A positioning carrier structure for automatic painting of automobile bumpers

A technology for positioning vehicles and bumpers, which is applied in the direction of spraying booths and spraying devices, which can solve the problems of affecting the construction cost, uneven painting, and high cost, so as to save area and construction cost, prevent mutual influence, and reduce quantity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

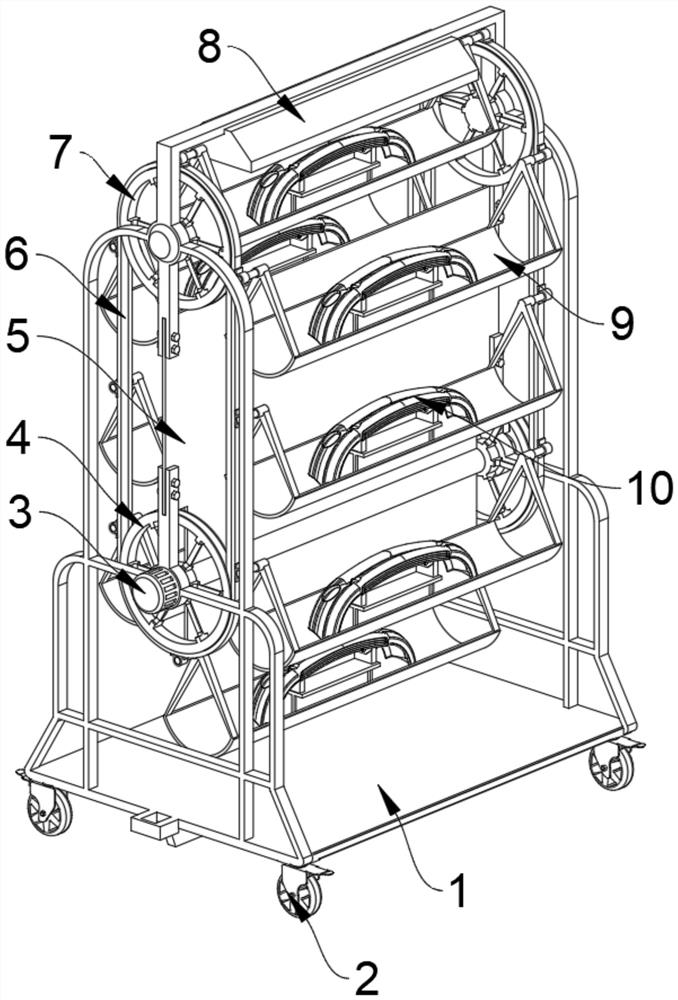

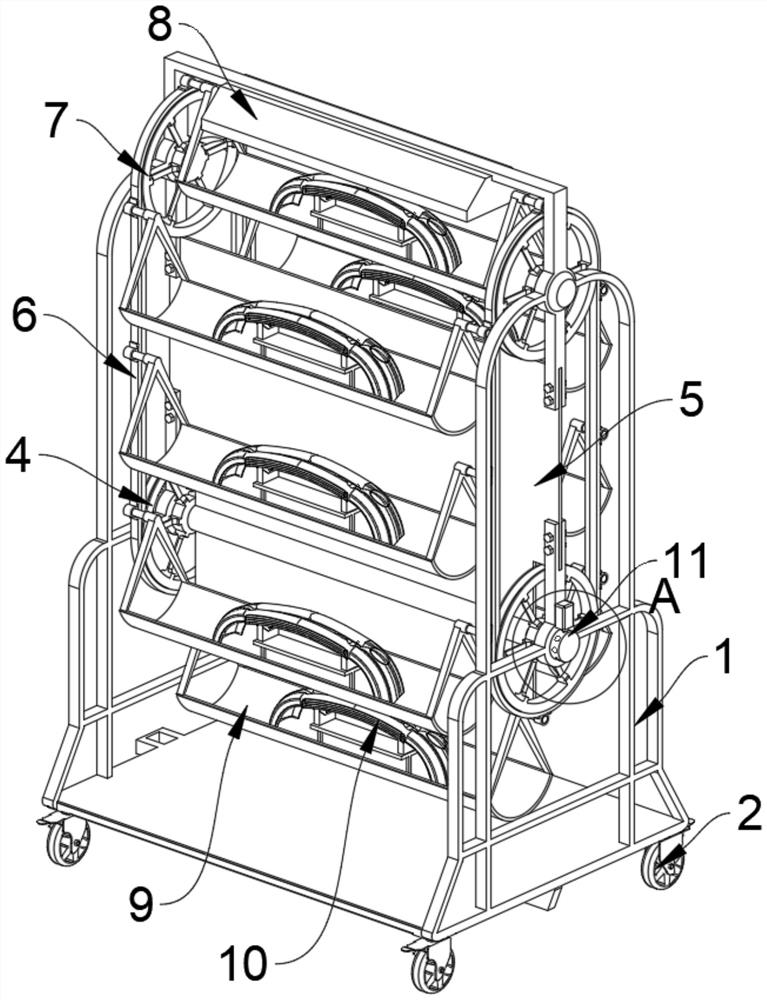

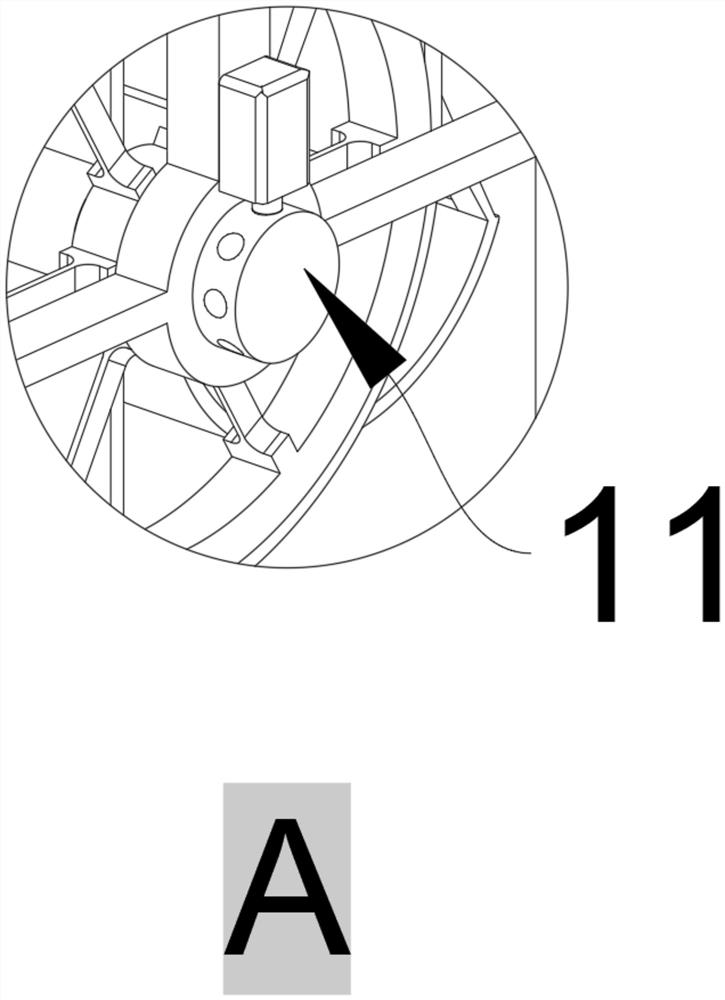

[0037] as attached figure 1 To attach Figure 12 Shown:

[0038] The present invention provides a positioning carrier structure for automatic painting of automobile bumpers, comprising: a carrier moving frame 1; The moving wheel 2; the bottom side of the vertical frame body on both sides of the carrier moving frame body 1 is symmetrically rotated and installed with a driving wheel 4, and the upper side of the driving wheel 4 is rotated and installed on the carrier moving frame body 1 There is a driven wheel 7, and the driving wheel 4 and the driven wheel 7 are all connected through the transmission of the V-belt 6. The outer ring of the V-belt 6 is equidistantly provided with eight fixed seats, and eight fixed seats are rotated and provided with eight spray paints. The hanger 9 and the bottom side of the paint spray hanger 9 are all provided with an upward arc-shaped partition structure, and the paint spray hanger 9 is always in an upward state through the partition structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com