Coking coal moisture control method and hammer crusher for realizing same

A hammer crusher and coking coal technology, which is applied in coking ovens, grain processing, petroleum industry, etc., can solve the problems of affecting the drying effect, failure to grasp and use coking coal violent impact, tumbling, large floor area, etc. , to achieve the effect of low initial investment and operating costs, economical and effective drying, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation of the present invention will be described in conjunction with the embodiments and accompanying drawings. Since the method of the present invention and the crushing machine for realizing the method are inseparable, they will be comprehensively described together.

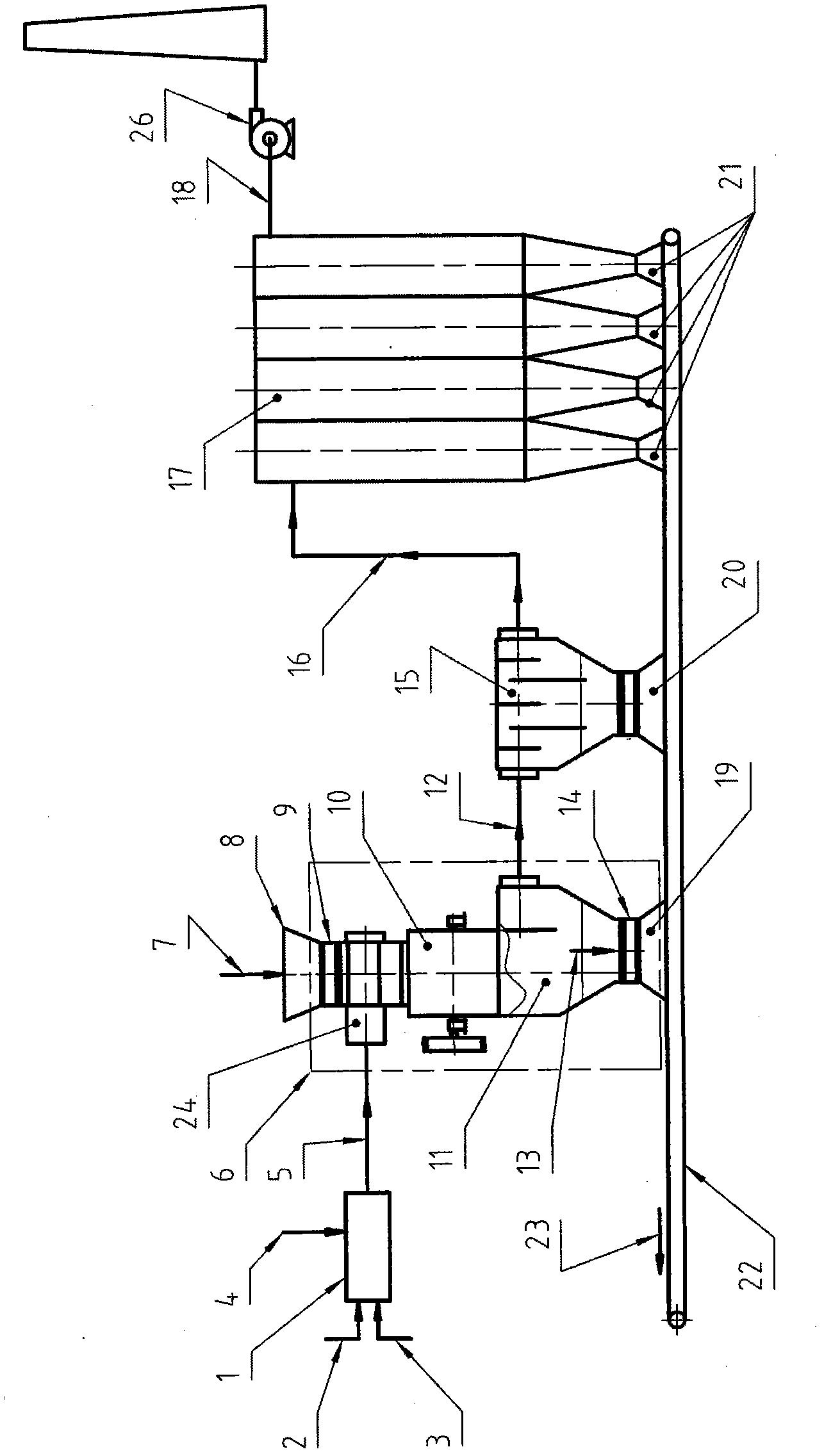

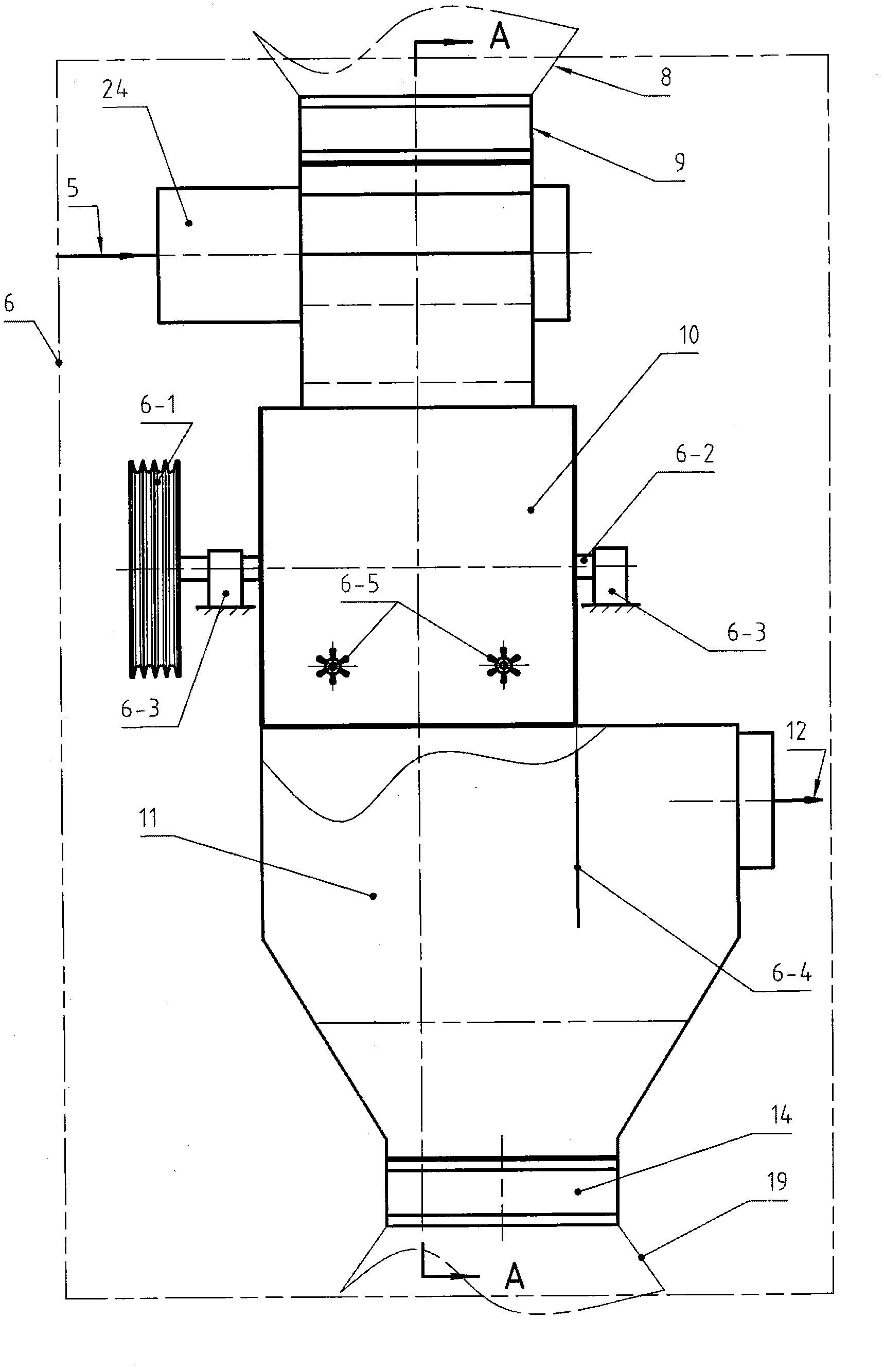

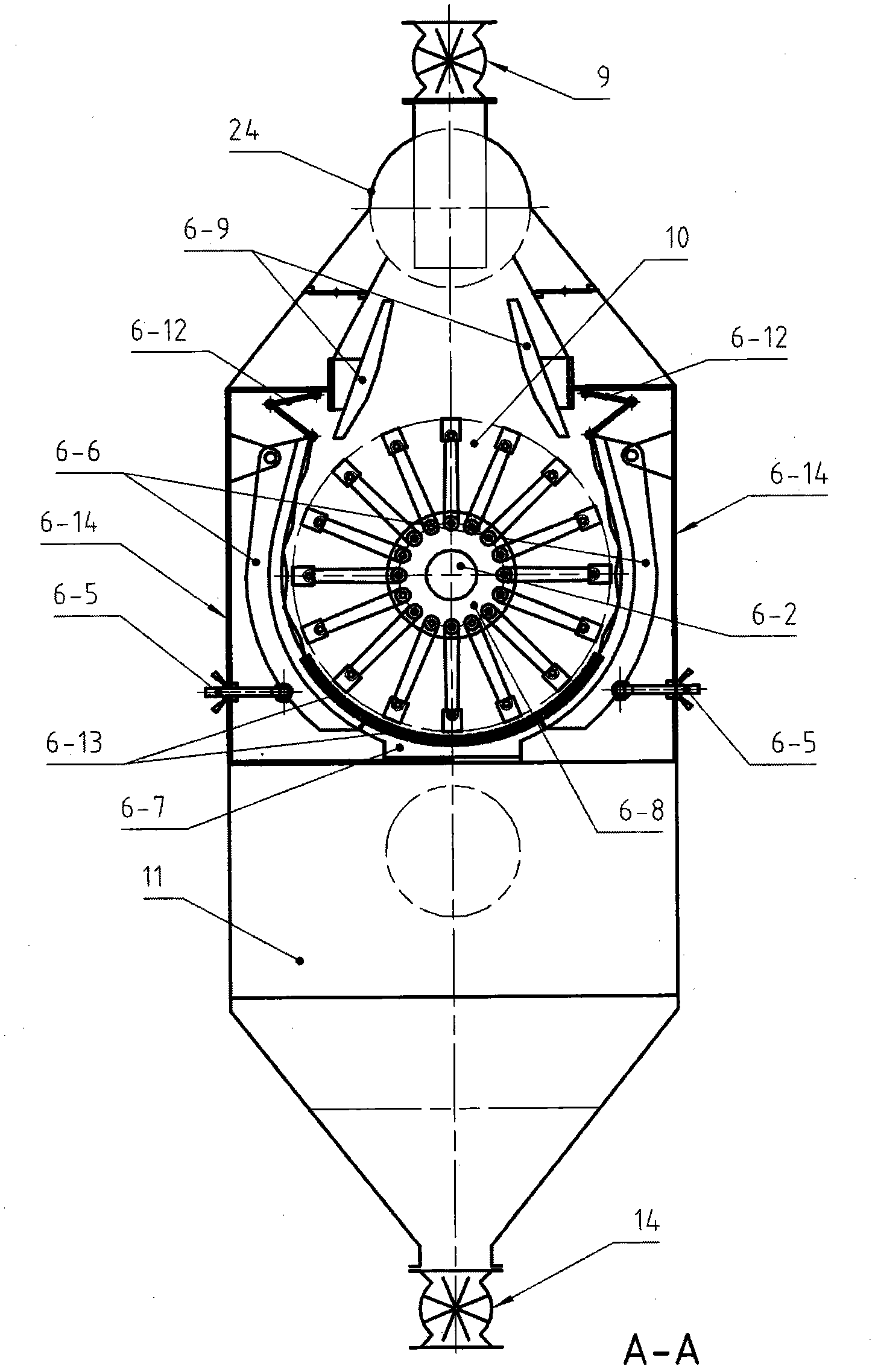

[0040] Comprehensive embodiment 1, such as Figure 1-6 shown.

[0041] exist figure 1 Among them, 1 is a flue gas generator, which is used to produce hot flue gas for drying at a temperature of about 400°C. 2 is the fuel inlet channel of the flue gas generator, and it is recommended to use converter or blast furnace gas as fuel. 3 is the inlet passage of combustion air. 4 is the channel for mixing inert gas with lower temperature for temperature adjustment when necessary, such as other waste flue gas or nitrogen with lower water content, or even the waste gas discharged by the present invention (note: due to the waste gas discharged by the present invention The water content i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com