to wash a foot by only wearing the shoe and walking without continuously filling and discharging water in and from the shoe, so that the user can wash the foot for a long time to maintain foot cleanliness and recover the foot from fatigue; prevents water ina receiving space inside a main body part from leaking to the outside during use; allows water to be easily filled therein; allows sweat and a callus to be easily removed from a user's foot; and is easy to dry after use.

Owner:崔沃先

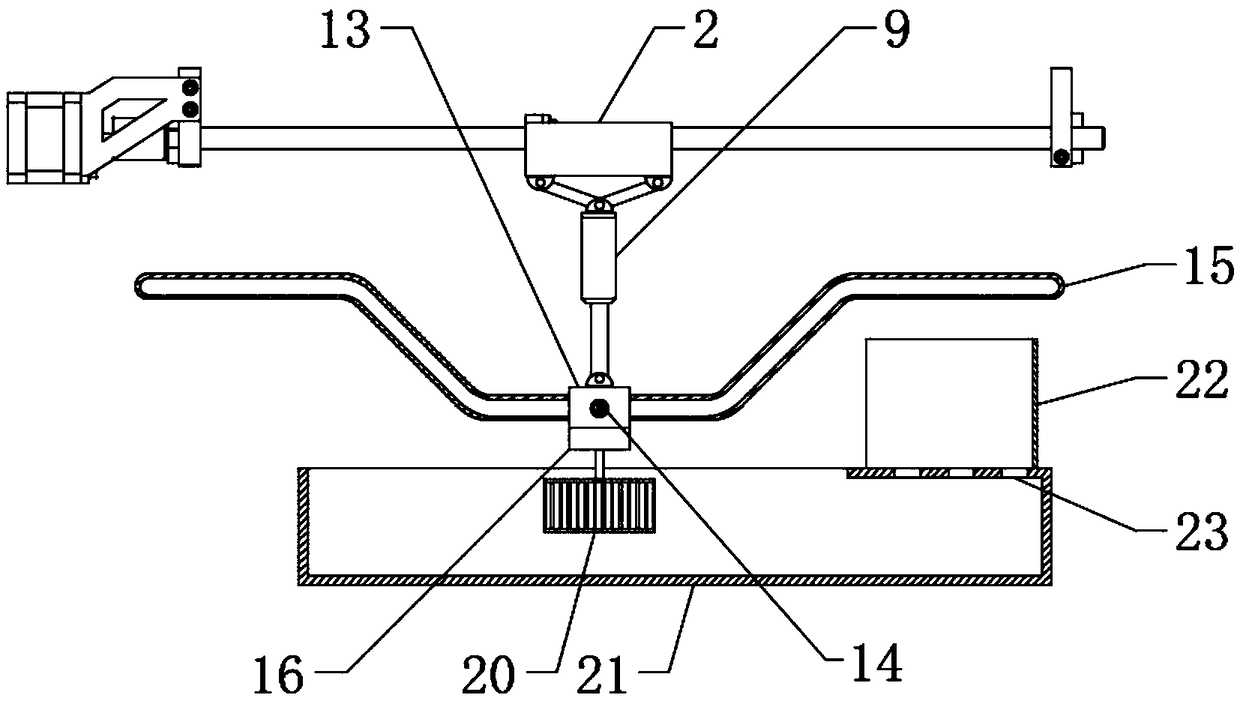

Cleaning device provided with water throwing function and used for landscape pruning

PendingCN112275698AIncrease centrifugal forceConvenient for centralized collectionDrying solid materials without heatCleaning using liquidsFiltrationElectric machinery

The invention belongs to the technical field of landscape greening, and particularly relates to a cleaning device provided with a water throwing function and used for landscape pruning. The cleaning device comprises a machine body, a framework, spray heads, a motor A, rotary rollers and a conveyor belt, wherein the framework is in the shape of an inverted U-shaped structure, and is fixedly connected to the top of the machine body; the multiple spray heads are transversely and symmetrically arranged on the top of the framework; the output ends of the spray heads penetrate through the frameworkand extend into the framework; the rotary rollers are transversely and symmetrically arranged in the machine body and are rotatably connected to the machine body; and the rotary rollers mutually sleeve. A tool is sufficiently in contact with water, so that cleaning efficiency is guaranteed; water seep holes can control filtration of water stains in a chamber, so that accumulation of the water stains is avoided; while a motor B works, a cam can be driven to rotate for repeatedly jacking a movable plate, so that impurities on the movable plate have height drop and downwards slide into a materialbox along the movable plate, and thus, the impurities are intensively collected by people conveniently.

Owner:杨雪

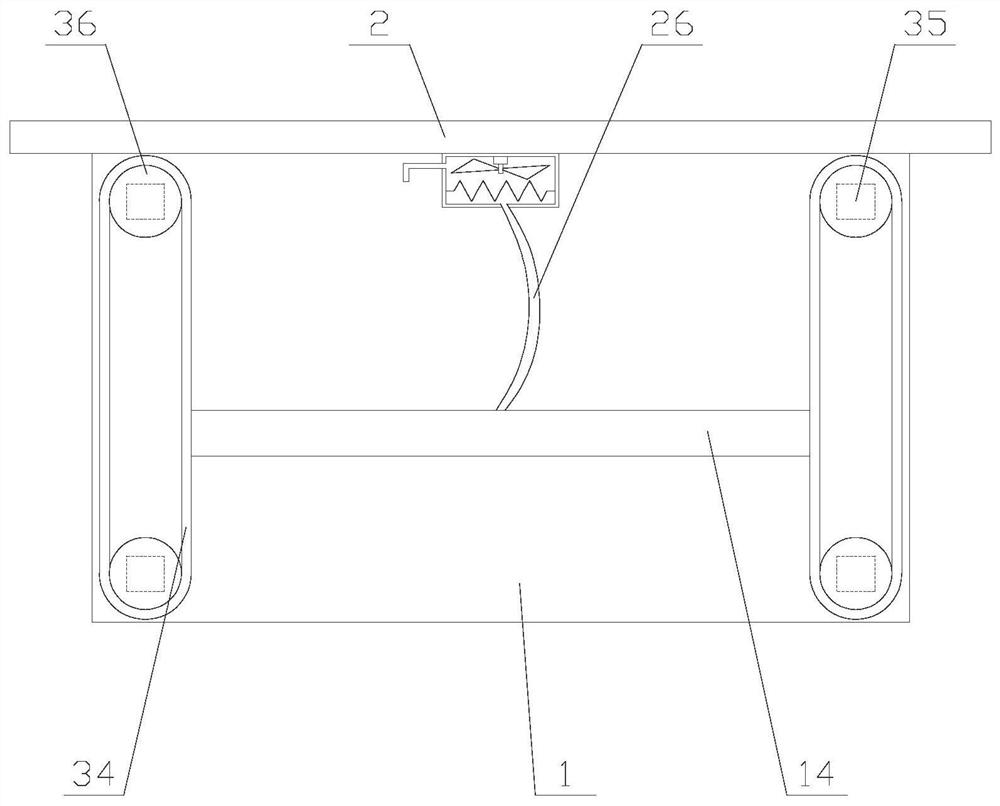

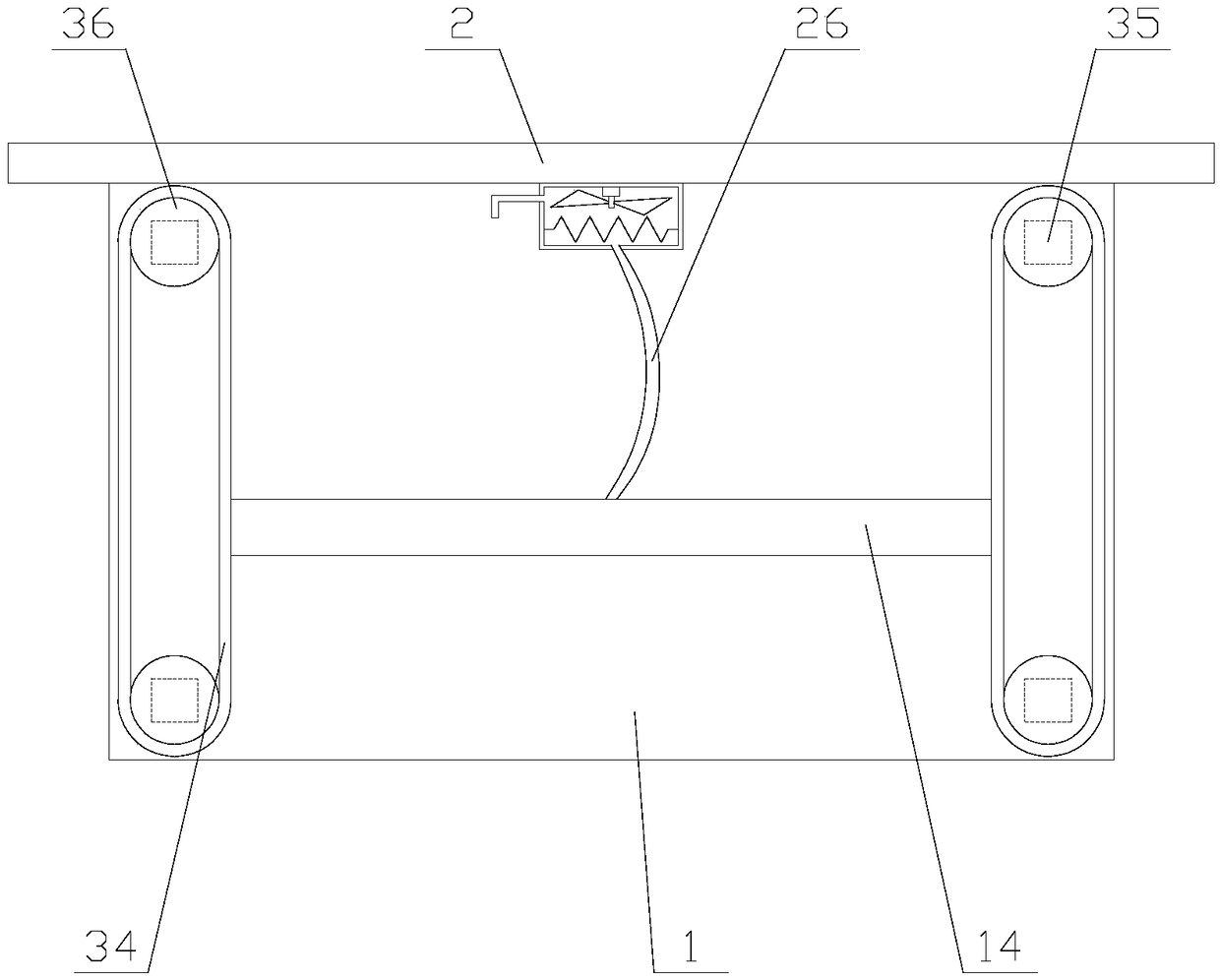

Recyclable three-dimensional textile printing and dyeing equipment

PendingCN114481497AIncrease the number of recyclingQuality improvementTextile storage in wounded formLiquid/gas/vapor removal by squeezing rollersTextile printerEngineering

The recycling three-dimensional textile printing and dyeing equipment comprises a base and a first connecting plate, two sets of supporting columns arranged front and back are installed at the top of the base, and a top plate is installed at the tops of the supporting columns; symmetrically-arranged sliding grooves are formed in the top of the top plate in a penetrating mode, connecting rods which are symmetrically arranged front and back are slidably installed in the sliding grooves, connecting blocks are installed at the top ends of the front connecting rod and the rear connecting rod, and inserting holes which are distributed at equal intervals are formed in the back face of the front connecting block. Inserting rods which are arranged at equal intervals are installed on the front face of the rear connecting block, extrusion rollers are installed at the bottom ends of the front connecting rod and the rear connecting rod, and connecting holes are formed in the outer walls of one sides of the two extrusion rollers. By arranging the base, the sliding grooves, the extrusion rollers and the connecting blocks, the connecting blocks are moved, then the connecting rods are driven to move in the sliding grooves, redundant dye on textile cloth is extruded and scraped off through the extrusion rollers, and then the number of times of cyclic utilization of the dye is increased.

Owner:海安富邦纺织科技有限公司

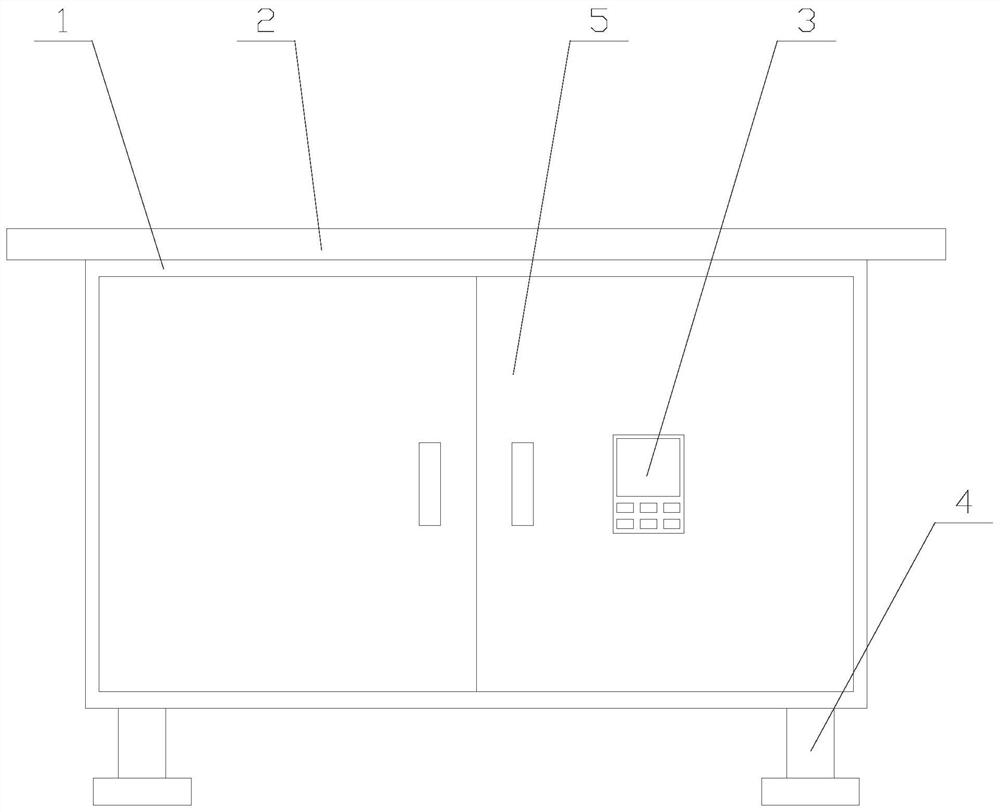

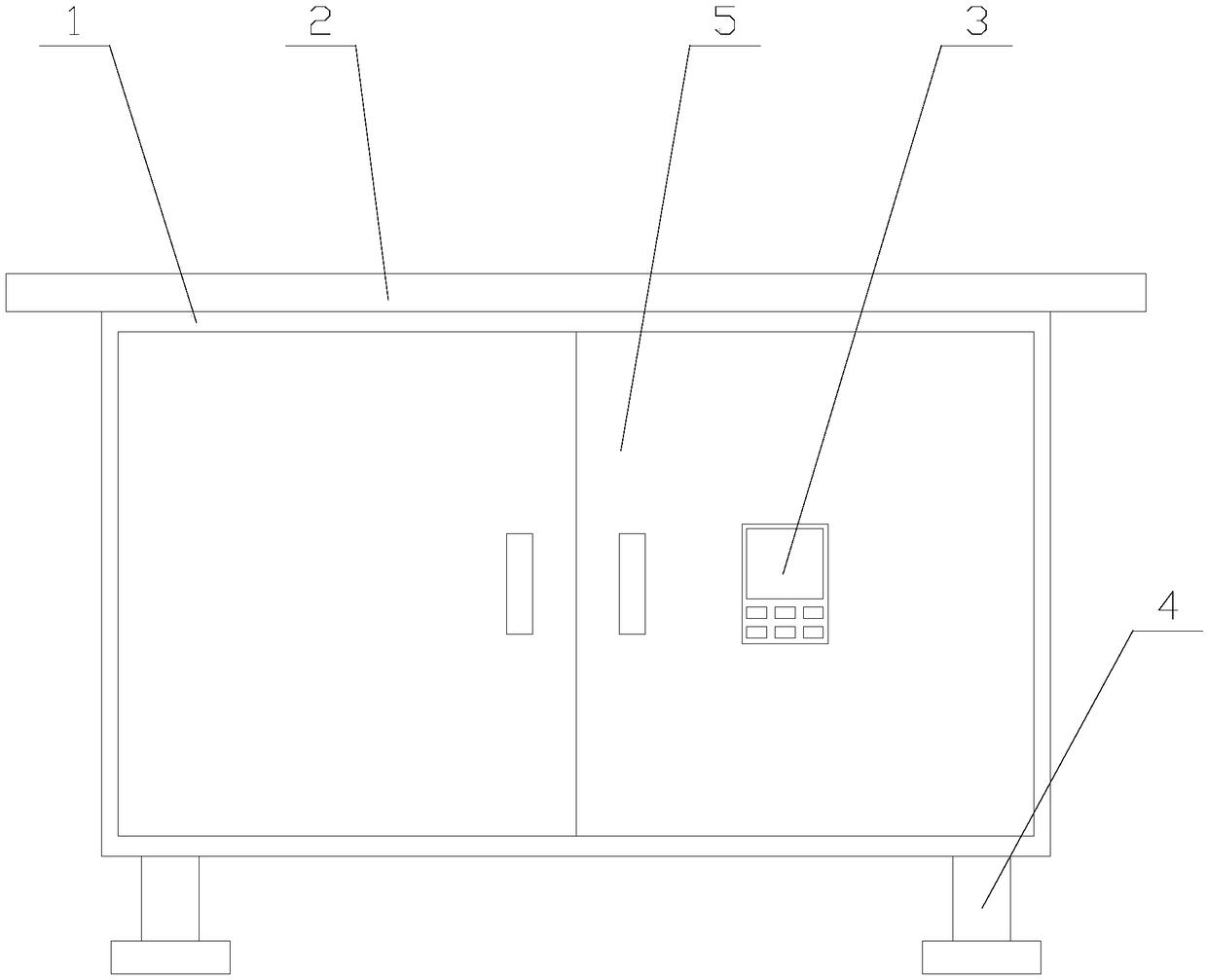

An anti-corrosion bathroom cabinet with adjustment function

ActiveCN109044145BWith adjustment functionEnsure stabilityWash-standsDrying gas arrangementsStructural engineeringBevel gear

The invention relates to an anti-corrosion bathroom cabinet with a regulating function, which comprises a cabinet body, a plate, a controller and four supporting legs, wherein a drying mechanism is arranged on the back surface of the cabinet body, a plurality of placing mechanisms are arranged in the cabinet body, the placing mechanism comprises a placing plate, a driving component and tow supporting components, the supporting component comprises a supporting plate and two supporting units, wherein the supporting unit comprises a lantern ring, a sleeve, a screw rod, a sliding block, a supporting rod and a first bevel gear, the drying mechanism comprises a lifting pipe, a heat supply component, a drying component and two lifting components, wherein the drying component comprises a power unit, a plurality of drying units and a plurality of connecting rods, in the anti-corrosion bathroom cabinet with the adjusting function, the height position of the placing plate can be adjusted throughthe placing mechanism, the user can flexibly adjust the height position according to the requirements per se, the inner space of the cabinet body is fully utilized, more than that, the back surface ofthe cabinet body is dehumidified and dried through the drying mechanism, so that the back surface of the cabinet body is prevented from being damaged through water vapor corrosion, and the practicability of the device is improved.

Owner:佛山市南海高通卫浴有限公司

Anti-corrosion bathroom cabinet with regulating function

ActiveCN109044145AWith adjustment functionEnsure stabilityWash-standsDrying gas arrangementsWater vaporEngineering

The invention relates to an anti-corrosion bathroom cabinet with a regulating function, which comprises a cabinet body, a plate, a controller and four supporting legs, wherein a drying mechanism is arranged on the back surface of the cabinet body, a plurality of placing mechanisms are arranged in the cabinet body, the placing mechanism comprises a placing plate, a driving component and tow supporting components, the supporting component comprises a supporting plate and two supporting units, wherein the supporting unit comprises a lantern ring, a sleeve, a screw rod, a sliding block, a supporting rod and a first bevel gear, the drying mechanism comprises a lifting pipe, a heat supply component, a drying component and two lifting components, wherein the drying component comprises a power unit, a plurality of drying units and a plurality of connecting rods, in the anti-corrosion bathroom cabinet with the adjusting function, the height position of the placing plate can be adjusted throughthe placing mechanism, the user can flexibly adjust the height position according to the requirements per se, the inner space of the cabinet body is fully utilized, more than that, the back surface ofthe cabinet body is dehumidified and dried through the drying mechanism, so that the back surface of the cabinet body is prevented from being damaged through water vapor corrosion, and the practicability of the device is improved.

Owner:佛山市南海高通卫浴有限公司

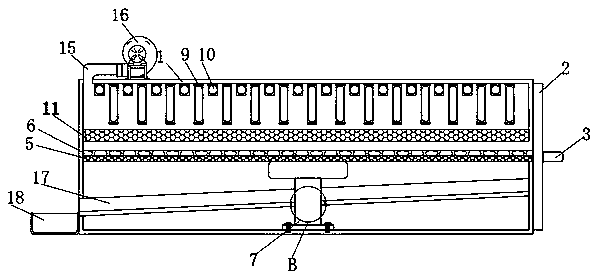

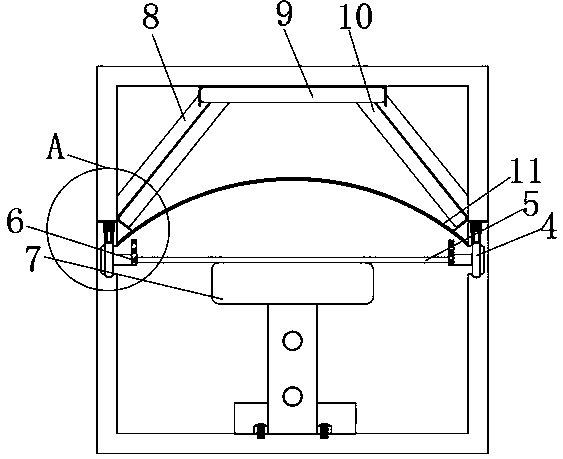

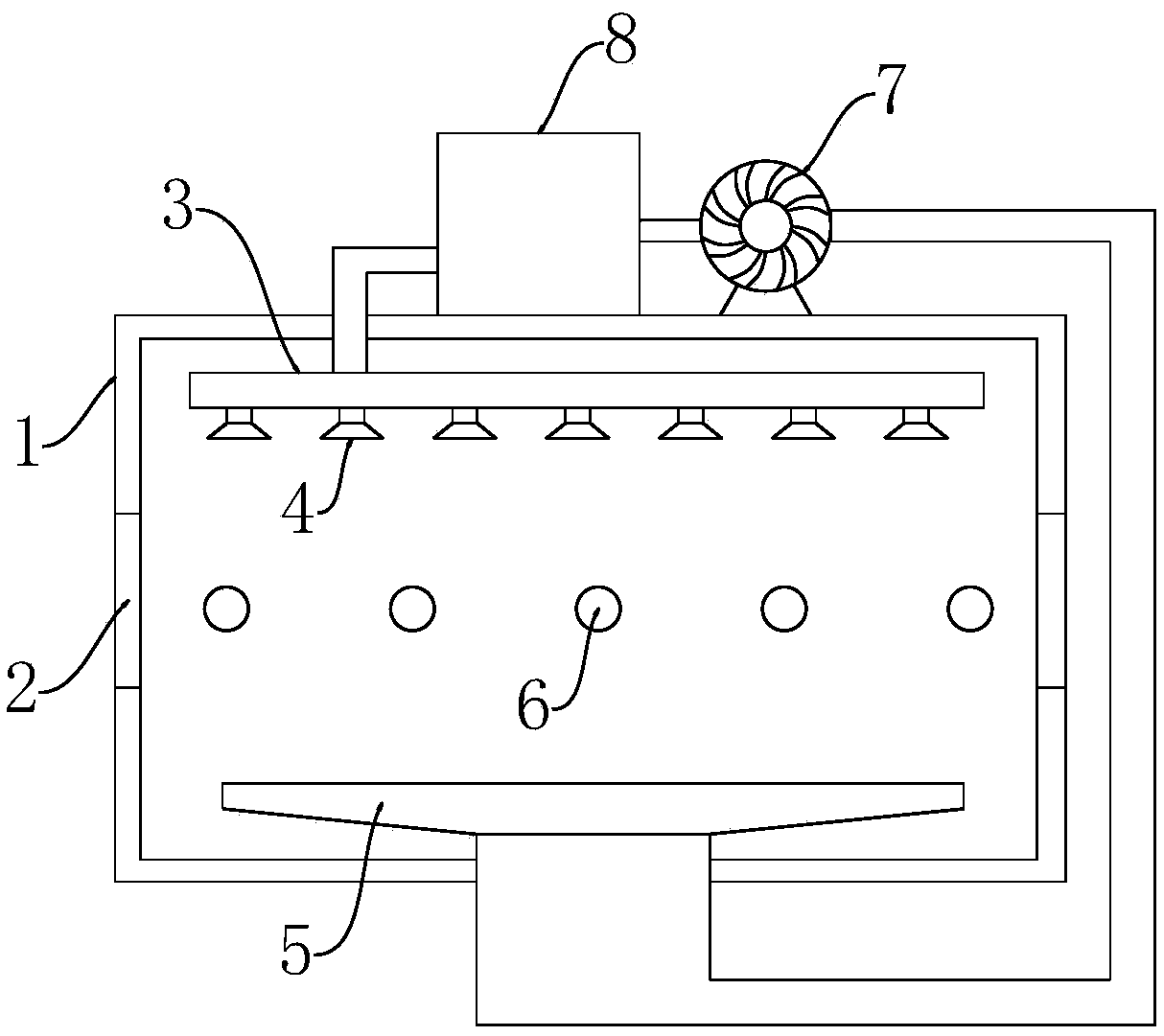

Rapid drying device for printed cloth

InactiveCN110733243ARealize drying operationImprove drying efficiencyPrinting press partsHot blastEngineering

The invention particularly relates to a rapid drying device for printed cloth. The rapid drying device comprises an oven, wherein outlets are arranged in the left side and the right side of the oven;an air supply pipe with the two closed ends is arranged at the top of the inner side of the oven; a plurality of air nozzles are arranged on the air supply pipe; an air suction hood is arranged at thebottom of the inner side of the oven; a hot air component is arranged at the top of the oven; a hot air outlet of the hot air component communicates with the air supply pipe through a pipeline; and acold air inlet of the hot air component communicates with the air suction hood through a pipeline. With the device, the cloth drying operation can be quickly realized, hot air can be recycled after drying, the drying efficiency of the device is improved, and energy is saved.

Owner:成都世纪凯德贸易有限公司

Grinding wheel cleaning equipment

InactiveCN109894409ASimple structureEasy to maintain and cleanCleaning using gasesCleaning using liquidsAgricultural engineeringRotational axis

The invention relates to the field of equipment design, in particular to grinding wheel cleaning equipment. According to the following technical scheme, the grinding wheel cleaning equipment comprisesa housing, a rotating device, a water spraying device and a blow-drying device, the rotating device is arranged in the housing, the rotating device comprises a rotating shaft, a rotating frame, a first gear, a second gear and a motor, the rotating frame is fixed to the rotating shaft, the first gear is arranged at the upper end of the rotating shaft, twenty teeth are evenly arranged on the surface of the first gear, the first gear is matched with the second gear and rotatably connected with the second gear, four teeth are evenly arranged on the surface of the second gear, the second gear is arranged on a rotating shaft of the motor, the water spraying device and the blow-drying device are arranged on the inner surface of the housing, and a grinding wheel clamping device is arranged on therotating frame. According to the grinding wheel cleaning equipment, the structure is simple, a grinding wheel is maintained and cleaned conveniently, operation of blow-drying of the grinding wheel can be realized, and use of human resources is reduced advantageously.

Owner:吴晓洁

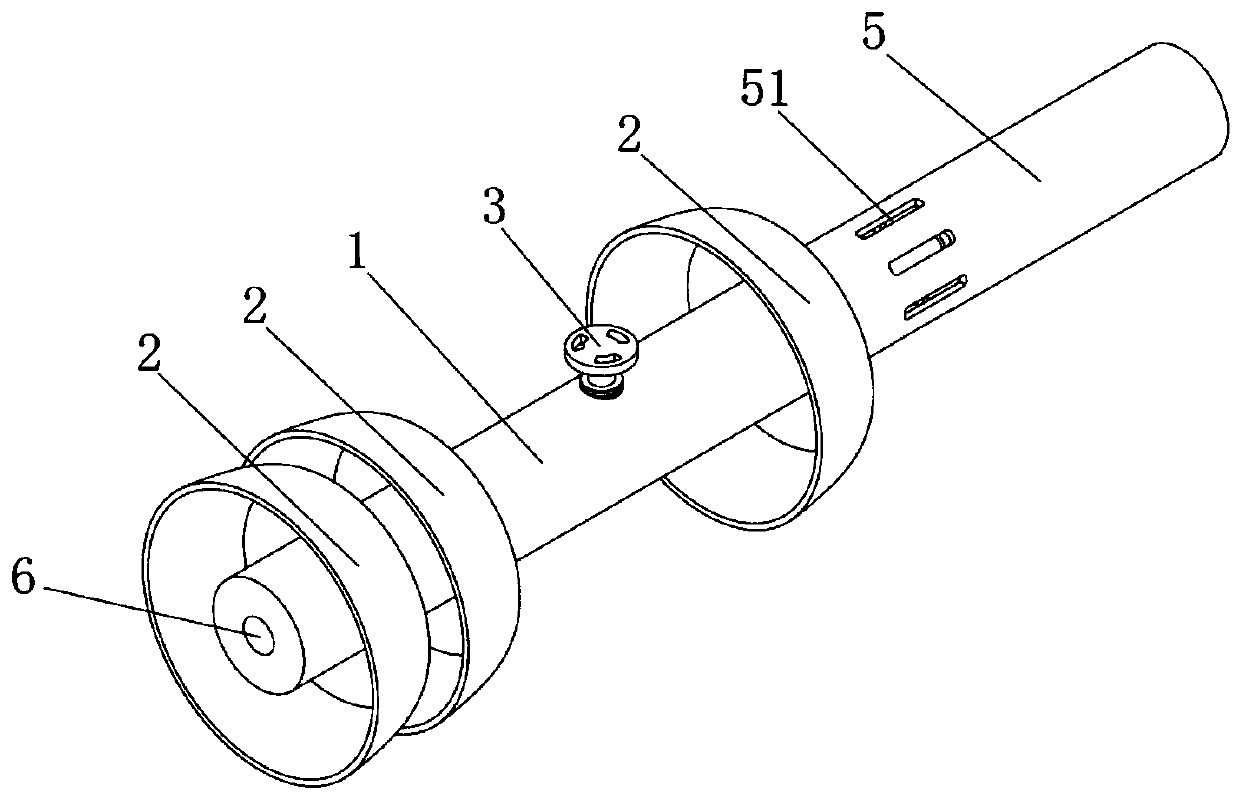

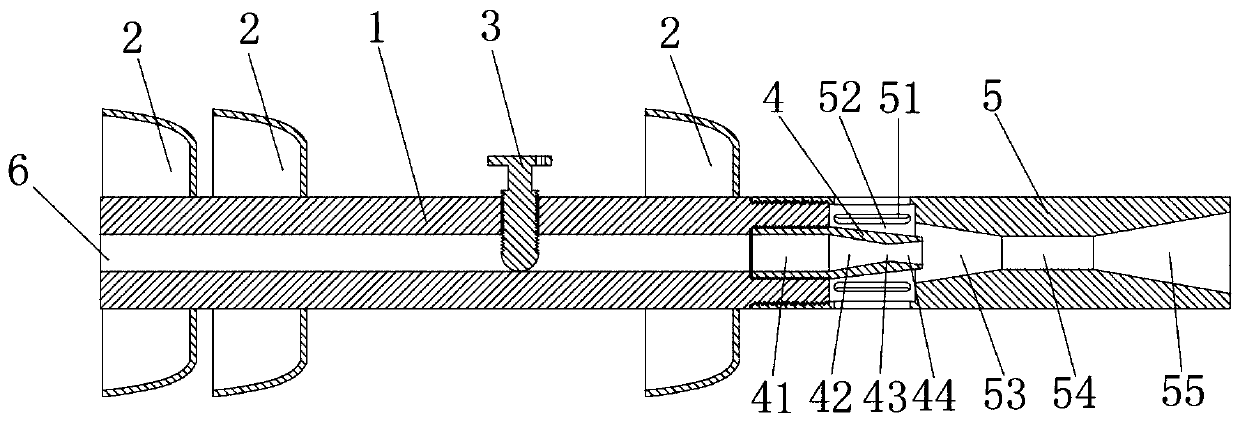

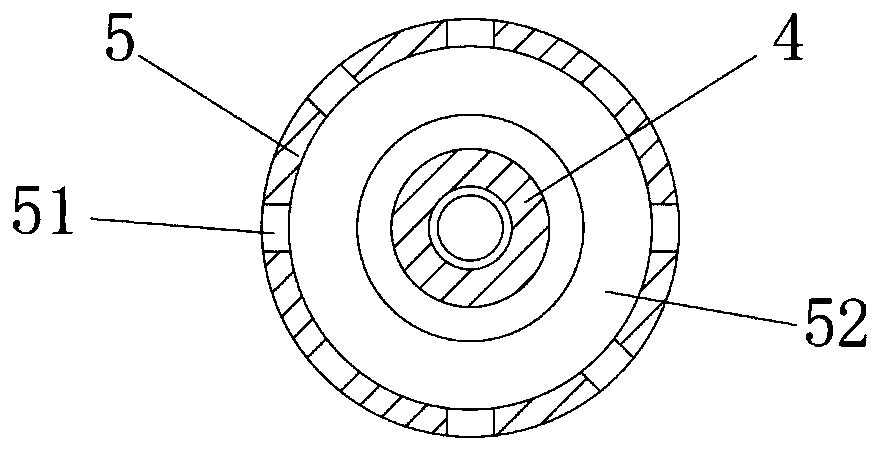

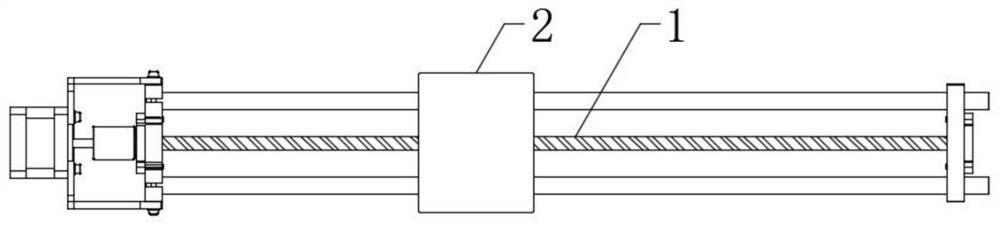

Oil and gas pipeline injection drying pipe cleaner

PendingCN110883029ARealize drying operationImprove drying efficiencyDrying solid materials without heatHollow article cleaningControl valvesPetroleum engineering

The invention provides an oil and gas pipeline injection drying pipe cleaner. The oil and gas pipeline injection drying pipe cleaner comprises a pipe cleaner cylindrical shell, an inlet gas control valve mounted in the middle of the pipe cleaner cylindrical shell, supporting leather cups fixed to the sidewall of the pipe cleaner cylindrical shell, a laval spray pipe connected with an internal thread of the pipe cleaner cylindrical shell and a venturi pipe connected with an external thread of the pipe cleaner cylindrical shell. Compared with the prior art, the oil and gas pipeline injection drying pipe cleaner has the advantages that no moving component is arranged in the oil and gas pipeline injection drying pipe cleaner; and the oil and gas pipeline injection drying pipe cleaner is simplein structure, can dry a pipeline by moving in the pipeline and improves the drying efficiency.

Owner:JIANGSU FORGED PIPE FITTINGS

Vacuum drying device for pharmacy

InactiveCN112146405AImprove athletic abilityImprove completenessDrying solid materials without heatDrying chambers/containersPharmacy medicinePharmaceutical technology

The invention belongs to the technical field of pharmacy, and particularly relates to a vacuum drying device for pharmacy. The vacuum drying device aims to solve the problem that in the prior art, themedicine vacuum drying effect is poor. According to the scheme, the vacuum drying device comprises a drying box, wherein a top box and a bottom box are fixed to the top and the bottom of the drying box respectively, vacuum exhaust pipes are connected to the bottom of the top box, and heating pieces are connected to the top of the bottom box; and a fixing frame with the section of a rhombus structure is fixed to the inner wall of the drying box, a placement cavity is formed in the middle position of the fixing frame, and a plurality of auxiliary cavities are formed between the outer wall of the fixing frame and the inner wall of the drying box. According to the vacuum drying device for pharmacy, the airflow movement effect is improved through the change of the width in the vertical direction, connecting holes of the rhombus structures of the fixing frame are matched, then airflow around medicine on a supporting plate generates flow speed change and direction change, and the contact effect of the airflow with the medicine is improved through irregular collision, so that the actual vacuum drying completeness and drying efficiency of the medicine are improved.

Owner:ANHUI YONSENT PHARMA

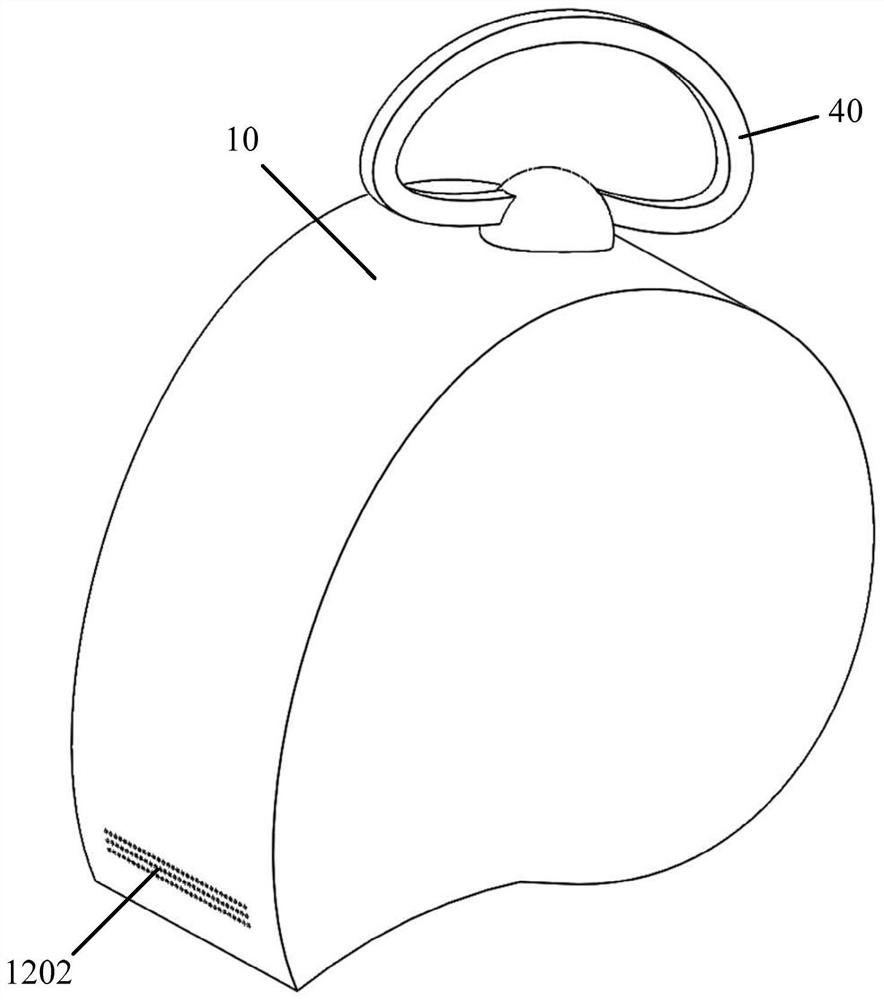

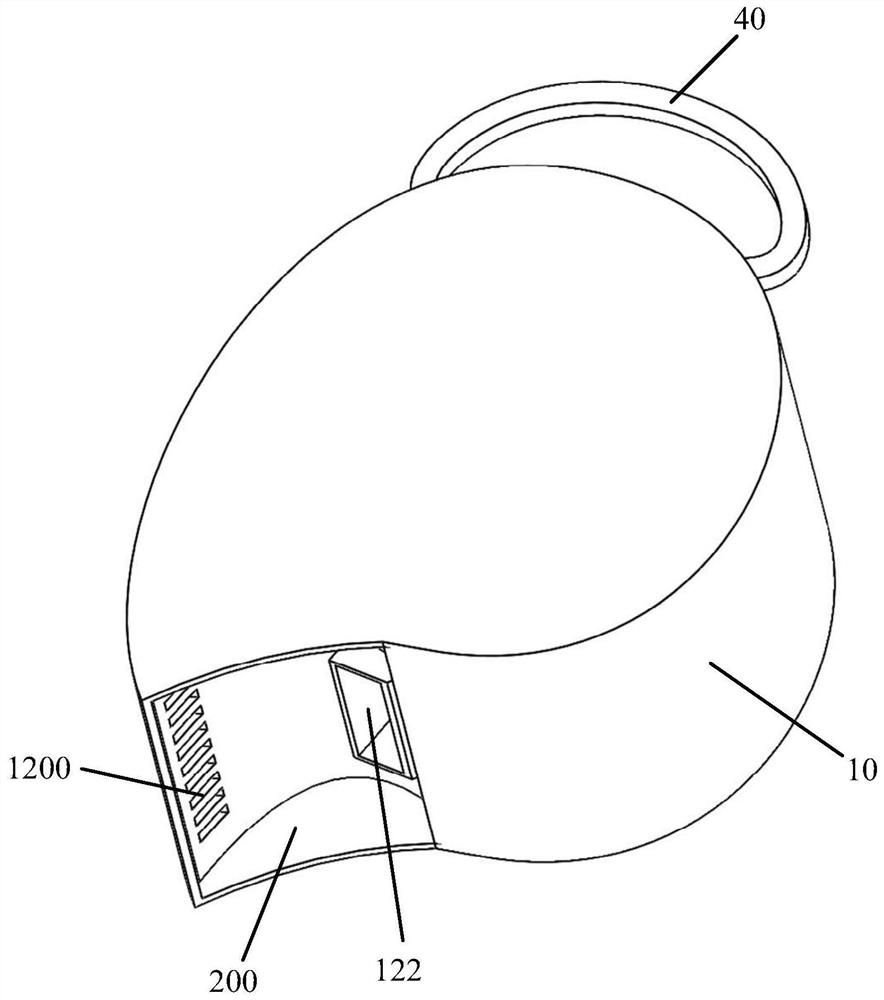

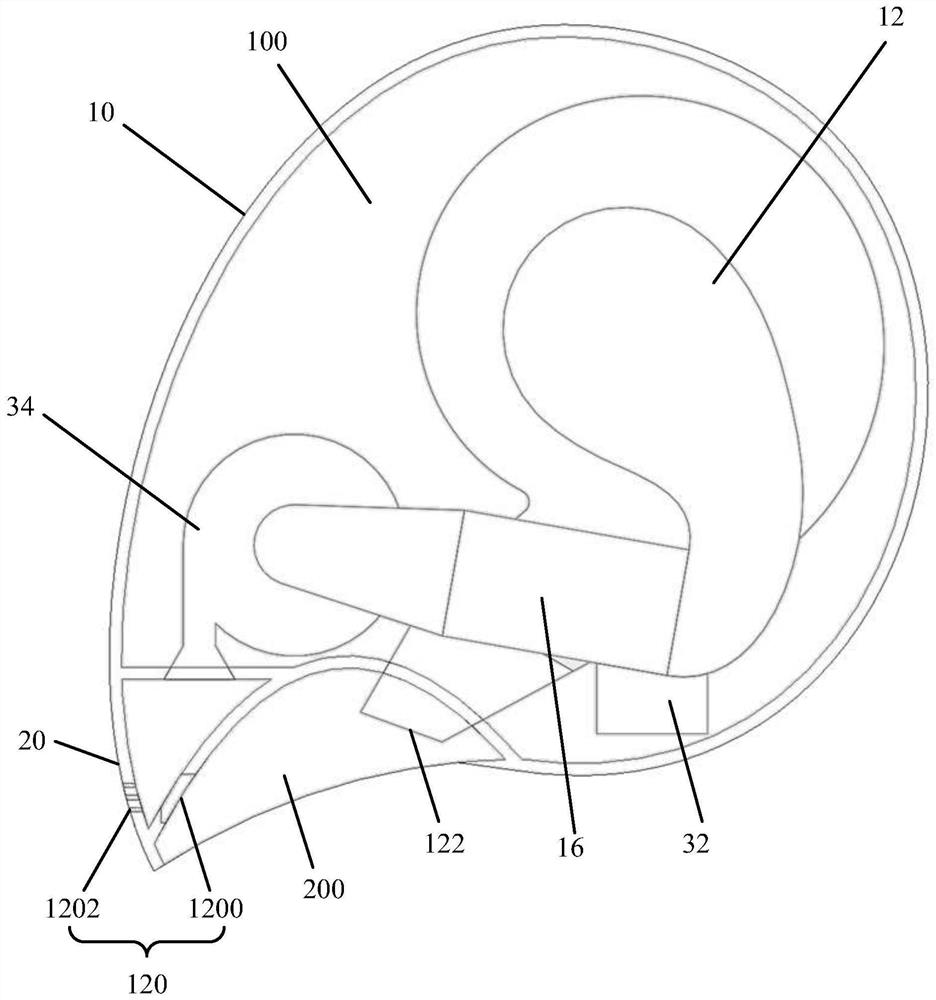

Pet dryer

The invention provides a pet drying machine which comprises a first shell, a second shell and a drying device. The air duct is partially arranged in the containing cavity, and the air duct is provided with an air inlet part and an air outlet part; the fan is arranged in the air duct and is positioned between the air inlet part and the air outlet part; the dehumidification part is arranged in the air duct and located between the air inlet part and the fan, and the dehumidification part is used for dehumidifying air; the heating part is arranged in the air duct and located between the air outlet part and the fan, and the heating part is used for heating air; the second shell is connected with the first shell, an opening is formed in the second shell, and the air inlet part and the air outlet part are both arranged in the opening. According to the technical scheme, in the hair drying process of the pet, emotional fluctuation of the pet can be reduced, the safety of drying work is improved, the drying work is mainly achieved through dehumidification and heating, and convenience and rapidness are achieved.

Owner:GUANGDONG MIDEA WHITE HOME APPLIANCE TECH INNOVATION CENT CO LTD +1

Device with photovoltaic direct-current drying module

PendingCN113503704ARealize drying operationSave electricityBatteries circuit arrangementsDrying chambers/containersEngineeringMechanical engineering

The invention relates to the technical field of photovoltaic direct-current drying, in particular to a device with a photovoltaic direct-current drying module. The device comprises a main body, a photovoltaic panel for converting solar energy into electric energy is fixedly connected to the upper part of the main body, a drying cylinder for drying internal materials is rotatably connected to the upper part of the middle part in the main body, and a connecting frame arranged above the drying cylinder and used for bearing materials. The solar energy drying device has the beneficial effects that solar energy is converted into electric energy through the photovoltaic panel, drying operation can be achieved, and electric power needed by drying can be saved; and through the arrangement of the connecting frame, the drying cylinder and a rolling block, in the heating and drying process of materials in a filter screen, the drying cylinder rotates to drive the filter screen to rotate, the rolling block rolls and crushes the materials in the filter screen, and the materials are heated and dried more uniformly.

Owner:宁夏永和光福新能源有限公司

Anti-rust treatment device for hardware workpieces after ultrasonic cleaning

The invention discloses an anti-rust treatment device for hardware workpieces after ultrasonic cleaning, which comprises an oil immersion tank, a ball screw, a slide rail and a material cage suspended above it, the nut of the ball screw is fixedly connected to the upper base block, and the upper base block The bottom is fixedly connected to the first hinge support and the second hinge support, the first hinge support and the second hinge support are respectively hinged with the first connecting rod and the second connecting rod, and the first connecting rod and the second connecting rod are hinged to the third connecting rod. The hinge support, the third hinge support is fixedly connected to the fastener, the fastener is threaded to connect the sleeve, the sleeve is provided with an elastic element, the elastic element abuts the sleeve rod, and the sleeve rod penetrates through the sleeve to hinge the fourth hinge support , the fourth hinge support is fixedly connected to the lower base block, and the present invention carries out the lower base block along the direction of the slide rail, which can well realize the immersion and removal operations, and drives the stepper motor to drive the material cage to rotate, which can be very good Realize the drying operation, replace the traditional manual oil immersion and drying process, and realize the mechanical automation operation.

Owner:深圳市博思创环保设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com