Raw material drying machine for organic silicone production

A dryer and silicone technology, applied in the field of daily chemical industry, can solve the problems of cumbersome drying process, large equipment investment and time-consuming, etc., and achieve the effects of high heat exchange efficiency, improved efficiency and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

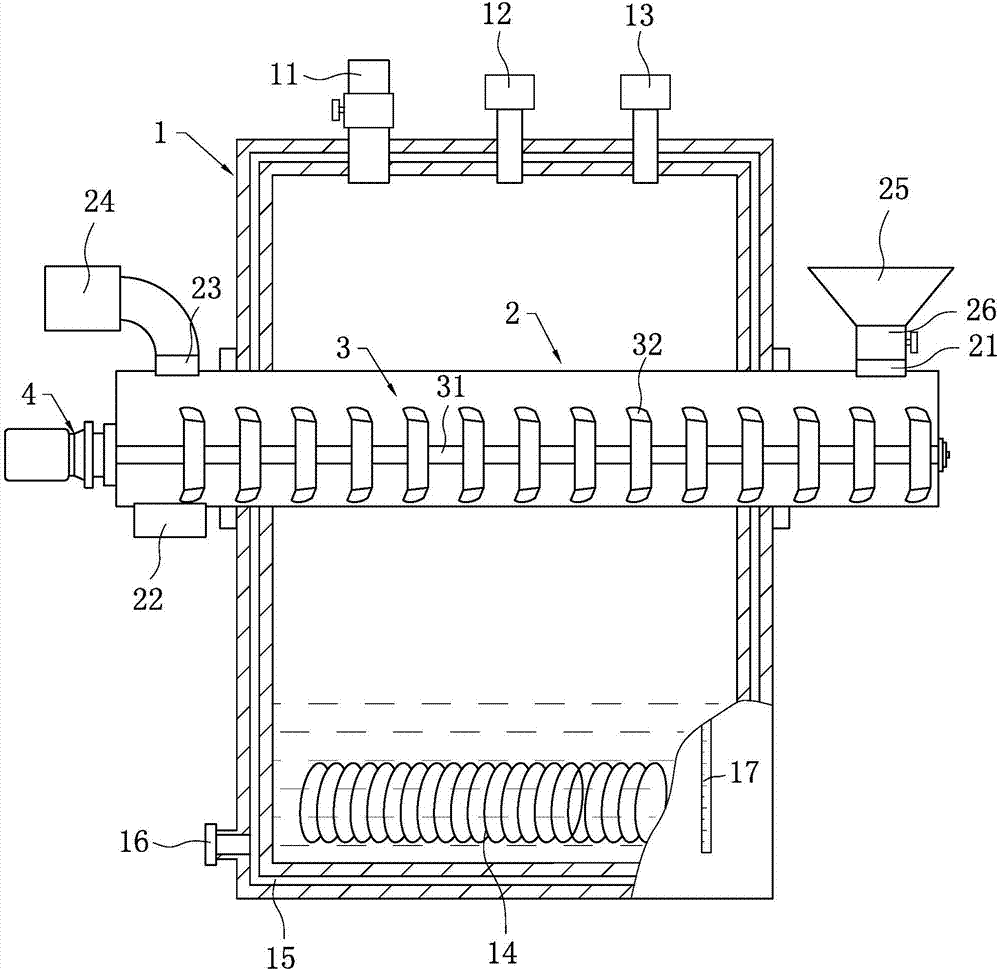

[0023] Depend on figure 1 As shown, a raw material dryer for organosilicon production includes a drying drum 1 , a feeding pipe 2 passing through the drying drum 1 transversely, and a stirring and conveying device 3 installed inside the feeding pipe 2 . The upper part of the drying cylinder 1 is provided with a water inlet 11 , a pressure gauge head 12 and a one-way valve 13 , and the bottom of the drying cylinder 1 is provided with a heating pipe 14 arranged in a spiral shape. A vacuum interlayer 15 is provided in the cylinder wall of the drying cylinder 1 , and a vacuum outlet 16 communicating with the vacuum interlayer 15 is provided on the drying cylinder 1 . A transparent observation port 17 is provided on the side wall of the drying cylinder 1, and a scale is marked on the observation port 17. The design of the drying cylinder 1 can well control the heating temperature of the feeding pipe 2 . The upper part of the drying drum 1 is provided with a pressure gauge head 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com